Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

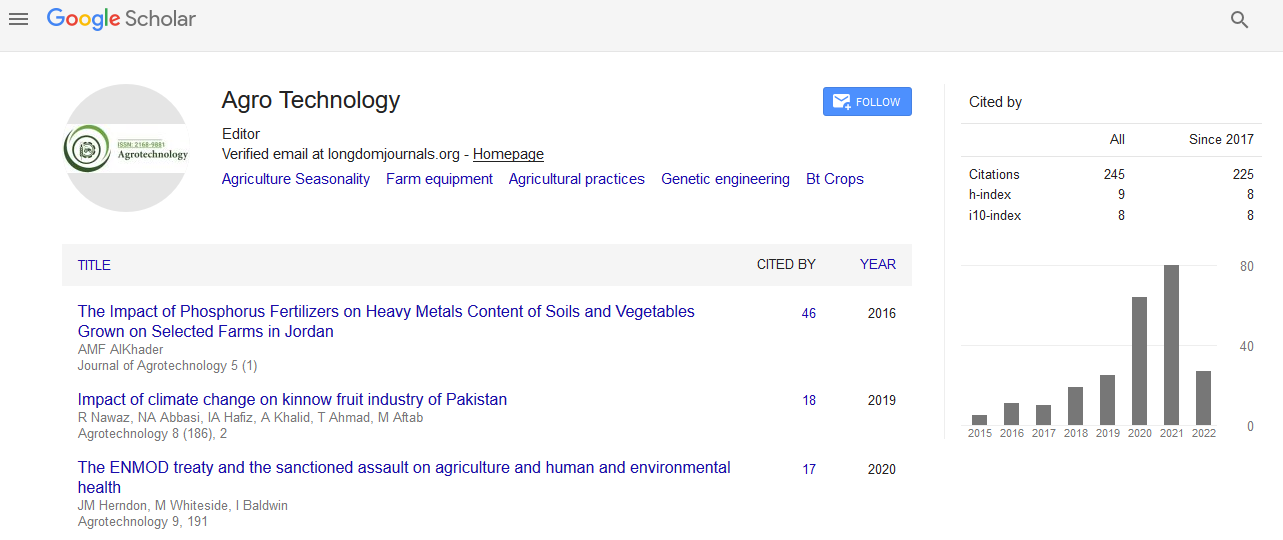

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Commentary - (2024) Volume 13, Issue 3

The Application of Several Cartesian Robot Arms in Kiwifruit Harvesting

Jun Cui*Received: 23-Aug-2024, Manuscript No. AGT-24-26689; Editor assigned: 26-Aug-2024, Pre QC No. AGT-24-26689 (PQ); Reviewed: 10-Sep-2024, QC No. AGT-24-26689; Revised: 17-Sep-2024, Manuscript No. AGT-24-26689 (R); Published: 25-Sep-2024, DOI: 10.35248/2168-9891.24.13.382

Description

Kiwifruit, renowned for its unique taste and nutritional benefits, presents a significant challenge in agricultural harvesting due to its delicate nature and specific harvesting window. Traditional manual harvesting methods are labor-intensive and require skilled workers to handle the fruit without causing damage. In recent years, the integration of robotic technology into agriculture has gained momentum, offering innovative solutions to enhance efficiency and precision. Among these technologies, multiple Cartesian robot arms are emerging as a potential tool for kiwifruit harvesting. This article describes the role and benefits of using multiple Cartesian robot arms in kiwifruit harvesting, addressing their operational principles, advantages, and the challenges they face. Cartesian robot arms, also known as linear robots, operate based on three perpendicular axes (X, Y, and Z) that allow them to move in straight lines.

This configuration provides a high degree of precision and stability, making Cartesian robots well-suited for tasks requiring accurate positioning and repeatability. Each arm consists of a base, an extendable arm, and an end effector, which can be customized for various functions, including gripping and manipulation. In the context of kiwifruit harvesting, multiple Cartesian robot arms are deployed to handle the delicate task of picking fruit efficiently. These robots work in a coordinated manner to ensure that the harvesting process is both effective and gentle on the fruit.

Operational principles of multiple cartesian robot arms

Coordination and synchronization: The effectiveness of multiple Cartesian robot arms in kiwifruit harvesting relies heavily on their coordination and synchronization. Typically, a set of robotic arms is installed on a central platform or structure that allows them to work in tandem. Advanced control systems and software are used to synchronize the movements of the arms, ensuring they operate seamlessly together to cover the entire harvesting area.

Precision and adaptability: Each Cartesian robot arm can be equipped with sensors and vision systems to detect ripe kiwifruit. These sensors provide real-time feedback to the control system, allowing the robots to make precise adjustments based on the fruit's location and ripeness. The adaptability of Cartesian robots enables them to handle different sizes and shapes of kiwifruit, accommodating variations within the crop. The end effectors of the Cartesian robot arms are designed to gently grasp and detach kiwifruit from the vine. These effectors can be customized with soft grippers or suction mechanisms to minimize damage to the fruit. The robots' ability to work with high precision reduces the risk of bruising or crushing the kiwifruit, ensuring that the harvested produce remains in optimal condition.

Advantages of using multiple cartesian robot arms: Increased Efficiency: One of the primary advantages of deploying multiple Cartesian robot arms is the significant increase in harvesting efficiency. By working simultaneously in different sections of the field, these robots can cover a larger area in a shorter amount of time compared to manual labor. This efficiency not only speeds up the harvesting process but also helps in meeting tight harvesting windows and reducing overall labor costs. Multiple Cartesian robot arms provide a high level of consistency and precision in kiwifruit harvesting. Unlike human workers, who may experience fatigue and variability in performance, robotic arms maintain consistent speed and accuracy throughout the harvesting process. This precision ensures that each kiwifruit is picked at the optimal ripeness, enhancing the quality of the harvested produce. The use of multiple Cartesian robot arms reduces the reliance on manual labor, addressing the challenges associated with labor shortages in agriculture. By automating the harvesting process, farms can mitigate the impact of labor shortages and associated costs, allowing human workers to focus on other essential tasks that require greater skill and oversight.

Challenges and considerations

Cost and investment: Implementing multiple Cartesian robot arms involves a significant upfront investment in robotics technology and infrastructure. The cost of purchasing, installing, and maintaining these systems can be substantial, which may pose a barrier for smaller farms or those with limited financial resources. However, the long-term benefits of increased efficiency and reduced labor costs can offset the initial investment over time.

Maintenance and technical expertise: Maintaining and operating multiple Cartesian robot arms requires specialized technical expertise. Farms must invest in training for operators and technicians to ensure the smooth functioning of the robotic systems. Regular maintenance is also essential to prevent downtime and ensure the robots perform at their best.

Integration with existing systems: Integrating Cartesian robot arms with existing harvesting systems and workflows may present challenges. Farms need to ensure that the robotic technology is compatible with their current practices and infrastructure, requiring careful planning and adaptation to achieve seamless integration.

Multiple Cartesian robot arms represent a significant advancement in the field of agricultural robotics, offering a essential solution for kiwifruit harvesting. Their ability to operate with high precision, efficiency, and consistency addresses many of the challenges associated with traditional harvesting methods. While there are costs and technical considerations to address, the benefits of reduced labor, increased efficiency, and improved fruit quality make Cartesian robot arms a valuable tool for modern kiwifruit harvesting. As technology continues to evolve, it is likely that the role of robotic systems in agriculture will expand, further transforming the industry and enhancing productivity.

Citation: Cui J (2024). The Application of Several Cartesian Robot Arms in Kiwifruit Harvesting. Agrotechnology. 13:382.

Copyright: © 2024 Cui J. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.