Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

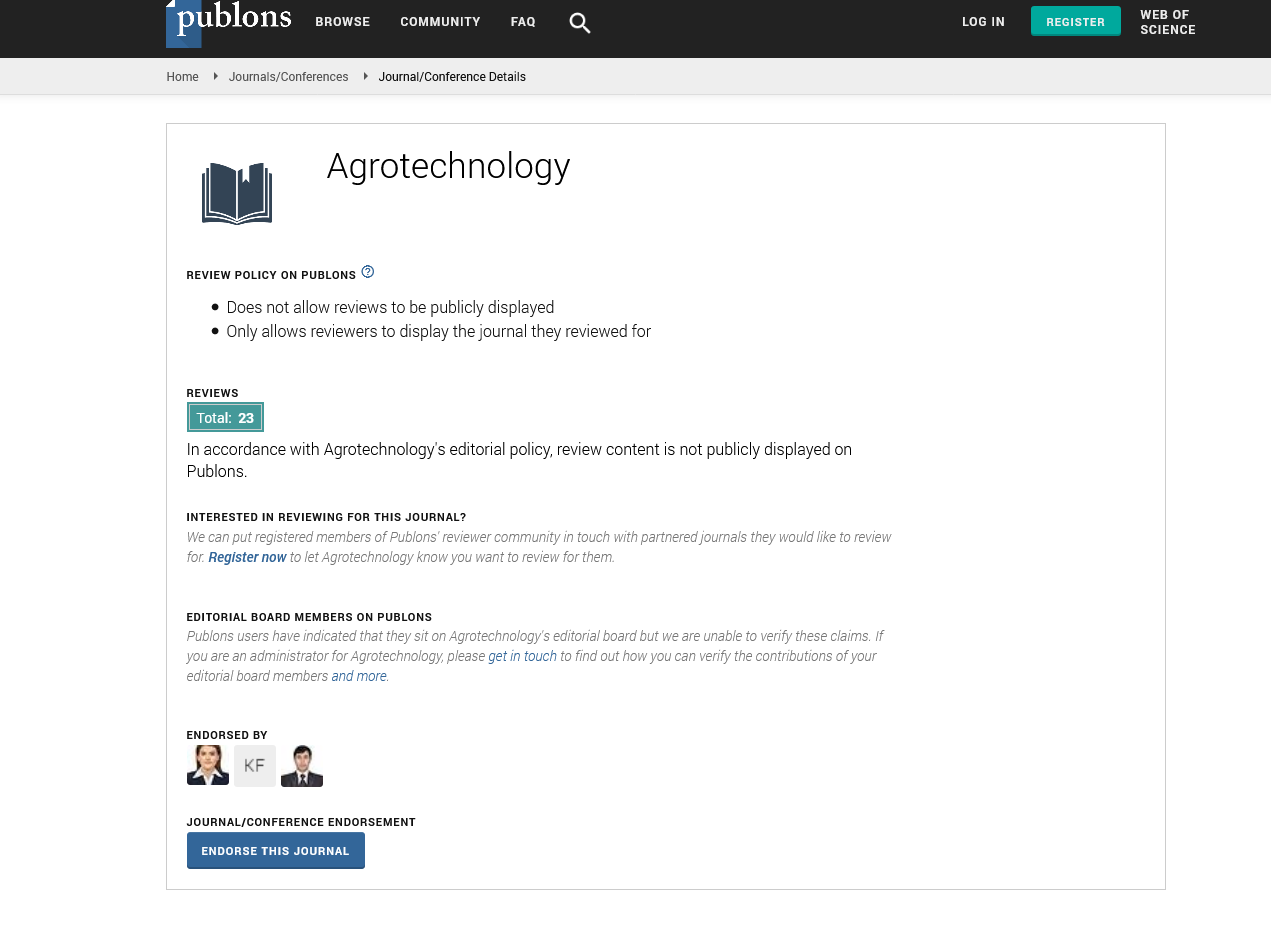

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

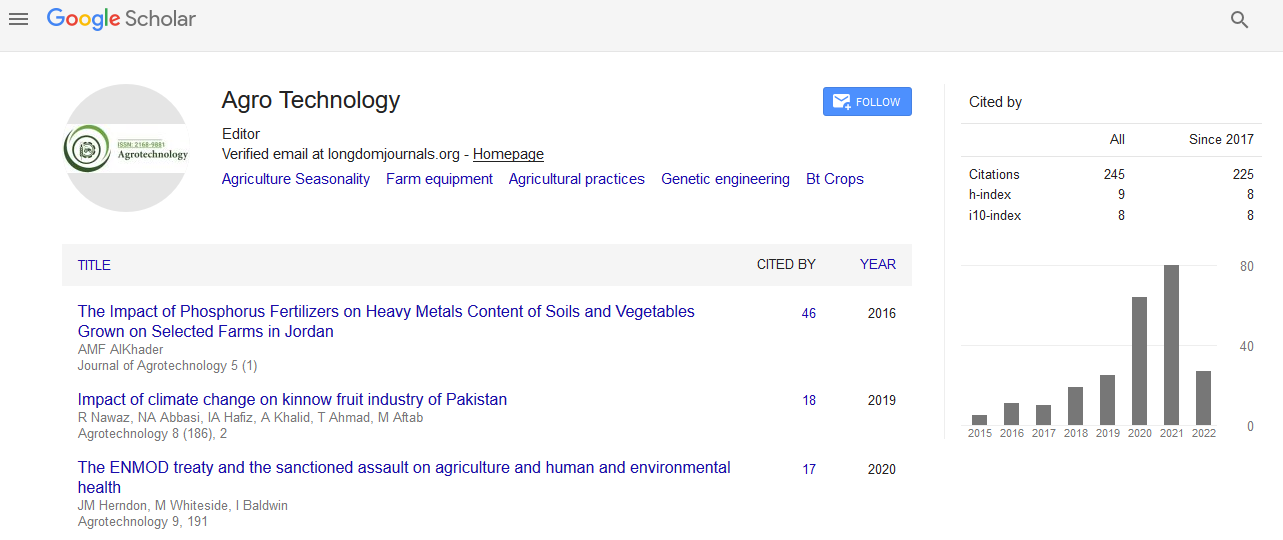

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Thermal activation of charcoal produced from pigeon pea stalk

2nd International Conference on Agricultural & Horticultural Sciences

Radisson Blu Plaza Hotel, Hyderabad, India February 03-05, 2014

Sandip Gangil, Harsha M.Wakudkar and Lata Tripathi

Scientific Tracks Abstracts: Agrotechnol

Abstract:

The crop residues can be used for preparation of low cost activated charcoal. Pigeon stalk was converted in charcoal using slow pyrolysis in two different type of charring systems, namely vertical reactor bio-char unit and closed charring kiln. Iodine value was taken as indicator of adsorbent ability of charcoal. The iodine values charcoal produced were of the order of 20010 mg/g. This level of iodine value is relatively low in comparison to iodine value of commercial laboratory grade activated carbon (114010 mg/g). The iodine values of raw char obtained from vertical cylinder bio-char unit were ranged from 200 to 320 mg/g; the higher value being for lower pyrolysis temperature when the pyrolysis temperature varied from 250 to 450C. Thermal activation of charcoal was conducted at 630C for different durations in muffle furnace. It was found that the duration of half hour is better than higher durations. The iodine value could be enhanced until 650 mg/g by half hour thermal treatment for the charcoal produced at 250C. The iodine value of the char produced in closed charring kiln was 200 mg/g which could also be improved by thermal activation process till 600. Thus, the iodine values of 62525 mg/g are obtainable for pigeon pea based char after thermal processing of raw charcoal. In reference to the iodine value of raw charcoal, the iodine value could be improved until 2-3 times. In comparison with commercial activated carbon this iodine value is about 45%. In other experiment, we produced the charcoal from wood using downdraft gasifier. The activation of wood based charcoal obtained through gasification was achieved till iodine value level of 900 mg/m. This level was nearly 80% of the activation level of commercial activated carbon. Thus, the activation of gasification generated wood charcoal was better than the activation of pyrolysis generated crop residue charcoal. It was due to two reasons viz., the char obtained from gasifier was generated at higher temperatures; the wood contains relatively lower volatiles, moisture and ash content than the experimented crop residues.

Biography :

Sandip Gangil has completed his doctorate from Shizuoka University, Japan. He is Principal Scientist at Central Institute of Agricultural Engineering, Bhopal India. He has published several papers in reputed journals.