Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

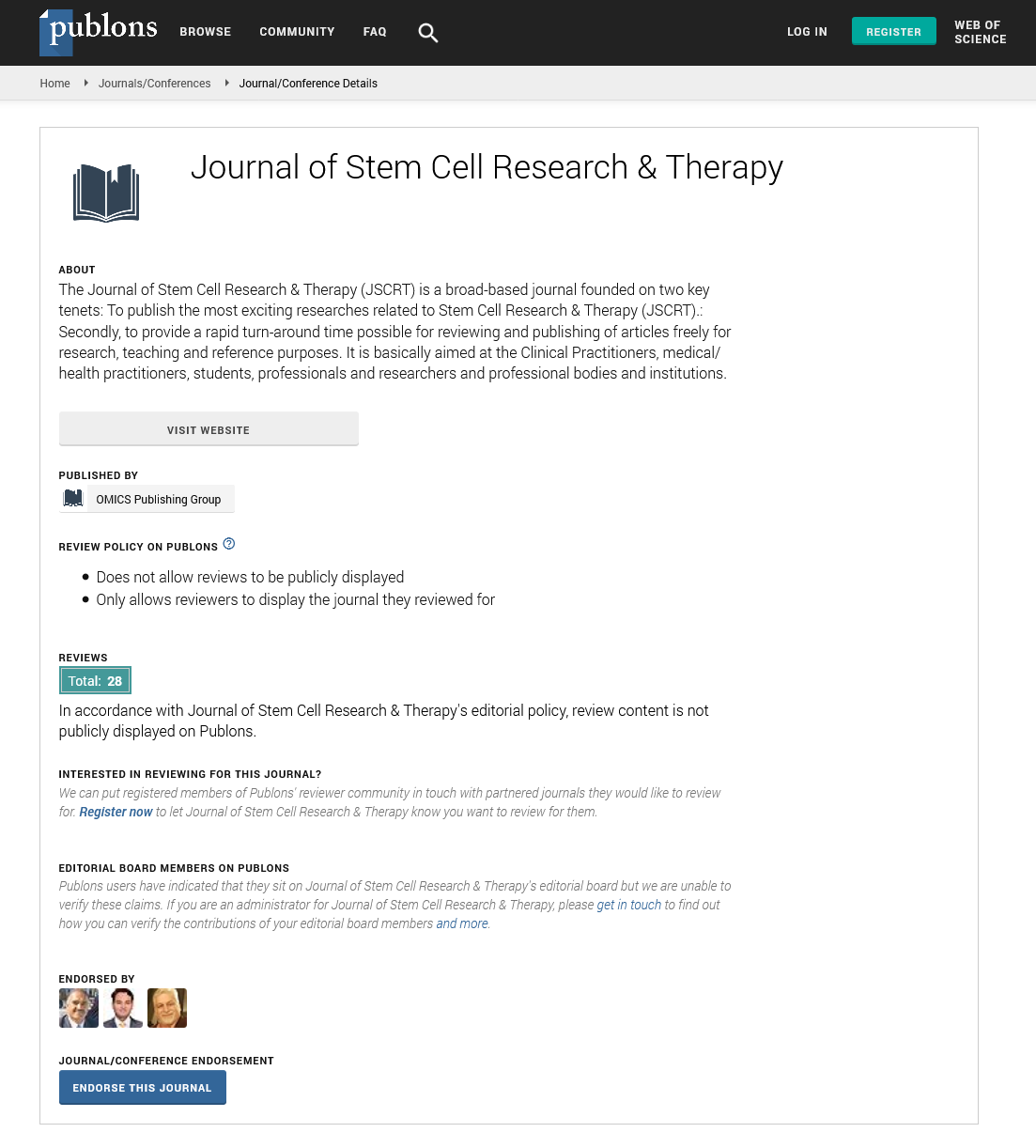

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Mechanical characterization and cytotoxicity assessment of porous stainless steel structure for biomedical applications

17th World Congress on Tissue Engineering, Regenerative Medicine and Stem Cell Research & 10th Global Conference on Physiotherapy, Physical Rehabilitation and Sports Medicine

October 28, 2022 | Webinar

Niyou Wang

National University of Singapore, Singapore

Scientific Tracks Abstracts: J Stem Cell Res Ther

Abstract:

Stainless Steel 316L (SS316L) has been considered as a suitable option for its use as an orthopedic implant due to its low cost, easy availability and processing, good workability as well as its high fatigue life and fracture toughness. However, due to its high elastic modulus, making an implant entirely out of SS316L will result in stress shielding, which can impede the healing process instead of supporting it. Thus to address this issue, porous compositions in the form of lattice structures are being introduced into the implants in order to reduce the elastic modulus to match that of the human bone. Due to the complex nature of lattice structure, additive manufacturing (Selective laser melting (SLM)) is the preferred method as it addresses the limitations of conventional machining methods. Therefore, Octet of SS316L were designed, manufactured, and characterized at 0.5/0.6/0.7 mm strut diameters in this study. They could also retain their load-bearing capabilities with yield strength and compression strength that are higher than that of the human bone. The cytotoxicity results indicate that these structures demonstrated outstanding biocompatibility. Keywords: SS316L, biomaterials, SLM, Mechanical Property, Cytotoxicity, Lattice Structure.

Biography :

Niyou Wang is currently a postdoc at National University of Singapore. He is working on collaboration projects between Mechanical Engineering and Anatomy department. His research focus on 3D printing, cytotoxicity, particles, bone implants. He has solid mechanical background, strong biological knowledge, and rich hands-on experience. He has published multiple research and review papers in many reputable international journals.