Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

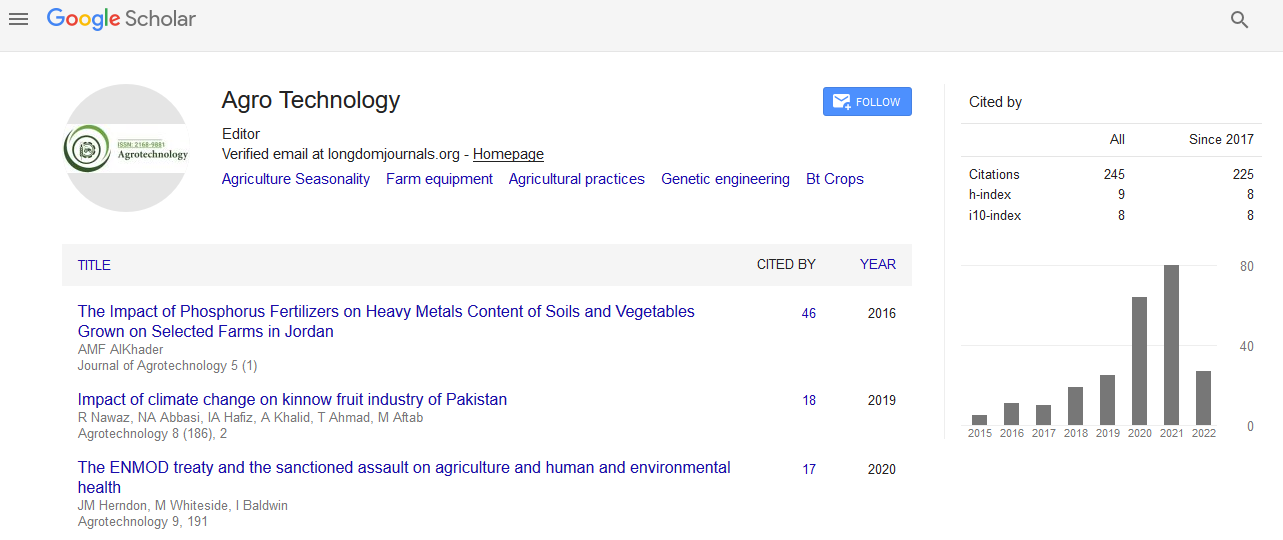

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Prediction of commuting effects of varying hydraulic cylinder movements on soil-plough breast interaction with a HRP

13th International Conference on Agriculture & Horticulture

September 10-12, 2018 | Zurich, Switzerland

Lin Zhu, Min Wei, Feng Luo, Jia Ru Ge and Tien Chien Jen

National Natural Science Foundation of China, China

Posters & Accepted Abstracts: Agrotechnology

Abstract:

Hydraulic Cylinder (HC) of Horizontally Reversible Plough (HRP) is commonly used for the commuting tillage of HRP. The mechanics of commuting due to HC movements surely affects the tillage performances, but whether this load has adverse effects on the two essential engaging components of HRP, i.e. ploughshare and moldboard is an underlying question. Based on our previously related work, the objective of this study is to characterize the dynamics behaviors of HRP and thus examine the commuting effects on plough-breast and most especially on plough-shank. Uniform motion was applied for HC. A combined finite element analysis (FEA) and multi-body dynamics analysis (MDA) approach was used to characterize the dynamic behaviors of the plough-breast. Five different HC movement scenarios and two actual HRP tilling conditions were involved, and the maximum operation depth of HRP was kept constant at 0.36 m. The five HC movement scenarios were specified from 15 to 25mm/s in 2.5 mm increments, and the two actual HRP tilling conditions were HRP commuting either between left and right or between left and middle continuously and alternatively. The loading data due to the HC movements were obtained from an MDA and applied to load a finite element modal of the plough-breast. Results show that the HC movements do result in the maximum stress and strain at the plough-shank, however, has no adverse effects on the service life of the plough-breast. The current HC absolutely favors the actual HRP tillage.

Biography :

E-mail: zl009@mail.ustc.edu.cn