Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

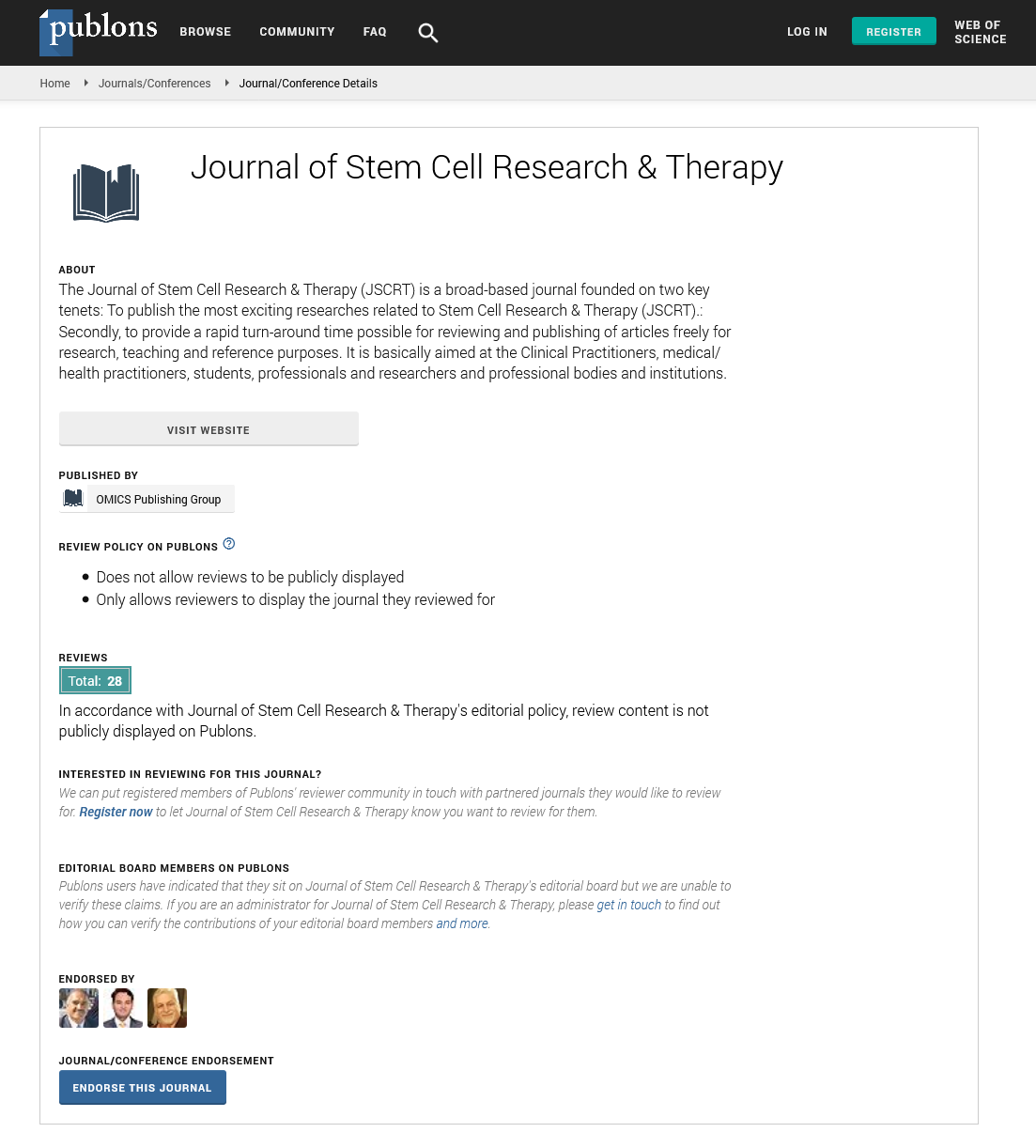

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Fabrication of Mg-4Y-2Nd-0.4Zr-0.25La microtubes for using as biodegradable stent in biomedical science

Joint Event on 12th Annual Conference on Stem Cell and Regenerative Medicine & 4th Annual Conference on Biomaterials

June 04-06, 2018 | Prague | Czech Republic

H Torabzadeh Kashi

University of Tehran, Iran

Scientific Tracks Abstracts: J Stem Cell Res Ther

Abstract:

Coronary heart disease (CHD) is the main cause of many deaths in our current world in which the coronary arteries are partially blocked or narrowed by the formation of plague. To solve this disease, angioplasty with stent placements has attracted a great deal of attention based on its lower levels of risk and acceptable efficacy. The traditional stents are made of 316L stainless steel and cobalt???chromium alloy which will indefinitely remain in the patients??? body and result in serious side effects like inflammation and thrombosis. In recent years temporary stents made from biodegradable metals especially Mg and its alloys have been considered as an alternative solution instead of the permanent ones, however, they face some profound limitations in their production process. In the current study, a new fabrication method including severe plastic deformation (SPD) process, direct extrusion, drilling, and microtube extrusion is proposed to produce Mg microtubes with improved mechanical properties. Based on previous studies, stents which are made from a material with an ultimate strength of >300 MPa and elongation of >15% can be a promising candidate for being used as biodegradable stents. By using the current method, large plastic strains are successively applied to the as-cast Mg at 400�C and consequently, the homogenous microstructure of the final microtube contains fine and ultrafine grains which cause high strength and high ductility Mg microtubes can overcome low formability of Mg alloys and facilitate the using of this promising material as biodegradable stents.

Biography :

H Torabzadeh Kashi is a PhD student in the field of Mechanical Engineering at the University of Tehran. He holds a BA in Manufacturing Engineering from Iran University of Science & Technology (2008-2012) and MA in Manufacturing Engineering from University of Tehran (2013-2015). He achieved the Iran National Elite Foundation award as a superior technician graduated in 2016. His research is primarily concerned with the production and characterization of nanostructured materials for different industries especially biomedical applications. He has published several papers and conference presentations and a book sponsored by Elsevier publication around Severe Plastic Deformation (SPD) methods for production of nanostructured materials.

E-mail: hessamtorabzadeh@gmail.com