Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research - (2021) Volume 12, Issue 7

The Traditional Processing of Rice-Based Injera, Ethiopian Fermented Flat Bread

Yassin Hassen1*, Ivan Muzira Mukisa2 and Henok Kurabachew12Department of Food Technology and Nutrition Kampala, University of Makerere, Uganda

Received: 08-May-2021 Published: 14-Jun-2021, DOI: 10.35248/2157-7110.21.12.894

Abstract

The knowledge about engineering properties of coffee beans is important in case of design of machine/equipment, developing processes and handling procedures, packaging practices and transporting the processed powders. This work primarily focused on evaluating engineering properties of Roasted, Unroasted coffee beans and Coffee powder. These engineering properties were listed by researchers as size, dynamic angle of repose, coefficient of static friction, bulk and true densities, and porosity. The geometrical statistical data collected for these coffee seeds and beans in terms of their average length, width and thickness are 8.57 mm, 6.91 mm and 4.39 mm for unroasted and 11.43 mm, 8.61 mm, 5.66 mm for roasted coffee beans. Bulk density, True density, Angle of repose, Specific gravity, Porosity, Moisture content are calculated for Unroasted, Roasted coffee seeds and Coffee powder. Porous density, Compact density, Compressibility index, Hauser ratio, Sieve analysis, Static coefficient of friction is calculated for coffee powder on Glass, Paper board, Thermocol. There is no doubt that the work done here definitely will aid optimal design of machines required for harvesting, processing and handling of coffee seeds and beans for good quality products at high efficiency.

Keywords

Fermentation; Rice; Injera

Introduction

Fermented products can play an important role contributing to the livelihoods of rural and periurban dwellers alike through enhanced food security and income generation via a valuable small scale enterprise option. Traditional fermented foods are those which are indigenous to particular area and have been developed by the local people using age-old techniques and locally available raw material [1]. The production processes of traditional fermented foods are generally not uniform and depend on locally available materials, fuel, regional tastes, acceptability and tradition. In nearly all areas of the world, some types of fermented foods native to the region are prepared and consumed. As a result, there are a variety of traditional fermented foods through the world [2]. Due to lack of scientific and technological knowledge, the indigenous fermentation operation is plagued with many problems, which include non-reproducible quality of products, lack of uniformity in taste and flavor and short shelf life [3]. According to the art of traditional processes needs to be transformed into a technology to standardize quality of the end products without losing their desirable traits [4].

Injera is yeast-leavened fermented flat bread with a unique, slightly spongy texture. It is owne of the national staples in Ethiopia that is eaten daily in virtually every household. Injera is served with a variety of stews and sauces and accounts for a substantial quantity of an average Ethiopian’s food intake [5]. Injera is mainly produced from the flour of teff seeds. Teff (Eragrottis teff), a tiny, iron-rich cereal mainly grown in Ethiopia is the most valued grain used to make injera [6]. Other grains that are used include: millet, sorghum, maize, wheat, and their combinations [7]. Indicated that teff is more expensive than other cereals used for making injera. The dependence of many Ethiopians on teff as a major cereal grain for making injera is creating a problem at a national level [5]. Since it is not produced for human consumption in other countries, teff cannot be exported (when a surplus is produced) or imported (in case of drought and shortage). Finding substitutes for teff in injera which possess the desired taste in combination with wot (sauce) is unquestionably important.

Rice (Oryza sativa) is the most important grain with regard to human nutrition and caloric intake, providing more than one fifth of the calories consumed worldwide by humans [8]. In Ethiopia, there is about six million hectare of land, which is suitable for rain fed rice (CARD, 2010). In countries such as Japan and China rice is fermented either by using mixed culture(s) into alcoholic beverages, or by natural fermentation into leavened batter formed dough breads which are usually baked or steame [9]. Rice or rice/teff injera is increasingly becoming popular in African countries such as Uganda, Tanzania and Kenya as well as in Europe and America.

Traditional fermentation processes and the potential for their modernization are increasingly attracting the attention of scientists and policy makers as a vital part of food security strategies [10] and commercial use. The Production processes of traditional Ethiopian products such as tella, tej, ergo, siljo, kocho, bulla, borde and teff injera have been documented [11,12].

Earlier studies on injera mainly focused on the traditional fermentation of other cereals such as teff and sorghum, and microbial diversity of teff injera [13]. Generally, fermentation of injera relies on chance inoculation (that is either natural contamination or back slopping). This may result in a product of unpredictable and inconsistent quality. In order to maintain and sustain African indigenous fermented foods and beverages, controlled fermentation [14,15] and product quality characteristics [16,17] are strongly recommended. Controlled fermentation involves the use of pure or mixed starter cultures with appropriate technology [18,19] in the study on isolation, characterization and identification of lactic acid bacteria and yeast involved in fermentation of teff (Eragrostis tef) batter found that the teff injera batter contained both lactic acid bacteria and yeast species, which have great potential to impart the particular characteristics in the final product of injera [20]. In their study on improvement of injera shelf life through the use of chemical preservatives found out that the effectiveness of preservation was ranked as sodium benzoate>benzoic acid>potassium sorbate>blend of sodium benzoate, benzoic acid, potassium sorbate and calcium propanoate>calcium propionate showing that benzoate and benzoic acid are the most effective [21]. In their study on effects of sorghum cultivar on injera quality concluded that sorghum cultivar has an influence on both injera making and keeping qualities. According to Zewdie, (1997) the injera prepared from cofermented dough of kocho and barely was found to be acceptable to Ethiopian consumers and had very good keeping qualities [22] indicates that teff injera is getting popularity in Ethiopia as well as in the developed world because of its gluten free nature and being a whole grain product. The contribution of globulin fraction alone ranged from 51% to 61% making it as the major storage protein in tef flour [23] indicates that the longer fermentation time and the requirement of some skills make injera preparation usually difficult. Tef injera being fermented food from whole grain flour dough by lactic acid and yeasts has pre- and pro-biotic potential .In many respects it favors toward complete nutrient supply with functional food character for consumers, particularly for celiac opatients [24].

Information on the traditional production technology of rice injera is limited as is the case for many other traditional fermented foods in Uganda and Ethiopia. As a baseline study leading up to research on traditional production and the spontaneous fermentation of rice injera, a survey was carried out in Kampala district (Uganda) and Fogera woreda in Ethiopia. The objective of the present study was to document the rice injera production methods in the Ethiopian communities. In this study, a survey on the methods of production and consumption, fermentation process, storage and shelf life are presented. The acquired knowledge can be used to develop improved methods for small-scale and industrial commercial production of rice injera.

Materials and Methods

Study design

A cross sectional survey was conducted to document the production methods of rice injera. A semi-structured questionnaire was used to interview sixty (60) randomly selected rice injera producers in the Kampala district (n=30), covering the divisions of Rubaga (Nakulabye and Namirembe) Kampala Central (Old Kampala) and Makindye (Kabalagala); and Fogera Woreda in Ethiopia (n=30). Information pertinent to rice injera preparation techniques, the raw materials used and duration of fermentation, types and amount of injera production,sales volume and price and major clients were gathered through interview, observation, discussion and questionnaire The respondents were also asked to explain major problems encountered during rice injera production. This study was conducted from August 2014 to January, 2015.

Data analysis

The survey data was analyzed using descriptive statistics such as percentage and frequency using SPSS software (version 16.0 for windows, Chicago: SPSS Inc.). The survey data results were presented as frequencies and/or percentages.

Results

Demographic characteristics

A total of 60 injera processors and consumers of rice injera (43 females and 17 males respondents) ranging from 24 to 58 years old were involved in this study both from Kampala, Uganda and Fogera woreda, Ethiopia. Their experience in injera processing ranged from 2 years to over 10 years (Table 1).

| Demographic characteristics | No of respondents | Proportion (%) |

|---|---|---|

| Age | ||

| 24-30 | 10 | 16.7 |

| 31-40 | 30 | 50 |

| 41-50 | 15 | 25 |

| 51-60 | 5 | 8.3 |

| Sex | ||

| Male | 17 | 71.7 |

| Female | 43 | 28.3 |

| Education level | ||

| Illiterate | 5 | 8.3 |

| Primary school | 25 | 41.7 |

| Secondary school | 20 | 33.3 |

| College/University graduate | 10 | 16.7 |

| Experience in injera processing | ||

| 2-4 | 6 | 10 |

| 5-7 | 25 | 41.7 |

| 8-10 | 29 | 48.3 |

Values (percentage) are based on data from 60 respondents

Table 1: Socio-demographic characteristic of the study populations.

Main raw materials for rice injera

The main raw materials used in the preparation of rice injera in Kampala include: rice, wheat and maize flours, water, irsho (traditional starter) and baking powder (100% of the respondents). Most of the processors at Fogera woreda in Ethiopia do not use wheat and maize in their recipes (90% respondents), while 10% use Maize. The X-Jigna is the commonest variety of rice used in Fogera woreda, Ethiopia (80%) while Pakistan (20%) and Mbale (80%) varieties are used in Kampala, Uganda (Table 2 and3).

| Response (%) | ||

|---|---|---|

| Raw materials | Ethiopia (Fogera) | Uganda(Kampala) |

| Rice | 100 | 100 |

| Maize | 20 | 100 |

| Wheat | 0 | 100 |

| Water | 100 | 100 |

| Teff | 100 | 0 |

| Baking powder | 0 | 100 |

| Irsho | 100 | 100 |

Values (percentage) are based on data from 60 respondents

Table 2: Raw materials for rice injera preparation in Ethiopia (Fogera) and Uganda (Kampala).

| Respondents (%) | ||

|---|---|---|

| Variety | Ethiopia (Fogera) | Uganda (Kampala) |

| Embale | 0 | 80 |

| Pakistan | 20 | 20 |

| X-Jinga | 80 | 0 |

Values (percentage) are based on data from 60 respondents

Table 3: Variety of rice for injera making in Ethiopia (Fogera) and Uganda (Kampala) .

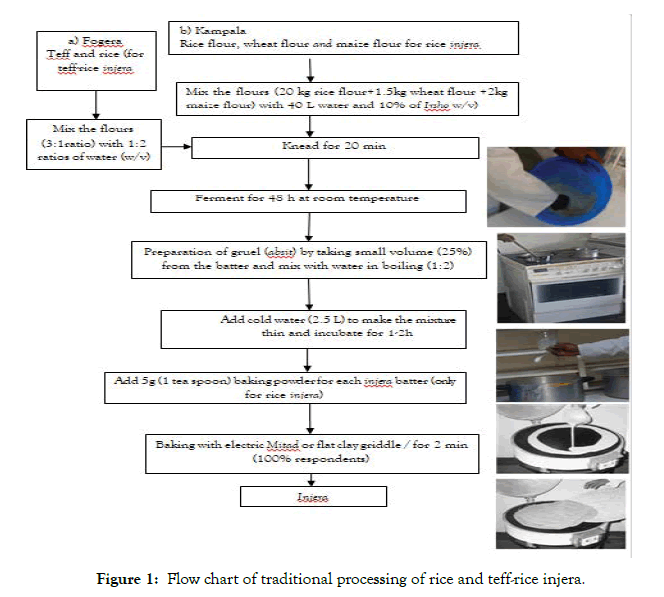

Traditional processing of rice injera

The procedure for the traditional preparation of rice injera is summarized in (Figure 1). The traditional processing of rice injera initially involves cleaning of the grains to remove debris and stones, milling to produce rice, maize and wheat flours separately. The processors in the Fogera woreda of Ethiopia only use rice and teff flours for the preparation of rice-based injera. For rice injera all the flours (rice, maize and wheat) in the ratios of (10: 1.5: 2) w/w and for teff-rice injera both teff and rice flour in the ration of 3:1 w/w were mixed with water in 1:2 ratios w/v in a plastic bucket. Irsho (fermented thin fluid batter from the previous fermentation batch) about 10% was added to the mixture of the flours and water on flour weight basis. The mixture was kneaded for 20 minutes (Table 4).

Figure 1: Flow chart of traditional processing of rice and teff-rice injera.

| Country | Production volumes (pieces of injera) | Sales volumes (pieces of injera) | |

|---|---|---|---|

| Daily (range) | Daily (range) | Unit Price in USD | |

| Ethiopia (Fogera) | 100-120 | 110-115 | 0.15 |

| Uganda (Kampala) | 75-87 | 75-80 | 0.2 |

Values (ranges) are based on data from 60 respondents

Table 4: Production and sales volumes and price of injera in Fogera and Kampala on a daily and weekly basis.

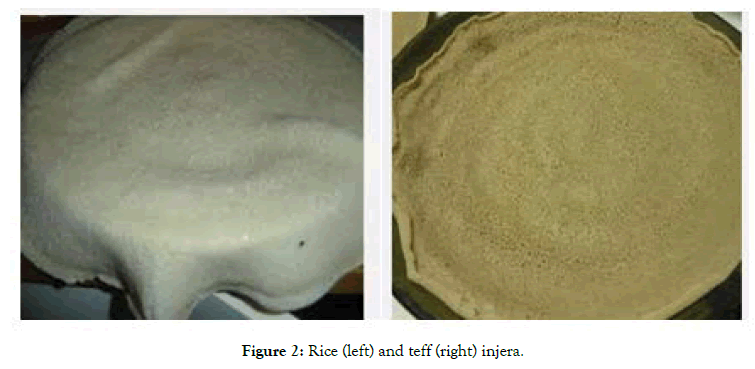

Fermentation of the resulting batter is carried out at room temperature in a closed container and proceeds in two stages. The first stage of fermentation takes 48 h (80% respondents) and results in a liquid/solid separation. After 48 hours of fermentation, the yellowish liquid that settles on top of the paste is decanted. Prior to the second stage of fermentation about 25% of the fermented paste is mixed with three times its volume of water and boiled to form absit, a batter enhancer. The absit is cooled to room temperature and mixed with the rest of thick batter in the fermentation vat (Table 5). This process signals the initiation of the second stage of fermentation. Fermentation is allowed to progress for two hours after the addition of absit. Some processor (40%) use hot water instead of absit. After fermentation, cold water is added to the fermented rice and teff blend to produce a batter of desired consistency. Prior to baking, 5 g (or one tea spoon) of baking powder (sodium bicarbonate) is added to about 500 ml of the fermented batter to make one injera pan cake (100% respondents in kampala ,Uganda ). Baking of rice injera is carried out on a 50 cm diameter hot flat clay griddle or electric Mitad. About 500 ml of the batter is poured in a circular manner on the Mitad, covered, and baked for 2 minutes (Figure 2). The final product usually has smooth texture and consistency, and white in color (Table 6).

| Major clients | Response (%) | |

|---|---|---|

| Ethiopia (Fogera) | Uganda(Kampala) | |

| Ethiopia | 80 | 45 |

| Eritreans | 15 | 35 |

| Somalis | 15 | 13 |

| South Sudanese | 0 | 4 |

| Ugandian | 0 | 3 |

Values (percentage) are based on data from 60 respondents

Table 5: Major clients of injera.

Figure 2: Rice (left) and teff (right) injera.

| Shelflife (in days) | Response (%) | |

|---|---|---|

| Country | ||

| Ethiopia (Fogera) | Uganda (Kampala) | |

| 2 | 60 | 55 |

| 3 | 40 | 40 |

| 4 | 0 | 5 |

Table 6: Shelflife of rice and teff-rice injera at room temperature.

Discussion

Main raw materials for rice injera

Rice (Oryza sativa), maize (Zea mays Linaeus.) and wheat (Triticum aestivum L.) are the main cereal grains used for rice injera processing in Kampala, Uganda while teff and rice are the main raw materials for teff-rice injera production in Fogera woreda, Ethiopia. These cereals are important dietary sources of energy, protein, minerals and vitamins in Africa and Asia. Rice has been found to be very easy to digest, low in fat, low in cholesterol, high in starch, and has a high nutritional content(ref needed here). In Uganda the Mbale of type rice is preferable due to the availability of the raw materials in the nearest market. The X-Jinga is the commonest rice variety used for making injera in Fogera woreda due to its availability and affordable price. This is because most farmers have used the X-Jigna variety to expand rice into in the upland system, probably because of better yield potential, especially at times and locations when and where water availability was not limited [25]. Wheat flour and maize are added in the ratio of (10:1.5:2) as rice, wheat and maize respevtively small proportions to give the desire texture and consistency for the rice injera. The processors use Irsho, a fluid salvaged from previously fermented dough as traditional starter. Irsho is also used in traditional processing of teff, sorghum and in co-fermented kocho with barely injera [16,26]. In Fogera woreda, Ethiopian processors do not use wheat but uses maize in their recipes. Other studies show that teff is also mixed with sorghum for injera making. In this study, 100% of the respondents from Fogera woreda, Ethiopia produced teff-rice injera. This is an indication that the use of formulations without teff for injera production has prior to this not been evaluated for the commercial production of injera in Ethiopia.

Traditional process of rice injera

From the survey it was observed that the traditional production of rice injera involves spontaneous fermentation process. This process of rice injera production was similar to that of teff injera with minor modifications. Processing of rice injera require the use of baking powder to facilitate formation of the spongy texture (eyes) while baking powder is not added in teff and teff-rice injera. Baking powder works by releasing carbon dioxide gas into a batter or dough through an acid-base reaction, causing bubbles in the wet mixture to expand and thus leavening the mixture. It is used where the batter lacks the elastic structure to hold gas bubbles for more than a few minutes, or to speed the production. This study is in line with which indicated that injera baked without absit or with less absit than the required will have fewer eyes (pits) on the upper surface. Difference in fermentation time of rice injera is also observed from that of teff injera in this study which takes 24 h-48 h while teff injera takes 56 h-72 h This result is also in agreement with findings of [27] who reported that the fermentation of sorghum based injera lasts 24 h-48 h and aflegna injera takes 24 h [19] also reported that the fermentation of teff injera lasts 24 h-96 h. The shorter fermentation time of rice injera batter can result in production of low acidic teff. Therefore rice injera can be recommended for people suffering from gastritis and those who do not tolerate acidic foods. Processing conditions of rice injera, including fermentation time and temperature are uncontrolled resulting in product of variable quality and stability, which is often peculiar to most traditional processes. Injera baking practice is similar in all over the study areas with a slight difference, which is that injera, is most commonly baked on a clay plate called Mitad that is placed over a three stone stove or on specialized electric stove. When a fermented dough is poured on a hot clay pan and covered until the boiling temperature is reached; bubbles from the forming thousands of tiny craters (eyes) that give the peculiar injera texture. Similar method is used for baking teff, sorghum injera [28]. The traditional Mitad consists of a griddle plate of ‘black’ clay put on a base of stone and clay [19]. The baking time of rice injera is 2 minutes. This finding is also consistent with that of [29] which indicated baking time of teff injera as 2 minutes-3 minutes and sorghum injera as 2 minutes respectively. In other studies by [30] it was indicated that the use of biomass powered cookstoves during commercial injera production significantly contributes to the Indoor Air Pollution (IAP) and selfreported respiratory symptoms. As injera is the staple foodstuff of Ethiopia, a widespread conversion to electric cookstoves is likely to have a significant impact. However, as high levels of IAP were also observed within the electric bakeries, further identification of pollution sources is required.

The average number of pieces of rice injera produced per producer in Kampala Uganda is less than that of teff-rice injera produced per processor in the Forega Woreda, Ethiopia. This could be because injera is eaten in every household in Ethiopia as it is a national staple unlike in Kampala, Uganda where it is mainly eaten by the Ethiopina community. All the processors of rice injera interviewed in Uganda and Ethiopia commonly use plastic polyethylene bags to cover and store the baked injera at room temperature. At this storage temperature, the injera reportedly has a shelf life of 3-4 days on average [31]. found that the shelf life of teff injera is 3-4 days at room temperature. The main consumers of rice injera in Kampala are Ethiopians, Eritreans, Somali, South Sudanese and some Ugandans while in Ethiopia rice injera is consumed by Ethiopians. Rice injera is popular in Kampala because teff is not readily available in Kampala. Results of the survey indicated that, teffrice based injera is becoming popular in Fogera woreda of Ethiopia due to the potential of the woreda for rice production and the low price of rice compared to that of teff. Moreover teff is becoming expensive due to global demand owing to its gluten free nature [32]. Rice injera is sold in local markets, supermarkets, restaurants and private homes in kampala, Uganda In the local market one piece of injera is sold on average at an equivalent of 0.20 USD while teff-rice injera is sold at 0.15USD. However, the price of teff injera has increased quite a bit. Teff, the grain that is used to produce injera, has, in recent years, experienced inflated prices (1 kg teff is 1 USD), which is usually attributed to the price increase of injera. On the other hand, the price of one kilogram of rice is 0.70 USD. The results from the survey revealed that the main challenges highlighted during rice injera preparation is the quality of rice due to its nature of stickiness which affect product quality [33]. Admasu(2012) also indicated that one of the difficulties in making injera baking inconsistency in product quality, appearance and texture due to quality of raw materials. These unique properties require a thorough understanding of the “overall” injera making process, i.e., fermentation of the flours under controlled environment, viscosity of the batter, amount of batter per injera, the precise temperature at which the injera is cooked, and its removal from the cooking surface using a delicate removing mechanism [34].

Conclusion

The current study documented the indigenous knowledge on the type and proportions of raw materials used and the traditional processing techniques, consumption, production capacities, storage and shelf life of rice injera. In Fogera woreda, Ethiopia on average 700-840 teff mixed injera pieces are produced while rice injera in the range of 525-609 pieces is produced in Kampala, Uganda on weekly basis by each processor. Similarities exist in the processes of rice and teff injera production with the main differences being that rice injera production involves the use of baking powder and shorter fermentation time. Rice injera also has a short shelf life (3-4 days). This could serve as useful and informative baseline data for further studies to scale-up production of rice injera. There is a need for research on preservation of rice injera and use of standard starter cultures to hasten the fermentation process and scale up the production of rice injera.

REFERENCES

- Achi OK. The potential for upgrading traditional fermented foods through biotechnology. Afr J Biotechnol. 2005;4:375-380.

- Valyasevi R, Rolle RS. An overview of small-scale food fermentation technologies in developing countries with special reference to Thailand: scope for their improvement. Int J Food Microbiol. 2002;75:231-239.

- Kimaryo VM, Massawe GA, Olasupo NA, Holzapfel WH. The use of a starter culture in the fermentation of cassava for the production of “kivunde”, a traditional Tanzanian food product. Int J Food Microbiol. 2000;56:179-190.

- Nout H D. Applications of Biotechnology to Traditional Fermented Foods. National Academy Press, Washington, D.C. 1992:8-47

- Zegeye A. Acceptability of injera with stewed chicken. Food Qual Prefer. 1997;8:293-295.

- Doris Piccinin, MSRD Ethiopian Food: Teff. 2010

- Tesfay AH, Kahsay MB, Nydal OJ. Solar powered heat storage for Injera baking in Ethiopia. Energy Procedia. 2014;57:1603-1612.

- Smith BD. The emergency of agriculture. Scientific American Library. 1995

- Yokotsuka T, Japanese shoyu, In K H Steinkraus. Handbook of indigenous fermented foods. Marcel Dekker. 1993:511-517.

- van de Sande T. Socio-economic pitfalls of enhancing indigenous capabilities in household fermentation. Food Control. 1997;8:303-310.

- Bekabil F, Befekadu B, Rupert S, Tareke B. Strengthening the teff value chain in Ethiopia. Ethiopian Agricultural Transformation Agency. 2011.

- Abegaz K, Beyene F, Narvhus J, Abrahamsen RK. Evaluation of new isolates of lactic acid bacteria as a starter for cultured milk production. SINET: Ethiopian Journal of Science. 1998;21:67-80.

- F, Langsrud T, Narvhus JA. Indigenous processing methods and raw materials of borde, an Ethiopian traditional fermented beverage. Journal of Food Technology in Africa. 2002;7:59-64.

- Idris, Tetemke Mehari, Mogessie Ashenafi A. Some microbiological and biochemical studies on the fermentation of 'awaze' and 'datta', traditional Ethiopian condiments. Int J Food Sci Nutr. 2001;52:5-14.

- Sadeghi A, Shahidi F, Mortazavi SA, Mahallati MN, Koocheki A, Mokarram RR. Sourdough effect on reduction of Barbari bread staling. J Sci Technol Agri Nat Res. 2009;13:37-47.

- Agarry OO, Nkama I, Akoma O. Production of Kunun-zaki (A Nigerian fermented cereal beverage) using starter culture. Int Res J Microbiol. 2010;1:18-25.

- Kabeir BM, Shuhaimi M, Muhammad K, Abd-Aziz S, Yazid AM. A nutritious medida (sudanese cereal thin porridge) prepared by fermenting malted brown rice flour with Bifidobacterium longum BB 536. Malays J Nutr. 2004;10:183-193.

- Taiwo O. Physical and nutritive properties of fermented cereal foods. Afr J Food Sci. 2009;3:023-027.

- Glover RL, Sawadogo-Lingani H, Diawara B, Jespersen L, Jakobsen M. Utilization of Lactobacillus fermentum and Saccharomyces cerevisiae as starter cultures in the production of'dolo'. J Appl Biosci. 2009;22:1312-1319.

- Desiye A, Abegaz K. Isolation, characterization and identification of lactic acid bacteria and yeast involved in fermentation of teff (Eragrostis tef) batter. Adv. Res. Biol. Sci. 2013;1:36-44.

- Ashagrie Z, Abate D. Improvement of injera shelf life through the use of chemical preservatives. Afr J Food Agric Nutr Dev. 2012;12:6409-6423.

- Senayit Y, Henriette L D K. Rooney L W, John R N Taylor. Effects of Sorghum Cultivar on Injera Quality. Cereal Chemistry. 2004;81.

- Abiyu HT, Woldegiorgis AZ, Haki G. Preparation of injera from pre-fermented flour: Nutritional and sensory quality. International Journal of Science Innovations and Discoveries. 2013;3:165-175.

- Habtu S A , Sieglinde P, and Katleen R. Tef protein : solubility characterization, in-vitro digestibility and its suitability as a gluten free ingredient. J Food Sci. Technol. 2018;89:697-703

- Bergamo P, Maurano F, Mazzarella G, Iaquinto G, Vocca I, Rivelli AR, et al. Immunological evaluation of the alcohol‐soluble protein fraction from gluten‐free grains in relation to celiac disease. Mol Nutr Food Res. 2011;55:1266-1270.

- Gebey T, Berhe K, Hoekstra D, Alemu B. Rice value chain development in Fogera woreda based on the IPMS experience. CGSpace 2012

- Ashenafi M. A review on the microbiology of indigenous fermented foods and beverages of Ethiopia. Ethiop. J. Biol. Sci. 2006;5:189-245.

- George S D, Hugo P Z, Leon S, Kees M, Yifokire T, J Rosales C, et al. Occupational exposure to indoor air pollution among bakery workers in Ethiopia; A comparison of electric and biomass cook stoves. Environ. Pollut. 2018

- Boka B, Woldegiorgis AZ, Haki GD. Antioxidant properties of Ethiopian traditional bread (Injera) as affected by processing techniques and tef grain (Eragrostis tef (Zucc.)) varieties. Can Chem Trans. 2013;1:7-24.

- Mbata TI, Ikenebomeh MJ, Ahonkhai I. Nutritional status of maize fermented meal by fortification with bambara-nut. Afr J Food Agric Nutr Dev. 2007;7:1-4.

- Beyene F, Narvhus J, Abrahamsen RK. Evaluation of new isolates of lactic acid bacteria as a starter for cultured milk production. SINET: Ethiopian Journal of Science. 1998;21:67-80.

- Samuel S, Berhanu AG. The microbiology of tella fermentation. Sinet. 1991;14:81-92.

- Wudneh A. The making of injera/Enjera. 2012. Unpublished.

- CARD. Rice the popular staple foods in Fogera (Ethiopia). 2010.

Citation: Hassen Y, Ivan Muzira M, Kurabachew H (2021) The Traditional Processing of Rice-Based Injera, Ethiopian Fermented Flat Bread J Food Process Technol 12:894

Copyright: © 2021 Hassen Y, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.