Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

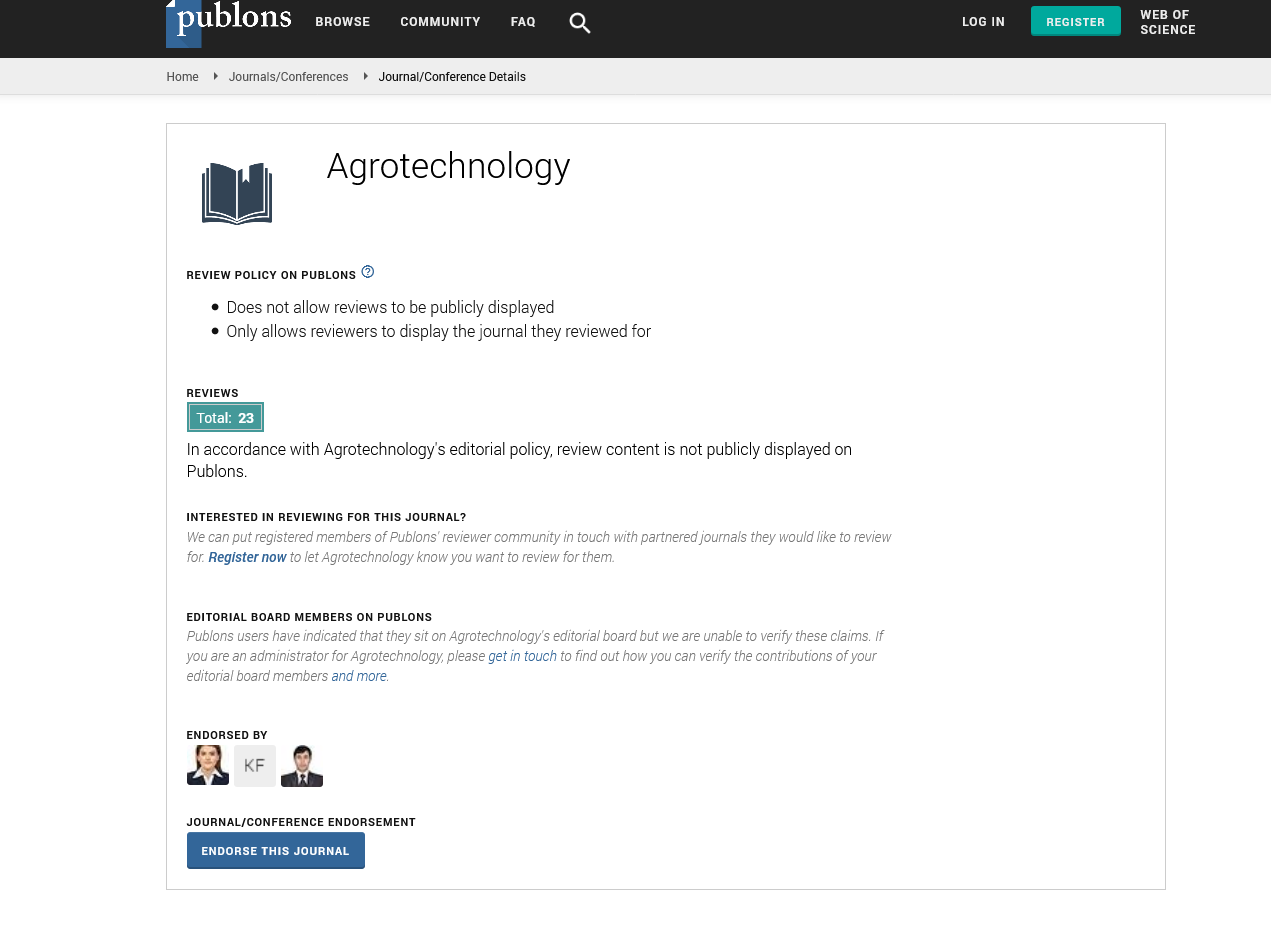

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

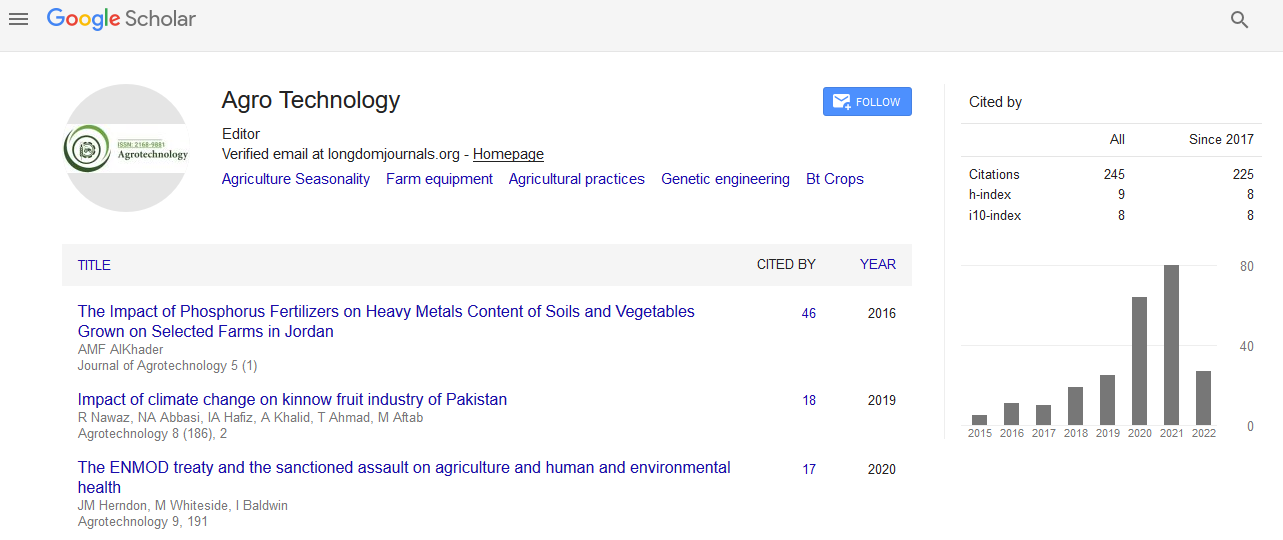

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Effect of modified atmosphere packaging on functional quality and shelf life of minimally processed garlic cloves

2nd International Conference on Agricultural & Horticultural Sciences

Radisson Blu Plaza Hotel, Hyderabad, India February 03-05, 2014

Shruti Sethi, J. Venu Madhav, Charanjit Kaur and Krishan Lal

Scientific Tracks Abstracts: Agrotechnol

Abstract:

Garlic is being widely used as a therapeutic food and a flavouring agent in Indian households. Rapid urbanization and more women joining the workforce, has led to an increase in the demand of shelf stable, ready-to-eat, convenience foods with consistent functional quality. Peeled garlic cloves offer convenience but have short shelf life as they have high tendency towards surface discoloration, moisture loss and microbial spoilage. The nature of the demand for minimally processed products requires that they be fresh-like, visually acceptable and appealing. Reports suggest that commercial ready-to-use garlic products such as paste, powder, flakes etc. do not retain the fresh like characteristics and the required functionality owing to the harsh processing procedures followed for their manufacture. Modified atmosphere packaging is a potent tool to maintain the freshness and functional quality of minimally processed garlic cloves in terms of its total antioxidant capacity, total phenolic content, pungency and nutritional value. In the present investigation, the effect on quality of minimally processed garlic cloves of two varieties, viz., Yamuna Safed (G-1) and Yamuna Safed-4 (G-323) was evaluated during modified atmosphere storage. Freshly peeled garlic cloves were packed in different modified atmosphere conditions of oxygen (1-3%) and carbon dioxide (5- 15%) concentrations and stored for 28 days at 10C and 75-85% RH. It was observed that there was a non-significant increase in PLW for both the varieties under various modified atmospheric storage conditions in all the samples. Modified atmospheric packaging of samples was found to be most effective for retaining firmness, colour and other quality parameters such as total soluble solids, total antioxidant activity, total phenols and pyruvic acid and minimizing respiration and ethylene evolution rates throughout the storage period irrespective of and variety used.

Biography :

Shruti Sethi is currently working as Senior Scientist in the Division of Post Harvest Technology, Indian Agricultural Research Institute (IARI), New Delhi with more than 11 years of research, teaching and extension experience. She obtained her PhD from Punjab Agricultural University, Ludhiana, India in Food Science and Technology. Her research interests centre primarily on processing and value addition of horticultural and arable crops. She has standardized technology for development of ready-to-use gravy bases, spiced fruit appetizers and protein rich cookies and is currently engaged in development of nutritionally enriched baked products and drinks. She has more than 50 publications to her credit and has also co-authored a book entitled Processing of Fruits and Vegetables for Value Addition.