Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2021) Volume 12, Issue 1

Performance Evaluation Of Ncam Dry Beans Dehulling Machine

Ogunjirin OA1, Oladipo NO1, Abiodun LO1 and Ola OA2*2National Centre for Agricultural Mechanization Kwara, Nigeria

3Farm Power and Machinery Department, National Centre for Agricultural Mechanization Kwara, Nigeria

Received: 01-Jan-2021 Published: 17-Feb-2021, DOI: 10.35248/2157-7110.21.12.865

Abstract

Beans are from the families of legumes which are rich in protein. It has possibility of alleviating poverty and undernutrition amongst the lower-class families, because every part of cowpea is useful. The traditional method of dehulling beans (soaking in water to ease hull removal) are time consuming, hazardous and associated with lots of drudgery.

This report presents the performance evaluation of NCAM developed dried beans dehulling machine. Thirty-six (36) kilogram of beans with 9.2% moisture content was used for the evaluation in which the feed regulator opening was varied. From the result obtained, it showed that the wider the feed opening, the higher the dehulling rate and the dehulling efficiency. The average capacity of the machine is 771 kg/hr.

Keywords

De-hulling; Beans; Ncam; Dehulling Machine; Evaluation

Introduction

Cowpea (Vigna unguiculata) a family of legumes is one of the most important domestic legumes in the world, it had been cultivated in Nigeria, Latin America and Tropics for many decades because of its high protein, fiber and complex carbohydrates. Cowpea is consumed in many forms and this has increased its demand in Nigeria. In Nigeria majorly, it is refined into other products such as bean cake locally known as moin-moin, bean soup etc. It has about 25%-30% of protein depending on its variety, the grain provides essential nutrients including Zinc and Iron which are necessary for healthy living. It also has potential to alleviate poverty and malnutrition among the poor. All parts of the plant; its leaves, peas, pods, and grain eaten as various dishes due to its nutrition.

Bean is cultivated by majority of farmer in the northern part of Nigeria such as Sokoto, Zamfara, Kano, Yobe and Borno. And it was also rated 4th most consumed after cassava, yam and rice.

One of the post-harvest challenges of beans is dehulling. Dehulling is described as separation of the seed coat (hull) from its grain in order to distinguish the cotyledons from the hull. The traditional method of dehulling is typically achieved using the wet process by which the beans are immersed for several minutes in water, then rubbed between the palms or pounded in mortar to extract the hulls. The hulls are then cleaned off using water. A lot of water is used in this process; it is time consuming and associated with lots of drudgery. Processing of beans into different products is very low because of manual method of dehulling, these prolong wet processing method was upgraded into a dry de-hulling mechanism.

This report presents the performance evaluation of dried beans dehulling machine fabricated in NCAM with the aim of producing dehulled beans on a medium scale basis to meet the consumption of the populace and to ease the problems associated with the traditional method of dehulling beans [1-5].

Materials and Methods

Machine description

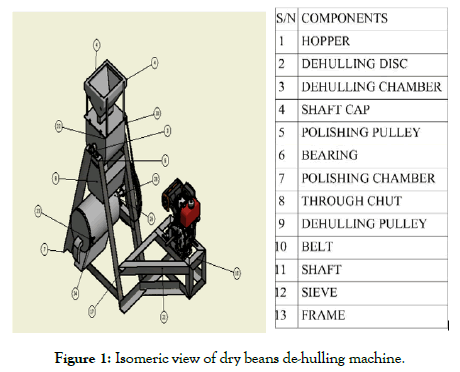

The machine comprises of a frame, hopper, dehulling chamber, polishing chamber and the discharge chute which are powered by a 5 hp petrol engine via a belt pulley arrangement.

Hopper: The hopper is the device through which bean seed are fed into the machine. A regulator is incorporated at the base of the hopper between the hopper and the dehulling chamber.

Dehulling chamber: This chamber is made from 2 mm thick galvanized iron sheet with eight (8) rotating abrasive discs for bean dehulling.

Polishing chamber: The polishing chamber is cylindrical in shape; it consists of a perforated sieve that houses the brushes that clean the surface of the dehulled beans thereby polishing the seeds.

Supporting frame: The frame is made of 25mm-by-25mm angle iron of height 400 mm. The frame supports the whole machine.

Discharge chute: The discharge chute is the final outlet of the dehulled beans through which it is released into a collecting trough. It was welded to the polishing chamber.

Power unit: The power units of the beans dehuller consist of electric motor, belt and pulley.

Feed regulator: The feed regulator is made of 190 mm by 32 mm rectangular bar. The dry beans poured into the hopper are released to the dehulling chamber through the regulator at the base of the hopper.

Operation of the Machine

The bean seeds are poured into the hopper. The dehulling chamber has within it 8 rotating abrasive discs which are activated by means of pulley and belt arrangement connected to the prime mover. Dry beans poured into the hopper are released to the dehulling chamber through the regulator at the base of the hopper. The bean seeds are dehulled by the action of the rotating abrasive discs that are moving relative to the gyrating seeds within the dehulling chamber. When the dehulling process is completed, the seeds are released through the spout that leads to the polishing chamber. The brushes within the polishing chamber rub the dehulled seeds against each other and against the perforated sieve that houses the brush. This action helps to uniformly clean off the surface of the cotyledon of the dry seed thereby polishing them; after which the seeds are finally released to the collecting trough.

Test Procedure and Evaluation

Apparatus

The apparatus used in the evaluation include: tachometer, Analog weighing scale, digital weighing, measuring cylinder, sacks, bowls, John Deere moisture content meter, etc.

Sample preparation and testing: The white beans specie used was bought from Oja-Oba market in Ilorin. No special treatment was done on it. Thirty-six (36) kilogram of beans seed with 9.2% moisture content were used for the experiment which was divided into nine samples of 4 kg each. The evaluation of the machine was based on the feed regulator opening of 190 mm by 32 mm, 190 mm by 21 mm and 190 mm by 11 mm in three replicates.

At each feed opening, 4 kg of beans were fed into the dehulling machine through the hopper, the time taken; the weight of the dehulled beans and weight of chaff were noted.

The results of the performance test are shown in Table 1.

| Samples | Weight of sample (kg) |

Feed opening(mm) | Dehulling time (sec) | Weight of dehulled (kg) |

Weight of chaff (mm) | % efficiency | % damaged | Dehulling rate Kg/hr |

|---|---|---|---|---|---|---|---|---|

| A | 4.00 | 11 | 1260 | 3.41 | 0.59 | 85.25 | 14.25 | 9.74 |

| B | 4.00 | 21 | 1140 | 3.43 | 0,57 | 85.75 | 11.25 | 10.83 |

| C | 4.00 | 32 | 960 | 3.46 | 0.54 | 86.0 | 9.75 | 12.98 |

Table 1: The mean data obtained from the evaluation of the dry beans’ seeds dehulling machine.

Performance indices: The performance indices employed involve; efficiency of de-hulling (%) and Percentage damaged (%).

Dehulling efficiency - DE(%) : This illustrates how the machine dehulls the sample effectively. This is the ratio

Where,

DE = Dehulling efficiency

Wd = Weight of dehulled

Wt = Total weight of sample

Percentage damaged -Pd (%): this is the ratio of the weight of the damaged seed to the total weight of the sample used expressed in percentage.

Where,

Pd = Percentage damaged

Qd = Weight of damaged seed

Wt = Total weight of sample

Dehulling rate (Dr)

Where,

Dr = Dehulling rate

Wd = Weight of dehulled

T = Time taken

Results and Discussion

The effect of feed opening variation on performance parameters

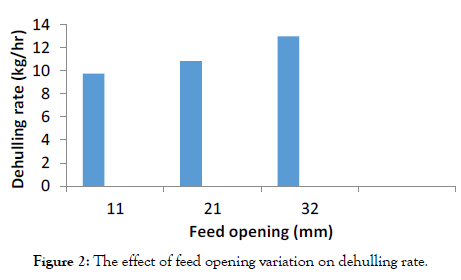

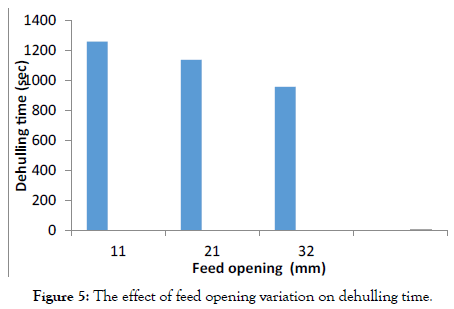

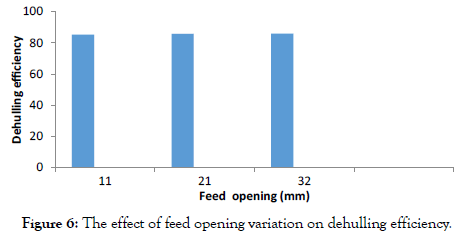

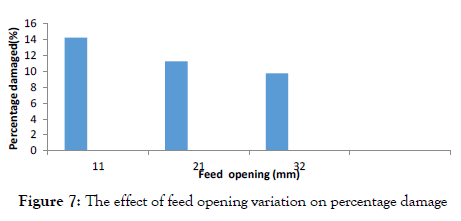

Effects of feed opening on performance parameters were presented in (Figures 1-7). An increase in the feed opening results in resultant increase of the weight of dehulled beans and the dehulling efficiency. Dehulling time needed to dehull the beans was reduced because the beans flow easily to the dehulling chamber. Figure 2 shows the relationship between the feed opening and the dehulling rate. Dehulling rate increases as the feed opening becomes wider.

Figure 1: Isomeric view of dry beans de-hulling machine.

Figure 2: The effect of feed opening variation on dehulling rate.

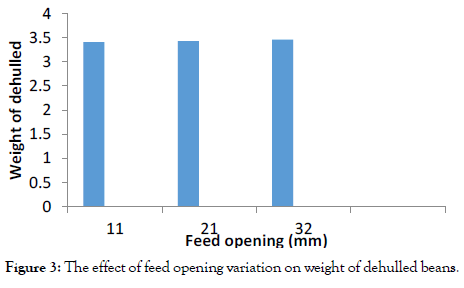

Figure 3: The effect of feed opening variation on weight of dehulled beans.

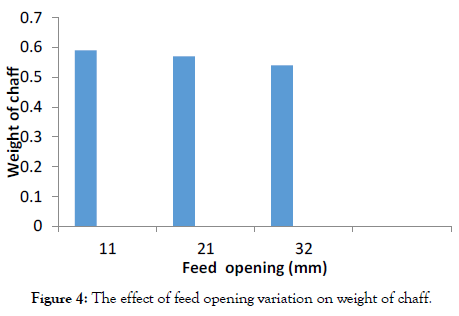

Figure 4: The effect of feed opening variation on weight of chaff.

Figure 5: The effect of feed opening variation on dehulling time.

Figure 6: The effect of feed opening variation on dehulling efficiency

Figure 7: The effect of feed opening variation on percentage damage

From figure 3, it was observed that an increase in feed opening result in an increase in the weight of the dehulled beans and vice versa. The increase in the feed opening allows the easy flow of beans into the dehulling chamber thereby increasing the weight of dehulled.

weight of beans chaff. As the feed opening increases, the weight of chaff decreases.

From figure 5, it shows that the more the feed opening, the lower the dehulling time needed to dehull the beans. This might be due to the easy flow of the beans into the dehulling chamber unlike with small openings that require more time.

From figure 6, it was found that as dehulling efficiency increases as the feed opening increases and in Figure 7, percentage damaged was reduced with increase in feed opening [6-10].

Conclusion

In this study, performance evaluation of dry beans dehuller fabricated in NCAM was evaluated by varying the feed opening. Therefore, from the above presented results and discussion, it was discovered that the higher the feed opening the higher the weight of dehulled, dehulling rate and the dehulling efficiency but at reduced dehulling time, weight of chaff and percentage damaged. The average capacity of the machine is 771kg/hr and the dehulling efficiency is 86% at the maximum feed opening.

REFERENCES

- Adejuyigbe SB, Bolaji BO. Design, fabrrcation and performance evaluation of beans dehuller. J Sci Technol. 2005;25:132.

- Gbabo A, Lukman A, Kuku A, Baba N. Design & performance assessment of a spiked toothed drum mechanism for shelling of castor. Int J Innov Sci Eng Technol. 2016:3;229-38.

- Akinjayeju OA. Effects of dehulling on functional and sensory properties of flour from black beans (Phaseolus Vulgaris). J Food Nutr Sci. 2011;2:344-49.

- Bassey MW, Schmidt OG. Abrasive-disk dehullers in Africa: From research to dissemination. International Development Research Centre 1989.

- Boukar O, Massawe F, Muranaka S, Franco J, Dixion M, C.Fatokun. Evaluaion of cowpea germplasm lines for minerals and protain content in grains. Plant Genet Resour. 2011;9:515-22

- Oruç E, Uzunoz M, Bal GS. Post-harvest losses in tomato and fresh bean production in tokat province of turkey. Sci Res Essays. 2011;6:1656-1666.

- Etoamaihe UJ, Ndubueze CK. Evaluation of a dehulling machine for african breadfruit (treculia african). J Eng Appl Sci. 2010;5:312-15.

- Anosike N, Brown E, Maduka C. Performance Evaluation of a Prototyped Bread fruit Seed Dehulling Machine. Machines. 2016.4(2);11.

- Olaoye OJ, Olotu FB. Design And Fabrication of Hydro-Separating Cowpea Dehuller. ASABE Annual International Meeting 2015.

- Obi, Okey, Akubuo, Clement. Performance Evaluation of African Breadfruit (Treculia Africana) Seed Dehuller. Agri Eng 2018.

Citation: Ogunjirin OA, Oladipo NO, Abiodun LO, Ola OA (2021) Performance Evaluation of Ncam Dry Beans Dehulling Machine. J Food Process Technol 12: 865.

Copyright: © 2021 Ola OA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.