Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

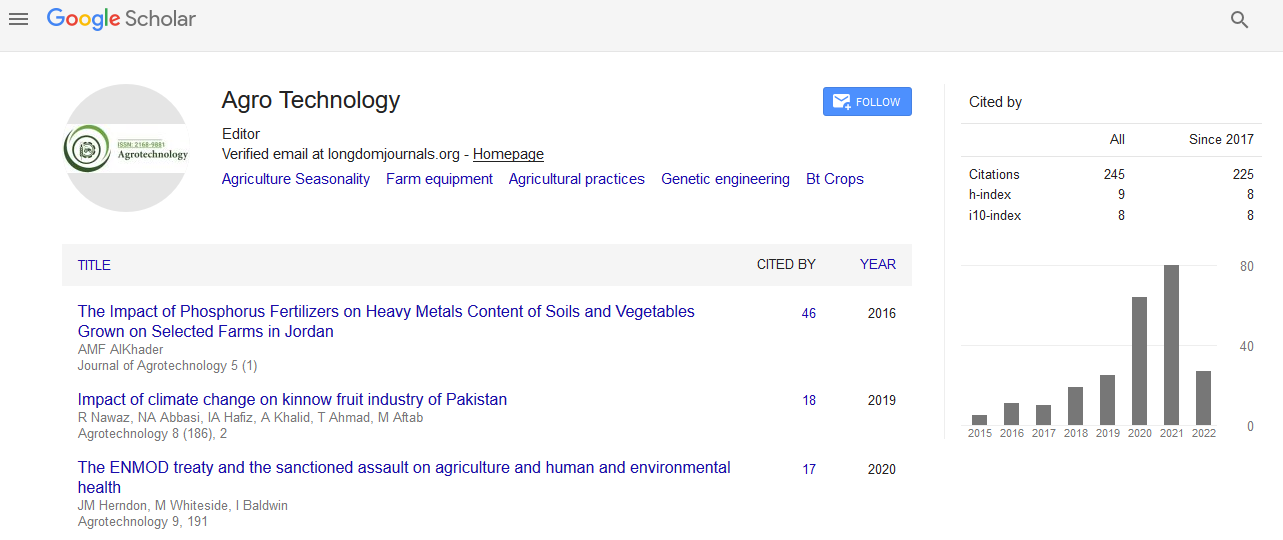

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Performance evaluation of bullock operated rotary mode agro-processing technology: Flour mill

3rd International Conference on Agriculture & Horticulture

October 27-29, 2014 Hyderabad International Convention Centre, India

Pawar Savita Gangadharrao, Shailaja Deshvena, Solanki S N, Gopal U Shinde and A A Waghmare

Posters: Agrotechnol

Abstract:

The bullock energy can be used in rotary mode set up for post-harvest operations like Flour milling, chaff cutting, Daal mill operations, Spice Grinding, threshing, cotton ginning, briquetting and other stationery operations. The proposed research work presents the performance evaluation of Flour mill unit. The draft requirement varied in the range 509 N to 450.8 N with the mean draft as 476.9 N which was 5.52 %of weight of the paired bullocks. The pulse rate as usual decreased with duration the mean respiration rate, for bullockB1 and B2 was 25.75 and 31.7 5bpm, 56.0 and 55.0bpm with the body temperature as 38.07 and 38.17oc at rpm of bullocks were 66 to 61respectively. The mean rpm of the flour mill shaft was observed to be 720. The output of machine gradually decreased with duration may be due to decrease in the speed of shaft of the Flour mill. The mean output 8 kg/h as with an electric motor was 10 kg/h. The mean power output was 0.550 kW. The operation of Flour mill was found to be feasible considering the draft ability of Red Kandhari type bullocks. The total cost of operation of unit was calculated Rs. 87.74 Rs / h with an output capacity of flour mill observed 1.0 hp. Keywords: Flour mill, Red Kandhari bullock, draft, pulse rate, rotary mode agro processing unit.