Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

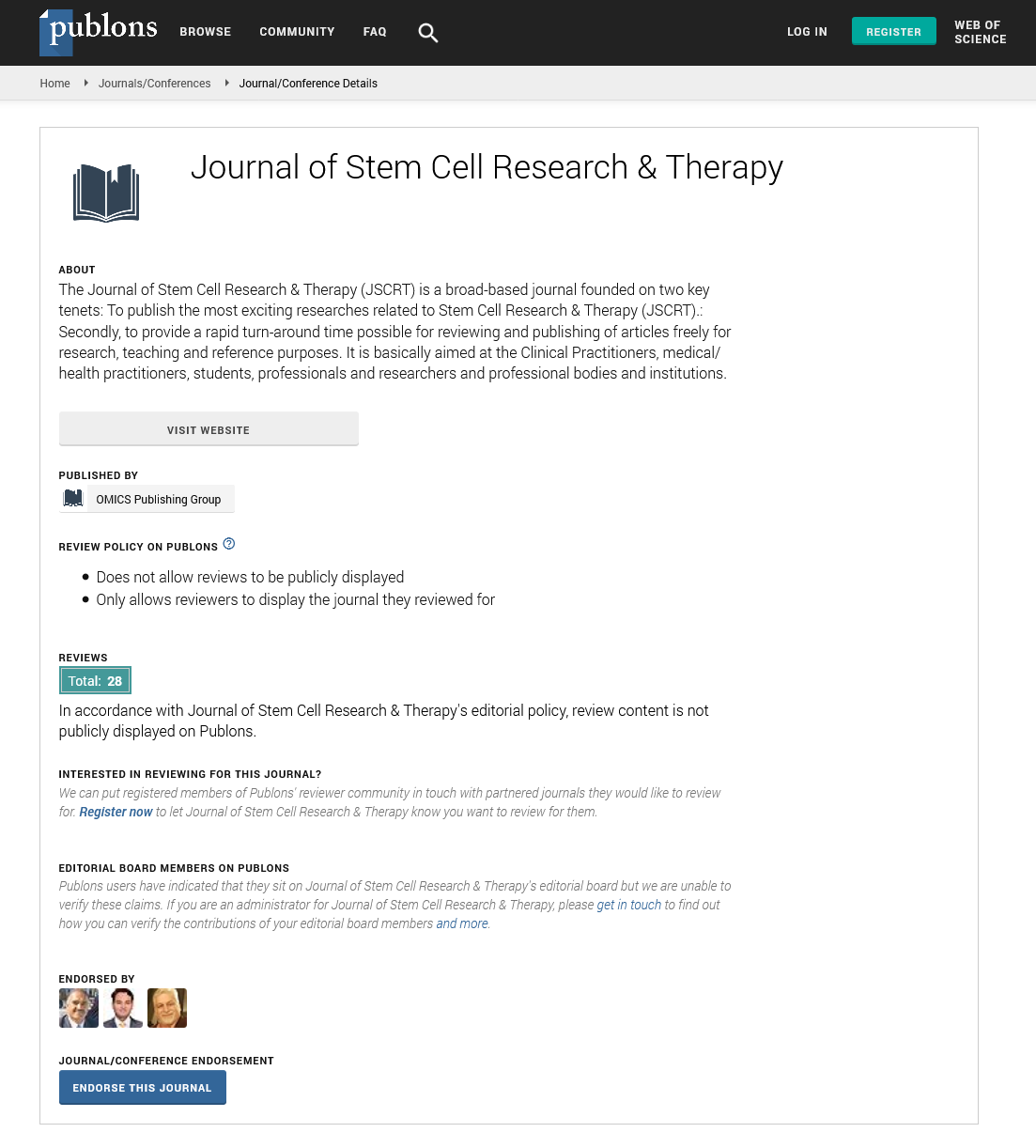

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Development of cost efficient platforms for the industrial manufacturing of pluripotent stem cellderived products for cell therapy: Cell expansion is the starting point

6th International Conference and Exhibition on Cell and Gene Therapy

March 27-28, 2017 Madrid, Spain

Ricardo Baptista

Cell and Gene Therapy Catapult, UK

Keynote: J Stem Cell Res Ther

Abstract:

The commercialization of allogeneic stem cell derived medicines is committed to the development of processes. This process is done to generate consistent large amounts of pluripotent stem cells (PSCs) to be further differentiated to target somatic cell products. The pluripotent program of the cell and gene therapy catapult (CGT) focuses on the development of cost-effective bioprocesses for the industrial manufacturing of PSC-derived products in 2D and 3D culture systems. Here, we present a strategy for the development of closed, scalable, and controlled processes to generate high-density cultures of PSCs in aggregate-based stirred suspension culture, and highlight achievements in 2D-expansion process development. Cell banks of PSCs which are adapted to commercially available culture systems were established and characterized to industry standards. An iPSC line has been established from a pre-seed lot of the cell line. CGTRCiB10 was generated according to GMP principles. The ambr15® tool along with DOE methodology have been employed to support the establishment of a baseline process for the expansion of PSCs in stirred tank reactor (STR). This data suggests that the mixing parameters, energy dissipation and Kolmogorov size could support the scale-up of the vessel mixing properties and enable size-controlled cell aggregates in larger STR. We are currently exploring strategies for process intensification. Enzymatic dissociation of aggregates in the vessel was achieved, and rapid, closed medium exchange was possible using cell retention technologies. Defined media were evaluated for the expansion of CGTRCiB10 in adherent cultures. We used the quantum and the kSep® to develop an integrated, closed and semi-automated process for a cost-effective manufacture of iPSCs. Gene expression and metabolic patterns have been identified for PSCs cultured in adherent and dynamic suspension culture. This work shows the achievements of our program so far, and shows a bioengineer approach to develop scalable STR-processes for the controlled growth of PSCs in high-density aggregate-based suspension culture. This data suggests the potential use of cell retention technologies to support multiple unit operations such as feeding (perfusion culture) and cell harvest. Integration of the upstream processes of cell expansion and differentiation and downstream operations in the same vessel, would represent a step change in the development of cost-efficient processing platforms for the large-scale manufacturing of PSC-derived medicines.

Biography :

Ricardo Baptista is a lead Scientist in the Process Development Team at Cell Therapy Catapult, London, UK. He is currently working on the development of scalable bioprocesses for manufacturing of human pluripotent stem cells, and on the industrialization of the production of stem cell derived products. He is also involved in projects aiming the automation and translation of bioprocesses for cell therapy manufacture. Previously in Cell Therapy Catapult, he held the role of Project Manager and Scientist in Product and Process Development team at CCRM-Centre for Commercialization of Regenerative Medicine, in Canada. His work on the production of NK-92 cells using stirred-tank reactor technology allowed for a reduction in the manufacturing costs over 50%, and facilitated initiation of Phase II trials with NK-92 cells in Princess Margaret Cancer Centre, in Toronto. He is a Biological Engineer and has obtained his PhD Degree in Biotechnology and Biochemical Engineering at Technical University of Lisbon, in 2005. His Post-Graduate work on the optimization of the production of human recombinant cytokines in mammalian cell bioreactors has supported projects in stem cell research at Dr. Joaquim Cabral and Dr. Peter Zandstra Stem Cell Bioengineering Labs. His second Post-doctoral work at Zandstra Lab in University of Toronto led to two relevant publications in stem cell bioprocessing. Recently, he has been invited as a Speaker in courses and workshops of cell therapy bioprocessing with lectures on Bioreactor Technologies and Process Intensification.