Indexed In

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2024) Volume 15, Issue 3

Utilization of Leachate as Inoculum in Bioremediation of Oil Sludge on Total Petroleum Hydrocarbon, C/N Ratio, Polycyclic Aromatic Hydrocarbon and Heavy Metals Content

Nia Rossiana*, Ida Indrawati and Yulisa MustikaReceived: 20-Nov-2019, Manuscript No. JPEB-24-2747; Editor assigned: 25-Nov-2019, Pre QC No. JPEB-24-2747 (PQ); Reviewed: 09-Dec-2019, QC No. JPEB-24-2747; Revised: 01-Jul-2024, Manuscript No. JPEB-24-2747 (R); Published: 29-Jul-2024, DOI: 10.35248/2157-7463.24.15.573

Abstract

Study on utilization of leachate as inoculum of microorganism in bioremediation of oil sludge on Total Petroleum Hydrocarbon (TPH), C/N ratio, Polycyclic Aromatic Hydrocarbon (PAH) and heavy metals content was conducted during 45 days. The aim of the present work was to assess the ability of leachate inoculum in degrading oil sludge. The main parameters in this study, TPH and C/N ratio were analyzed within 15 days of interval while PAH and heavy metals were measured at the beginning of experiment (day 0) and at the end of experiment (day 45). Supporting parameters such as pH, temperature and humidity of medium were also analyzed. Our finding showed that the leachate inoculum reduced TPH and Cr content as much as 24.20% and 5.88%, respectively. On the other hand, C/N ratio in the oil sludge medium 30% increased as much as 1.14%. The PAH compounds that can be degraded by leachate and were not redetected at day 45 are 9-Octadecenoic acid, methyl ester (C19H36O2) and Hexacosane (C26H54). These results led us to conclusion that the leachate could be alternatively used in optimization of oil sludge bioremediation.

Keywords

Bioremediation; Oil sludge; Organic fertilizer; Leachate

Introduction

Until today, the demand of fuel oil has been increased rapidly, hence enhancing its exploration and processing. However, although this sector has increased the country’s income and foreign exchange, petroleum mining has carried the risk of environmental pollution. Soil contamination due to petroleum industrial activities is commonly occurred in developing country, where the law enforcement is lacking.

Petroleum waste can be defined as an industrial waste resulting from the exploration and refining processes, which potentially produce waste such as oil sludge. This oil waste contains various toxic compounds, for instance PAHs, as well as heavy metals that could be detrimental to environment.

Based on Indonesian government regulation No.101/2014, oil sludge is classified into hazardous and toxic waste material (LB3) with code B 351-3. In this the present study, oil sludge used is originating from PT. Pertamina operation site Balongan. According to the analysis carried out in 2016, the oil sludge from this site has TPH level as much as 29.50% and C/N ratio as much as 149.5.

The minister of environment’ decree No.128/2003 states that the quality standard for TPH level in oil sludge must not excess 15%. Thus, when TPH level is more than that is stated, further treatment must be conducted. Additionally, according to Chevron Indonesia, the petroleum-contaminated soil can be declared safe and can be moved from the processing location to the environment when the TPH level reach ≤ 1%.

Bioremediation is a natural process to clean up the hazardous chemical substances. This process involves biodegradation by the microbes, which will produced water and non-hazardous gas such as CO2. The rate of biodegradation in remediation of oilcontaminated soil can be enhanced by the addition of bulking agents to improve the permeability, water holding capacity and porosity to increase speed up bioremediation process [1].

Previous study from Riansyah and Putu as well as Nurhasanah revealed that leachate contains high nutrients and can be used as liquid fertilizer. Gelardiansyah et al., leachate is produced when rainwater falls, flows and seeps into the waste. This wastewater carries rich dissolved material along its journey. The leachate is generally acidic, rich in organic materials, contains sulfate ions and has a high metal concentration as well as characterized by its distinctive odor.

The main purpose of this study was to evaluate the possibility of leachate as source of microorganism inoculum and nutrients that can stimulate microbial growth hence it can degrade oil sludge. The assessment on the ability of leachate in degrading the oil sludge was evaluated by measuring the Total Petroleum Hydrocarbon (TPH) and Polycyclic Aromatic Hydrocarbon (PAH) content, C/N ratio and also heavy metal content during 45 days.

Materials and Methods

The present work was conducted from February to July 2017 in the microbiology laboratory, department of biology, universitas Padjadjaran. The heavy metals analysis was done in the laboratory of geology survey center Bandung. The TPH analysis was performed in the ruminant animal nutrition laboratory and food chemistry faculty of animal husbandary universitas Padjadjaran. As for the PAH and C/N ratio were conducted in the laboratory of chemistry universitas Padjadjaran and the laboratory of soil chemistry faculty of agriculture universitas Padjadjaran, respectively [2].

Experimental method with single factor, which is the leachate as inoculum to degrade oil sludge at concentration 30%, was carried out for this study. The main parameters in this study were the number of microbial colonies (CFU/mL), TPH and PAH content, C/N ratio and heavy metals content. The TPH content and C/N ratio were analyzed for each 15 d of intervals, while the PAH and heavy metals content were measured at the beginning and the experiment (day 0 and day 45, respectively). The supporting parameters were analyzed are the pH, temperature (°C) and medium humidity (%).

The TPH content (%) was analyzed using soxhlet, while the C/N ratio (%) was analyzed following protocol from Walkley and Black. The number of microbial colony (CFU/mL) was measured using Total Plate Count (TPC) methode, whereas the heavy metals content (Pb, Ni, Cd, Cr and Hg) were analyzed using Atomic Absorption Spechtrophotometer (AAS). On the other hand, the PAH content was measured using GCMS. The main and supporting parameters were analyzed descriptively [3].

Experimental set up

Addition of oil sludge with inoculum: The oil sludge medium (oil sludge, soil and sand) was prepared and placed into the glass bottle and sterilized, the leachate was added into the glass bottle (500 ml) and sterilized, then 25% from the total of leachate was added as much as 500 g. Stirring of medium in the bottle was performed regularly and sampling was carried out every 15 days. The composition of treatment is presented in (Table 1).

| Materials | Dose |

|---|---|

| Oil sludge | 30% (150 g) |

| Soil | 30% (150 g) |

| Sand | 15% (75 g) |

| Leachate | 25% (125 g) |

Table 1: Composition of treatment.

Results and Discussion

Bioremediation of oil sludge waste was carried out by combining the oil sludge with the uncontaminated soil in order to improve the porosity of the waste. Indeed, porosity of the waste has important role in facilitating oxygen exchange. Adequate oxygen may support the microbial work in order to degrade the waste. These microbes need high porosity to obtain the oxygen during hydrocarbons biodegradation. Therefore, the oil sludge concentration is proportionally to the time of degradation process. The success of bioremediation also depends on the nutrients availability and the environmental condition such as the optimum pH for the microbes.

In the present study, bioremediation was performed aerobically. The oxygen was obtained from the regular stirring during bioremediation thus the oxygen in the medium did not easily deplete. According to Aliyanta et al., the addition of organic matters can increase the soil porosity that will influence the aeration levels and water content in the soil.

Identification of leachate bacterial

A total of four species have been selected from the selection and identification on the leachate water, namely: Bacillus subtilis, Bacillus licheniformis, Bacillus pumilus and Pseudomonas putida. Analysis on biodegradation of leachate water revealed that the bacterial consortium of Bacillus subtilis, Bacillus licheniformis, Bacillus pumilus, Pseudomonas putida, Nitrobacter and Nitrosomonas was the most efficient in degrading Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solid (TSS), ammonium, chromium and lead as much as 67%, 80%, 67%, 92%, 90% and 90%, respectively [4].

Total Petroleum Hydrocarbon (TPH) content

The TPH content in the medium of oil sludge 30% that was added by leachate inoculum was analyzed using Soxhlet. The observation was conducted during 45 d with 15 d of intervals from the beginning (d-0) to the end of the experiment (d-45). The initial TPH content in the oil sludge 100% prior to the treatment was 29.50%. Mean of TPH content in the oil sludge medium 30% with leachate inoculum during experiment is presented in (Table 2).

| Type of inoculum | (d-0) | (d-15) | (d-30) | (d-45) |

|---|---|---|---|---|

| Leachate | 23.8 | 23.32 | 21.21 | 18.04 |

Table 2: Mean of TPH content in the oil sludge medium 30% with leachate inoculum during 45 d.

A significant decrease on TPH content appeared in the oil sludge medium with leachate inoculum from d-0 to d-45 as much as 24.20%. The TPH content in oil sludge medium 30%with leachate inoculum on d-0 was 23.80% and reduced to 18.04% on d-45.

This reduction may be due to the growth of indigenous microbes that are stimulated by the presence of nutrition in leachate inoculum thus the microbes can actively degrade the hydrocarbons and use them as their source of energy (Table 3).

| Type of inoculum | Nitrogen (N, %) | Phosphorus (P, %) | Potassium (K, %) |

|---|---|---|---|

| Leachate | 0.32% | 0.10% | 0.87% |

Table 3: Nutrients content in leachate inoculum.

According to the criteria from Hardjowigeno, when the Ntotal> 0.75, P>0.035 and K>0.006, they can be categorized as very high. This category confirms the present study that all of nutrients presences in leachate were very sufficient to support microbial growth. High availability of nutrients will affect the microbes in degrading hydrocarbons because these nutrients are consumed during remediation.

Addition of nutrients such as nitrogen, phosphorus and potassium will give an ideal soil condition to support bioremediation. The augmentation of nutrients level can stimulate the growth and reproduction of microbes that can degrade hydrocarbons. Indeed, nutrition has the crucial role in synthesis and cell growth as well as enzyme activities that produced by the microbes in degrading pollutants. Basically, all microorganisms need carbon as their source of energy for supporting their activities. Nitrogen and phosphorus are the essential elements to catabolize important compounds in the cell that determine the growth activity in microorganisms. Nitrogen indeed has significant role in the synthesis of nucleic acids, amino acids and enzymes. In contrast, phosphorus has essential role in synthesis of nucleic acids and phospholipids. These elements must be presence in exact ratio to achieve the optimum microbial growth.

The decomposition of hazardous compounds in pollutant was conducted by using enzymes possessed by the microorganisms. The aerobic microorganisms are known for their quick and efficiency in degrading hydrocarbons because the aerobic reaction requires less free energy to initiate and produce more energy. Several enzymes will degrade the hydrocarbons consecutively where the oxygen acts as external acceptor. For instance, degradation of alkanes involves the formation of fatty acids, alcohols and aldehydes. These fatty acids will be broken and released by CO2, forming new fatty acids that consist 2 unites of carbon that are shorter than the original molecules. This process is known as β-oxidation.

Specifically, the breakdown of hydrocarbon n-alkane molecule by the microbes was initiated by the multicomplexes enzyme system (ω-hydroxylase) that can oxidize alkane into primary alcohol. Afterwards, this newly formed primary alcohol is oxidized into aldehyde compound and then into fatty acid. The fatty acid produced can be breakdown either into CO2 through α-oxidation or used as nutrition to support the cell growth through β- oxidation. The half of CO2 gas formed will react with the oil fraction thus consequently degrade the hydrocarbon content in the oil.

C/N ratio

The initial C/N ratio in the oil sludge 100% was 149.45. The mean of change in C/N ratio during 45 d of remediation is presented in Table 4.

| Type of inoculum | (d-0) | (d-15) | (d-30) | (d-45) |

|---|---|---|---|---|

| Leachate | 137.79 | 141.07 | 116.35 | 139.36 |

Table 4: Mean of change in C/N ratio during bioremediation.

A fluctuation in C/N ratio in the leachate inoculum can be observed. The C/N ratio increased in d-0 (137.79) until d-15 (141.07) and reduced in d-30 (116.35) then re-increased in d-45 (139.36). During 45 days, C/N ratio in the leachate from d-0 to d-45 appeared to increase as much as 1.14%.

The organic carbon is generally used as source of energy for the microorganisms to form new cells by releasing CO2 and other products. Low carbon content will provoke faster decomposition, because half of carbons are used as energy by the microorganisms and the rest will be released in form of CO2 (Table 5).

| Type of inoculum | Organic carbon (C, %) | Nitrogen (N, %) | C/N ratio |

|---|---|---|---|

| Leachate | 1.59 | 0.32 | 4.96 |

Table 5: The organic carbon, nitrogen and C/N ratio content in leachate inoculum.

According to the national standard (SNI 19-7030-2004), the C/N ratio in oil sludge must be between 10 and 20. Therefore, the C/N ratio of leachate in the present work can be categorized very low. The elevated C/N ratio produced during remediation may be due to the addition of soils and sands that can increase the C/N ratio. According to Anwar and Untung, C/N ratio in the soil is found approximately 10 [5].

The augmentation of C/N ratio also could be due to the formation of new compounds during the oil sludge remediation, as showed in Nurhusnayain. The authors found that the pyrene (C16H10) and chrysene (C18H12) compounds that have been degraded on d-15 caused the formation of new compound Naphthalene (C12H12) hence increasing the number of carbon molecules. Additionally, the carrier inoculum may contain high polysaccharides/cellulose content which may affect the augmentation in C/N ratio.

The degraded polyhydrocarbons will produce new compounds either in form of polyaromatic (double bonds hydrocarbon compounds in ring form) or the polyalycyclic (double bonds of hydrocarbon chain) that probably may increase or decrease the carbon content. Moreover, the nitrogen content in oil sludge and the presence of inoculum change the nitrogen content by the microbes thus also change the C/N ratio.

Relationship between TPH, C/N ratio and the number of microbial colony in function time of remediation

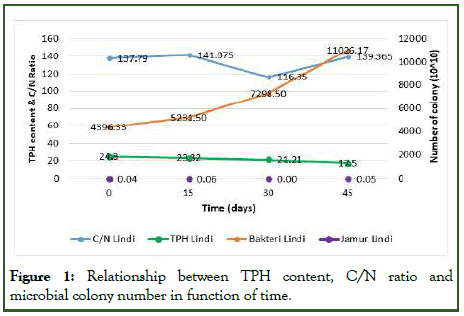

In the present work, the microbial colony counting was carried out by using Total Plate Count (TPC) method. According to Vasudevan and Rajaram, the number of microbial population has significant role in accelerating biodegradation of hydrocarbons. Indeed, the number of microbial population is positively correlated to the percentage of degradation of hydrocarbons (Figure 1) [6].

Figure 1 explains the relationship between the number of microbial colony in the oil sludge medium 30% with leachate inoculum and the TPH content as well as C/N ratio. It was appeared that in the remediation in oil sludge medium 30% with leachate inoculum, the bacterial role was more dominant compared to that of fungal.

Figure 1: Relationship between TPH content, C/N ratio and microbial colony number in function of time.

The number of microbial colony during remediation increased from d-0 to d-45. The indigenous microbes in the leachate inoculum were more adaptable than the fungal leachate.

Fungi is the main hydrocarbons degrader. Biodegradation of hydrocarbons by the fungi, will then be used up by the microbes thus creating competition between the fungal and microbial growth in the medium. Previous study demonstrated that higher microbial population may suppress the fungal growth that can reduce the fungal population.

The augmentation in the number of microbial colony was inversely correlated to the reduction of TPH content. Indeed, the TPH content was continuously decreased from d-0 to d-30, which is when the microbial colony number increased. However, C/N ratio was tend to fluctuate during remediation [7].

Significant increase in the number of microbial colony in the oil sludge medium 30% with leachate inoculum indicates that the indigenous microbes in the leachate inoculum are able to adapt and use hydrocarbons as their source of energy. Microorganisms also can use the nutrition in each inoculum for their survival.

The TPH content decreased during remediation. This condition may cause the synthesis of new toxic compounds such as PAH thus decreasing the number of microbial colony yet increasing the C/N ratio.

The reduction in TPH content may also provoke the synthesis of polyalyscyclic compounds that have lower toxicity thus the microorganisms can adapt and increase their colony number with reduction in C/N ratio. According to Rossiana, the degraded polyhydrocarbon will produce new compounds in form of polyaromatic rings or polyalycyclic chains, which probably will increase or reduce the carbon content. Furthermore, the nitrogen content in the oil sludge and all inoculums can change nitrogen content by the microbes thus change the C/N ratio.

Polycyclic Aromatic Hydrocarbon (PAH) content

The PAH content was analyzed on the beginning (d-0) and the end of experiment (d-45). A total of 10 hydrocarbon compounds was detected in the oil sludge medium with leachate inoculum. These compounds had carbon chain between C6 and C54. Change in proportion of each compound during remediation experiment is presented in Table 6 [8].

| No | Type of compounds | Number of C and H | Area at d-0 (mm2) Area/height (A/H) | Area at d-45 (mm2) Area/height (A/H) |

|---|---|---|---|---|

| 1 | Hexane | C6H14 | 1.11 | 1.13 |

| 2 | Cyclopentane | C6H12 | 0.99 | 0.98 |

| 3 | Hexadecane | C20H42 | 2.22 | 2.19 |

| 4 | Pentacosane | C25H52 | 1.82 | 1.75 |

| 5 | 9-Octadecenoic acid, methyl ester | C19H36O2 | 1.92 | Undetected |

| 6 | Hexacosane | C26H54 | 1.8 | Undetected |

| 7 | Dotriacontane | C32H66 | 3.1 | 1.62 |

| 8 | Hexatriacontane | C36H74 | 2.07 | 1.88 |

| 9 | Tetrapentacosan | C54H110 | 2.3 | 1.72 |

| 10 | Tricosane | C23H48 | 2.4 | 2.46 |

Table 6: Polycyclic Aromatic Hydrocarbon (PAH) content in the oil sludge medium containing leachate inoculum during remediation.

In the present work, it was found that degradation in 9- Octadecenoic acid, methyl ester (C19H36O2) and hexacosane (C26H54) compounds were occurred until they were undetected on d-45. Qualitatively, other compounds that are presence in the oil sludge medium and leachate inoculum were degraded according to the reduction on their area/height ratio from the beginning till the end of experiment. Change in carbon chains and the number of compounds detected during remediation suggests that there is degradation from the complex carbon chain into the more simple carbon chain by the activity of microorganisms.

The degradation of PAH is closely related to the mechanism of action of dioxygenase and dehydrogenase enzymes. The first step in PAH degradation involving oxygen atom on 2 carbons in benzene structure by dioxygenase enzyme. This interaction will form cis-dihydriol structure. The dehydrogenase enzyme then re-aromatisize this structure, thus forming dihydroxylated intermediet. This structure will then experiences division in its aromatic ring to form Tricarboxylic Acid Cycle (TCA) intermediate that will be simplified thus it can be processed into the source of energy [9].

According to Nugroho, the microbial activity in degrading oil sludge is done by cutting down the long chain aliphatic hydrocarbon compounds then transforming the aromatic hydrocarbon compounds, hence the composition of hydrocarbon fraction in oil sludge will be revealed. The fragmentation of heavy hydrocarbon fraction into the lighter fraction affects the number of lighter fraction hydrocarbons produced.

Heavy metals content

The level of heavy metals in the oil sludge medium was analyzed on d-0 and d-45. The national regulation of republic of Indonesia (PPRI No. 85/1999) about the management of hazardous and toxic waste aforementioned that the maximum concentration of heavy metals such as Pb, Ni, Cd, Cr and Hg must not exceed 5.0, 0.4, 1.0, 5.0 and 0.2 ppm respectively. Based on this regulation, it was found that several heavy metals such as Pb, Ni, Cr and Hg have exceeded the maximum standard limit.

Reduction in concentration of heavy metals was only occurred for Cr (5.88%). This reduction is probably due to the natural biodegradation by the microorganisms that are able to adapt and grow in their contaminated environment. Previous studies from Vijayaraghavan and Sang Yun and Evelyn demonstrated that bacteria could act as heavy metals biosorbent agents. Indeed, mechanism of biosorption of heavy metals by the microorganisms is the complex process. This process consists: Transport of heavy metals through the cell membrane, ion exchange and production of organic acids by the microorganisms.

Another study demonstrated that the microbes live in the heavy metals-rich environment are tend to be more resistant to the heavy metals than that of found in control. Additionally, Nithya et al., explained that one of the mechanisms of resistance in microbes against metals are the presence of Resistance, Nodulation, Cell Division (RND) protein that regulates metals transportation via cell membrane [10].

Environmental parameters in the treated medium

The main mediator in bioremediation are the degrading microbes and their products, for instance, the biotransformation or mineralization of pollutants thus reducing the mass and toxicity that are different from other components form the surroundings. The success of bioremediation is influenced by three important factors: 1) microbial availability, contaminant accessibility and the supportive environment. Additionally, the efficiency of bioremediation depends on the ability of microbes to degrade complex compounds to a simpler level.

In the present study, the measured environmental factors were the temperature, pH and humidity. The average temperature in the treated medium during remediation ranged from 25°C to 28°C. According to Udiharto, the optimum temperature for oil sludge bioremediation is between 25°C and 40°C, because the mesophilic bacteria that have significant role in bioremediation live in that range of temperature. Therefore, the temperature of medium during the remediation found to be in optimum range [11].

It appeared that the pH during remediation ranged from 6.5 to 5.7. The pH in the medium decreased after 6 weeks of remediation. This perhaps due to the metabolism activity in biodegradation of oil sludge that produces fatty acids as the end products.

In this study, the average humidity in the medium ranged from 47% to 54%. Study from Cookson explained that the optimum humidity for bioremediation of petroleum based products and their derivate are between 50% and 60%. When the humidity is less than 40%, rate of bioremediation will decelerate. In contrast, when the humidity was more than 70% it may alter the oxygen transfer thus reducing the aerobic activity [12].

Conclusion

The present work showed that leachate inoculum can reduce the TPH content as much as 24.20%. This inoculum can also decrease the Cr level as much as 5.88% yet increase the C/N ratio in the oil sludge medium 30% as much as 1.14%. The PAH compounds that can be degraded by the leachate and not redetected at the end of experiment (d-45) are the 9-octadecenoic acid, methyl ester (C19H36O2) and hexacosane (C26H54). Our results suggest that a longer remediation time is required in the oil sludge medium 30% thus the TPH, C/N ratio, PAH and heavy metals content reduced until meet the national standards. Moreover, further research is needed especially on the microbes in leachate inoculum that have significant role in biodegradation of oil sludge.

Acknowledgement

The authors gratefully acknowledge the chief of the Academic Leadership Grant (ALG) Prof. Dr. Poniah Andayaningsih, M.S. for her endless supports in this project. The authors also wish to thank to the rector of universitas Padjadjaran for financing this research through ALG granted to NR.

References

- Basumatary B, Saikia R, Bordoloi S. Phytoremediation of crude oil contaminated soil using nut grass, Cyperus rotundus. J Environ Biol. 2012;33(5):891.

[Google Scholar] [PubMed]

- Vasudevan N, Rajaram P. Bioremediation of oil sludge-contaminated soil. Environ Int. 2001;26(5-6):409-411.

[Crossref] [Google Scholar] [PubMed]

- Nithya C, Gnanalakshmi B, Pandian SK. Assessment and characterization of heavy metal resistance in Palk Bay sediment bacteria. Marine Environ Res. 2011;71(4):283-294.

[Crossref] [Google Scholar] [PubMed]

- Cai Y, Wang R, Rao P, Wu B, Yan L, Hu L, et al. Bioremediation of petroleum hydrocarbons using Acinetobacter sp. SCYY-5 isolated from contaminated oil sludge: Strategy and effectiveness study. Int J Environ Res Public Health. 2021;18(2):819.

[Crossref] [Google Scholar] [PubMed]

- Asgari A, Nabizadeh R, Mahvi AH, Nasseri S, Dehghani MH, Nazmara S, et al. Biodegradation of total petroleum hydrocarbons from acidic sludge produced by re-refinery industries of waste oil using in-vessel composting. J Environ Health Sci Eng. 2017;15:1-9.

[Crossref] [Google Scholar] [PubMed]

- Imam A, Kanaujia PK, Ray A, Suman SK. Removal of petroleum contaminants through bioremediation with integrated concepts of resource recovery: A review. Indian J Microbiol. 2021;61:250-261.

[Crossref] [Google Scholar] [PubMed]

- Koolivand A, Rajaei MS, Ghanadzadeh MJ, Saeedi R, Abtahi H, Godini K. Bioremediation of storage tank bottom sludge by using a two-stage composting system: Effect of mixing ratio and nutrients addition. Bioresour Technol. 2017;235:240-249.

[Crossref] [Google Scholar] [PubMed]

- Karimpoor R, Ebrahimi S, Malekzadeh E, Hassanpour-Bourkheili S. Bioremediation of total petroleum hydrocarbons in oil sludge-polluted soil using active carbon remediator. Int J Environ Sci Technol. 2022;19(8):7649-7660.

- Aguelmous A, Zegzouti Y, Khadra A, El Fels L, Souabi S, Hafidi M. Landfilling and composting efficiency to reduce genotoxic effect of petroleum sludge. Environ Technol Innovat. 2020;20:101047.

- Ke CY, Qin FL, Yang ZG, Sha J, Sun WJ, Hui JF, et al. Bioremediation of oily sludge by solid complex bacterial agent with a combined two-step process. Ecotoxicol Environ Saf. 2021;208:111673.

- Jagaba AH, Kutty SR, Lawal IM, Birniwa AH, Affam AC, Yaro NS, et al. Circular economy potential and contributions of petroleum industry sludge utilization to environmental sustainability through engineered processes-A review. Cleaner Circular Bioecon. 2022;3:100029.

- Soroldoni S, Silva G, Correia FV, Marques M. Spent lubricant oil-contaminated soil toxicity to Eisenia andrei before and after bioremediation. Ecotoxicology. 2019;28:212-221.

[Crossref] [Google Scholar] [PubMed]

Citation: Rossiana N, Indrawati I, Mustika Y (2024) Utilization of Leachate as Inoculum in Bioremediation of Oil Sludge on Total Petroleum Hydrocarbon, C/N Ratio, Polycyclic Aromatic Hydrocarbon and Heavy Metals Content. J Pet Environ Biotechnol. 15:573.

Copyright: © 2024 Rossiana N, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.