Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Review Article - (2021) Volume 11, Issue 3

Waste Management in Large Distribution Chains Transformation of Food

Santiago Ruiz*Received: 02-Feb-2021 Published: 24-Feb-2021, DOI: 10.35248/2252-5211.21.11.400

Abstract

At present, there are numerous supermarket chains destined to the sale of food. The paper analyses the possibility to generate energy from the waste food of the supermarkets, which final destination is the municipal dump. Through the Circular Economy Action Plan, proposals are included to achieve the revaluation of the generated waste. Focusing on the meat and fish collection that is not sold by these well- known supermarket chains, two possible destinations can be analysed: One is the generation of biogas and the other is the production of meal and fat for animal consumption.

Keywords

Food waste; Animal meals; Animal fats

Introduction

The current COVID-19 Since the Ministry of Agriculture, Food and Environment established the creation of the strategy “more food, less waste” in 2013, this programme was based on the reduction of food waste and the recovery of the discarded food [1]. Nowadays, the international situation associated to food waste has considerably progressed. In the last studies, alarming figures show us that 3% of the sales in the distribution sector in Spain is linked to food waste. One third of the global production of food that is destined for human consumption is wasted throughout the world. This fact means that 1.300 million tons of food are wasted in a year. This quantity covers the 30% of the agricultural area in the world (1.400 million of hectares in size) and 250 million of cubic metres of water (almost 75 times the annual use in Spain) to produce food that ends in the rubbish [2].

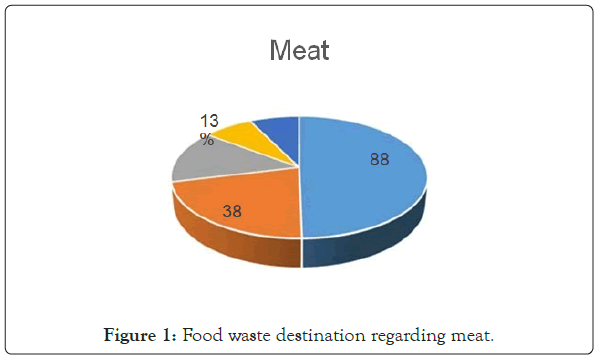

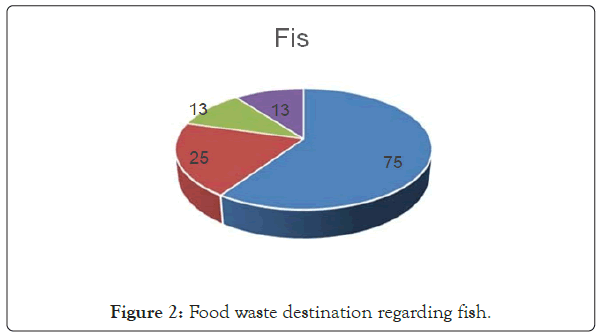

This food when is decomposed produces a carbon footprint of 3.300 million tons of CO2, only overtaken by USA and China emissions. Economically speaking, it also means a high cost since 2,5 billion euros per year are lost, equal to gross domestic product of France[3]. Therefore, diverse workgroups and forums have been created in different levels, both international and in a multitude of countries, to determine what is waste, the amount of waste that is produced, how and why. In addition, what can be done to solve this problem? In Spain, an agreement with the European Union has been reached regarding sustainability through the Circular Economy Action plan where numerous legislative proposals about waste have been examined and included. This plan means a change from the actual lineal economy, where the products destined to human use have a determined use and at the end, they are discarded to a circular economy where the wasted products become resources. This approach of a circular economy is also applied to food production since sustainable food system establishments are essential to face the increasing challenges of food safety. Fish products are the most affected: they indicate an average waste of 5,5 % of their sales. Followed by fruits with 3.2 % and meat with 2,7%. Food waste is lower than 3 years ago. In the following chart, the destination of food waste can be analysed [4]. (Figures 1-2) According to the regulation (CE) Nº 1069/2009; of the European Parliament and of the Council, and the regulation (EU) Nº 142/2011, of the Commission, constitute, since the 4th of March 2011, the community legal frame work applicable to animal sub-products that are not destined to human use and the products derived of them The establishments or plants that generate more than 20kg a week of SANDACH, independently of the kind of origin, must have an authorised agent to collect this sub product.

Figure 1: Food waste destination regarding meat.

Figure 2: Food waste destination regarding fish.

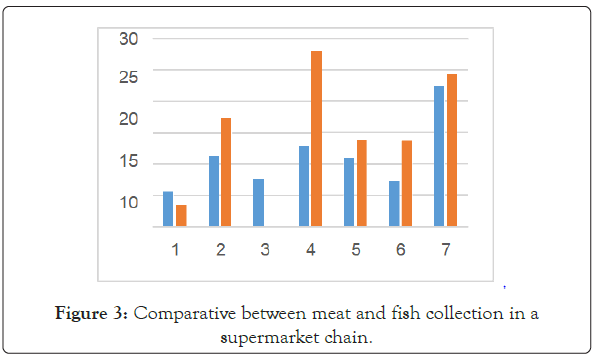

Consecutively, we will analyse the following collection numbers in seven establishments of a well-known supermarket chain in Madrid where animal by-products not intended for human consumption of meat and fish collected. The comparative made corresponds to the year 2018. (Table-1) (Figure-3).

| Comparative of a supermarket chain | |||

|---|---|---|---|

| Madrid's supermarket examples |

Meat (Tn) | Fish (Tn) | Total amount |

| 1 | 5,60 | 3,54 | 9,14 |

| 2 | 11,34 | 17,30 | 28,64 |

| 3 | 7,63 | 12,95 | 20,58 |

| 4 | 12,90 | 27,91 | 40,82 |

| 5 | 11,00 | 13,88 | 24,88 |

| 6 | 7,26 | 13,82 | 21,08 |

| 7 | 22,45 | 24,30 | 46,75 |

| Total amount | 78,17 | 113,70 | 191,87 |

Table 1: Comparative of meat and fish collection in the supermarket chain.

Figure 3: Comparative between meat and fish collection in a supermarket chain.

Analysing the data of this supermarket chain, it is notably reflected that there is more fish waste. This increase in fish waste in relation to meat waste is due to the following reasons:

• There is an elaboration and processing plant in the supermarket chains.

• It is a product that is more rapidly deteriorated than meat.

Performance

If we analyse the performance that this food can produce, we could determine that its recovery can be achieved out in two possible ways:

Obtention of animal meal and fat

Through digestion and thermal treatment processes, animal proteins and fat could be obtained. The performance for these products is the following.

Meat sub-products: Animal meal production for this type of waste is close to 28%, which would generate around 28 tons/year. The obtention of animal fat is estimated to be around 24%, which means the production of about 19 tons/year.

Fish sub-products: Production coming from fish waste in terms of meal production is around 25,5%, which would mean the valorisation of 20 tons of fish flour. Additionally, with the 113,70 tons of fish, 7 tons of fish fat can be obtained

To get Biogas through vegetal food waste

Pre-treatment: This process intends to accelerate the process of hydrolysis of organic waste to increase production, biogas quality and it reduces the period of resistance in the digester due to an increase in the biodegradability, favouring optimum conditions for the microbial growth[5]. The facility receives waste collected from raw material reception pits. Elastic cords and tapes are used in the lines, which transport waste to the sorting cabin or triage, in which, manually, the removal of those materials that due to its excessive volume would cause problems downstream the productive process, takes place.

At this stage, fractions of products that independently of their volume have an objective value in the market (cardboard, plastic, metals, etc.), and that are deposited because of seriousness in prepared locations, are removed.

Wet matter treatment: The materials that are separated with a diameter lower than 80 mm are transported through tapes to metal separation equipment’s via electromagnets to remove ferromagnetic and non-ferromagnetic particles. The rest of waste to initiate the hydrolysis process. A “lung pit” will be provided to keep the supply of this stage homogenous.

Co-digestion, anaerobe, bio digestion: Co-digestion is the anaerobic fermentation of two or more substrates that complement each other chemically, increasing stability, and the production of biogas and the equilibrium of the process.

The colloid or bio waste is sent to digestion tanks, of 3500 m3, where the anaerobic fermentation of biodegradable compounds will be carried out, extracting in the 21 days of resistance the total practice of the volatile organic compounds of the organic matter.

The mass agitation to allow the bio digestion process is carried out through the use of part of the generated biogas, that is pressured in the upper part and conducted through a vertical interior pipe causing an agitation that allows the active maintenance of the totality of the mass[6].

The solid substratum called digestate decants in the lower part of the digesters and is extracted with a peristaltic pump that transports it to a middle deposit which regulates the proceedings over this product.

Depuration and exploitation: Depending on the use of biogas, depuration should be more or less strict. Biogas is stored in gasholders and can be valorised in boilers, cogeneration engines (more generalised system), vehicles, its introduction to the natural gas transportation network or in batteries as we will see later.

Digestates and its exploitation: The digestate is a material of homogeneous composition, where bad smells have been totally reduced and that contains all the nutrients that the initial organic material contained. It can be used as organic- mineral fertilizer of crops, either directly or after being subjected to a solid-liquid separation process and later the solid fraction can handle, either alone or mixed with other substrates.

It contains approximately 90% of water. Thus, it should be reduced to achieve an adequate anaerobic fermentation. By using a centrifugal separator, 75 % of humidity could be reduced. Once it is anaerobically fermented in digestate tunnels, pruning and gardening wastes are added to fluff the mixture and create a defibration, which also allows the incorporation of nutrients to the final product. All this mixture will be introduced in fermentation tunnels, permanently controlling the physicochemical parameters of the combination[7]. After a two weeks period and with the desired parameters achieved to its maturation as a preliminary stage to the refining operations that allow us to obtain a product with an adequate texture and granulometry for its use as fertiliser. Refining consists in subjecting the product to successive granulometric sieves and a densimetric separation. The combination of this food waste previously mentioned, through the previous biomethanisation process, in mesophilic stage between 35-38°C single-stage, with a dilution of 30% of dry matter and 70% of water and an approximately retention time of 21 days, can decompose the mixture of all this waste to obtain biogas[8].

Through biomethanization via humidity processes, in mesophilic phase between 35-38 º C single- stage, with a dilution of 30% of dry matter and 70% of water and with an approximately retention time of 21 days, the mixture of all this food waste can be decomposed for the getting of methane. The efficiency of these 192 tons, considering the best available techniques is of 176 Nm3/ Tn raw material, what entails the generation of 33.792 Nm3 of biogas, injectable to the network under certain technical specifications of the supply company, or that could become electric power through moto generation to obtain about 187 MWh, what would mean electric energy for around 18.700 households, in addition to the obtainment of a digest for the acquisition of compost or fertilisers of 59%, in other words, other 113 tons[9]. (Table-2).

| Raw Material | 192 tons |

|---|---|

| Methane generation | 33792Nm3 |

| Electricity generation | 187 MWh |

| Energy for households | 18,700 house holds |

| Avoid the emission of methane | 13,3 tons |

Table 2: Generation to obtain about 187 MWh, what would mean electric energy for around 18.700 households.

Conclusion

Food sub-products or waste transformation companies are based on the new economic model of a circular economy that nowadays is being implemented in the Europe 2020 strategy, which intends to generate an intelligent growth, sustainable and conciliator, where all waste and/or sub-product has a second life.

With the transformation of food waste from a food commercial macro- area, the emission of 20.275 Nm3 of methane could be avoided, which pollutes more than CO2. In other words, we would avoid the emission of 13,3 tons of this gas to the atmosphere due to food waste degradation in dumping sites.

REFERENCES

- ECLAC N. Strategic alliance between the Economic Commission for Latin America and the Caribbean (ECLAC) and the Federal Ministry for Economic Cooperation and Development (BMZ) of Germany. Fed de Coop Econ Des. 2018.

- AECOC. 6th Meeting Point Against Food Waste. (2018). Aprovech de rec y reval de resid agroal. 2018.

- Vaqué LG. Food waste in the EU: an unsolvable problem ? CESCO Magazine of Consumer Law. 2017; 132-46.

- Aguilar-Cabezas FX, Botero-Botero R. The total economic benefits of biogas production using a low-cost polyethylene biodigester. Economic benefits of biogas production using a low-cost polyethylene biodigester. Tropical Land: Sustainability, Environment and Society. 2006; 2:15-25.

- Báez Alcántara NM. Comparison of waste management between various European cities (Barcelona, Paris, Hamburg and Prague) and proposal for improvement in collection logistics '' (Master's thesis, Universitat Politècnica de Catalunya).

- Daza M, Oviedo OE, Marmolejo RL, Torres LP. Selection of agro- environmental systems with potential use of municipal bio-waste compost. Acta Agronómica. 2020; 64:134-145.

- Galera. Bio-waste: Management and use alternatives. 2014.

- FAO, Biogas Manual. 2020.

- M. H. Alanbari, Santiago Ruiz. Study of energy generation from organic waste from the community of Madrid. 2019.

Citation: Santiago R, Waste Management in Large Distribution Chains Transformation of Food. Int J Waste Resour. 11:400.

Copyright: © 2021 Santiago Ruiz. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.