Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

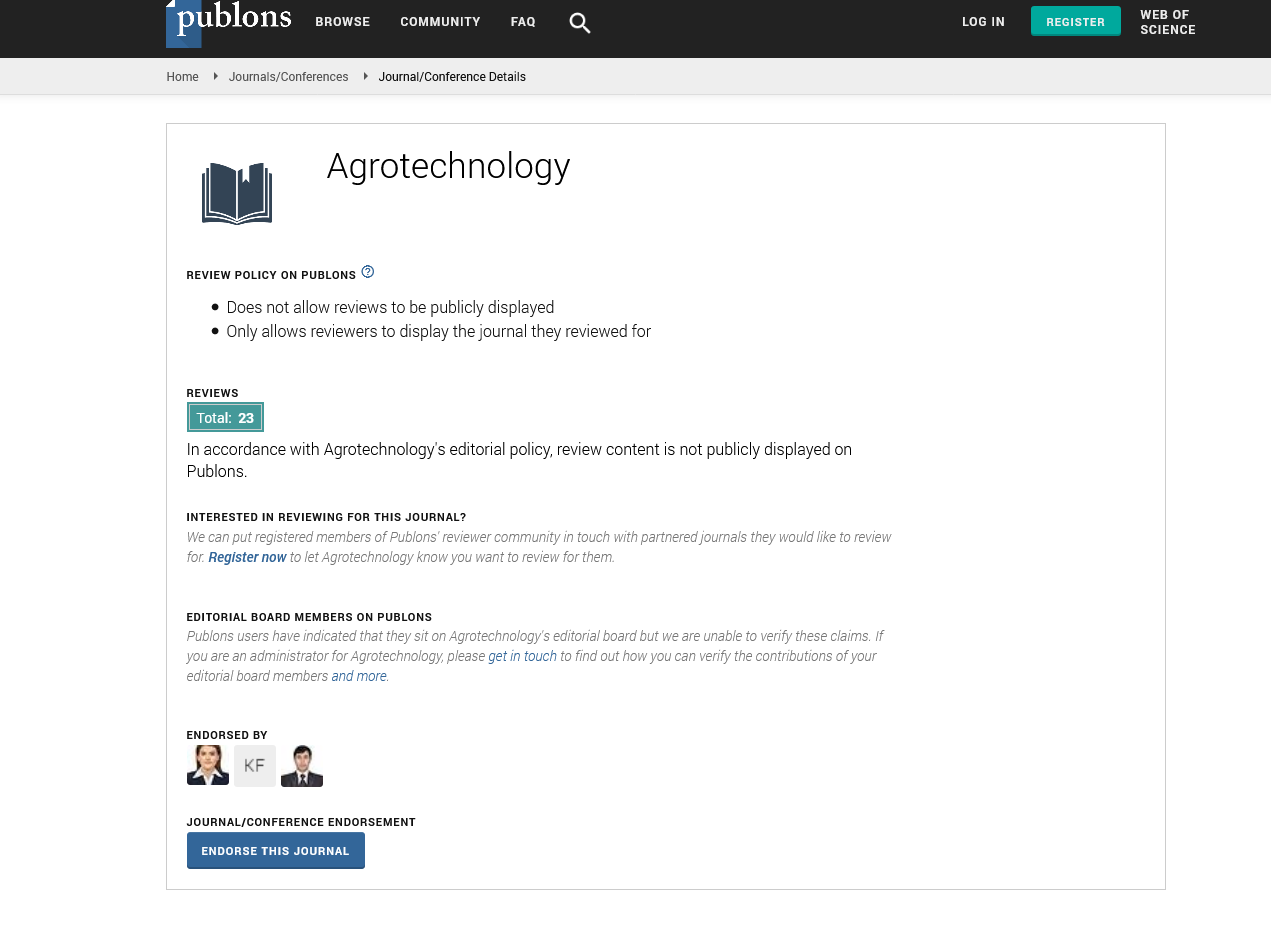

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

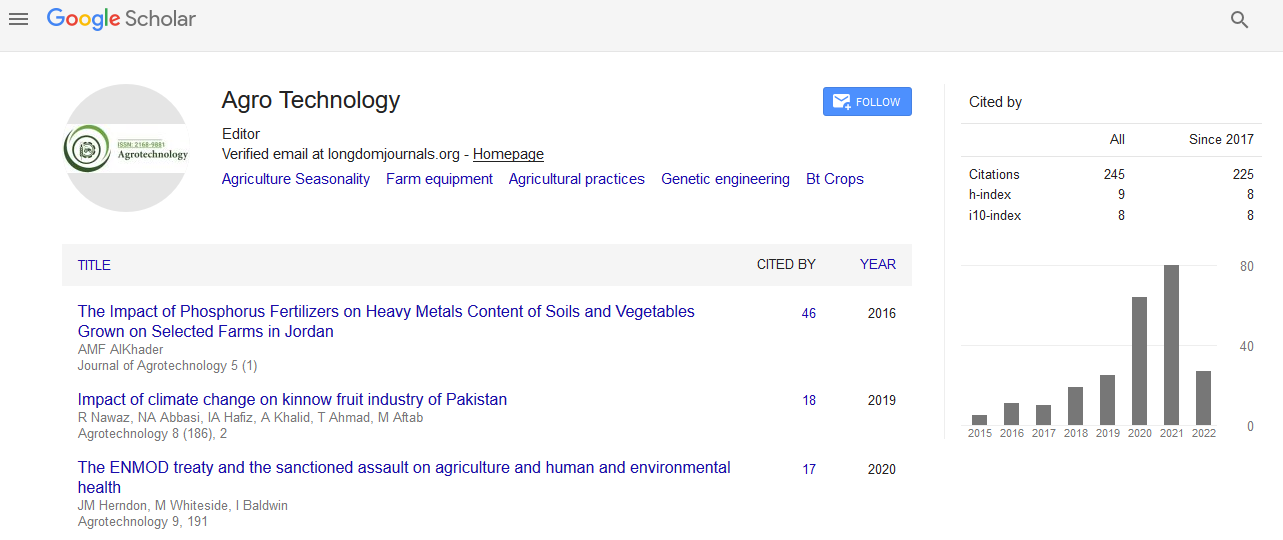

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Comparative study of various threshers for different crops

International Conference on Agricultural & Horticultural Sciences

September 14-15, 2012 Hyderabad International Convention Centre, India

Sunil Kumar, Dushyant Singh, M B Tamhankar and PC Bargale

Scientific Tracks Abstracts: Agrotechnol

Abstract:

Timeliness is very crucial in all farm operations in general and in threshing particularly. Slightly delay in threshing opera - tion may lead to tremendous loss in production, productivity and sometimes quality of the grains. In India various types of threshers namely Multicrop thresher, Paddy thresher, High capacity multicrop thresher, Pigeon pea thresher, Semi-axial flow multicrop thresher, Groundnut thresher, Sunflower thresher, Single earhead thresher, Maize thresher etc. are used for threshing of various crops. Among these threshers, multicrop thresher with medium and high capacity are most common. These threshers can be used for various crops with little adjustments in cylinder speed & clearance between cylinder and concave. These threshers provide good quality grains for seeding and human consumption as well as bhusa for animal feed. The losses during operation are also in the range of 0.5 3.0 % with broken grains 0.2 1.4 % which are in the acceptable range of BIS standard. Present study was carried out to study the performance of various threshers for different crops like wheat, paddy, gram, soybean, maize, pigeon pea, sunflower, groundnut etc. It is revealed from the experiment that multicrop thresher with medium and high capacity are working better for wheat, gram, maize, mustard, pigeon pea and soybean and also found more economical as compared to other evaluated threshers. The capacity of high capacity multicrop thresher ranging from 425 kg/h (mustard) to 2900 kg/h (maize). In case of sunflower thresher no broken grain was found.