Indexed In

- Academic Journals Database

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Scimago

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

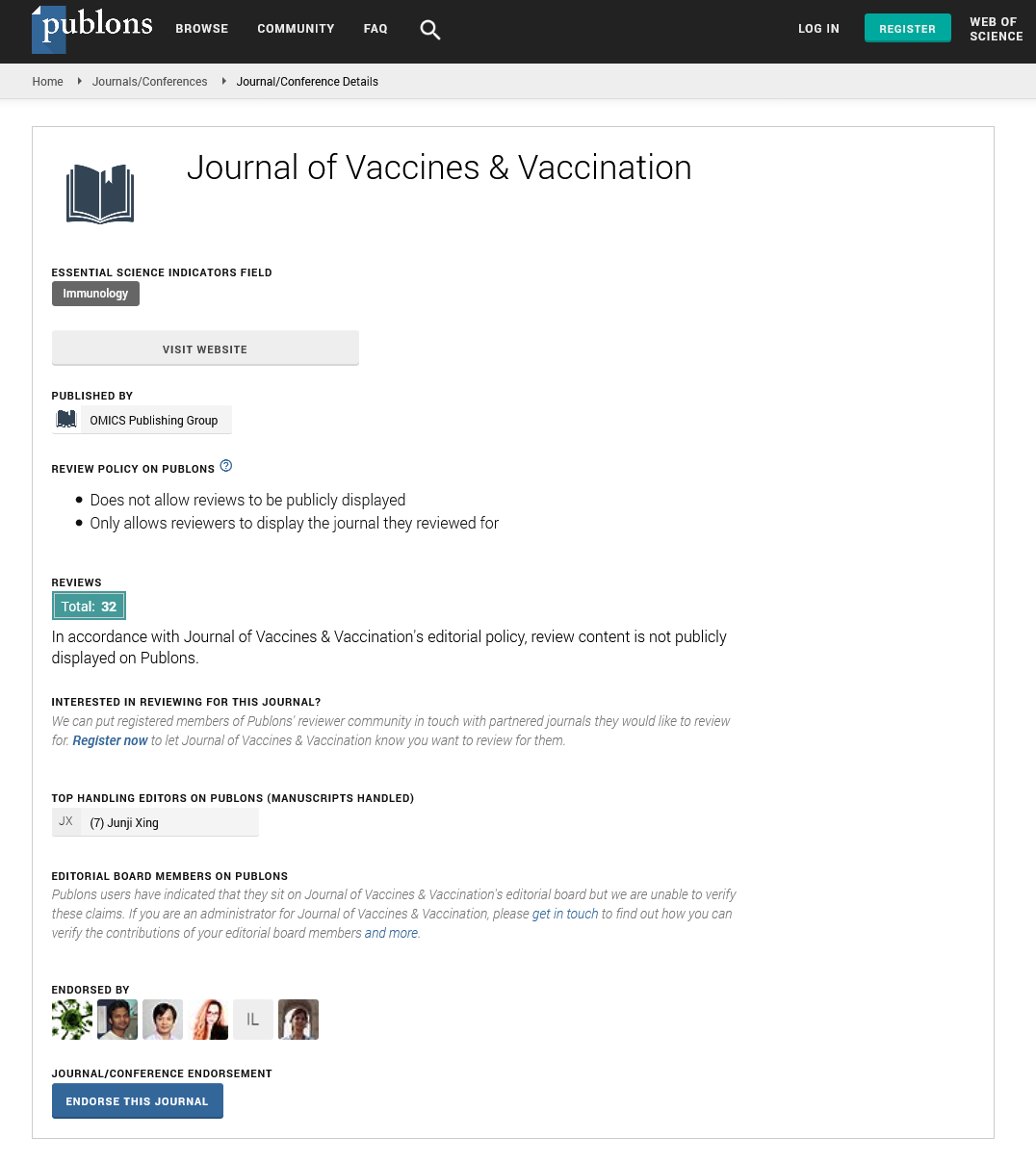

- Publons

- MIAR

- University Grants Commission

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Development of an anti-idiotypic Mab as cancer vaccine: From discovery to approval

6th Euro Global Summit and Expo on Vaccines & Vaccination

August 17-19, 2015 Birmingham, UK

kathya Rashida de la Luz Hernandez1, Julio Santo-Tomás1, Yoan Machado1, Yadira Aguilar1, Svieta Víctores1, Yadira Prieto1, Orlando Morales1, Amparo Macías1, María C Barroso1, Tania Crombet1, Eduardo Ojito1, Yudisleydis Fortunato1, Yanitzia Crespo1, Dasha Fuentes2, Danais Vidal1, Yamilet

Scientific Tracks Abstracts: J Vaccines Vaccin

Abstract:

Background & Novelty: Racotumomab (1E10) is a murine anti-idiotypic antibody that mimics N-glycolyl-GM3 gangliosides.

This antibody has been tested in some countries as an anti-idiotypic vaccine adjuvated in Al (OH)3 in several clinical trials

Phase II and III for NSCLC, melanoma and breast cancer. Recently this product was approved for treatment for NSLC by

regulatory authorities in Cuba and Argentina. This study describethe novel and complete development strategy allowed taking

the product from the original idea in the laboratory to test the concept in advanced clinical trials and approval, including its

scale-up and comparability studies.

Experimental Approach: Initially the product was obtained from mice ascites fluid (AF), however a new pilot scale cGMP

process based in stirred tank continuous mode cell culture using protein free medium was developed (ST). Further the

production was scaled up to 1000 L bioreactor and a culture medium was optimized in order to increase productivity and cell

growth. Bioequivalence between vaccine products obtained from ascites, different stirred tank scales and different cell culture

media through a comparability tests was studied. Also, the influence of pH, ionic strength and phosphate concentration of

buffer on the adsorption of the Mab to the aluminum gel was investigated. Formulations with different adsorption percentages

and antibody/adjuvant ratios were characterized by DLS. Different characteristics as primary, secondary and tertiary structure,

micro heterogeneity, identity, purity and biological activity of obtained Mabs, as well as vaccine formulation characteristics

as stability, absorption to AlOH3, immunogenicity and antitumor activity “in vivo” were analyzed. Techniques like mass

spectrometry, liquid chromatography, circular dicroism, fluorescence, SDS-PAGE and immuno detection. In case of in vivo

analysis, two animal models were used (Leghorn chickens for immunogenicity and mouse for anti-tumoral activity of vaccine).

Results & Discussion: Some differences were observed like charge heterogeneity and glycans attached to Fc-γ, mainly due

to varying amount of sialylated species, asparagine deamination and oxidation in each condition. These characteristics did

not affect the immune response elicited in chicken and antitumor effect on F3II carcinoma model. Moreover optimization of

product formulation significantly increased the percentage of adsorbed protein to alumina and stability. In vivo experiments

using Leghorn chickens were performed to evaluate effects on immunogenicity of the different vaccine formulations. However

no influence of the adsorption and the racotumomab/Alumina ratio on the immunogenicity of the vaccine was observed. In

summary, the introduction of a well-established process platform for the production of monoclonal antibodies, which led

to increased levels of vaccine safety and reducing production costs, yielded a product very similar in each case, enabling the

scaling and clinical development of the product until its health record.