Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

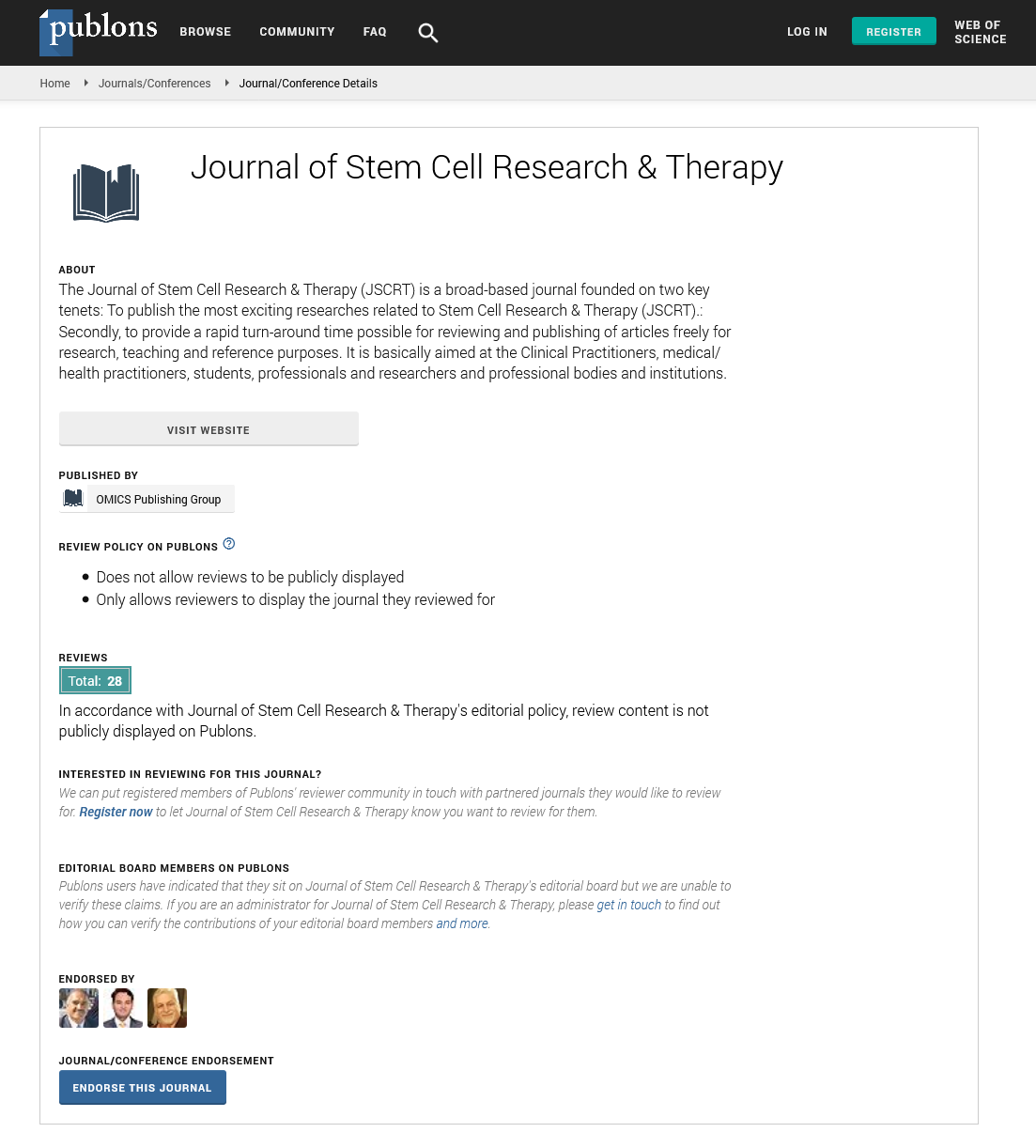

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Regulation and development in cell-based therapeutics: The need for comparability and implications for new business models

3rd International Conference and Exhibition on Cell & Gene Therapy

October 27-29, 2014 Embassy Suites Las Vegas, USA

Nicholas Medcalf

Scientific Tracks Abstracts: J Stem Cell Res Ther

Abstract:

The development and delivery of novel cell-based therapeutic products requires ongoing improvement in methods for ensuring consistency of quality, safety and efficacy. Issues that must be addressed for cost-effective, regulatory-compliant supply include the design of suitable control systems, validation of transit arrangements and management of overall costs. This is especially important for healthcare indications that are of moderate, rather than life-saving value-release where the margins are more sensitive. The introduction of automation is often cited as a solution to these challenges but investment choices for process improvement using automation must take place within a whole-operation context if effective automation is to take place. This presentation examines the current options for production and supply for new cell therapy businesses and highlights the strengths and weaknesses of these in the light of supply-chain robustness, ease of clinical introduction and cost of manufacture. Some conclusions are presented about the likely direction of new business models and the technology required to enable these to be used while satisfying issues of process comparability.

Biography :

Nicholas Medcalf has more than 30 years? experience in the healthcare industry. A significant part of his work has addressed design for manufacture and production cost analysis. He has recently transferred to academia under an EPSRC Fellowship to conduct research aimed at finding innovative solutions to regenerative medicine manufacture based upon alternative business models. This involves a systems approach to the business processes and the technology required to satisfy the regulations and accelerate commercialisation. He has led industry-academia collaborations including collaboration with TERC, Japan, and Project CARA at NUI Galway. His current role is Professor of Regenerative Medicine Manufacture, Loughborough University.