Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

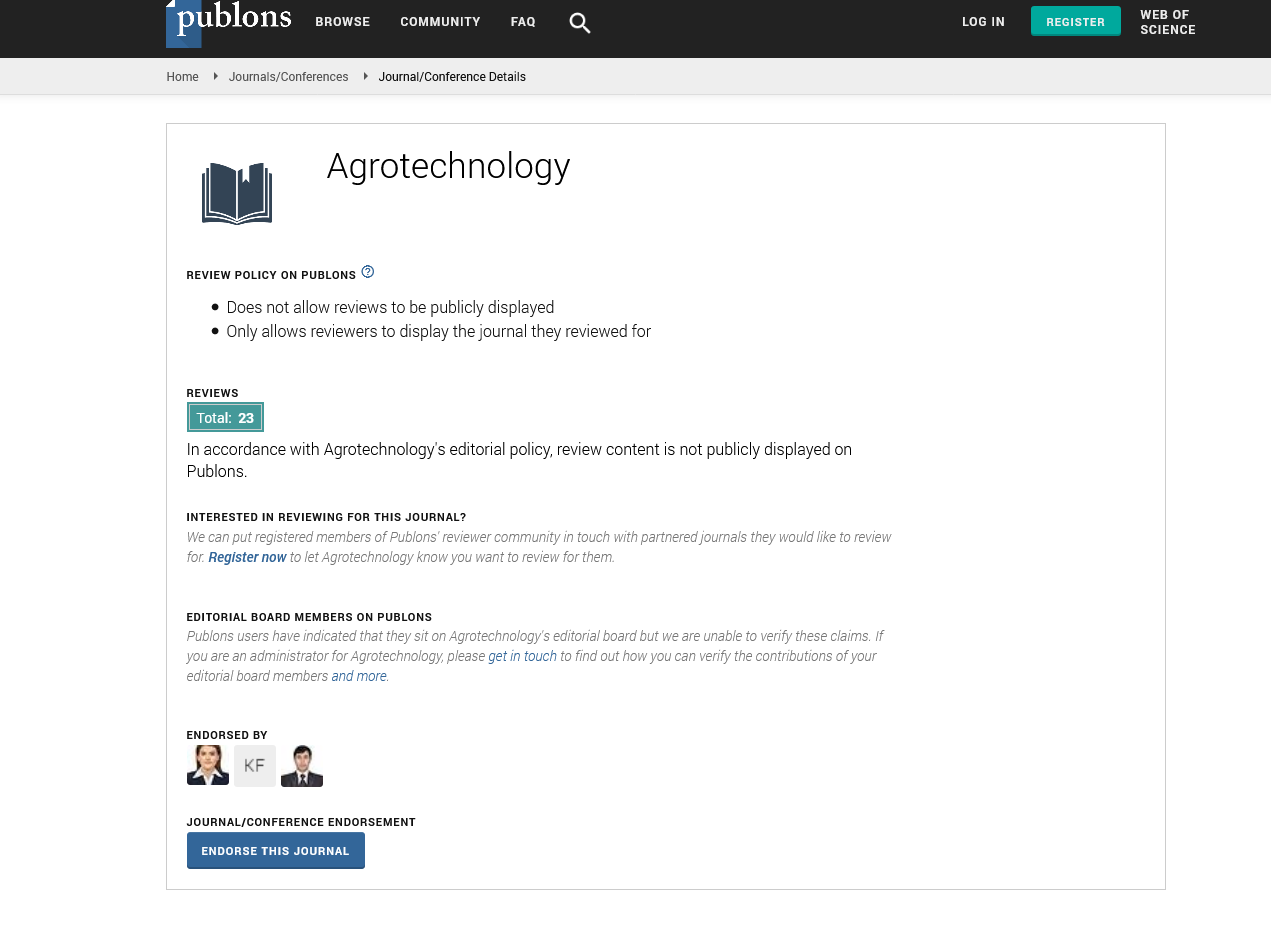

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

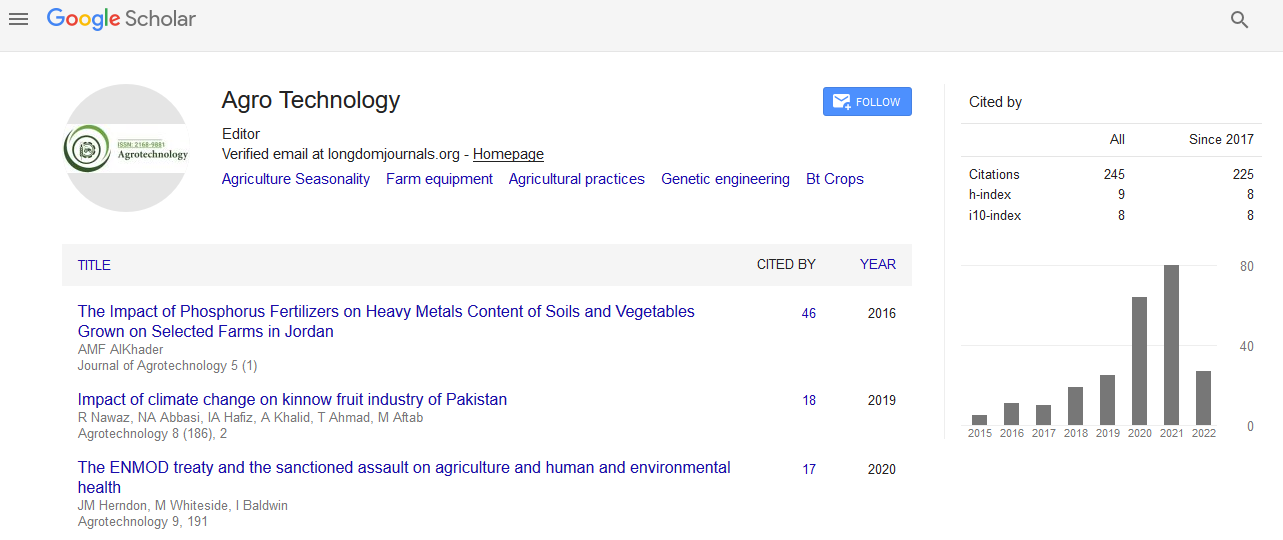

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Drying of coconut using bio-mass fired copra dryer: A livelihood option for rural households in Island Ecosystem

International Conference on Agricultural & Horticultural Sciences

September 14-15, 2012 Hyderabad International Convention Centre, India

Sachidananda Swain

Scientific Tracks Abstracts: Agrotechnol

Abstract:

In tropical and sub-tropical Island climate, coconut is the major plantation crop cultivated throughout the Islands as a source to sustain the small livelihood to the small and marginal family. Copra is produced after drying coconut either through sun dry - ing or other traditional method Machan. Again, due to adverse effect of heavy rainfall (2800-3500mm), temperature (25-32 o C) and relative humidity (75-95%) year round, high microbial infection to the product is observed, causing low quality of copra leading to lower income to the producers. Moreover, the traditional method of producing copra is quite tedious, fetching lower remuneration price in the domestic market. Keeping in view, a biomass fired copra dryer has been designed, developed and tested in the Island conditions at Port Blair, Andaman and Nicobar Islands, India which is located at 11 40 N and 92 46 E. The aim was to increase in employment generation to the rural households who are engaged with traditional method of copra production. The capacity of dryer is 1000 coconuts per batch using MS frame (2.4 m x 1.2 m x 1.6 m). The drying bed made of M.S bar grill kept at a height of 1 meter above the ground level. The results indicated that the biomass fired dryer took 20hrs including 3 hrs of preheating time to reduce the initial moisture content of 55 % (w.b) to the safe final moisture content of 6% (w.b) where as in comparision to solar dryer and open sun drying, it saves 37 % and 50% of total drying time respectively. The average temperature recorded in the drying chamber was 50-55 0 C. The dryer About 80 kg of fuel is used and it requires three man powers to obtain better quality copra. The coconut shell may be used for fuel which saves manpower and energy, thereby enhancing net return to the farmers.