Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2024) Volume 15, Issue 4

Optimization of Micronutrient Fortified Pasta Using Multi-Component Mixture Design

Akhila Macharla*Received: 23-Jul-2020, Manuscript No. JFPT-24-5571; Editor assigned: 28-Jul-2020, Pre QC No. JFPT-24-5571 (PQ); Reviewed: 11-Aug-2020, QC No. JFPT-24-5571; Revised: 01-Aug-2024, Manuscript No. JFPT-24-5571 (R); Published: 29-Aug-2024, DOI: 10.35248/2157-7110.24.15.1120

Abstract

Pasta is widely consumed all over the world and is a staple food for many countries which can be enriched, supplemented, fortified easily with convenience. The present study aims at the development and optimization of the micronutrient fortified pasta using the multi-component mixture design. The pasta is fortified using natural fortificants like Green Leafy Vegetable Powder (GLVP), Pulse Flour (PF), Millet Flour (MF) incorporated in the level of 40%-55%, 25%-40%, 10%-20% respectively and the binder (black rice flour) is added at 2%. These formulations were optimized using the experimental design and certain trails were obtained. The formulations were prepared according to the obtained trails. The effects of fortification of pasta with the combination of different ingredients at different levels were assessed on the nutritional and sensory quality of pasta. Results showed that the pasta incorporated with the higher amounts of GLVP is having more amounts of micronutrients (i.e., calcium and iron).

Keywords

Multi-component mixture design; Micronutrients fortified pasta; Green leafy vegetable powder; Millet flour; Pulse flour

Introduction

Nutritional deficiencies are serious global health issues now-adays and are observed more in developing countries due to the high population, unavailability of resources and lack of government control [1]. Reduction in these deficiencies can contribute to improved health and human well-being. There are three major strategies to control micronutrient deficiencies i.e., dietary modifications, supplementation and food fortification. Among these strategies, food fortification is a long-term approach and seems to be more practical, economical and flexible to improve nutrition that greatly reduced the occurrence of deficiencies. However, the success of these strategies depends upon the bioavailability of the nutrients to humans. Iron, iodine, zinc and vitamin A deficiencies are the global problems affecting at least 30% of the world’s population causing diseases like anemia, goiter and vitamin A deficiency syndrome. Over the last two decades, the impact of nutrition on bone health has been extensively considered and many studies studied the effect of various diets, foods and nutrients on bone health. Among the micronutrients, calcium and vitamin D are frequently studied in the studies involving supplements and their effects on bone [2].

As wheat flour is the staple diet for most of the population in the Indian sub-continent and also in the countries like China, European Union, Russia, USA, etc. An emphasis has been laid to fortify the wheat flour with multiple micronutrients and it was identified as a suitable vehicle for mineral fortification.

Pasta is consumed as a staple food in many countries across the world. Durum wheat semolina or wheat flour and water are the main ingredients in pasta products. Functional properties of the pasta are improved by the addition of non-conventional ingredients like vitamins, minerals, dietary fiber and antioxidants through the process of enrichment or fortification. Technically, pasta acts as an ideal vehicle for delivering the nutritional advantages inexpensively because it is a cold extruded product and fortificants can be easily blended into this formula. It is an important source of carbohydrates especially starch but is poor in protein and micronutrient content. A portion of 100 g uncooked pasta contains about 68.1 g starch, 4.2 g soluble sugars, 2.7 g fiber, 10.9 g protein and 1.4 g fat, providing about 353 kcal [3].

The present investigation was studied with the following objective.

• To develop and optimize the micronutrient fortified pasta

using the multi-component mixture design.

• To evaluate the physico-chemical and organoleptic properties

of the developed pasta.

Materials and Methods

Procurement of raw materials

The raw materials (refined wheat flour, millets (finger millet, foxtail millet, kodo millet), pulses (black gram, green gram, bengal gram), green leafy vegetables (amaranthus and spinach), black rice) required for the preparation of the pasta were procured from the local market of Kakinada [4].

Processing of raw materials

Millets and pulses flour: Millets and pulses were soaked for 8 hr, germinated, and tray-dried at 60°C (4 hr-5 hr). Then the dried grains were made into flour using a lab-scale miller. The obtained flour was sieved using a 100 mm mesh size sieve to get fine flour. The flour was then packed and stored in polyethylene bags until further use.

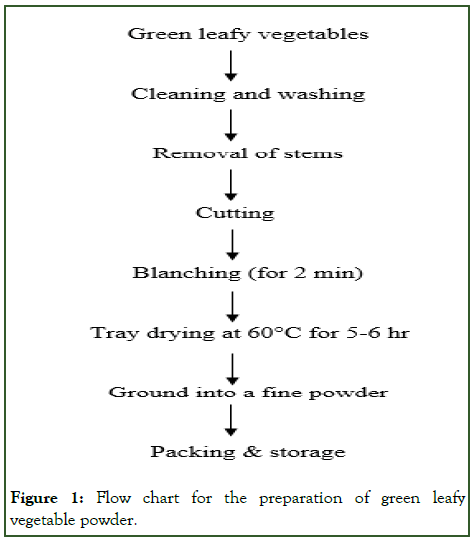

Black rice flour: The rice was cleaned and milled using a labscale miller. The obtained flour was sieved using 100 mm mesh size sieve to get fine flour and it was then packed and stored until further use (Figure 1).

Figure 1: Flow chart for the preparation of green leafy vegetable powder.

Procedure for the preparation of pasta

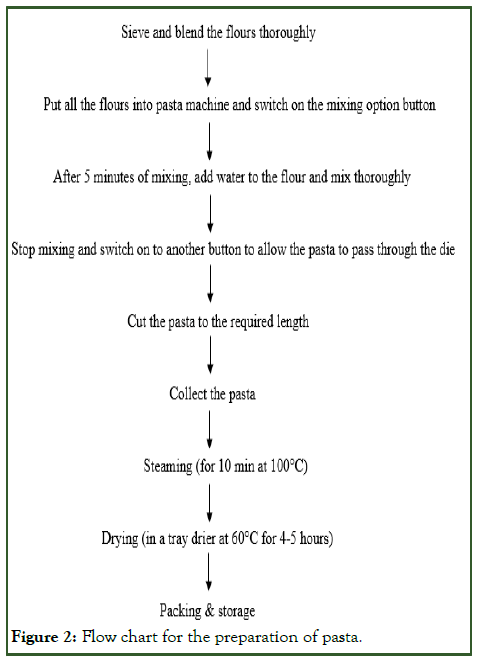

All the ingredients such as refined wheat flour, millet flour, pulse flour and green leafy vegetable powder were weighed according to the formulation as shown in Table 1. The composite flour that was sieved and blended thoroughly is kept into the pasta machine and the mixing option button is switched on. After 5 minutes of mixing, the required amount of water is added to the flour and is again mixed with the help of the screws present in the machine. After completion of the mixing, the mixing button is switched off and press another button that allows the pasta to extrude through the die. Extruded pasta is cut into the required size and allowed to steam for 10 min at 100°C. The steamed pasta was dried in a tray-drier at 60°C for 4-5 hours until it reaches the equilibrium moisture content. The dried and cooled pasta was packed and stored for further studies in polyethylene bags (Figure 2) [5].

Figure 2: Flow chart for the preparation of pasta.

Physico-chemical analysis

Each pasta sample prepared was analyzed for carbohydrates, crude protein, crude fat, ash, calcium and iron content. All the testing methods were performed according to the official methods of analysis of the Association of Official Analytical Chemists (AOAC). Total carbohydrate content was determined by phenol sulphuric acid method, crude protein by Micro-Kjeldahl method (AOAC method 960.52); crude fat by Soxhlet extraction method (AOAC method 963.15); ash content by dry ashing method (AOAC method 923.03).

Sensory evaluation

Sensory evaluation was carried out on cooked pasta by a panel of 10 semi-trained members using a 9-point hedonic scale technique. The semi-trained members were not professional sensory analysts, but they were made acquainted with the use of a 9-point hedonic scale and the parameters to be analyzed for sensory analysis. Pasta samples were given to each judge separately. The judges were asked to score different quality characteristics of the pasta including color, taste, texture, appearance and flavor on a 9-point scale [6].

Experimental design

Optimization of micronutrient fortified pasta was carried out by multi-component mixture design using design expert software (ver. 12). It involves the design of experiments, selection of levels of variables in experimental runs, fitting mathematical models and finally selecting variables’ levels by optimizing the response [7].

The formulation for the preparation of pasta was optimized using the above- mentioned design and the following runs were obtained.

| Trials | Refined Wheat Flour (RWF) (g) | Millets Flour (MF) (g) | Pulse Flour (PF) (g) | Green Leafy Vegetable Powder (GLVP) (g) | Binder (Black rice flour) (g) |

|---|---|---|---|---|---|

| Control | 100 | - | - | - | 2 |

| T1 | - | 15 | 40 | 45 | 2 |

| T2 | - | 15 | 35 | 50 | 2 |

| T3 | - | 10 | 35 | 55 | 2 |

| T4 | - | 12.5 | 35 | 52.5 | 2 |

| T5 | - | 17.5 | 30 | 52.5 | 2 |

| T6 | - | 15 | 30 | 55 | 2 |

| T7 | - | 17.5 | 37.5 | 45 | 2 |

| T8 | - | 20 | 25 | 55 | 2 |

| T9 | - | 15 | 37.5 | 47.5 | 2 |

| T10 | - | 17.5 | 33.75 | 48.75 | 2 |

| T11 | - | 15 | 32.5 | 52.5 | 2 |

| T12 | - | 12.5 | 37.5 | 50 | 2 |

| T13 | - | 12.5 | 36.25 | 51.25 | 2 |

| T14 | - | 10 | 40 | 50 | 2 |

| T15 | - | 10 | 37.5 | 52.5 | 2 |

| T16 | - | 20 | 40 | 40 | 2 |

| T17 | - | 20 | 32.5 | 47.5 | 2 |

Table 1: Formulation of micronutrient fortified pasta.

Results and Discussion

Chemical composition of pasta

Pasta made with Millet Flour (MF), Pulse Flour (PF), Green Leafy Vegetable Powder (GLVP) were analyzed for protein, carbohydrates, fat, ash, calcium and iron content. The results of this analysis are shown in Table 2.

| Trials | Carbohydrates (g/100 g) | Crude protein (g/100 g) | Total fat (g/100 g) | Ash (g/100 g) | Calcium (mg/100 g) | Iron (mg/100 g) |

|---|---|---|---|---|---|---|

| Control | 48.4 | 12.83 | 3.5 | 1.02 | 20.4 | 1.77 |

| T1 | 41.17 | 21.312 | 5.341 | 3.544 | 907.8 | 12.92 |

| T2 | 39.402 | 21.408 | 5.571 | 3.572 | 990.271 | 13.624 |

| T3 | 36.924 | 22.14 | 5.846 | 3.634 | 1072.741 | 14.34 |

| T4 | 38.161 | 21.776 | 5.707 | 3.604 | 1031.501 | 13.99 |

| T5 | 38.869 | 21.144 | 5.662 | 3.667 | 1031.518 | 13.972 |

| T6 | 37.634 | 21.509 | 5.8 | 3.598 | 1072.75 | 14.345 |

| T7 | 41.523 | 20.999 | 5.317 | 3.533 | 907.806 | 12.917 |

| T8 | 38.288 | 20.85 | 5.75 | 3.57 | 1072.58 | 14.309 |

| T9 | 40.288 | 21.367 | 5.455 | 3.564 | 949.038 | 13.277 |

| T10 | 40.195 | 21.064 | 5.489 | 3.551 | 969.676 | 13.44 |

| T11 | 38.455 | 21.434 | 5.681 | 3.581 | 1031.338 | 13.974 |

| T12 | 39.047 | 21.732 | 5.591 | 3.595 | 990.268 | 13.635 |

| T13 | 38.469 | 21.7 | 5.641 | 3.588 | 1010.483 | 13.805 |

| T14 | 38.692 | 22.044 | 5.616 | 3.606 | 990.269 | 13.636 |

| T15 | 37.81 | 22.101 | 5.73 | 3.625 | 1031.508 | 14 |

| T16 | 43.643 | 20.578 | 5.066 | 3.489 | 825.325 | 12.204 |

| T17 | 40.928 | 20.698 | 5.406 | 3.526 | 948.864 | 13.257 |

Table 2: Chemical composition of the micronutrient fortified pasta.

Protein

The highest protein content (i.e., 22.14 g) was recorded in the pasta incorporated with a blend of 10% MF, 35% PF, 55%GLVP (i.e., T 3 sample) followed by T 15 and T 14 samples due to higher amounts of PF and GLVP that contribute to the more amount of protein. Cardenas-Hernandez. A, et al. studied that pasta enriched with dried amaranth leaves powder and amaranth seed powder showed a positive effect on protein content (i.e., highest protein).

Carbohydrates

The highest carbohydrate content was recorded in the control sample followed by T16 sample (20% MF, 40% PF, 40% GLVP) which may be due to the incorporation of high amounts of MF that contribute to the more amount of carbohydrates and the lowest carbohydrate content was recorded in T3 sample [8].

Fat

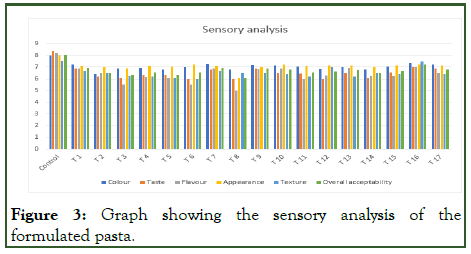

The highest fat content was recorded for the pasta with a blend of 10% MF, 35% PF, 55% GLVP (i.e., T3 sample) followed by T6 and T15 samples due to high amounts of PF that contribute to the more amount of fat and the lowest was recorded in the control sample (Figure 3) [9].

Figure 3: Graph showing the sensory analysis of the formulated pasta.

Ash

The highest ash content was observed in the pasta with a blend of 17.5% MF, 30% PF, 52.5% GLVP (i.e., T5 sample) followed by T3 and T15 samples due to the incorporation of more amounts of MF and GLVP that contribute to high ash content [10].

The lowest was recorded in the control sample due to the absence of any fortificants. Cardenas-Hernandez. A, et al. studied that pasta enriched with dried amaranth leaves powder and amaranth seed powder showed an increase in the ash content (Table 3) [11].

| Trials | Color | Taste | Flavor | Appearance | Texture | Overall acceptability |

|---|---|---|---|---|---|---|

| Control | 8 | 8.4 | 8.2 | 8 | 7.55 | 8.03 |

| T1 | 7.23 | 6.9 | 6.9 | 7.1 | 6.7 | 6.966 |

| T2 | 6.4 | 6.2 | 6.5 | 7 | 6.5 | 6.52 |

| T3 | 6.9 | 6.1 | 5.5 | 6.9 | 6.25 | 6.33 |

| T4 | 6.96 | 6.3 | 6.15 | 7.09 | 6.18 | 6.536 |

| T5 | 6.8 | 6.3 | 6.1 | 7.05 | 6.1 | 6.34 |

| T6 | 7 | 6 | 5.5 | 7.2 | 6 | 6.56 |

| T7 | 7.25 | 6.82 | 6.91 | 7.1 | 6.7 | 6.956 |

| T8 | 6.8 | 6 | 5 | 6.1 | 6.5 | 6.08 |

| T9 | 7.19 | 6.9 | 6.87 | 7 | 6.5 | 6.892 |

| T10 | 7.14 | 6.5 | 6.89 | 7.2 | 6.4 | 6.826 |

| T11 | 7.02 | 6.45 | 6 | 7.1 | 6.2 | 6.554 |

| T12 | 6.85 | 6 | 6.26 | 7.15 | 7 | 6.652 |

| T13 | 7 | 6.5 | 6.95 | 7.12 | 6.2 | 6.754 |

| T14 | 6.8 | 6.1 | 6.22 | 7 | 6.5 | 6.524 |

| T15 | 7.05 | 6.53 | 6.24 | 7.12 | 6.42 | 6.672 |

| T16 | 7.35 | 7 | 7 | 7.2 | 7.5 | 7.21 |

| T17 | 7.2 | 6.9 | 6.5 | 7.12 | 6.4 | 6.824 |

Table 3: Sensory analysis of the pasta.

Conclusion

This study has revealed that the substitution of refined wheat flour in pasta formulation with different natural fortificants viz., GLVP, PF and MF affected the physico-chemical, textural and sensory properties of the pasta. A blend of 15% MF, 30% PF, 55% GLVP in the pasta showed higher amounts of calcium and iron content which makes it highly nutritious. Results showed that the incorporation of different fortificants increased the nutrition value of the conventional pasta and also the incorporation of more amounts of GLVP decreased the organoleptic properties of the product.

Based on sensory analysis, the sample with a blend of 20% MF, 25% PF, 55%GLVP (i.e., T8 sample) has obtained less acceptance because of a higher amount of GLVP. Significant variations were observed regarding the organoleptic properties of the micronutrient fortified pasta. Present data suggest that the pasta fortified with the natural fortificants may be used as an alternative for the people with special nutritional requirements.

References

- Akhtar S, Anjum FM, Anjum MA. Micronutrient fortification of wheat flour: Recent development and strategies. Food Res Int. 2011;44(3):652-659.

- Kumar A, Tomer V, Kaur A, Kumar V, Gupta K. Millets: A solution to agrarian and nutritional challenges. Agric Food Secur. 2018;7(1):1-5.

- Whiting SJ, Kohrt WM, Warren MP, Kraenzlin MI, Bonjour JP. Food fortification for bone health in adulthood: A scoping review. Eur J Clin Nutr. 2016;70(10):1099-1105.

[Crossref] [Google Scholar] [PubMed]

- Gupta S, Prakash J. Nutritional and sensory quality of micronutrient-rich traditional products incorporated with green leafy vegetables. Int Food Res J. 2011;18(2).

- Nilusha RA, Jayasinghe JM, Perera OD, Perera PI. Development of pasta products with nonconventional ingredients and their effect on selected quality characteristics: A brief overview. Int J Food Sci. 2019;2019:6750726.

[Crossref] [Google Scholar] [PubMed]

- Webb D. Pasta’s history and role in healthful diets. Nutr Today. 2019;54(5):213-220.

- Sarita ES, Singh E. Potential of millets: Nutrients composition and health benefits. Int J Innov Res Sci Eng Technol. 2016;5(2):46-50.

- Natesh HN, Abbey L, Asiedu SK. An overview of nutritional and antinutritional factors in green leafy vegetables. Hortic Int J. 2017;1(2):58-65.

- Khan MA, Mahesh C, Semwal AD, Sharma GK. Effect of spinach powder on physico-chemical, rheological, nutritional and sensory characteristics of chapati premixes. J Food Sci Technol. 2015;52(4):2359-2365.

[Crossref] [Google Scholar] [PubMed]

- Gupta S, Gowri BS, Lakshmi AJ, Prakash J. Retention of nutrients in green leafy vegetables on dehydration. J Food Sci Technol. 2013;50(5):918-925.

[Crossref] [Google Scholar] [PubMed]

- Patterson CA, Curran J, Der T. Effect of processing on antinutrient compounds in pulses. Cereal Chem. 2017;94(1):2-10.

Citation: Macharla A (2024) Optimization of Micronutrient Fortified Pasta Using Multi-Component Mixture Design. J Food Process Technol. 15:1120.

Copyright: © 2024 Macharla A. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.