Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Review Article - (2023) Volume 13, Issue 5

The Role of Hospital Wastewater for Producing Bioenergy towards a Circular Bioeconomy

Reethu Thomas, Angela Alin Binoy, Anena Amrithraj E, Arya S. Raj, Aadil Ahmed Irshath and Anand Prem Rajan*Received: 14-Apr-2023, Manuscript No. IJWR-23-21040; Editor assigned: 17-Apr-2023, Pre QC No. IJWR-23-21040 (PQ); Reviewed: 01-May-2023, QC No. IJWR-23-21040; Revised: 14-Jun-2023, Manuscript No. IJWR-23-21040 (R); Published: 21-Jun-2023, DOI: 10.35248/2252-5211.23.13.548

Abstract

This paper aims to assess how hospital wastewater can be utilized to produce bioenergy in order to create a circular bioeconomy. The real potential of wastewater is often underestimated and not realized. Wastewater, especially hospital wastewater consists of many chemicals, metabolites, enzymes etc., which can be purified and utilized in industries. Moreover, wastewater acts as a precious resource which can be employed in various bioprocess and fermentation industries. Clean energy and oxygen can be generated from wastewater using MFCs. The basic principle of MFCs is to use the metabolic processes of microorganisms to convert organic matter in the wastewater into electrical energy. In addition, biogas and manure can be obtained using anaerobic digestion. Anaerobic digestion is a biological process in which microorganisms break down organic matter in the absence of oxygen, producing biogas as a byproduct. The integration of these processes into the wastewater treatment plant leads to the production of clean water while simultaneously producing the additional products, which contributes to sustainable development. The core idea behind the project is to enhance our social cause by generating more employment opportunities, prevention of waterborne diseases, sustainable management of resources and utilizing our profits to do the same.

Keywords

Wastewater treatment plant; Microbial fuel cell; Bio-electro-chemical systems; Pharmaceutically active substances; Multi-national companies; Biogas

Introduction

Hospitals require special attention because they consume enormous quantities of water while producing significant amounts of effluent. As a result, effective management, purification, and discharge of hospital wastewater are critical. The international scientific community has conducted several studies focusing on the characterization of hospital wastewater.

Hospital wastewaters also comprise a diverse spectrum of pollutants, such as pharmaceutical chemicals, chemical residues, radioactive elements, antibiotic resistant strains, and microorganisms, all of which have the potential to be highly harmful.

Using waste water as a substrate and the addition of cow dung to accelerate the process, microorganisms convert organic matter into electricity, which captures CO2 entering the cathode chamber and converts it into biogas which is then combusted or oxidized with oxygen to release energy, allowing biogas to serve as an alternative fuel for heating purposes [1].

Microbial Fuel Cells (MFCs) can be used as a promising technology that can break down a variety of resistant organic substances, such as insecticides and dyes, along with the production of electrical energy from chemical energy by utilizing the residual organic sources [2].

The effective treatment and disposal of hospital wastewater can be crucial in eradicating water scarcity and providing clean water and sanitation. This review outlines a novel strategy as to how hospital wastewater can be utilized in an integrated approach to generate clean water and as a social enterprise generating profit.

Literature Review

Harmful constituents of hospital wastewater

Hospital wastewater is a source of several macro and micro pollutants. E. coli can be employed as a marker of fecal contamination of wastewater. Other microorganisms include Staphylococcus aureus, Salmonella typhi, Pseudomonas aeruginosa, and pathogenic viruses such as Rotavirus, Norovirus, Enterovirus, Aadenovirus, and Hepatitis A [3].

The heavy metal composition of wastewater includes mainly mercury and platinum. Platinum is excreted by oncology patients undergoing treatment with cisplatin [4]. Gadolinium is used to improve the clarity of Magnetic Resonance Imaging (MRI) and can be found in wastewater due to patients undergoing MRI.

An analysis of the pharmaceutical components of wastewater revealed the presence of certain chemicals such as morphine, ibuprofen, and acetaminophen in higher compositions. Other pharmaceutical components include anti-metabolites and anthracycline, epirubicin, doxorubicin, daunorubicin and 5- fluorouracil. Norflaxin is a widely used antibiotic which has serious impacts on environmental health such as limiting algae production and making alterations in plankton systems. Oflaxin and ciproflaxin are other antibiotics which have a significant impact on the aquatic system and can lead to micro ecosystem imbalance [5].

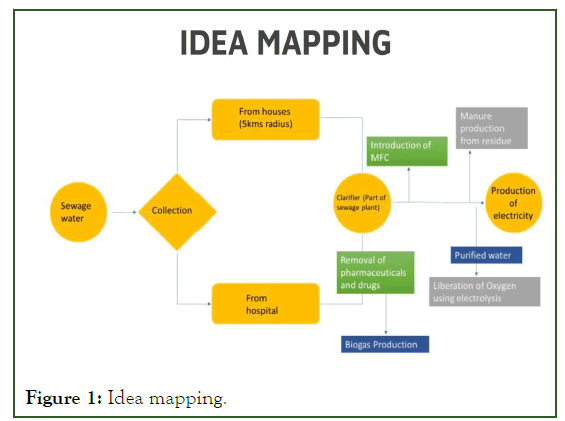

Other common pollutants found in hospital wastewater include personal care products, surfactants, gasoline additives and other products [6]. Thus, effective treatment methods must be employed to effectively remove these contaminants and make the wastewater fit for discharge into the environment (Figure 1).

Figure 1: Idea mapping.

Use of MFC to generate electricity

Microbial Fuel Cells (MFC), generate energy from the metabolism of microorganisms, appear to be appealing enough to justify energy generation. The use of MFC as an alternative source for generating electricity is seen as a trustworthy, clean, and efficient process that makes use of renewable resources and produces no hazardous byproducts. MFCs have thus proven to be a powerful technology for recovering and in-place converting chemical energy into electricity in recent years [7].

In an MFC, bacteria use a series of processes to transform chemical energy from the oxidation of organic and inorganic chemicals into ATP. These reactions result in the transport of electrons to a terminal electron acceptor, which creates an electrical current. Anode and cathode compartments are separated by a cationic membrane in a conventional MFC. In the anode compartment, microbes digest organic substances like glucose, which serves as an electron donor. These organic molecules produce electrons and protons during metabolism. The anode surface then receives the electrons. The protons migrate through the electrolyte and subsequently through the cationic membrane as they migrate from the anode to the cathode through the electrical circuit.

By reducing soluble electron acceptors like oxygen or hexacyanoferrate and acidic permanganate, electrons and protons are utilized in the cathode [8]. By connecting a load between the two electrode chambers, electrical power is generated.

The use of wastewater as a source of energy has a dual advantage; first, the power produced is cheap, and second, it leads to the treatment of wastewater. Bio-Electro-chemical Systems (BESs) are biological processes that transform chemical energy into electrical energy or other high-value products [9]. MFCs provide several advantages like direct electricity generation, energy savings from anaerobic treatment due to elimination of aeration, low sludge yield, and centralized and decentralized applications, environmental benefits like water reclamation, low carbon footprint, lower volumes of sludge for disposal, economic benefits like revenue from energy and valueadded products-chemicals, low operational costs, elimination of downstream processes, and operational benefits like selfgeneration of microorganisms, self-cleaning, etc. [10]. MFCs generate clean power directly from organic material in wastewater without the requirement for the energy products to be separated, purified, or converted. In contrast, methane and hydrogen can be created during the anaerobic digestion process, but they must first be separated and purified before being used. Since MFCs may directly generate clean electricity and work in a variety of situations, notably at ambient temperatures, they are considered environmentally beneficial technology. Up to 1.43 kWh/m3 of primary sludge or 1.8 kWh/m3 of treated effluent can be produced using MFCs [11]. MFCs use on average just 0.024 kW or 0.076 kWh/kg COD, which is a significant reduction from activated sludge based aerobic processes [12,13].

•Treatment of hospital wastewater using MFCS: MFCs as a remediation technique can accelerate the degradation of pharmaceutical contaminants and shorten reaction times. They are used therapeutically to get rid of antibacterial agents [14].

• Removal of antibiotics: Antibiotics are discharged in large quantities by the hospitals. Traditional physicochemical and biochemical methods. Using materials (photocatalysts) for removing antibiotics from sewage water is a cumbersome process. Hence, MFCs play an important role here. MFCs are used to break the organic compounds.

• Other pharmaceutical pollutants: Organic substances that is dangerous or challenging to breakdown. Major pollutants include benzene, nitrobenzene, phenol, and their derivatives. A double-chamber MFC has been shown by Sharma, et al. to break down pharmaceuticals. The wastewater from the production of steroidal drugs was treated and power was produced using single-chamber MFCs. For improved medicinal herb sewage treatment, Birjandi, et al. developed a microbial propulsion system with anodic bio-oxidation injected with seed sludge as an effective biocatalyst mixed with cathodic electrofenton integrated with a Fe2O3/graphite composite electrode.

Production of biogas

One of the most important aspects of this wastewater treatment method is the production of biogas as a byproduct [15]. Biogas generated by fermentation can be used to generate Combined Heat and Power (CHP) and lighting during the manufacturing process [16]. Biogas systems that produce high-quality biogas can be used to generate electricity, which is extremely beneficial to environmental protection and development. Hospital effluents are contaminated with toxic pharmaceuticals and hospital waste, which can harm human health as acute or chronic diseases [17]. Hundreds of tons of bio solids are present in the millions of gallons of wastewater that pass-through treatment plants each day. According to the USEPA report, bio solids produce biogas through anaerobic digestion, which can contain 55% to 70% methane and 25% to 30% carbon dioxide Nonetheless, due to the complex physical and chemical properties of organic waste, which affect metabolic pathways and methane content, biogas production from biomass waste and its utilization for energy applications remain challenging [18]. As a result, focus has shifted to opportunities for further improvement in biogas yield and quality.

The amount of degradable organic material in wastewater is the most important factor in determining its methane generation potential. Properly managed sludge generated by the beverage wastewater treatment plant could potentially yield significant energy in the form of biogas, transforming the wastewater treatment plant from a net energy consumer to a net energy producer. In addition to increasing energy production, the anaerobic digestor reduced total wastewater treatment plant costs biogas energy generated from various sustainable feedstocks can be used to generate electricity and vehicle fuel as an alternative to fossil fuels. Biogas production via anaerobic digestion is critical for maximizing energy production and lowering overall treatment costs in WWTP [19]. Using biogas for power and fuel instead of natural gas has several environmental advantages, including a lower carbon footprint. Like this, to maximize GHG mitigation, biogas should be used for on-site CHP rather than being upgraded to biomethane. Biogas-generated electricity, on average, has a lower environmental impact than fossil-fuel-generated electricity.

Hospital wastewater treatment

Hospital Wastewater (HWW) is also characterized by the presence of several new pollutants, including persistent viruses, Pharmaceutically Active Substances (PhACs), and several microorganisms, including Antibiotic Resistant Bacteria (ARB) and Antibiotic Resistant Genes (ARG). HWW typically contains higher concentrations of ammonia, nitrogen, Chemical Oxygen Demand (COD), and Biochemical Oxygen Demand (BOD) than household wastewater, because of its great susceptibility to the outbreak of various diseases, hospital wastewater poses a serious threat to the safety of human health. Also, the COVID-19 pandemic epidemic necessitated a global focus on the detection and elimination of viruses and other infectious pathogens in hospital wastewater.

To give the hospital wastewater a pre-treatment, primary treatment is necessary. ASP, MBR, MBBR, and CWs are only a few biological processes that can be used to treat the resultant effluent. To improve the removal of resistant organic contaminants, these biological units can also be integrated with other disinfection, adsorption, or advanced oxidation methods. After pre-treatment, tertiary treatment can also be offered; however, the performance of these processes is typically hampered by excessive organic and nutritional loading [20].

Chlorine was used to treat the aeration tank effluent, and an average PhAC reduction of 51.45% was achieved. Diclofenac was discovered to have negative removal among the PhACs.

Membrane bio reactors, or MBRs, are devices that use membranes to separate solids from liquids using microfiltration or ultrafiltration in addition to biological treatment methods. They have received a lot of attention recently due to their effectiveness and small environmental impact compared to other treatment methods, such CWs, with a low bandgap, which are stimulated by photons from a specific light source, is a key component of photocatalytic therapy. Electron-hole pairs are produced when the photons' energies exceed the photocatalysts' bandgap. Hole formation causes hydroxyl radicals to be produced, which then interact with organic pollutants to cause their degradation.

Additional treatments, such as virus inactivation and bacterial eradication, can be carried out appropriately. A comprehensive set of guidelines for managing HWW has been developed by the WHO and concern organizations in a select few countries. Literature on the precise methods of source segregation/ separation of HWWs and the potential effects of direct or indirect discharges to the environment is noticeably lacking. The local/central governments as well as hospital managements need to take immediate action on these issues related to human and environmental health.

It is necessary to create and implement regulations correctly, and it is also necessary to take appropriate legislative action against organizations that disregard the regulations. Before being disposed of, hospital sewage sludge that contains high levels of helminths and other pathogens needs to be adequately treated by aerobic/anaerobic digestion/composting. The top layers of the root of the plant could be filled with the dewatered sludge.

Discussion

Challenges

Challenges faced during collection of wastewaters from different sources: Water collected from hospitals contains toxic pharmaceutical wastes, which can harm water quality and it can also harm the microbes which are an important part of MFC. So, it is essential to properly treat the wastewater by removing the toxicants present. Pollutants are inevitably introduced to our food chain at trace concentrations. Pharmaceuticals cannot be fully treated by standard wastewater treatment methods due to practical restrictions. The present study indicates that many pharmaceutical residues found in wastewater can be removed with activated carbon in a cost-efficient system that delivers higher resource utilization and security than other carbon systems. The experiment revealed a substantial separation of the analyzed compounds, notwithstanding their relatively high solubility in water and dissimilar chemical structures. This suggests that ozone treatment may be competitively replaced by beds of activated carbon.

Challenges while using and operating MFC

Thermodynamic limitations and energy losses: In practical applications, the actual voltage output of an MFC is less than the predicted thermodynamic voltage due to irreversible losses (i.e., over potentials). The major limiting factors (losses) that affect MFC performance have been identified: Most notably, activation losses; mass transfer losses; and ohmic losses.

Costs: MFC costs are typically divided into three categories: The material, component, and labor (design and fabrication) costs. The high cost of MFC is principally caused by material costs including electrode material, separator material, catalysts, and current collector.

Labor: The labor costs can be divided into two categories: The design and fabrication. It should be mentioned that labor cost can be reduced through mass manufacturing. With a significant advantage of having no moving parts, the fabrication of MFCs should be less expensive than other BESs. In addition, the use of construction materials that could be readily found in developing countries should be prioritized, as well as the use of local labor during the construction process.

Challenges while using cryogenic separation unit

This method is used for production of oxygen from water, these also causes four main hazards related to air separation units: Rapid oxidation, embrittlement, and pressure excursions due to vaporizing liquids and oxygen-enriched or deficient atmospheres.

Service as a social enterprise

This project is basically plotted based on social enterprise by utilizing the wastes produced from the hospital wastewater along with the idea of social service. Based on the collection source we selected houses around 5 km radius along with hospital waste, this mainly aims to appoint unemployed people in these areas as technicians which can provide income. Apart from this they are given the profit obtained from the manure sales and if they need the fertilizer for their farm they can approach.

Hospital wastewater contains lots of pharmaceutical toxicants and it is removed so that it will not further affect the population. During the pandemic time we had faced scarcity of oxygen which took thousands of lives, using MFCs we can produce both electricity as well as oxygen required for hospital use. Pollution caused by the fertilizers are increasing day by day as a part of preventing this demand for organic manure increased so that pure organic manure produced from our project has higher demand among MNCs which can provide more profit price for the working and maintenance of the system.

Conclusion

Henceforth, the energy generation from hospital waste which involves multiples projects and researches still going on. The syringes, chemicals, used tools for surgery, cotton everything can be recycled or can be conducted mouled treated into different forms and then under certain process these can be converted into useful clean energy. The study has been conducted in large hospital complexes and proved their economic aspects also. The building, hospital, incineration waste which also perform basic utilization role that provides high efficiency in energy production. As in, this system is been adapted and taken off by many people around the world.

References

- Kaur R, Yadav B, Tyagi RD. Microbiology of hospital wastewater. Current Devel Biotechnol Bioeng. 2020:103-148.

- Abourached C, English MJ, Liu H. Wastewater treatment by Microbial Fuel Cell (MFC) prior irrigation water reuse. J Clean Prod. 2016;137:144-149.

- Ogwugwa VH, Oyetibo GO, Amund OO. Taxonomic profiling of bacteria and fungi in freshwater sewer receiving hospital wastewater. Environ Res. 2021;192:110319.

[Crossref] [Google Scholar] [PubMed]

- Khan NA, Ahmed S, Farooqi IH, Ali I, Vambol V, Changani F, et al. Occurrence, sources and conventional treatment techniques for various antibiotics present in hospital wastewaters: A critical review. TrAC Trends Anal Chem. 2020;129:115921.

- Ajala OJ, Tijani JO, Salau RB, Abdulkareem AS, Aremu OS. A review of emerging micro-pollutants in hospital wastewater: Environmental fate and remediation options. Results Eng. 2022:100671.

- Verlicchi P, Galletti A, Petrovic M, Barcelo D. Hospital effluents as a source of emerging pollutants: An overview of micropollutants and sustainable treatment options. J Hydrol. 2010;389(3-4):416-428.

- Chaturvedi V, Verma P. Microbial fuel cell: A green approach for the utilization of waste for the generation of bioelectricity. Bioresour Bioprocess. 2016;3:1-4.

- Rabaey K, Boon N, Siciliano SD, Verhaege M, Verstraete W. Biofuel cells select for microbial consortia that self-mediate electron transfer. Appl Environ Microbiol. 2004;70(9):5373-5382.

[Crossref] [Google Scholar] [PubMed]

- Kumar AK, Reddy MV, Chandrasekhar K, Srikanth S, Mohan SV. Endocrine disruptive estrogens role in electron transfer: Bio-electrochemical remediation with microbial mediated electrogenesis. Bioresour Technol. 2012;104:547-556.

[Crossref] [Google Scholar] [PubMed]

- Gude VG. Wastewater treatment in microbial fuel cells-an overview. J Clean Prod. 2016;122:287-307.

- Ge Z, Zhang F, Grimaud J, Hurst J, He Z. Long-term investigation of microbial fuel cells treating primary sludge or digested sludge. Bioresour Technol. 2013;136:509-514.

[Crossref] [Google Scholar] [PubMed]

- Zhang F, Ge Z, Grimaud J, Hurst J, He Z. Long-term performance of liter-scale microbial fuel cells treating primary effluent installed in a municipal wastewater treatment facility. Environ Sci Technol. 2013;47(9):4941-4948

[Crossref] [Google Scholar] [PubMed]

- Zhang F, Ge Z, Grimaud J, Hurst J, He Z. In situ investigation of tubular microbial fuel cells deployed in an aeration tank at a municipal wastewater treatment plant. Bioresour Technol. 2013;136:316-321.

[Crossref] [Google Scholar] [PubMed]

- Thapa BS, Pandit S, Patwardhan SB, Tripathi S, Mathuriya AS, Gupta PK, et al. Application of Microbial Fuel Cell (MFC) for pharmaceutical wastewater treatment: An overview and future perspectives. Sustainability. 2022;14(14):8379.

- Ngoc UN, Schnitzer H. Sustainable solutions for solid waste management in Southeast Asian countries. Waste Manag. 2009;29(6):1982-1995.

[Crossref] [Google Scholar] [PubMed]

- Admasu A, Bogale W, Mekonnen YS. Experimental and simulation analysis of biogas production from beverage wastewater sludge for electricity generation. Sci Rep. 2022;12(1):9107.

[Crossref] [Google Scholar] [PubMed]

- Li J, Hao X, van Loosdrecht MC, Luo Y, Cao D. Effect of humic acids on batch anaerobic digestion of excess sludge. Water Res. 2019;155:431-443.

[Crossref] [Google Scholar] [PubMed]

- Rathore D, Nizami AS, Singh A, Pant D. Key issues in estimating energy and greenhouse gas savings of biofuels: challenges and perspectives. Biofuel Res J. 2016;3(2):380-393.

- Liu X, Shi L, Gu JD. Microbial electrocatalysis: Redox mediators responsible for extracellular electron transfer. Biotechnol Adv. 2018;36(7):1815-1827.

[Crossref] [Google Scholar] [PubMed]

- Carraro E, Bonetta S, Bertino C, Lorenzi E, Bonetta S, Gilli G. Hospital effluents management: Chemical, physical, microbiological risks and legislation in different countries. J Environ Manage. 2016;168:185-199.

[Crossref] [Google Scholar] [PubMed]

Citation: Thomas R, Binoy AA, Amrithraj EA, Raj AS, Irshath AA, Rajan AP (2023) The Role of Hospital Wastewater for Producing Bioenergy towards a Circular Bioeconomy. Int J Waste Resour. 13:548.

Copyright: © 2023 Thomas R, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.