PMC/PubMed Indexed Articles

Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 13, Issue 1

Production of Methane from Aquatic Weeds and Other Organic Substrates through Anaerobic Digestion under Different Climates

Imtiyaz Jahangir Khan*, Hazhar Sami Hajib, Farooq Ahmad Lonec, Imran Khand, Shabir Ahmad Bangrooe and Farooq Ahmad KhanReceived: 30-Nov-2022, Manuscript No. IJWR-22-17953; Editor assigned: 05-Dec-2022, Pre QC No. IJWR-22-17953(PQ); Reviewed: 26-Dec-2022, QC No. IJWR-22-17953; Revised: 02-Jan-2023, Manuscript No. IJWR-22-17953(R); Published: 09-Jan-2023, DOI: 10.35248/2252-5211.23.13.508

Abstract

Biogas is a renewable source of energy, generally a mixture of methane and carbon dioxide which are naturally released when organic materials including aquatic weeds, agricultural residue, animal waste, food waste etc. decomposes under anaerobic conditions. The experiment was conducted under two conditions viz. room temperature and poly- house temperature and included four treatments T1 (Dal weed 100%), T2 (Dal weed+agricultural residue), T3 (Dal weed+food waste) and T4 (Dal weed+agricultural residue+food waste) with four replications for each treatment and statistically designed as Completely Randomized Design (CRD) to investigate biogas production. The maximum methane production was observed in T1 (531.25 mL kg-1) and T4 (436.25 mL kg-1) under poly-house and room temperature, respectively. However, the increase of pH, TS, VS and total nitrogen caused a corresponding increase in biogas production. Whereas, the decrease in ammonium nitrogen, total phosphorus, and COD triggered an increase in the production of biogas.

Keywords

Biogas; Dal-weed; Food waste; Agricultural waste; Biomass

INTRODUCTION

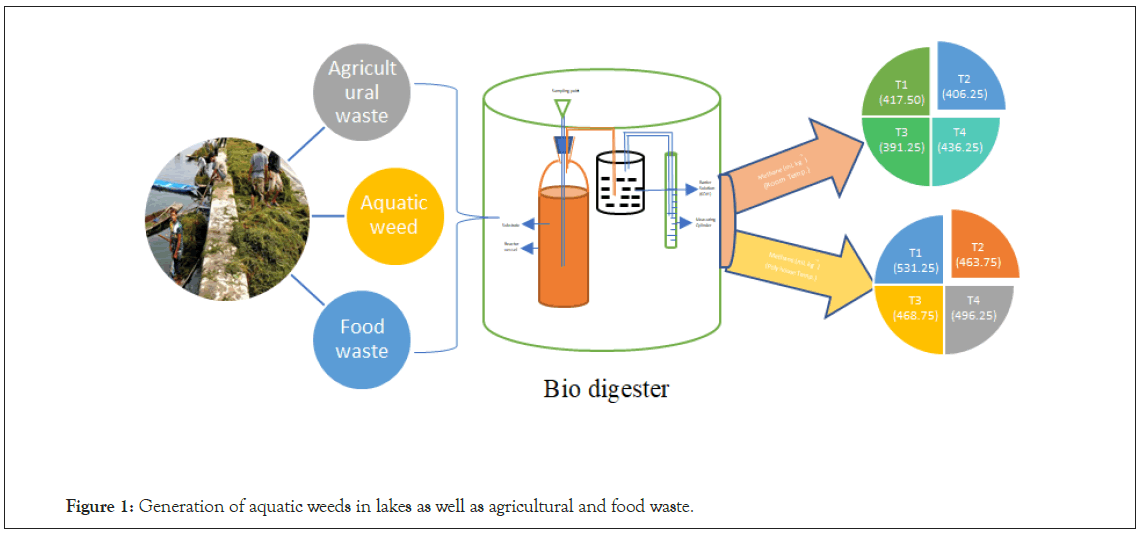

Considering the huge generation of aquatic weeds in lakes as well as agricultural and food waste, there are various management practices for their conversion to energy which includes anaerobic digestion in the form of biogas, pyrolysis, gasification, liquefaction, bio-hydrogenation, combustion, etc. For residues containing more moisture content, biogas production through anaerobic digestion for its conversion to energy is the preferred method. Biogas is an environment friendly fuel which is part of nature’s own cycle. It consists of a mixture of methane and carbon dioxide which are produced naturally when organic materials such as animal, agricultural, domestic and industrial waste decompose under anaerobic conditions [1]. In recent years, agricultural residues have become an important pollution source, and the problem caused by poultry and animal faeces is of global attention. Random straw burning and livestock excrement in the world especially in developing nations have caused a series of environmental problems [2]. Therefore, energy generation from agricultural residues is among the most effective methods for disposing of agricultural waste. It refers to the conversion of agricultural waste into clean energy. This includes the use of crop field residues such as crop straw, crop process residues such as rice husk and corncob, livestock breeding waste such as farm bedding and manure, slaughter house waste such as carcasses and wastewater. Accordingly, a great variety of by- products are generated during the process of energy utilization of agricultural waste, such as biogas residue which latter is being used as fertilizers [3].

The production of energy from renewable sources is becoming an urgent target to reduce the impact of Greenhouse Gases (GHG), mainly derived from fossil fuel combustion [4]. Biogas from wastes, residues and aquatic weeds will play a vital role in future. The production of biogas through anaerobic digestion offers significant advantages over other forms of bioenergy production. It has been evaluated as one of the most energy-efficient and environmentally beneficial technology for bioenergy production [5]. The digestate is an improved fertilizer in term of its availability to crops which can substitute mineral fertilizer. Production of biogas using anaerobic digestion is a multistep biological and chemical process that is beneficial in not only waste management but also energy creation. The breakdown of substrates in the absence of oxygen is facilitated by a combination of microorganisms present in each stage of the digestion process. There are four fundamental steps of anaerobic digestion that include hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Throughout this entire process, large organic polymers that make up biomass are broken down into smaller molecules by chemicals and microorganisms. Upon completion of the anaerobic digestion process, the biomass is converted into biogas, namely carbon dioxide and methane, as well as digestate and wastewater [6].

There have been a number of studies conducted throughout the world on biogas production by anaerobic digestion using aquatic weeds, agricultural residues and food waste as substrates. Keeping this in view, this investigation on biogas production using different substrates, namely, aquatic weeds from Dal Lake, agricultural residues (falling apples and crop substrates), and food waste (kitchen waste) through anaerobic digestion was carried out to study the effect of substrates on biogas production under poly-house and room temperature condition, and the relationship of physico- chemical parameters of substrates with methane production.

Methodology

Description of study area

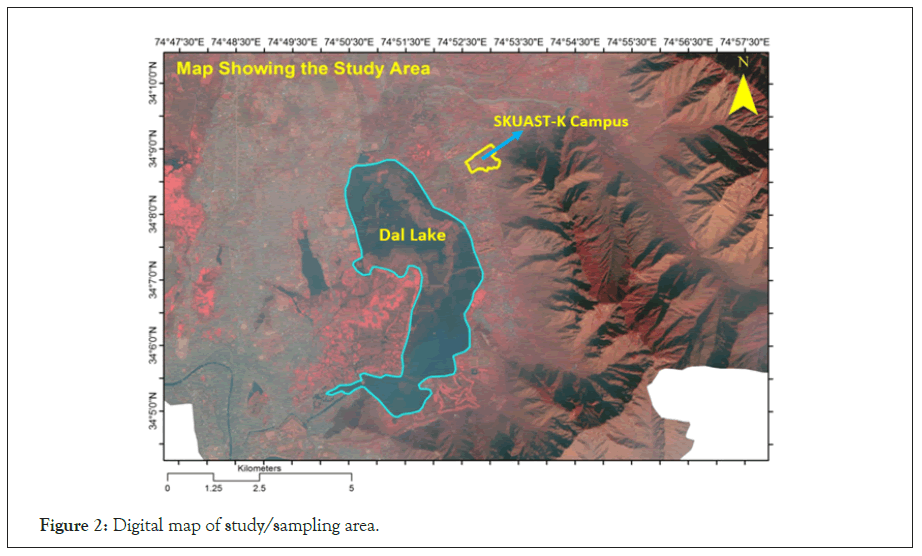

The area of study were based on two locations, 1st one was Dal Lake located between 34°04' – 34°11' N, 74°48' – 74°53' E in the northeast township of Srinagar in the heart of Kashmir Valley in western Himalayas (1583 m above the sea level) and the 2nd was Sher-e-Kashmir University of Agricultural Sciences and Technology – Kashmir Shalimar Campus located between 34°08' 10" – 34°09' 00" N, 74°52' 40" – 74°53' 10" E in the northeast of Dal Lake in Srinagar City as shown in Figure 1. Total area of the Dal Lake is about 23 km2 of which approximately 12 km2 is the total open water spread area [7,8]. Dal Lake is integral to Kashmir tourism and recreation, though it sustains commercial benefits from fisheries, water plant harvesting and vegetable production in floating gardens. Human interference by way of settlement in the lake to facilitate pedestrian traffic and establishment of lake tourism by providing floating residences (house-boats) got accelerated. The length of the lake is 7.44 kilometers (4.62 miles) with a width of 3.5 kilometers (2.2 miles). The average elevation of the lake is 1,583 meters (5,190 ft). The depth of water varies from 6 meters (20 ft) at its deepest in Nagin Lake to 2.5 meters (8.2 ft), the shallowest at Gagribal [9].

Figure 1: Generation of aquatic weeds in lakes as well as agricultural and food waste.

Sample collection

The research was conducted using three types of substrates, namely: Dal weed, agricultural residue and food waste. Dal weed was collected randomly by boat men from weed collection points of the banks of Dal Lake on 1st September, 29th September, 13th June and 11th June 2020 without specifying species. Agricultural residues were collected on 17th August and 20th August 2020 from agricultural field of SKUAST-K Shalimar campus which comprised of tomato straw and fallen apples. Food waste was collected on 17th August 2020 from the vegetarian mess of boy’s hostel, SKUAST-K Shalimar campus. About 2-4 kg of food waste was collected daily and taken to laboratory to be prepared for digesters.

Experimental design

Experimental research was conducted in two different environments to distinguish them on the basis of temperature, via; under room conditions and poly-house conditions. The total number of treatments was four, each having four replications giving a total of 16 digesters as shown in Table 1, which were used for the bio- digestion of the waste materials for the production of biogas. The statistical design used for data analysis was Completely Randomized Design (CRD) (Table 1 and Figures 2a and 2b).

| Under room conditions | Under poly-house condition |

|---|---|

| Study area: Dal lake and SKUAST-K Shalimar campus | Study area: Dal lake and SKUAST-K Shalimar campus |

| Experimental material: Dal weed, agricultural residue and food waste | Experimental material: Dal weed, agricultural residue and food waste |

| Treatments: 4 | Treatments: 4 |

| Replications: 4 | Replications: 4 |

| Design: CRD | Design: CRD |

Table 1: Experimental design showing room and poly-house conditions of study for biogas production.

Figure 2: Digital map of study/sampling area.

Figure 2a: Digester sets under room temperature.

Figure 2b: Digester sets under poly-house temperature.

Substrate composition

The ratio of substrates varied in digesters based on the composition of dal weed, agricultural residue and food waste as given in Table 2. In each digester, 1.5 kg of substrate was used constituting different weight of substrates. The water used in digesters was collected from irrigation channels of the university campus. For each digester, 10 L of water was mixed with 500 g fresh cow dung as inoculum in a bucket and stirred well with a rod. The solutions/inoculum was then added to each labeled digester. First condition (room temperature) of bio-digestion commenced on the 15th October 2020; Second condition (poly-house temperature) of bio-digestion commenced on the 1st February 2021 (Table 2).

| Treatment | Substrates used for anaerobic digestion | Ratio |

|---|---|---|

| T1 | Dal weed | -100% |

| T2 | Dal weed+Agricultural residue | 02:01 |

| T3 | Dal weed+Food waste | 02:01 |

| T4 | Dal weed+Food waste+Agricultural residue | 2 : 0.5 : 0.5 |

Table 2: Substrate ratio used for production of biogas through anaerobic digestion.

Design of bio-digesters

A batch-type biogas digester that has been used by many researchers was designed and constructed to generate biogas from different substrates which includes Dal weed, Agricultural residue and Food waste [10-12]. The components of the digesters include: plastic tank of capacity 20 L, conical flask of 1 L capacity containing the barrier solution which is composed of 20 g sodium hydroxide (NaOH 2%) in 1 L distilled water. A rubber pipe connected with tap fitted in between each digester tank and conical flask. Methane gas was measured using measuring cylinders connected to each digester, and each cylinder contained 50 ml of distilled water. By opening the tap on each digester, the total gas (CH4, CO2, H2O(g) etc.) goes to the barrier solution connected to each digester respectively and reacts with gases such as CO2 and H2S filtering out the pure methane CH4 which then enters the measuring cylinder of each digester causing a rise in water level in the cylinders. The rise in water level is seen as the total volume of methane entering the cylinders from each digester. The digester ensures the anaerobic degradation of the feedstock in order to generate biogas.

Results and Discussion

Parameters for initial substrate analysis

The data in Table 3 shows the variation in the parameters analyzed for the initial substrates used for biogas production. The variations in pH obtained in the initial bio digestion of various substrates are: 6.23 (Dal weed), 4.69 (Agricultural residue) and 5.51 (Food waste). The higher pH of Dal weed might be because of the lake water pH, temperature and presence of various minerals [13]. The lower pH in agricultural residue may be attributed to its composition (tomato straw and fallen apple) which are acidic in nature and have been proven to be of lower pH [14-16]. The low pH of Food waste may be due to the microbial decomposition of food materials which has a correlating effect on odor and pH [17- 19]. The close proximity in the data for Total Solids (TS) has been reported by several researchers who did their work using different substrate [20-22]. This might be due to the fact that each of the substrates was chopped and grinded before analysis. It is this total solid that is converted into volatile solids which are then used by methanogenic bacteria to produce biogas [23-26]. With respect to moisture content, agricultural residues had the highest percentage (46.57%). It was reported by Saputra and Putri in 2017 that aquatic weeds contain high moisture content, reaching more than 90%. Nevertheless, the moisture content for all initially analyzed substrates was below 90% as before analysis they were shade dried. The higher content of total nitrogen (3.35%) in Dal weed may be due to the fact that macrophytes absorbs large amount of nitrogen in the form of nitrates for the development of chlorophyll and amino acids. Also Yu et al., (2015) and Su et al. (2019) reported that the higher concentration of total nitrogen was present in aquatic weed. On the other hand, agricultural residue exhibited high content of ammonium nitrogen (62.21 mg/L). Bacteria can only get nitrogen in the form of ammoniacal-nitrogen (NH4-N), which is soluble in nature. After the hydrolysis stage, nitrogen is converted to ammonium ions for bacterial use [27,28]. Lowest concentration of total phosphorus was recorded from Dal weed as compared to the other substrates. This can be attributed to its less availability in water due to its fixation in sediments. High pH in Dal weed and effect of temperature, might have allowed Dal weed to frequently release phosphorus under reducing circumstances [29,30]. In relation to Chemical Oxygen Demand (COD), food waste exhibited the highest level (20.28 g/L) which may be due to its high content of biodegradable organic matter, allowing bacteria to easily break it down. A higher bio-degradation rate at higher temperatures indicates a greater level of biological activity [31,32]. With respect to the analyzed heavy metals (Pb, Cd, and Cu), Dal weed exhibited higher concentrations. Aquatic weed (macrophytes), have been examined for their ability to bio-accumulate and bio-magnify heavy metals from water bodies [33,34]. Also, the concentration of heavy metals in all the substrates were less than Central Pollution Control Board (CPCB) 1986 standards for effluent discharge into both surface water and public sewers as given in Table 4 (Tables 3 and 4).

| Parameters | Dal weed | Agricultural residue | Food waste |

|---|---|---|---|

| pH | 6.23 | 4.69 | 5.51 |

| Total solids (g/L) | 18.65 | 18.59 | 19.95 |

| Volatile solids (g/L) | 9.89 | 10.62 | 12.47 |

| Moisture content (%) | 23.61 | 46.57 | 17.01 |

| Total nitrogen (%) | 3.35 | 1.95 | 3.27 |

| NH4-N (mg/L) | 27.69 | 62.21 | 44.93 |

| Total phosphorus (mg/L) | 0.8 | 6.39 | 2.65 |

| COD (g/L) | 10.43 | 17.36 | 20.28 |

| Pb (mg/L) | 0.22 | 0.18 | 0.18 |

| Cd (mg/L) | 0.03 | 0.03 | 0.03 |

| Cu (mg/L) | 0.03 | 0.006 | 0.001 |

Table 3: Parameters analyzed for initial substrates used for biogas production.

| Heavy metals | Into surface water | Into public sewers |

|---|---|---|

| Lead (Pb) mg/L | 0.1 | 1 |

| Cadmium (Cd) mg/L | 2 | 1 |

| Copper (Cu) mg/L | 3 | 3 |

Table 4: CPCB standards 1986 (anaerobic digestion in heavy metals).

Physico-chemical parameters of substrates in anaerobic batch digestion under room and poly-house conditions

PH

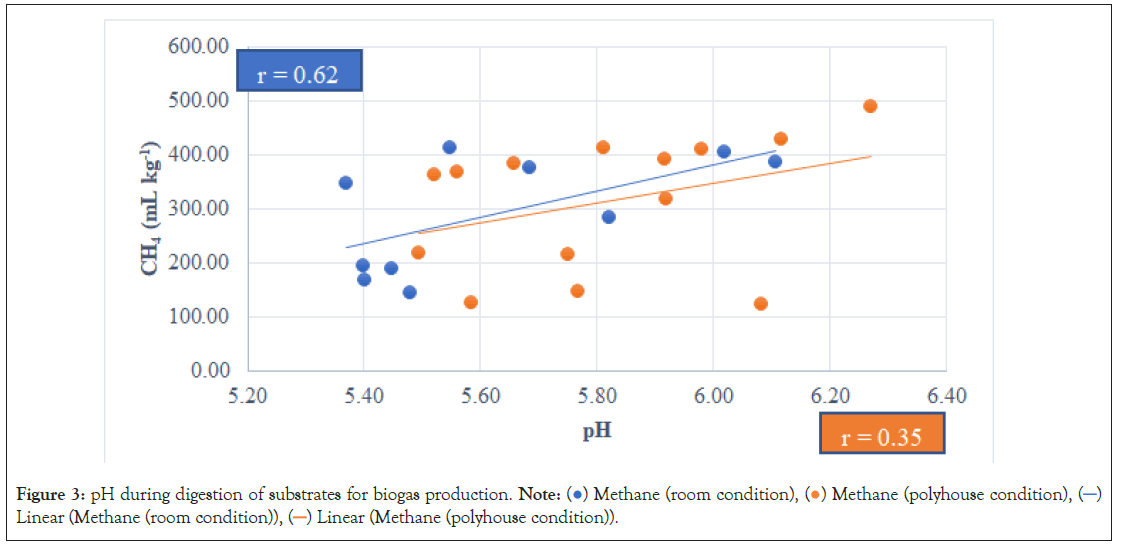

The results presented in Table 5 of pH under both the conditions (room and poly-house) on weekly basis showed that under room temperature pH ranged from 5.15 to 6.58 and under poly-house temperature it ranged between 7.29 to 5.21. T1 (Dal weed 100%) recorded highest pH under both room and poly-house temperature ranging from 5.70 – 6.58 and 6.00 – 7.29, respectively. This might be due to the fact that the initial substrate of Dal weed recorded highest pH (6.23) in Table 3 which can help to keep the digestors in optimal condition for better biogas production. Cioabla et al. in 2012 stated that, in an anaerobic digester, the pH range of 6.8 to 7.2 is optimal for biogas production, but the procedure can withstand a pH range of 6.5 to 8.0. Also, the increase or decrease in temperature can also influence the pH level in digesters [35]. Having lower pH than the range might be due to the high concentration of Volatile Fatty Acids (VFAs), which has been reported by many researchers as one of the main factors influencing pH levels [36- 38]. Statistically pH as shown in Figure 3 has a significant (p ≤ 0.05) positive correlation with methane gas production. Which means the increase in pH will lead to a corresponding increase in methane production. Towards neutral range of pH, methane is highly generated and as it approaches toward acidity (decrease in pH), methane production decreases too (Figure 3 and Table 5).

| Under room condition | Under poly-house condition | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Date (week) | T1 Dal weed 100%) | T2 (Dal weed+agricultural residue) | T3 (Dal weed+food waste) | T4 Dal weed+food waste) | Date (week) | T1 (Dal weed 100%) | T2 (Dal weed+agricultural residue) | T3 (Dal weed+food waste) | T4 (Dal weed+agricultural residue+food waste) |

| 22/10/2020 (1) | 5.83 ± 0.27 | 5.15 ± 0.04 | 5.46 ± 0.21 | 5.48 ± 0.16 | 08/02/2021 (1) | 6.50 ± 0.66 | 6.25 ± 0.19 | 5.74 ± 0.17 | 5.84 ± 0.29 |

| 29/10/2020 (2) | 5.84 ± 0.20 | 5.22 ± 0.09 | 5.37 ± 0.16 | 5.38 ± 0.10 | 15/02/2021 (2) | 6.19 ± 0.59 | 5.89 ± 0.12 | 5.40 ± 0.13 | 5.59 ± 0.27 |

| 05/11/2020 (3) | 6.10 ± 0.19 | 5.64 ± 0.08 | 5.75 ± 0.09 | 5.80 ± 0.04 | 22/02/2021 (3) | 6.00 ± 0.60 | 5.36 ± 0.06 | 5.32 ± 0.25 | 5.29 ± 0.30 |

| 12/11/2020 (4) | 6.00 ± 0.19 | 5.48 ± 0.09 | 5.59 ± 0.10 | 5.68 ± 0.03 | 01/03/2021 (4) | 6.02 ± 0.49 | 5.31 ± 0.06 | 5.38 ± 0.26 | 5.37 ± 0.30 |

| 19/11/2020 (5) | 6.44 ± 0.23 | 5.82 ± 0.10 | 5.84 ± 0.08 | 5.97 ± 0.10 | 08/03/2021 (5) | 6.11 ± 0.39 | 5.21 ± 0.09 | 5.45 ± 0.37 | 5.48 ± 0.36 |

| 26/11/2020 (6) | 6.58 ± 0.21 | 5.94 ± 0.11 | 5.83 ± 0.06 | 6.07 ± 0.19 | 15/03/2021 (6) | 6.15 ± 0.34 | 5.34 ± 0.08 | 5.60 ± 0.36 | 5.55 ± 0.39 |

| 03/12/2020 (7) | 5.84 ± 0.20 | 5.52 ± 0.03 | 5.39 ± 0.04 | 5.45 ± 0.04 | 22/03/2021 (7) | 6.18 ± 0.29 | 5.41 ± 0.05 | 5.79 ± 0.29 | 5.86 ± 0.18 |

| 10/12/2020 (8) | 5.70 ± 0.19 | 5.35 ± 0.03 | 5.21 ± 0.05 | 5.22 ± 0.05 | 29/03/2021 (8) | 6.21 ± 0.34 | 5.41 ± 0.04 | 6.01 ± 0.40 | 6.04 ± 0.11 |

| 17/12/2020 (9) | 5.74 ± 0.20 | 5.38 ± 0.04 | 5.22 ± 0.05 | 5.25 ± 0.04 | 05/04/2021 (9) | 6.25 ± 0.39 | 5.45 ± 0.11 | 6.16 ± 0.42 | 6.07 ± 0.20 |

| 24/12/2020 (10) | 5.73 ± 0.21 | 5.39 ± 0.06 | 5.23 ± 0.05 | 5.25 ± 0.02 | 12/04/2021 (10) | 7.02 ± 0.67 | 5.65 ± 0.10 | 6.24 ± 0.40 | 6.18 ± 0.19 |

| - | - | - | - | - | 19/04/2021 (11) | 458.63 ± 13.81 | 410.25 ± 22.78 | 415.13 ± 56.54 | 430.00 ± 46.62 |

| - | - | - | - | - | 26/04/2021 (12) | 368.00 ± 14.57 | 276.38 ± 46.98 | 287.13 ± 27.72 | 341.88 ± 64.05 |

| - | - | - | - | - | 03/05/2021 (13) | 255.50 ± 16.11 | 195.88 ± 4.97 | 185.25 ± 24.73 | 219.25 ± 33.21 |

| - | - | - | - | - | 10/05/2021 (14) | 154.63 ± 28.38 | 114.38 ± 5.54 | 110.38 ± 14.97 | 127.63 ± 20.58 |

Table 5: pH of substrates under room and poly-house condition.

Figure 3: pH during digestion of substrates for biogas production. Note: ( ) Methane (room condition), (

) Methane (room condition), ( ) Methane (polyhouse condition), (

) Methane (polyhouse condition), ( )

Linear (Methane (room condition)), (

)

Linear (Methane (room condition)), ( ) Linear (Methane (polyhouse condition)).

) Linear (Methane (polyhouse condition)).

Temperature

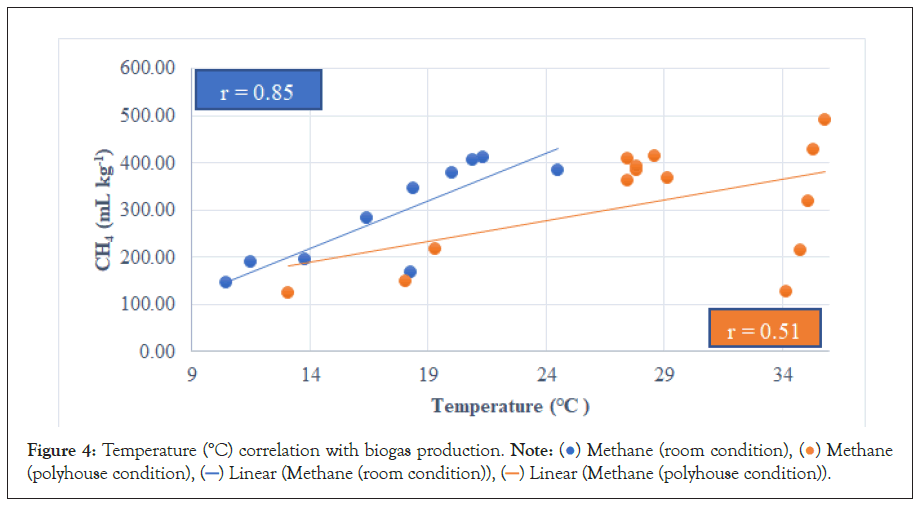

Data on temperature (°C) under both the conditions (room and poly-house temperature) is given in Table 6. It is clear from the data that the temperature under poly-house was higher than room temperature. Nevertheless, the production of biogas in all the treatments was dependent on the temperature in both the conditions as shown on the correlation graph of Figure 4. Temperature had a significant (p ≤ 0.05) positive correlation with biogas production that with increase in temperature is strongly related with increase in biogas production regardless of the pH effect especially when temperatures are low (Figure 4 and Table 6) [39].

| Under room condition | Under poly-house condition | ||||

|---|---|---|---|---|---|

| Date (Week) | Temperature (°C) | Date (Week) | Temperature (°C) | ||

| 22/10/2020 (1) | 10.42 | 08/02/2021 (1) | 13.08 | - | |

| 29/10/2020 (2) | 11.48 | 15/02/2021 (2) | 18.02 | - | |

| 05/11/2020 (3) | 16.4 | 22/02/2021 (3) | 19.28 | - | |

| 12/11/2020 (4) | 20 | 01/03/2021 (4) | 27.44 | - | |

| 19/11/2020 (5) | 20.86 | 08/03/2021 (5) | 29.14 | - | |

| 26/11/2020 (6) | 24.5 | 15/03/2021 (6) | 27.82 | - | |

| 03/12/2020 (7) | 21.36 | 22/03/2021 (7) | 28.6 | - | |

| 10/12/2020 (8) | 18.4 | 29/03/2021 (8) | 27.82 | - | |

| 17/12/2020 (9) | 13.78 | 05/04/2021 (9) | 27.48 | - | |

| 24/12/2020 (10) | 18.28 | 12/04/2021 (10) | 35.8 | - | |

| - | - | 19/04/2021 (11) | 35.3 | - | |

| - | - | 26/04/2021 (12) | 35.1 | - | |

| - | - | 03/05/2021 (13) | 34.8 | - | |

| - | - | 10/05/2021 (14) | 34.2 | - | |

Table 6: Average temperature (°C) variation under room condition.

Figure 4: Temperature (°C) correlation with biogas production. Note: ( ) Methane (room condition), (

) Methane (room condition), ( ) Methane

(polyhouse condition), (

) Methane

(polyhouse condition), ( ) Linear (Methane (room condition)), (

) Linear (Methane (room condition)), ( ) Linear (Methane (polyhouse condition)).

) Linear (Methane (polyhouse condition)).

Total and volatile solids

A decreasing trend from initial to finial of total solids in all treatments under both conditions (room and poly-house) as depicted in Table 7 and similar decreasing trend was observed with volatile solids in all treatments as shown in Table 8. Decreasing effect can be related to the fact that in anaerobic digestion Total Solids (TS) which is the organic and inorganic components of matter had to be broken down necessarily into volatile solids which is the organic component of total solids upon which the production of biogas is dependent which further decreases in the process by decomposition. The amount of TS in feedstock which is degraded into volatile solids has an impact on anaerobic digestion performance, particularly biogas production efficiency [40,41]. Methane production has been noted to be exactly proportional to the rate of Volatile Solids (VS) decomposition [42]. However, methane generation has been noted to decrease when the total solids level increased from 10 to 25% in an anaerobic digestion (Tables 7 and 8) [43].

| Under room condition | Under poly-house condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Treatments | Treatments details | Initial (15th – 29th Oct.) |

Middle (12th – 26th Nov.) |

Final (17th – 31st Dec.) |

Treatments | Treatments details | Initial (1st – 15th Feb.) | Middle (15th – 29th Mar.) | Final (19th Apr. – 3rd May) | |

| T1 | Dal weed 100% | 29.94 ± 3.23 | 28.61 ± 2.11 | 26.03 ± 1.60 | T1 | Dal weed 100% | 70.64 ± 13.45 | 67.73 ± 12.73 | 64.77 ± 13.36 | |

| T2 | Dal weed+agricultural residue | 24.50 ± 4.07 | 24.14 ± 3.80 | 23.23 ± 3.18 | T2 | Dal weed+agricultural residue | 49.03 ± 9.13 | 46.67 ± 9.56 | 43.72 ± 9.87 | |

| T3 | Dal weed+food waste | 23.80 ± 1.51 | 22.86 ± 1.71 | 22.22 ± 1.50 | T3 | Dal weed+food waste | 81.71 ± 30.42 | 79.45 ± 29.71 | 76.10 ± 30.82 | |

| T4 | Dal weed+agricultural residue+food waste | 29.03 ± 1.19 | 28.32 ± 1.66 | 27.22 ± 2.02 | T4 | Dal weed+agricultural residue+food waste | 109.11 ± 1.50 | 107.21 ± 1.41 | 105.69 ± 0.56 | |

| C.D. (p ≤ 0.05) | 3.26 | C.D. (p ≤ 0.05) | 22.10 | |||||||

Table 7: Total solids (g/L) under room and poly-house conditions.

| Under room condition | Under poly-house condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Treatments | Treatments details | Initial (15th – 29th Oct.) | Middle (12th – 26th Nov.) | Final (17th – 31st Dec.) | Treatments | Treatments details | Initial (1st – 15th Feb.) | Middle (15th – 29th Mar.) | Final (19th Apr. – 3rd May) | |

| T1 | Dal weed 100% | 13.41 ± 0.92 | 12.50 ± 1.22 | 10.91 ± 1.29 | T1 | Dal weed 100% | 29.54 ± 6.33 | 27.26 ± 5.90 | 25.02 ± 5.58 | |

| T2 | Dal weed+agricultural residue | 15.22 ± 0.53 | 14.58 ± 0.38 | 14.09 ± 9.64 | T2 | Dal weed+agricultural residue | 26.61 ± 7.22 | 23.02 ± 5.29 | 21.03 ± 5.66 | |

| T3 | Dal weed+food waste | 14.67 ± 0.53 | 14.26 ± 0.75 | 13.85 ± 0.79 | T3 | Dal weed+food waste | 30.35 ± 9.68 | 29.53 ± 9.12 | 28.06 ± 9.14 | |

| T4 | Dal weed+agricultural residue+food waste | 18.92 ± 0.48 | 18.63 ± 0.48 | 18.27 ± 0.80 | T4 | Dal weed+agricultural residue+food waste | 60.65 ± 3.54 | 57.28 ± 3.90 | 56.81 ± 3.74 | |

| C.D. (p ≤ 0.05) | 1.11 | C.D. (p ≤ 0.05) | 22.10 | |||||||

Table 8: Volatile solid (g/L) treatment under room conditions.

Total nitrogen and ammonium-nitrogen

Data reveals a decreasing trend of total nitrogen in all treatments from initial to final stage under both conditions (room and poly-house) as shown in Table 9. Similarly, decreasing trend of ammonium nitrogen was observed in all treatments from initial to final stage under both conditions (room and poly-house as shown in Table 10. Decreasing trend in total nitrogen from initial to final is because nitrogen is converted into ammonium and ammonia which are used by microorganisms especially ammonium nitrogen to build-up their cell structure. The pH of digesters has been noted to affect the amount of ammonium composition [44,45]. Amount of ammonium will increase in more acidic conditions in the digestion process and the reverse is also true as reported by Syaichurrozi et al., 2013. Ammonium concentration is dependent on pH and temperature. The correct amount of ammonium- nitrogen (50 mg/L) is considered beneficial whereas free ammonia should be avoided if possible (Table 9 and 10) [46].

| Under room condition | Under poly-house condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Treatments | Treatments details | Initial (15th – 29th Oct.) | Middle (12th – 26th Nov.) | Final (17th – 31st Dec.) | Treatments | Treatments details | Initial (1st – 15th Feb.) | Middle (15th – 29th Mar.) | Final (19th Apr. – 3rd May) | |

| T1 | Dal weed 100% | 3.21 ± 0.42 | 3.08 ± 0.33 | 3.04 ± 0.33 | T1 | Dal weed 100% | 2.12 ± 0.36 | 2.10 ± 0.25 | 2.05 ± 0.20 | |

| T2 | Dal weed+agricultural residue | 2.38 ± 0.54 | 2.37 ± 0.56 | 2.34 ± 0.55 | T2 | Dal weed+agricultural residue | 1.53 ± 0.24 | 1.50 ± 0.19 | 1.47 ± 0.32 | |

| T3 | Dal weed+food waste | 3.06 ± 0.33 | 3.02 ± 0.34 | 3.01 ± 0.34 | T3 | Dal weed+food waste | 2.27 ± 0.02 | 2.16 ± 0.06 | 2.13 ± 0.05 | |

| T4 | Dal weed+agricultural residue+food waste | 3.08 ± 0.41 | 3.05 ± 0.40 | 3.05 ± 0.41 | T4 | Dal weed+agricultural residue+food waste | 2.20 ± 0.13 | 2.10 ± 0.16 | 2.09 ± 0.10 | |

| C.D. (p ≤ 0.05) | 0.55 | C.D. (p ≤ 0.05) | 0.28 | |||||||

Table 9: Total nitrogen (%) under room temperatures.

| Under room condition | Under poly-house condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Treatments | Treatments details | Initial (15th – 29th Oct.) | Middle (12th – 26th Nov.) | Final (17th – 31st Dec.) | Treatments | Treatments details | Initial (1st – 15th Feb.) | Middle (15th – 29th Mar.) | Final (19th Apr. – 3rd May) | |

| T1 | Dal weed 100% | 50.10 ± 2.51 | 48.89 ± 3.14 | 42.49 ± 8.81 | T1 | Dal weed 100% | 52.10 ± 3.87 | 52.00 ± 2.48 | 51.34 ± 3.89 | |

| T2 | Dal weed+agricultural residue | 55.44 ± 2.61 | 54.71 ± 2.61 | 52.68 ± 5.18 | T2 | Dal weed+agricultural residue | 58.02 ± 3.31 | 57.83 ± 3.54 | 56.78 ± 5.56 | |

| T3 | Dal weed+food waste | 60.27 ± 10.96 | 59.70 ± 10.47 | 58.97 ± 10.49 | T3 | Dal weed+food waste | 61.58 ± 11.42 | 60.65 ± 11.43 | 60.45 ± 10.81 | |

| T4 | Dal weed+agricultural residue+food waste | 57.69 ± 3.23 | 55.65 ± 4.19 | 54.48 ± 2.31 | T4 | Dal weed+agricultural residue+food waste | 59.37 ± 3.53 | 57.93 ± 2.71 | 57.93 ± 2.68 | |

| C.D. (p ≤ 0.05) | 8.56 | C.D. (p ≤ 0.05) | 8.26 | |||||||

Table 10: Ammonium-Nitrogen (mg/L) under room conditions.

Total phosphorus (TP)

Data of total phosphorus in all treatment under both the conditions (room and poly-house) showed no significant variation (p ≤ 0.05) at the initial, middle and final stage of the bio digestion. Total Phosphorus (TP) has little/no impact on anaerobic digestion of biogas production or it has no direct effect in methane production as reported by Moller and Muller in 2012. PH affects the solubility of Total Phosphorus (TP) and micronutrients; for example, raising the pH causes the chemical balance to shift toward the production of dissociated phosphate ions, which aids the precipitation of insoluble Ca and Mg phosphates in the digestors [47]. Though anaerobic digestion has no significant effects on Phosphorus (P) removal, anaerobic digestion effluent still contains a high level of phosphorus (either organic or inorganic phosphate) (Table 11).

| Under room condition | Under poly-house condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Treatments | Treatments details | Initial (15th – 29th Oct.) | Middle (12th – 26th Nov.) | Final (17th – 31st Dec.) | Treatments | Treatments details | Initial (1st – 15th Feb.) | Middle (15th – 29th Mar.) | Final (19th Apr. – 3rd May) | |

| T1 | Dal weed 100% | 1.97 ± 0.81 | 1.30 ± 0.30 | 1.20 ± 0.29 | T1 | Dal weed 100% | 2.00 ± 0.83 | 2.00 ± 0.92 | 1.95 ± 0.76 | |

| T2 | Dal weed+agricultural residue | 3.49 ± 1.72 | 2.48 ± 1.22 | 1.80 ± 0.70 | T2 | Dal weed+agricultural residue | 4.18 ± 1.34 | 4.12 ± 1.28 | 4.02 ± 1.28 | |

| T3 | Dal weed+food waste | 2.25 ± 1.69 | 2.25 ± 1.66 | 2.11 ± 1.45 | T3 | Dal weed+food waste | 3.57 ± 1.58 | 3.56 ± 1.56 | 3.51 ± 1.51 | |

| T4 | Dal weed+agricultural residue+food waste | 3.14 ± 1.71 | 2.36 ± 0.97 | 2.32 ± 0.99 | T4 | Dal weed+agricultural residue+food waste | 3.53 ± 1.47 | 3.25 ± 1.05 | 3.12 ± 1.12 | |

| C.D. (p ≤ 0.05) | 1.63 | C.D. (p ≤ 0.05) | 1.62 | |||||||

Table 11: Total phosphorus (mg/L) and treatment details.

Chemical oxygen demand (COD)

Chemical Oxygen Demand (COD) under room temperature showed a decreasing trend from initial to final in all the treatments as T1 decreased from 11.31 (initial) to 11.17 g/L (final); T2 decreased from 19.41 (initial) to 18.59 g/L (final); T3 decreased from 25.14 (initial) to 24.58 g/L (final) and T4 decreased from 30.31 (initial) to 29.16 g/L (final). Under poly-house temperature, Chemical Oxygen Demand (COD) also showed a decreasing trend from initial-final in all treatments as T1 decreased from 13.99 (initial) to 13.66 g/L (final); T2 decreased from 20.75 (initial) to 19.89 g/L (final); T3 decreased from 27.41 (initial) to 26.36 g/L (final) and T4 decreased from 31.92 (initial) to 31.08 g/L (final) as data given in Table 12. Similar finding of a decreasing trend in methane has been reported by Elaiyarju and Pratha (2016). Higher biogas production in bioreactors is linked to improved COD because producing more methane (in a relatively constant methane/biogas yield) implies that more organic matter has been consumed by anaerobic organisms, resulting in lower COD at the end of the digestion process as reported by Hallaji et al., in 2018. Chemical Oxygen Demand stabilization can also be used to estimate methane production. Biogas production is directly related to the decrease of COD in the wastewater. Therefore, COD removal rate is used as an alternative parameter for biogas production (Table 12) [48].

| Under room condition | Under poly-house condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Treatments | Treatments details | Initial (15th – 29th Oct.) | Middle (12th – 26th Nov.) | Final (17th – 31st Dec.) | Treatments | Treatments details | Initial (1st – 15th Feb.) | Middle (15th – 29th Mar.) | Final (19th Apr. – 3rd May) | |

| T1 | Dal weed 100% | 11.31 ± 0.11 | 11.26 ± 0.09 | 11.17 ± 0.09 | T1 | Dal weed 100% | 13.99 ± 0.76 | 13.82 ± 0.66 | 13.66 ± 0.71 | |

| T2 | Dal weed+agricultural residue | 19.41 ± 0.13 | 18.96 ± 0.31 | 18.59 ± 0.48 | T2 | Dal weed+agricultural residue | 20.75 ± 0.52 | 20.35 ± 0.51 | 19.89 ± 0.67 | |

| T3 | Dal weed+food waste | 25.14 ± 0.12 | 24.86 ± 0.23 | 24.58 ± 0.30 | T3 | Dal weed+food waste | 27.41 ± 0.57 | 26.78 ± 0.64 | 26.36 ± 0.94 | |

| T4 | Dal weed+agricultural residue+food waste | 30.31 ± 0.61 | 29.60 ± 0.48 | 29.16 ± 0.35 | T4 | Dal weed+agricultural residue+food waste | 31.92 ± 0.50 | 31.26 ± 0.48 | 31.08 ± 0.43 | |

| C.D. (p ≤ 0.05) | 0.48 | C.D. (p ≤ 0.05) | 0.83 | |||||||

Table 12: Chemical oxygen demands (mg/L) in agricultural and food waste.

Heavy metals (Pb, Cd and Cu)

The data on heavy metals (Pb, Cd, and Cu) has shown in Tables 13 and 14 for both the conditions reveals that there was no significant variation (p ≤ 0.05) in the concentrations of the analyzed heavy metals among treatments. The presence of heavy metals in all the substrates might be due to their absorption from water as in the case of Dal weed and soil with respect to agricultural residue and food waste [49]. Nevertheless, the concentrations of heavy metals in the substrates were all below the standard of the Central Pollution Control Board (CPCB) for effluent discharge into surface water and public sewers as given in Table 4 (Table 13 and 14).

| Treatments | Treatments details | Heavy metals | ||

|---|---|---|---|---|

| Pb (mg/L) | Cd (mg/L) | Cu (mg/L) | ||

| T1 | Dal weed 100% | 0.223 ± 0.045 | 0.029 ± 0.001 | 0.029 ± 0.007 |

| T2 | Dal weed+agricultural residue | 0.243 ± 0.063 | 0.028 ± 0.001 | 0.028 ± 0.007 |

| T3 | Dal weed+food waste | 0.273 ± 0.015 | 0.029 ± 0.001 | 0.036 ± 0.029 |

| T4 | Dal weed+agricultural residue+food waste | 0.275 ± 0.044 | 0.031 ± 0.002 | 0.037 ± 0.011 |

| C.D. (p≤ 0.05) | 0.063 | 0.002 | 0.023 | |

| Note: Pb-Lead, Cd-Cadmium, Cu-Cupper | ||||

Table 13: Heavy metals treatment in (Pb, Cd and Cu) mg/L.

| Treatments | Treatments details | Heavy metals | ||

|---|---|---|---|---|

| Pb (mg/L) | Cd (mg/L) | Cu (mg/L) | ||

| T1 | Dal weed 100% | 0.483 ± 0.051 | 0.017 ± 0.003 | 0.001 ± 0.001 |

| T2 | Dal weed+agricultural residue | 0.475 ± 0.068 | 0.017 ± 0.003 | 0.003 ± 0.003 |

| T3 | Dal weed+food waste | 0.515 ± 0.077 | 0.018 ± 0.002 | 0.001 ± 0.001 |

| T4 | Dal weed+agricultural residue+food waste | 0.515 ± 0.081 | 0.019 ± 0.003 | 0.005 ± 0.003 |

| C.D. (p ≤ 0.05) | 0.098 | 0.004 | 0.003 | |

| Note: Pb-Lead, Cd-Cadmium, Cu-Cupper | ||||

Table 14: Heavy metals (Pb, Cd and Cu) mg/L (anaerobic digestion).

Biogas production under room and poly-house conditions

Methane production on weekly basis in both the conditions (under room and poly-house temperature) is shown in Table 15. Under room temperature, T4 (Dal weed+agricultural residue+food waste) had the highest methane production of 436.25 mL kg-1 among all other treatments [50]. This might be due to the mixture of the different substrate in T4 (Dal weed+agricultural residue+food waste), and the effect of temperature which enhanced microbial growth and degradation of organic matter. The combinations of different substrates in several studies have proven to be excellent in the production of biogas [51,52]. However, under poly-house condition, T1 (Dal weed 100%) produced the highest methane gas of 531.25 ml kg-1 among all other treatments. Dal weed produces the most biogas because it has a higher water content and soft organic matter with a fine texture, which creates favorable circumstances for anaerobic digestion to produce more biogas (Table 15).

| Under room condition | Under poly-house condition | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Date (week) | T1 Dal weed 100%) | T2 (Dal weed+agricultural residue) | T3 (Dal weed+food waste) | T4 Dal weed+food waste) | Date (week) | T1 (Dal weed 100%) | T2 (Dal weed+agricultural residue) | T3 (Dal weed+food waste) | T4 (Dal weed+agricultural residue+food waste) |

| 22/10/2020 (1) | 126.25 ± 34.97 | 120.00 ± 21.60 | 162.50 ± 25.00 | 166.25 ± 24.96 | 08/02/2021 (1) | 130.00 ± 7.07 | 103.75 ± 20.16 | 120.00 ± 14.72 | 141.25 ± 4.79 |

| 29/10/2020 (2) | 185.00 ± 40.41 | 155.00 ± 23.80 | 202.50 ± 34.03 | 207.50 ± 30.96 | 15/02/2021 (2) | 156.25 ± 10.31 | 143.75 ± 8.54 | 140.00 ± 26.77 | 147.50 ± 20.62 |

| 05/11/2020 (3) | 247.50 ± 80.67 | 271.25 ± 61.29 | 298.75 ± 34.00 | 315.00 ± 23.80 | 22/02/2021 (3) | 220.00 ± 4.08 | 221.25 ± 6.29 | 201.25 ± 4.79 | 226.25 ± 22.50 |

| 12/11/2020 (4) | 392.50 ± 49.92 | 358.75 ± 33.76 | 347.50 ± 37.75 | 407.50 ± 19.36 | 01/03/2021 (4) | 368.75 ± 8.54 | 358.75 ± 8.54 | 350.00 ± 14.14 | 368.75 ± 20.97 |

| 19/11/2020 (5) | 417.50 ± 29.86 | 390.00 ± 65.95 | 391.25 ± 17.50 | 420.00 ± 20.41 | 08/03/2021 (5) | 382.50 ± 22.55 | 361.25 ± 20.56 | 346.25 ± 13.77 | 378.75 ± 36.37 |

| 26/11/2020 (6) | 397.50 ± 27.54 | 380.00 ± 44.16 | 383.75 ± 19.31 | 382.50 ± 30.14 | 15/03/2021 (6) | 415.00 ± 36.74 | 353.75 ± 26.58 | 381.25 ± 28.69 | 390.00 ± 20.41 |

| 03/12/2020 (7) | 410.00 ± 27.99 | 406.25 ± 14.93 | 387.50 ± 25.98 | 436.25 ± 13.15 | 22/03/2021 (7) | 435.00 ± 15.81 | 405.00 ± 27.99 | 405.00 ± 21.21 | 411.25 ± 29.83 |

| 10/12/2020 (8) | 343.75 ± 30.10 | 322.50 ± 54.24 | 346.25 ± 31.98 | 375.00 ± 7.07 | 29/03/2021 (8) | 423.75 ± 34.73 | 368.75 ± 38.16 | 378.75 ± 11.81 | 395.00 ± 15.81 |

| 17/12/2020 (9) | 217.50 ± 27.84 | 170.00 ± 24.15 | 191.25 ± 8.54 | 200.00 ± 22.73 | 05/04/2021 (9) | 416.25 ± 32.76 | 403.75 ± 22.13 | 405.00 ± 31.36 | 410.00 ± 29.72 |

| 24/12/2020(10) | 185.00 ± 44.16 | 153.75 ± 54.37 | 167.50 ± 41.13 | 168.75 ± 33.51 | 12/04/2021 (10) | 531.25 ± 16.52 | 463.75 ± 22.13 | 468.75 ± 25.94 | 496.25 ± 46.97 |

| - | - | - | - | - | 19/04/2021 (11) | 458.63 ± 13.81 | 410.25 ± 22.78 | 415.13 ± 56.54 | 430.00 ± 46.62 |

| - | - | - | - | - | 26/04/2021 (12) | 368.00 ± 14.57 | 276.38 ± 46.98 | 287.13 ± 27.72 | 341.88 ± 64.05 |

| - | - | - | - | - | 03/05/2021 (13) | 255.50 ± 16.11 | 195.88 ± 4.97 | 185.25 ± 24.73 | 219.25 ± 33.21 |

| - | - | - | - | - | 10/05/2021 (14) | 154.63 ± 28.38 | 114.38 ± 5.54 | 110.38 ± 14.97 | 127.63 ± 20.58 |

Table 15: Production of methane gas (mL kg-1) from anaerobic digestion using different treatments.

Conclusion

On the basis of results obtained during the present investigation, T1 (Dal weed 100%) was more effective for the production of biogas under poly-house condition. This is due to the fact that it is easily degradable by microbes due to its fine texture. On the other hand, due to different substrate mixture of T4 (Dal weed+agricultural residue+food waste), and because of favorable temperature resulted in enhancing the microbial growth and degradation of organic matter thus producing maximum biogas. Lower pH in the digesters is due to high concentration of Volatile Fatty Acids (VFAs), with the increase in pH results in the conversion of acids to methane during biogas production. Quantity of biodegradable solids will gradually decrease due to its microbial degradation into volatile solids which is later converted into biogas. Microbial degradation of organic matter results in conversion of Total Nitrogen (TN into NH3 and NH4 which are used by microbes to build up their cell structures. Decrease of total nitrogen in digestion process is expected due to microbial degradation and decrease of oxygen is due to anaerobic digestion. Chemical oxidation of organic matter results in high chemical oxygen demand. The relationship of the physico-chemical parameters of substrates with biogas is explained in this wise: The increase of pH, TS, VS and total nitrogen caused a corresponding increase in biogas production. Whereas, the decrease in ammonium nitrogen, total phosphorus, and COD triggered an increase in the production of biogas. Based on the observations made during the present investigations, Dal weed can be used as a single substrate for biogas production, and a higher temperature under controlled conditions (20°-40°C) is more favorable for the production of biogas.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

This work was financially supported by the National Mission on Himalayan Studies under the grant GBPNI/NMHS-2020-21/MG/ dated 16-06-2020.

References

- Abbassi-Guendouz A, Brockmann D, Trably E, Dumas C, Delgenes JP, Steyer JP, et al. Total solids content drives high solid anaerobic digestion via mass transfer limitation. Bioresour Technol. 2012;111:55-61.

[Cross Ref] [Google Scholar] [PubMed]

- Adeniran KA, Opara M, Iyanda MO. Development of a batch type bio-digester. 2014.

- Ali AH, Abdul Razaq Z, Tlaiaa Y, Khishala AD. Methane biogas production from mixing of algae and municipal solid waste by anaerobic digestion. Int J Environ Res. 2016;10(4):613-624. [Cross Ref]

[Google Scholar] [PubMed]

- Master list of typical pH and acid content of fruits and vegetables for home canning and preserving. 2021.

- Baldy V, Tremolieres M, Andrieu M, Belliard J. Changes in phosphorus content of two aquatic macrophytes according to water velocity, trophic status and time period in hardwater streams. Hydrobiologia. 2007;575(1):343-351.

- Bhat RA, Mehmood MA, Dervash MA, Mushtaq N, Bhat JI, Dar GH. Current status of nutrient load in Dal Lake of Kashmir Himalaya. J Pharmacogn Phytochem. 2017;6(6):165-169.

- Wang B, Dong F, Chen M, Zhu J, Tan J, Fu X, et al. Advances in recycling and utilization of agricultural wastes in China: Based on environmental risk, crucial pathways, influencing factors, policy mechanism. Procedia Environ Sci. 2016;31:12-17.

- Burton CH, Turner C. Manure management: Treatment strategies for sustainable agriculture. Editions Quae. 2003.

- Callander IJ, Barford JP. Precipitation, chelation, and the availability of metals as nutrients in anaerobic digestion. I. Methodology. Biotechnol Bioeng. 1983;25(8):1947-1957.

[Cross Ref] [Google Scholar] [PubMed]

- Chenhall N. Tomato plants and pH. 2021.

- Chua KH, Cheah WL, Tan CF, Leong YP. Harvesting biogas from wastewater sludge and food waste. IOP Conf Ser: Earth Environ Sci. 2013;16(1):012118.

- Cioabla AE, Ionel I, Dumitrel GA, Popescu F. Comparative study on factors affecting anaerobic digestion of agricultural vegetal residues. Biotechnol Biofuels. 2012;5(1):1-9.

[Cross Ref] [Google Scholar] [PubMed]

- CPCB, 1986. General standards for discharge of environmental pollutants part- a: Effluents. 2021.

- Elaiyaraju P, Partha N. Studies on biogas production by anaerobic process using agroindustrial wastes. Res Agric Eng. 2016;62(2):73-82.

- Fehrenbach H, Giegrich J, Reinhardt G, Sayer U, Gretz M. Kriterien einer nachhaltigen Bioenergienutzung im globalen Maßstab. UBA-Forschungsbericht. 2008;206:41-112.

- Gerardi MH. The microbiology of anaerobic digesters. John Wiley & Sons. 2003.

- Hallaji SM, Torabian A, Aminzadeh B, Zahedi S, Eshtiaghi N. Improvement of anaerobic digestion of sewage mixed sludge using free nitrous acid and Fenton pre-treatment. Biotechnol Biofuels. 2018;11(1):1-2.

[Cross Ref] [Google Scholar] [PubMed]

- Hobbs SR, Landis AE, Rittmann BE, Young MN, Parameswaran P. Enhancing anaerobic digestion of food waste through biochemical methane potential assays at different substrate: Inoculum ratios. Waste Manag. 2018;71:612-617.

[Cross Ref] [Google Scholar] [PubMed]

- Wei J, Liang G, Alex J, Zhang T, Ma C. Research progress of energy utilization of agricultural waste in China: Bibliometric analysis by citespace. Sustainability. 2020;12(3):812.

- Jingura RM, Kamusoko R. Methods for determination of biomethane potential of feedstocks: A review. Biofuel Res J. 2017;4(2):573-586.

- Lukitawesa, Patinvoh RJ, Millati R, Sarvari-Horvath I, Taherzadeh MJ. Factors influencing volatile fatty acids production from food wastes via anaerobic digestion. Bioeng. 2020;11(1):39-52.

[Cross Ref] [Google Scholar] [PubMed]

- Masih JC. Biogas production from cattle dung in winter using jaggery as a stimulant (Doctoral dissertation, Microbiology, CCSHAU, HIsar).

- Mathew AK, Bhui I, Banerjee SN, Goswami R, Chakraborty AK, Shome A, et al. Biogas production from locally available aquatic weeds of Santiniketan through anaerobic digestion. Clean Technologies and Environmental Policy. 2015;17(6):1681-1688.

- Michael B. Biomass to Biogas Anaerobic Digestion. Einstruments International, LLC. 2018.

- Moller K, Muller T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng Life Sci. 2012;12(3):242-257.

- Moody L, Burns R, Wu-Haan W, Spajic R. Use of biochemical methane potential (BMP) assays for predicting and enhancing anaerobic digester performance. In 44th Croatian & 4th International Symposium on Agriculture. 2009:930-934.

- Morse GK, Brett SW, Guy JA, Lester JN. Phosphorus removal and recovery technologies. Sci Total Environ. 1998 Mar 5;212(1):69-81.

- Sibiya NT, Muzenda E, Tesfagiorgis HB. Effect of temperature and pH on the anaerobic digestion of grass silage. In Proceedings of the 6th International Conference on Green Technology, Renewable Energy and Environmental Engineering, Cape Town, South Africa 2014: 15-16.

- Olivier JG, Schure KM, Peters JA. Trends in global CO2 and total greenhouse gas emissions: Summary of the 2017 report. PBL Netherlands Environ Assess Agency: The Hague, The Netherlands. 2017.

- Pavan P, Battistoni P, Mata-Alvarez J, Cecchi F. Performance of thermophilic semi-dry anaerobic digestion process changing the feed biodegradability. Water Sci Technol. 2000;41(3):75-81.

[Cross Ref] [Google Scholar] [PubMed]

- Rani A. Biogas production from vegetable foliage as supplement to cattle dung. Chaudhary Charan Singh Haryana Agri. University. Microbiology. 2013. 1-59.

- Riuji LC. Research on anaerobic digestion of organic solid waste at household level in Dar Es Salaam, Tanzania (Doctoral dissertation, ARDHI University).

- Rozy, 2016. Process optimization for biogas generation from water hyacinth and its supplementation in paddy straw-based digester. Punjab Agr. University.

- Saleem M, Jeelani G, Shah RA. Hydrogeochemistry of Dal Lake and the potential for present, future management by using facies, ionic ratios, and statistical analysis. Environ Earth Sci. 2015;74(4):3301-3313.

- Saputra AH, Putri RA. The determination of optimum condition in water hyacinth drying process by mixed adsorption drying method and modified fly ash as an adsorbent. InAIP Conference Proceedings 2017;1840(1):100005.

- Sibiya NT, Muzenda E, Tesfagiorgis HB. Effect of temperature and pH on the anaerobic digestion of grass silage. In Proceedings of the 6th International Conference on Green Technol, Renew Energ and Environ Eng, Cape Town, South Africa 2014:15-16.

- Singh R, Mandal SK, Jain VK. Development of mixed inoculum for methane enriched biogas production. Indian J Microbiol. 2010;50(1):26-33.

[Cross Ref] [Google Scholar] [PubMed]

- Su F, Li Z, Li Y, Xu L, Li Y, Li S, et al. Removal of total nitrogen and phosphorus using single or combinations of aquatic plants. Int J Environ Res Public Health. 2019;16(23):4663.

[Cross Ref] [Google Scholar] [PubMed]

- Sundberg C, Yu D, Franke-Whittle I, Kauppi S, Smars S, Insam H, et al. Effects of pH and microbial composition on odour in food waste composting. Waste Manag. 2013;33(1):204-211.

[Cross Ref] [Google Scholar] [PubMed]

- Sung S, Liu T. Ammonia inhibition on thermophilic anaerobic digestion. Chemosphere. 2003;53(1):43-52.

[Cross Ref] [Google Scholar] [PubMed]

- Syaichurrozi I, Sumardiono S. Predicting kinetic model of biogas production and biodegradability organic materials: Biogas production from vinasse at variation of COD/N ratio. Bioresour Technol. 2013;149:390-397.

[Cross Ref] [Google Scholar] [PubMed]

- Tang J, Wang XC, Hu Y, Zhang Y, Li Y. Effect of pH on lactic acid production from acidogenic fermentation of food waste with different types of inocula. Bioresour Technol. 2017;224:544-552.

[Cross Ref] [Google Scholar] [PubMed]

- Thiébaut G. Phosphorus and aquatic plants. InThe ecophysiology of plant-phosphorus interactions. 2008:31-49.

- Tiwari S, Dixit S, Verma N. An effective means of biofiltration of heavy metal contaminated water bodies using aquatic weed Eichhornia crassipes. Environ Monit Assess. 2007;129(1):253-256.

[Cross Ref] [Google Scholar] [PubMed]

- Veeken A, Kalyuzhnyi S, Scharff H, Hamelers B. Effect of pH and VFA on hydrolysis of organic solid waste. Journal of environmental engineering. 2000 Dec;126(12):1076-1081.

- Vietmeyer ND. Beautiful Blue Devil. Natural History. 1975;84(9):65-73.

- Wellinger A. Process design of agricultural digesters. ad-nett anaerobic digestion: making energy and solving modern waste problems. Ortenblad H. Ed. Herning Municipal Utilities. Denmark. 2000.

- Wu QL, Guo WQ, Zheng HS, Luo HC, Feng XC, et al. Enhancement of volatile fatty acid production by co-fermentation of food waste and excess sludge without pH control: The mechanism and microbial community analyses. Bioresour Technol. 2016;216:653-660.

[Cross Ref] [Google Scholar] [PubMed]

- Yang F. Mesophilic anaerobic digestion conducted in single unit reactor at increasing ammonia concentrations.

- Yi J, Dong B, Jin J, Dai X. Effect of increasing total solids contents on anaerobic digestion of food waste under mesophilic conditions: Performance and microbial characteristics analysis. PloS one. 2014;9(7):e102548.

[Cross Ref] [Google Scholar] [PubMed]

- Yu Q, Wang HZ, Li Y, Shao JC, Liang XM, Jeppesen E, et al. Effects of high nitrogen concentrations on the growth of submersed macrophytes at moderate phosphorus concentrations. Water Res. 2015;83:385-395.

[Cross Ref] [Google Scholar] [PubMed]

- Zhang C, Wang A, Jia J, Zhao L, Song W. Effect of parameters on anaerobic digestion EGSB reactor for producing biogas. Procedia Eng. 2017;205:3749-3754.

Citation: Khan JI, Hajib HS, Lonec FA, Khand I, Bangrooe SA, Khan FA (2023) Production of Methane from Aquatic Weeds and Other Organic Substrates through Anaerobic Digestion under Different Climates. Int J Waste Resour. 13:508.

Copyright: © 2023 Khan JI, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.