Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 14, Issue 9

Optimization of Process Parameters for the Development of Cake from Novel Flour Blends of Drynaria quercifolia and Ipomea batatas

Malavika Murugesan*, Dharani Muthusamy, Vigneshwaran Vidhyasalam, Maha Hariharan Gunaseelan and Ameena Benazir PeerbalReceived: 05-Oct-2023, Manuscript No. JFPT-23-23353; Editor assigned: 09-Oct-2023, Pre QC No. JFPT-23-23353 (PQ); Reviewed: 23-Oct-2023, QC No. JFPT-23-23353; Revised: 30-Oct-2023, Manuscript No. JFPT-23-23353 (R); Published: 06-Nov-2023, DOI: 10.35248/2157-7110.23.14.1056

Abstract

Development of functional bakery products has been trending due to their popularity and being preferred by the general population due to novel formulations. Providing nutritious and healthy cake remains a major challenge due to high sugar content which predisposes the consumers to obesity. Current project was focused to partially replace typical Refined Wheat Flour (RWF) used in the cake formulation by novel flour processed from Drynaria quercifolia (DQ) and Ipomoea batatas (IB) at different ratios. The product composition was optimized using factorial method in which 8 trails were carried. Based on sensory evaluation, Trail 8 was optimized (DQF 40%, IBF 20% and RWF 40%) in the ratio of 2:1:2. Physio chemical analysis (moisture, fat, crude protein, crude fibre and carbohydrate were analyzed. Compared to control sample, fibre content was increased by replacement of RWF with novel flour. Incorporation of IBF also reduced the level of added sugar to the batter. The sensory evaluation of developed cake was found to be similar with control sample without any off-flavours. Hence the study concludes that novel flour processed from DQ and IB can be used for the formulation of functional cake with higher acceptable sensory characteristics. This was the first study to develop food product from Drynaria quercifolia from best of the author’s knowledge.

Keywords

Cake; Drynaria quercifolia; Flour; High fibre; Ipomoea batatas; Reduced sugar

Introduction

Cakes have occupied a stable position in our diet for a long time, and their continued popularity has prompted the development of newer and more appealing items on the market today. It is frequently served as a dessert. Option for meals during ceremonial events, such as wedding anniversaries, funerals, birthdays. Cakes are sweet and frequently baked food products made mostly from wheat flour, sugar, shortening, baking powder, and egg. Replacement of RWF with functional flour from different natural sources was found to be appealing without any restriction in sensory characteristics of the product.

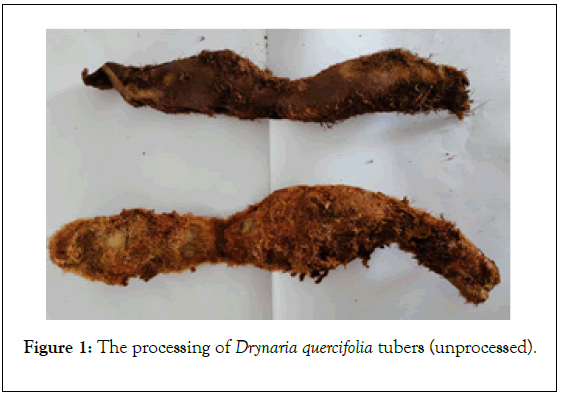

Drynaria quercifolia is an important ethno medicinal plant used in traditional Indian medicine to treat various health problems called as ‘Ashwakatri’ in Ayruveda and ‘Li ye hu jue’ in Chinese. Its ethanolic extract has antifungal exertion against dermatophytic species and gram-positive and gram-negative bacteria. Drynaria quercifolia native to tropical areas of East Asian countries, Africa and Australia. It is a high source of amino acid and sugars to treat various aliments in Ayurveda and Unani of Indian medicine and Chinese medicine. The plant was proved to have antimicrobial, antioxidant, cytotoxic activities and contains phytochemical agents like 3,4-dihydroxybenzoic acid, friedelin, epifriedelinol, β-amyrin, β-sitosterol, and 3-β-Dglucopyranosid [1]. The powder and extracts from the rhizome are used to treat rheumatic fever, dyspepsia, cough, and bone recovery (Figure 1) [2].

Figure 1: The processing of Drynaria quercifolia tubers (unprocessed).

Sweet potato is one of two main crops, along with common beans, that play an essential role in many countries' traditional cuisines. Sweet potato is one of a few novel crops that can help enhance the community's nutrient status by providing both energy and key nutritive components [3]. Sweet potatoes are high in beta-carotene, ascorbic acid, and minerals. It is a good source of fibre, which aids in the reduction of blood cholesterol levels [4]. Sweet potatoes are also high in anti-oxidative compounds such as beta-carotene, vitamin C, and vitamin E, which help to prevent the creation of free radicals, which have been linked to the development of coronary heart disease. Carotene and vitamin C are both potent antioxidants that help to remove free radicals in the body. Free radicals are substances that destroy cells and cell membranes, and they're linked to diseases including multiple sclerosis, diabetic heart disease, and colon cancer. Multiple food products like juice, ice cream, pasta have been developed using Sweet potatoes owing to their bioactive compounds [5]. The proximate composition of the raw materials Ipomoea batatas and Drynaria quercifolia are evaluated using standard method of analysis [6] and the values are tabulated in Table 1.

| Proximate | Ipomoea batatas | Drynaria quercifolia |

|---|---|---|

| Moisture (%) | 7.94 ± 0.10 | 7.61 ± 0.10 |

| Total Carbohydrate (g) | 74.04 ± 0.4 | 75.92 ± 0.6 |

| Crude fibre (%) | 0.45 ± 0.09 | 3.84 ± 0.04 |

| Sugar (%) | 9.33 ± 0.06 | 4.02 ± 0.09 |

| Protein (%) | 2.05 ± 0.02 | 2.44 ± 0.3 |

| Fat (%) | 0.90 ± 0.01 | 0.73 ± 0.05 |

| Ash (%) | 0.67 ± 0.01 | 0.86 ± 0.2 |

Table 1: Proximate Values of Ipomoea batatas and Drynaria quercifolia.

The present study was aimed to utilize sweet potato and Drynaria quercifolia for production of novel cake flour blend especially for improving the nutritional properties of ready-to-eat foods and improved physicochemical properties of the cakes.

Materials and Methods

Source of raw materials

The study was conducted in the laboratories of the Department of Food Technology, K.S. Rangasamy College of Technology, Namakkal. One of the important ingredients in the formulation of the cake was Drynaria quercifolia (locally called as Mudavattukal kilangu) a rare variety of tuber was collected from the hilly farms of Thalaisolai village, Yercaud Taluk, Salem district, Tamilnadu State, India. Mature Sweet potatos was procured from local farm of Salem district. Other ingredients like refined wheat flour, sugar, butter, baking powder and baking soda were purchased locally.

Processing of Drynaria quercifolia Flour (DQF) and Ipomea batatas Flour (IBF)

The procedure for drying of Drynaria quercifolia Flour (DQF) and Ipomea batatas Flour (IBF) was obtained as per Giri et al. [7]. The tubers of were cleaned, washed and peeled and sliced into 5 mm thickness slices and tray dried at the 65°C for 12 hrs. Dried slices were grounded and sieved through 80 mesh sieves to obtain fine flour (particle size of 0.177 mm). Then stored in Low Density Polyethylene (LDPE) packs and further sealed, finally kept at room temperature until use (Figure 2).

Figure 2: The drying powder of Drynaria quercifolia Flour (DQF).

Experimental trials

Refined Wheat flour was partially substituted with Drynaria quercifolia Flour and Ipomea batatas Flour at substitution ratios of 40:0:60, 0:30:70, 0:70:30, 0:80:20, 60:0:40, 25:25:50, 20:20:60, 40:20:40 of DQF, IBF and RWF Respectively. Sample with 100% Refined wheat flour served as control. All the flour samples were blended well for five minutes to achieve uniform mixing (Table 2).

| Trial no | Weight of DQF(g) | Weight of IBF (g) | Weight of RWF (g) |

|---|---|---|---|

| 1 | 40 | - | 60 |

| 2 | - | 30 | 70 |

| 3 | - | 70 | 30 |

| 4 | - | 80 | 20 |

| 5 | 60 | - | 40 |

| 6 | 25 | 25 | 50 |

| 7 | 20 | 20 | 60 |

| 8 | 40 | 20 | 40 |

Table 2: Proportion of Drynaria quercifolia Flour (DQF) and Ipomoea batatas Flour (IBF).

Proportion of ingredients

The ingredients used consists of flour (100 g), sugar (100 g), Butter (100 g), Eggs (73 g), Baking powder (5 g), Baking soda(5 g) and vanilla essence (5 ml) as described by Kim and Lee, (2013) with slight modification (reduction) in the quantity of sugar.

Preparation of cakes

The method of was adopted for the preparation of the cake. DQF, IBF and RWF are sieved and added with specified portions of baking powder, baking soda and salt of dry ingredients [8]. Wet ingredients (butter, icing sugar and egg) were added to dry mix steadily and constantly blended using power driven hand blender. Flavour was added and blended for even distribution. Batter (6 g) was then poured into greased silicon muffins mould, then baked for 140°c for 30 mins and cooled to room temperature. Each cake was packed separately in LDPE and sealed. The cakes were stored at room temperature in a closed environment until analysis and sensory evaluation.

Proximate analysis

Proximate parameters: moisture, protein, crude fibre, fat, ash, carbohydrate and energy values of cake samples were determined according to AOAC [6]. The carbohydrate content was determined by difference while Atwater factors were used to calculate the energy value of the samples.

Sensory evaluation

Sensory evaluation was carried in sensory lab of K.S. Rangasamy College of Technology, Namakkal, with 20 pre-trained sensory panellist of age group 20-30. All the panellist was provided with 3 packed samples with random number as label and subjected to evaluation based on 9 point hedonic scale (1=extremely dislike, 5=neither like nor dislike, 9=extremely like). Each panellist was provided with a glass of tap water to rinse the mouth between evaluations. All the treatments were evaluated for crust, colour, taste, flavour, texture and overall acceptability.

Statistical analysis

The given data were subjected to statistical analysis by means of one- way analysis of variance (one-way ANOVA) using IBM Statistical Package for Social Sciences (SPSS)® for Windows® software as per the procedure given by Snedecor et al., [9].

Results and Discussion

The proximate composition of all the treatments was given in Table 3.

| Contents | C | T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | F value |

|---|---|---|---|---|---|---|---|---|---|---|

| Protein | 5.12 ± 0.06 | 6.93 ± 0.05 | 5.26 ± 0.04 | 5.50 ± 0.03 | 5.89 ± 0.04 | 6.59 ± 0.03 | 6.01 ± 0.04 | 5.95 ± 0.04 | 7.96 ± 0.03 | 745.93 |

| Fat | 11.22 ± 0.03 | 10.12 ± 0.03 | 10.92 ± 0.04 | 9.57 ± 0.03 | 9.41 ± 0.02 | 9.90 ± 0.03 | 10.15 ± 0.03 | 10.34 ± 0.03 | 9.74 ± 0.02 | 1984.45 |

| Crude fibre | 0.79 ± 0.02 | 2.16 ± 0.03 | 1.08 ± 0.03 | 2.76 ± 0.08 | 2.83 ± 0.01 | 3.29 ± 0.03 | 2.85 ± 0.04 | 2.23 ± 0.04 | 3.58 ± 0.05 | 57.83 |

| Moisture | 15.57 ± 0.06 | 13.03 ± 0.05 | 13.37 ± 0.03 | 12.55 ± 0.06 | 12.01 ± 0.04 | 11.99 ± 0.04 | 11.73 ± 0.05 | 11.82 ± 0.04 | 17.2 ± 0.04 | 177.23 |

| Carbohydrate | 58.9 ± 0.02 | 19.66 ± 0.04 | 20.11 ± 0.03 | 22.07 ± 0.05 | 23.87 ± 0.04 | 23.22 ± 0.02 | 23.15 ± 0.05 | 23.45 ± 0.01 | 25.7 ± 0.03 | 695.01 |

| Ash content | 1.01 ± 0.04 | 1.08 ± 0.03 | 1.10 ± 0.02 | 1.15 ± 0.04 | 1.22 ± 0.01 | 1.31 ± 0.05 | 1.27 ± 0.03 | 1.25 ± 0.02 | 1.29 ± 0.01 | 82.88 |

Table 3: Physico-chemical properties for experimental trials.

Protein content

The protein of formulated tuber based cake was observed to be 7.96 ± 0.03% (T8), higher than the control (5.12 ± 0.06%) owing to the protein content of DQF (2.44 ± 0.3%). The protein content significantly increased as the DQF composition increased. The treatments had highly significant difference (p<0.01) and the results were found to be similar that incorporation of tuber increases the protein greatly [10].

Total fat

Total fat content in the formulated tuber Based cake significantly decreased as the RWF was substituted with different proportions of DQF and IBF. Lowest fat content was observed in T4 (9.41 ± 0.02%) and highest in T2 (10.92 ± 0.04%). But treatments T4 produced dominant egg flavour, whereas T2 showed less flavour than other treatments. The treatments showed highly significant difference (p<0.01) them and the results were comparatively similar to the results of Khan et al [11].

Crude fibre content

Highly significant difference (p<0.01) between the fibre content of the treatments was observed. As the tubers are naturally rich in fibre, since DQ has crude fibre content of 3.84% ± 0.04%, incorporation of DQF into cake resulted in increased fibre content ranging from 1.08% ± 0.03% to 3.58% ± 0.05%. As Recommended Daily Allowance (RDA) of dietary fiber intake was 30 g/per day, the developed product would be helpful to reach the intake value. The decrease in crude fiber might be due to the degradation of hemicelluloses and other structural polysaccharides during storage. Similar decline in crude fiber content was reported in pearl millet cake [12]. The results were also in accordance with in which the crude fibre increased with increase in jackfruit seed flour [11].

Moisture content

Increased fibre content increases the water retention capacity of the flour; hence during baking when exposed to higher temperature, moisture content is greatly reduced. The moisture content of cakes reduced from control to treatments, 15.57 ± 0.06% to 11.73 ± 0.05 respectively. All the treatments with substituted composite flour showed decreased moisture content with significant different (p<0.05). Similar reduction in moisture content of composite flour blends was observed from Kim et al. [8].

Ash content

No significant difference (p>0.05) in the ash content of the treatments was observed. Standard ash content present in the refined wheat flour cake was found to be 1.20%-1.4% (Megha Shrestha et al., 2018). Ash content of DQF was typically higher 4.06% ± 0.2%, which indicates higher level of extraction or milling process. Higher ash content also signifies increased mineral content [13].

Carbohydrate analysis

The trend of decrease in carbohydrate content in treatments was noticed as the composition of DQF and IBF increased. The decrease was mainly due to the fact that refined wheat flour is the crucial content for carbohydrates, replacement of RWF with fibre rich carbohydrate sources from tuber or seed flour may be the responsible factor in this reduction behaviour. Similar trend of decrease was observed when RWF was replaced with sesame flour [14].

Sensory evaluation

The sensory characteristics in 9 point hedonic scale of all the treatments were given in Table 4. As the amount of DQF and IBF content increased the fibre content present in the flour increased the water absorption capacity of the prepared cake batter, and results in increased viscosity of the batter which further mitigates the gluten matrix, that in turn responsible for the entrapment of gases [15]. This action further increased the spongy texture of the cake, as the trapped gases evaporated during baking when the vapour pressure is increased, leaving behind the airy texture of the cake.

| Attributes | T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | F value |

|---|---|---|---|---|---|---|---|---|---|

| Colour | 6.07 ± 0.03 | 6.02 ± 0.05 | 7.08 ± 0.01 | 7.05 ± 0.03 | 7.04 ± 0.03 | 8.06 ± 0.04 | 8.07 ± 0.04 | 9.08 ± 0.02 | 653 ± 0.02 |

| Taste | 7.06 ± 0.01 | 6.05 ± 0.02 | 7.02 ± 0.03 | 6.03 ± 0.04 | 8.06 ± 0.02 | 8.08 ± 0.02 | 7.04 ± 0.02 | 9.01 ± 0.02 | 743 ± 0.02 |

| Flavour | 7.02 ± 0.06 | 7.07 ± 0.04 | 6.08 ± 0.05 | 7.01 ± 0.02 | 7.05 ± 0.01 | 8.03 ± 0.04 | 8.09 ± 0.04 | 9.05 ± 0.04 | 185 ± 0.02 |

| Texture | 6.04 ± 0.01 | 6.09 ± 0.02 | 7.03 ± 0.02 | 6.06 ± 0.02 | 7.05 ± 0.03 | 7.07 ± 0.03 | 8.04 ± 0.03 | 8.01 ± 0.03 | 886 ± 0.02 |

| Overall acceptability | 7.05 ± 0.02 | 6.03 ± 0.03 | 7.09 ± 0.03 | 7.07 ± 0.05 | 7.04 ± 0.03 | 8.02 ± 0.05 | 8.01 ± 0.03 | 9.03 ± 0.01 | 926 ± 0.02 |

Table 4: Sensory evaluation of the experimental treatments.

The colour of the treatments differed significantly; increasing the composition of composite flour blend produced desirable brownish crust. The study found that incorporation of only IBF in the T2, T3 and T4 scored significantly lesser taste than other treatments. The sweetness perceived in the mentioned treatments was lower in spite of the fact, that all the treatments had same level of sugar added to their dough mixture. The added sugar content was reduced as the IBF as natural sweetening effect, the taste was better when IBF was blended with DQF (not sweeter than IBF). It shows that DQF increases the sweet taste of IBF when combined in the treatments (T6, T7 and T8). And in treatments T1 and T5, incorporation of DQF alone, increased the overall taste and texture significantly all the treatments showed reduced level of caramelized flavour as typical to normal commercial cakes. But the flavour was desirable to the panellist, and stated that the flavour was slightly different and perceived as mild, starchy flavour with little sweetness. The texture of baked good is one of the important quality characteristics of the product. Cakes enriched with starchy flour on baking results in greater loss of moisture and cracked crust with large fissures on the surface with dry appearance. Supporting this statement, T5 produced dry surface crust and T4 had darker crust that indicated excessive loss of moisture. Overall acceptability of the treatments showed that incorporation of composite blends of flour resulted in better sensory characteristic that treatments contained only single blend of either DQF or IBF with RWF. It is also evident that, use of IBF as a single blend with RWF (T2, T3 and T4) produced non- satisfiable results. The sensory evaluation of all eight treatments on 9 point hedonic scale determined that T8 (2:1:2 ratio of DQF: IBF: RWF) with overall acceptability score of 8.43 ± 0.01.

Conclusion

This study focuses on partial replacement of refined wheat to increase the nutritional value of the commercial cakes. Drynaria quercifolia flour and Ipomea batatas flour were identified as nutritional rich novel substitutes for preparing cakes. Physical, Chemical, Textural and Sensory analysis were conducted and the results of Sensory evaluation of all the developed cakes indicates that cakes of blend prepared with DQF:IBF:RWF in ratio of 2:1:2 (Trial-8) was optimized and most preferred cake out of all evaluated samples. Proximate analysis of optimized and control cakes showed that more than two-fold increase in nutrition was achieved which fulfil the objectives of the study. The outcome of the present research can be used as valuable information for the development of high nutritional cake.

Acknowledgements

The authors wish to express their profound gratitude Ms. Ameena Benazir, Ms. Dharani and Ms. Ramya for their contributions towards this work.

Conflict of Interests

The authors declare that there is no competing interest.

References

- Pargavi B, Sivakumar T. Review on antimicrobial, antioxidant, cytotoxic activity and phytochemical analysis of Drynaria quercifolia and Decalepsis hamiltonian. Int J Curr Res Chem Pharm Sci. 2017;4(3): 39-45.

- Kanimozhi NV, Kanna SM, Sukumar M. Drynaria quercifolia: A review on phytochemical and pharmacological profile. Infection. 2022;6(7):7-8.

- Neela S, Fanta SW. Review on nutritional composition of orange‐fleshed sweet potato and its role in management of vitamin A deficiency. Food Sci Nutr. 2019;7(6):1920-1945.

- Dereje B, Girma A, Mamo D, Chalchisa T. Functional properties of sweet potato flour and its role in product development: a review. Int J Food Prop. 2020;23(1):1639-1662.

- Alam MK. A comprehensive review of sweet potato (Ipomoea batatas [L.] Lam): Revisiting the associated health benefits. Trends in Food Sci Technol. 2021; 115:512-529.

- AOAC. Official Methods of Analysis, 17th edn. Association of Official Analytical Chemists. Washington DC. 2000.

- Giri NA, Sakhale BK. Development of sweet potato flour based high protein and low calorie gluten free cookies. Curr Res Nutr Food Sci. 2019;7(2):427-435.

- Kim JH, Lee KJ. Antioxidative activities and gelatinization characteristics of sponge cake added with purple sweet potato. J East Asian Soc Diet Life. 2013;23(6):750-759.

- Snedecor GW, Cochran WG. Statistical Methods. Iowa State University Press.1989.

- Gómez M, Oliete B, Rosell CM, Pando V, Fernández E. Studies on cake quality made of wheat–chickpea flour blends. Lwt-Food Sci Technol. 2008;41(9):1701-1719.

- Khan SA, Saqib MN, Alim MA. Evaluation of quality characteristics of composite cake prepared from mixed jackfruit seed flour and wheat flour. J Bangladesh Agric Univ. 2016;14(2):219-227.

- Singh P, Gupta N, Bhat A, Sood M, Bandral JD, Sharma S. Physico-chemical characteristics of pearl millet blended cake. Ind J Agric Biochem. 2022; 35(1):35-39.

- Al-Dmoor HM. Cake flour: Functionality and quality. Eur Sci J. 2013;9(3):28-29.

- Bhat MA, Bhat A. Study on physico-chemical characteristics of pumpkin blended cake. J Food Process Technol.2013;4(9):4-9.

- Yook HS, Kim YH, Ahn HJ, Kim DH, Kim JO, Byun MW. Rheological properties of wheat flour dough and qualities of bread prepared with dietary fiber purified from ascidian (Halocynthia roretzi) tunic. Korean J Food Sci Technol. 2000;32(2):387-395.

Citation: Murugesan M, Muthusamy D, Vidhyasalam V, Gunaseelan MH, Peerbal AM (2023) Optimization of Process Parameters for the Development of Cake from Novel Flour Blends of Drynaria quercifolia and Ipomea batatas. J Food Process Technol. 14:1056.

Copyright: © 2023 Murugesan M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.