Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

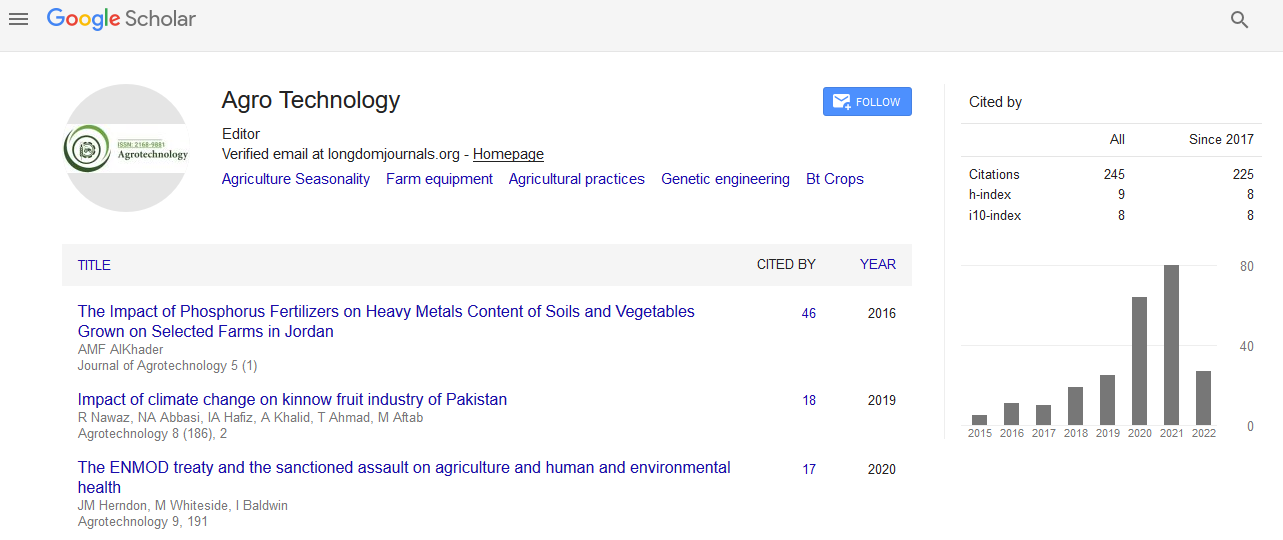

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Evaluation of handling and storage characteristics of an intermediate granulated food ingredient using a fabricated screw extruder

International Conference on Agri Biotech & Environmental Engineering

September 11-12, 2017 San Antonio, USA

Lynnel C Olpot

University of the Philippines Los BaƱos, Philippines

Posters & Accepted Abstracts: Agrotechnology

Abstract:

The laboratory scale screw extrusion agglomeration equipment was developed to assess its effectiveness in the granulation of pre-formulated food powders in which bitter gourd ampalaya powder as the main ingredient. The handling and storage properties of the agglomerated products obtained from mixtures which have three components (bitter gourd power, cassava flour and water) were determined under two screw speeds (80 rpm and 120 rpm). The effectiveness of the equipment was based on the product properties such as Carrā??s Index, Hausner Ratio, friability and disintegration time. The Carrā??s index of the agglomerates ranged from 0.0333 to 0.07333 while the Hausner ratio ranged from 1.0346 to 1.0792. Thus, the handling property of the agglomerates produced by the equipment was excellent. The lowest friability measured was 0.096 indicative of strong and stable agglomerate. The average disintegration time observed was 6.04 minutes. The maximum mass output efficiency and throughput of the agglomeration equipment was 96.15% and 0.3163 kg/kW, respectively.