Indexed In

- Genamics JournalSeek

- JournalTOCs

- CiteFactor

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research - (2019) Volume 8, Issue 2

Influence of POSS-PVP in Modification of CFRP Interlaminar Fracture Toughness

Kunal Mishra1*, Libin K. Babu1 and Ranji Vaidyanathan22School of Material Science and Engineering Oklahoma State University Tulsa, Oklahoma, USA

Received: 17-May-2019 Published: 31-May-2019

Abstract

The influence of polyhedral oligomeric silsesquioxanes (POSS) – polyvinylpyrrolidone (PVP) on the interlaminar fracture toughness of carbon fiber reinforced composites (CFRP) is investigated in this study. Baseline composite material is fabricated using novlac epoxy infused carbon fiber prepreg. Glycidyl isobutyl POSS (GI) is introduced in the CFRP at loading of 1, 3, 5, and 10 wt. % with respect to PVP used as a compatibilizer. Results of the double cantilever beam test indicates an increase of 70% in interlaminar fracture toughness for 5 wt. % GI-POSS loading compared to the baseline composite. Scanning electron microscopy shows POSS enhanced the adhesion between fiber and the resin that leads to the fiber pull-out. Dynamic mechanical analysis result captures the reduction in the storage modulus with addition of PVP due to the plasticization effect. Nonetheless, the introduction of POSS increases the storage modulus for the GI/PVP composite. Additionally, an increase in the glass transition temperature with the reinforcement of POSS is observed. Keywords: Interlaminar fracture toughness; Carbon Fiber Reinforced

Keywords

Interlaminar fracture toughness; Carbon Fiber Reinforced Composites (CFRP); Polyhedral Oligomeric Silsesquioxanes (POSS); Polyvinylpyrrolidone (PVP); Dynamic mechanical analysis (DMA)

Introduction

Over the past decade, significant research has been done to improve the fracture toughness of carbon fiber reinforced polymer composites (CFRP) by incorporation of rigid particles [1-3], and by inclusion of different nanofillers [4-10]. Nonetheless, CFRPs are known to be most susceptible to out-of-plane loading and failure by delamination. Efforts to improve the interlaminar strength of laminate composites have met with some success, including 3-D reinforcement and improvements in the toughness of the matrix through additives [11,12].

The addition of rigid micro fillers to polymers provides increase in its strength but decreases the toughness since these fillers agglomerate and may induce stress concentration, that may initiate cracks leading to potential failure [13]. Reinforcement with nanoparticles can improve the fracture toughness without compromising other mechanical properties due to its extremely high surface area to volume ratio. Various nanomaterials such as carbon nanotubes [14-16], nanoclay [17-20], graphene [21], and block copolymers [22,23] have shown an extremely high potential to improve both tensile strength and fracture toughness. However, these nanomaterials have demonstrated the formation of agglomerates at lower loading and tend to become the critical site of the failure [24].

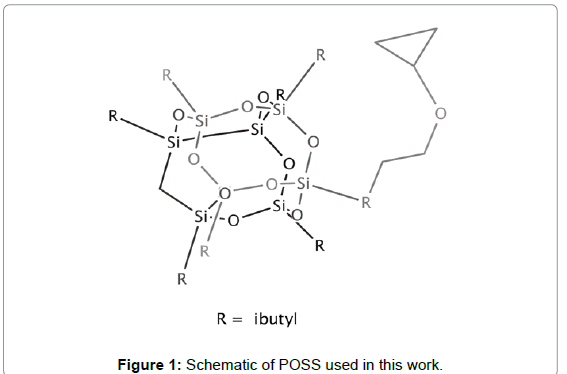

In our previous work [23,25], we have successfully demonstrated the reinforcement of epoxy polymer with a hybrid organic-inorganic nanoparticle known as polyhedral oligomeric silsesquioxanes (POSS). It has a cage-like structure of silica as the nucleus and different type of organic group is attached to it. The flexibility regarding the selection of the organic group makes the POSS a unique nanomaterial. The organic group can either be reactive (i.e., form a covalent bond with the host polymer) and/or non-reactive (i.e., exhibit compatibility with host polymer). Different investigations have been done on the formation of nanoscale structures using POSS reinforcement, and the enhancement of physical properties such as resistance to thermal degradation, mechanical properties, abrasion resistance, and glass transition temperature [26-33]. However, as reported in our previous work at higher loading of POSS in the polymer network the reactive organic group present on the silica cage has the tendency to self-aggregate and form a compliant domain. This can be circumvented by either extensive dispersion mechanism or the use of a compatibilizer. Past studies have used Polyvinylpyrrolidone (PVP) as a compatibilizer to increase the dispersion [34]. However, there is a lack of understanding about the influence of PVP-POSS on the overall behavior of the composite. The focus of this study will be to analyze the impact of PVP-POSS as the reinforcement in the carbon fiber reinforced composites.

Theory and Experimentation

Materials

The carbon fiber/epoxy prepregs TORAYCA® C105 carbon fibers of 3K weave and novalac epoxy system and a diamine curing agent (with the company code TEX016) were purchased from TCR composites, Ogden UT. The POSS selected for this work is Glycidyl Isobutyl POSS (GI), as shown in Figure 1. It was obtained from Hybrid Plastics, Hattiesburg, MS. The PVP K-60 was purchased from Sigma Aldrich, Milwaukee, WI. The solvents used in this work are ethanol for dissolving PVP and Tetrahydrofuran (THF) for dissolving Glycidyl Isobutyl POSS, which were purchased from Sigma-Aldrich, Milwaukee, WI.

Figure 1: Schematic of POSS used in this work.

The reason behind selecting the carbon fibers pre-impregnated with novolac epoxy is that these epoxy resin exhibits high chemical and heat resistance and significant mechanical properties [35].

The selection criteria of POSS is based upon comparing the effect of the one with the epoxide group, with only organic functional groups and the non-epoxide reactive group. Glycidyl Isobutyl POSS has seven non-reactive isobutyl groups and one reactive glycidyl group. Therefore, it is a good grafting agent and an epoxy chain terminator.

Sample fabrication

For double cantilever beam experiment, carbon fiber prepreg was layered up in sixteen layers. The GI/PVP solution was prepared by dissolving PVP in ethanol and mixed on a magnetic stirrer for thirty minutes at 300 rpm followed by mixing of POSS for one hour. GI was added to PVP in different ratios of 1%, 3%, 5% and 10% for all three functionalities. The GI/PVP solution was painted on the 8- and 9-layers using paint roller followed by evaporation of solvents. The nonadhesive insert (Teflon sheet) with a nominal thickness of 0.0005 inches was inserted for crack initiation at the midplane followed by curing at a temperature of 165°C for 6 hours. The same curing cycle was used for all the GI/PVP modified samples and the baseline. The samples for the double cantilever beam (DCB) experiment were prepared according to ASTM Standard D5528 [33] in the size of 125 mm × 25 mm. Sample thickness was evaluated as 4.3 mm. The initial delamination length was kept at 63 mm from the load line (the hinges) to the end of the Teflon Insert.

For Dynamic Mechanical Analysis (DMA) testing eight layers of laminates were prepared in the dimension size of 60 mm × 13 mm. The GI/PVP solutions were applied between every layer of the laminate.

Characterization

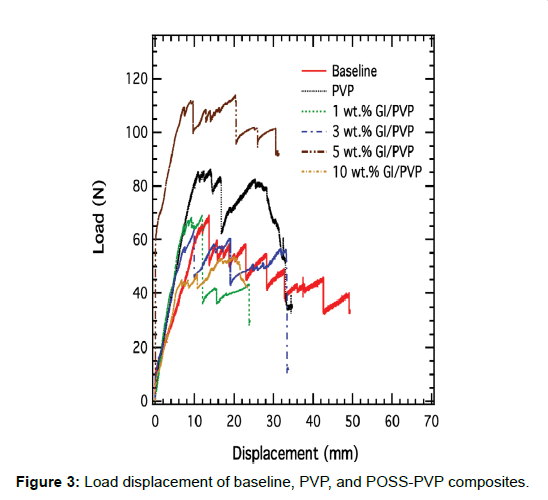

The mode I interlaminar fracture toughness of the composite laminates was determined using DCB test according to the ASTM D–5528-01 standard on the universal testing machine (Instron 5567, Norwood, MA) [36]. The tests were performed at a crosshead speed of 3 mm/min. The mode I interlaminar fracture toughness is calculated using a modified beam theory or compliance calibration method. In this study, we made use of the Modified Beam Theory (MBT) Method.

The beam theory expression for the strain energy release rate of a perfectly built-in (that is, clamped at the delamination front) double cantilever beam is as follows:

Where: P = Load,

δ = Load point displacement,

b = Specimen width, and

a = Delamination length.

|Δ|= Correction in the delamination length to account for the overestimation of G_I.

The value of GIC for all crack lengths and corresponding displacements is calculated and the average taken for all samples.

Dynamic mechanical analysis (DMA) of the POSS - nanocomposites samples for DGEBF based resin were analyzed using TA Instruments DMA Q800. Three-point bending test was carried out simultaneously with heating the sample from 30°C to 200°C at 3°C/min, and by applying a constant sinusoidal displacement of 20μm with 1 Hz frequency. The storage modulus, loss modulus, and damping were obtained from the sample response against applied frequency.

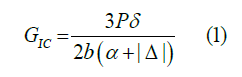

The fractured surface was studied using field emission scanning electron microscopy (Hitachi S-4800 FESEM, Dallas, TX, USA). Prior to imaging, the surfaces of the samples were coated with gold-platinum by an electro-deposition method using a sputter coater (Cressington Scientific Instruments Ltd, Redding, CA). This was done to make the sample conductive to prevent the accumulation of static electric charge during scanning electron microscopy. PVP and GI/PVP thin films were analyzed to check for the dispersion of GI in the PVP using Nikon Eclipse (Melville, NY, USA).

Results

Optical image

The PVP and 5 wt.% GI/PVP film as shown in Figure 2 exhibit that GI is very well dispersed in the PVP. There was no phase separation observed between GI and PVP and it support our selection of PVP as the compatibilizer between GI and epoxy matrix.

Figure 2: Optical image of PVP and POSS-PVP film shows that POSS is uniformly dispersed in PVP.

Mode I interlaminar fracture toughness

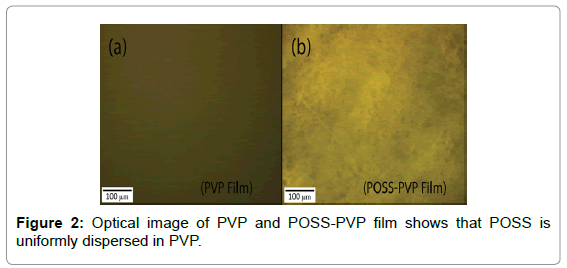

Figure 3 illustrates the load-displacement graph of GI reinforced CFRP obtained from double cantilever beam experiment. We observed that with the increase in the loading of GI, the critical load required to propagate the crack also increases. For GI/PVP we have found around 65% increase in critical load at 5 wt.% compared to the baseline composites. This increase in the critical load for crack propagation is due to the increasing adhesion between matrix and fiber because of the GI inclusion. The reactive of the POSS molecule react with the epoxy matrix and form covalent bond whereas non-reactive part shows compatibility with the carbon fiber due to physical interaction such as Van der Waal force.

Figure 3: Load displacement of baseline, PVP, and POSS-PVP composites.

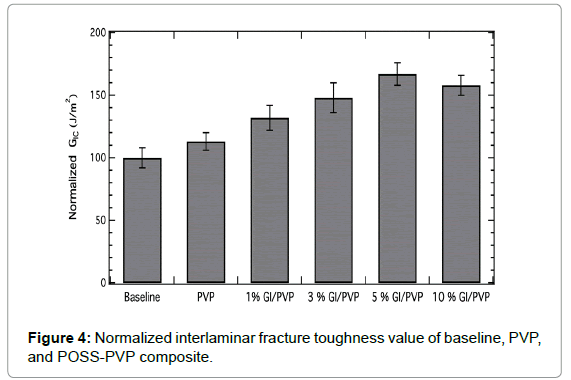

The increase in critical load for crack propagation with the inclusion of POSS molecule is further supported by the obtained normalized fracture energy of the composites as shown in Figure 4. As result indicates, GI/PVP showed an improvement of 65% increase in GIC at 5 wt.% compared to baseline composite. Interestingly, the PVP solution alone (no GI) also showed an increase in the GIC by 26% compared to baseline composite suggest that presence of PVP as the compatibilizer also influences the interlaminar fracture toughness. Nonetheless, at 10 wt.% POSS loading, there is a decrease in the GIC due to agglomeration of POSS molecules.

Figure 4: Normalized interlaminar fracture toughness value of baseline, PVP, and POSS-PVP composite.

Scanning electron microscopy

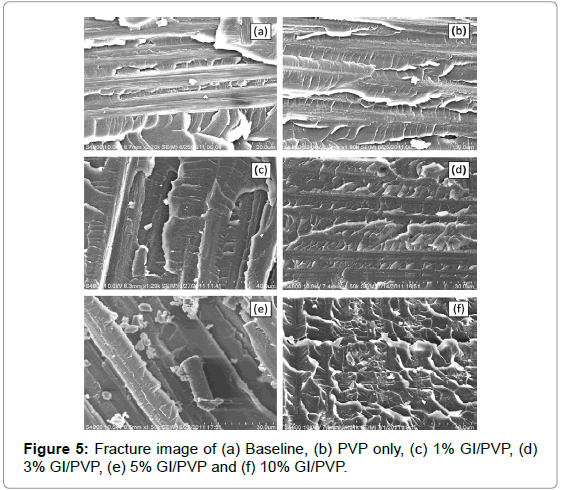

The fractured surfaces after the DCB experiment were characterized using scanning electron microscopy (SEM) to understand the extrinsic toughening mechanism. As shown in Figure 5a, for the baseline composites, the fibers are exposed on the surface after delamination. This indicates that the crack progressed across the fiber-matrix interface and the adhesion between fiber and matrix is low. For PVP reinforced composite, as shown in Figure 5b, we observe that fiber-matrix shows better adhesion than baseline composite as fiber cover resin is shown.

Figure 5: Fracture image of (a) Baseline, (b) PVP only, (c) 1% GI/PVP, (d) 3% GI/PVP, (e) 5% GI/PVP and (f) 10% GI/PVP.

The fractured surface of 1 wt. % GI/PVP reinforced composites didn’t show significant change compared to only PVP reinforced composite as shown in Figure 5c. With the increase of POSS content in the composite, we have observed that the surface is getting more rougher which results from better adhesion between fiber and matrix. Additionally, it indicates the tortuous path followed by crack propagation as shown in Figure 5d. At 5 wt.% GI/POSS, the fractured surface is significant, and the fiber pull out can be observed in Figure 5e. The fiber pull-out corroborates with the high interlaminar fracture toughness obtained for 5 wt.% GI/PVP reinforced epoxy composite. For the 10 wt.% GI/PVP incorporation as shown in Figure 5f, the fiber pullout is not observed indicating the reduction in the fiber-matrix adhesion due to POSS agglomeration.

Dynamic mechanical analysis

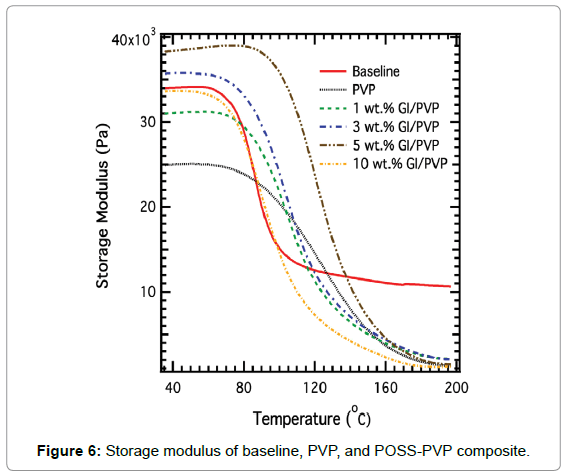

Dynamic mechanical analysis (DMA) was performed to study the changes in the thermos-mechanical properties of the CFRP composite laminates as a function of temperature. Figure 6 shows that inclusion of only PVP reduces the storage modulus of the composites. This indicates that PVP introduces plasticization in the composites. However, with the addition of the GI the storage modulus increases and reaches its maximum value at 5 wt.%, with an overall increase of 13% compared to the baseline composite. Interestingly at high temperature, the baseline composite shows higher modulus value compared to GI/PVP reinforced composites. This decrease of storage modulus at high temperature is due to the increase in the size of the polymer network due to POSS inclusion that aids the motion of polymer chain when temperature rises above its glass transition temperature.

Figure 6: Storage modulus of baseline, PVP, and POSS-PVP composite.

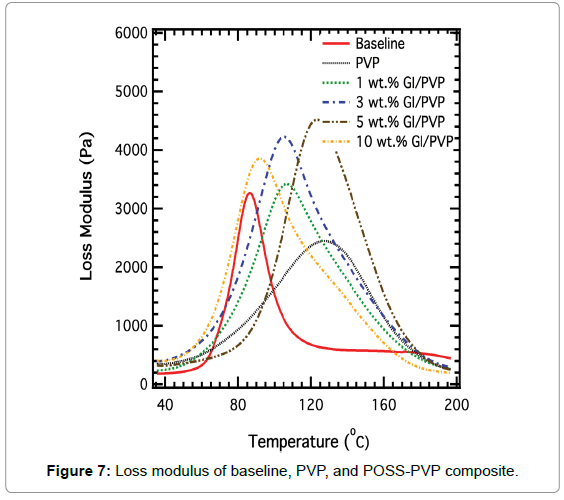

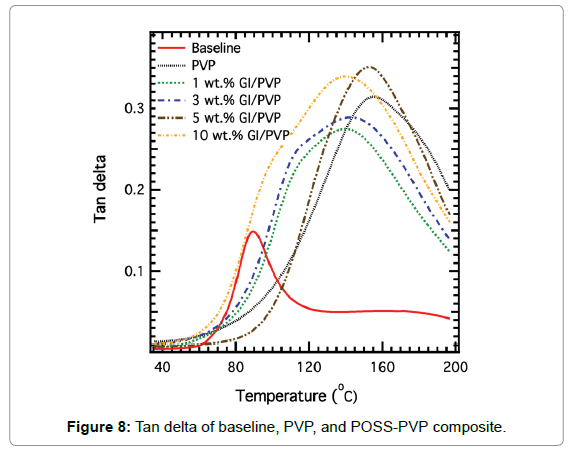

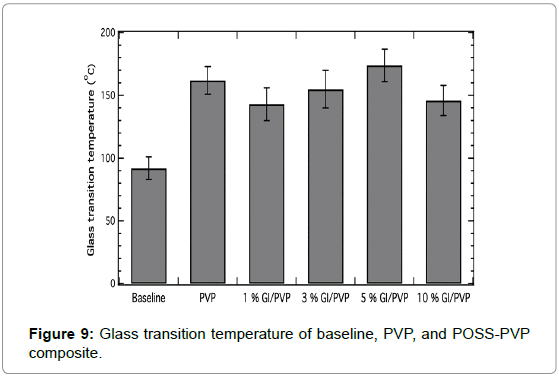

Figure 7 shows the loss modulus value of baseline and GI/PVP reinforced composites. We observed that energy dissipation of the composite increases with the inclusion of the POSS molecule and shows highest for the 5 wt.% GI inclusion. Due to plasticization introduced by PVP, the PVP reinforced composite shows a lower value of loss modulus. The similar trend was observed for the tan delta curve. Tan delta is also known as damping ratio which is the ratio of loss modulus to elastic modulus and provides understanding about the phenomena behind the viscous property of the material. We observed that the viscous property of the composite increases with the inclusion of GI as shown in Figure 8. The peak of the tan delta graph represents the glass transition value. The glass transition temperature of the composite increases with the POSS inclusion suggest the restriction of chain movement due to the presence of GI as shown in Figure 9. In contrast to the storage modulus value, with the PVP inclusion only the glass transition temperature increases by 50%. Addition of the POSS molecule does not provide any change in the glass transition temperature.

Figure 7: Loss modulus of baseline, PVP, and POSS-PVP composite.

Figure 8: Tan delta of baseline, PVP, and POSS-PVP composite.

Figure 9: Glass transition temperature of baseline, PVP, and POSS-PVP composite.

Discussion and Conclusion

Glycidyl isobutyl POSS is used as reinforcement in the carbon fiber reinforced composites along with the use of PVP as a compatibilizer between the POSS and the matrix. Increase in the interlaminar fracture toughness has been observed with the introduction of POSS molecule. For 5 wt.% GI/PVP, the interlaminar fracture toughness shows an increase of 65%. This increase in the interlaminar fracture toughness is attributed to the enhanced adhesion between fiber and epoxy resin due to the presence of the POSS molecule. This was further confirmed by scanned electron microscopy of the fractured surfaces, in which the extrinsic toughening phenomena of fiber pull-out was clearly observed for 5wt.% GI/PVP sample. Increase in the epoxy-fiber adhesion was corroborated by the 13% increase in the storage modulus for 5 wt.% GI/ PVP sample. Interestingly, the PVP only composite reduces the storage modulus due to its plasticization effect. Nonetheless, the glass transition temperature is significantly influenced only by PVP and the addition of GI does not provide any conclusive changes to the glass transition temperature.

Acknowledgment

We gratefully acknowledge that this work is funded in part or fully by a grant through the Oklahoma Nanotechnology Applications Project (ONAP) (Grant no. O9-20) and NASA Experimental Program to Stimulate Competitive Research (EPSCOR) (Grant no. NNXO9AP68A).

REFERENCES

- Wang WX, Takao Y, Matsubara T, Kim HS. Improvement of the interlaminar fracture toughness of composite laminates by whisker reinforced interlamination. Compos Sci Technol. 2002;62:767-774.

- Sager RJ, Klein PJ, Davis DC, Lagoudas DC, Warren GL. Interlaminar Fracture Toughness of Woven FabricComposite Laminates with Carbon Nanotube/Epoxy Interleaf Films. J Appl Polym Sci.2011;121:2394-2405.

- Sela N, Ishai O. Interlaminar fracture toughness and toughening of laminated composite materials: A review. Compos. 1989;20:423-435.

- Gojny FH, Wichmann MHG, Keopke U, Fiedler B, Schulte K. Carbon nanotube-reinforced epoxy-composites: enhanced stiffness and fracture toughness at low nanotube content. Compos Sci Technol. 2004;64:2363-2371.

- Bortz DR , Merino C, Gullon IM. Carbon nanofibers enhance the fracture toughness and fatigue performance of a structural epoxy system. Compos Sci Technol. 2011;71:31-38.

- Zeng Y, Mai YW, Du XS, Liu HY. Improving interlaminar fracture toughness of carbon fibre/epoxy laminates by incorporation of nanoparticles. Compos: Part B Eng. 2012;43:90-94.

- Wicks SS, Villoria RGD, Wardle BL. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos Sci Technol. 2010;70:20-28.

- Kim BC, Park SW, Lee DG. Fracture toughness of the nano-particle reinforced epoxy composite. Compos Struct. 2008;36:69-77.

- Xu Y, Hoa SV. Mechanical properties of carbon fiber reinforced epoxy/clay nanocomposites. Compos Sci Technol. 2008;68:854-861.

- Zhang H, Zhang Z, Friedrich K, Eger C. Property improvements of in situ epoxy nanocomposites with reduced interparticle distance at high nanosilica content. Acta Materialia. 2006;54:1833-1842.

- Partridge I, Cartie D. Delamination resistant laminates by Z-Fiber pinning: Part I manufacture and fracture performance. 2004;36:55-64.

- Mouritz AP, Cox BN, Chang P. Fatigue properties of z-pinned aircraft composite materials. 2006.

- Quaresimin M, Salviato M, Zappalorto M. Toughening mechanisms in nanoparticle polymer composites: experimental evidences and modeling. In Toughening mechanisms in composite materials. 2015;113-133.

- Allaoui A, Bai S, Cheng HM, Bai J. Mechanical and electrical properties of a MWNT/epoxy composite. Compos Sci Technol. 1998;62:1994-1998.

- Yurdakul H, Seyhan AT, Turan S, Lu MT, Bauhofer W. Electric field effects on CNTs/vinyl ester suspensions and the resulting electrical and thermal composite properties. Compos Sci Technol. 2011;70:2102-2110.

- Perez AH, Aviles F, Pat AM, Gonzalez AV, Franco PJH. Effective properties of multiwalled carbon nanotube/epoxy composites using two different tubes. Compos Sci Technol. 2007;68:1422-1431.

- Le Baron P. Polymer-layered silicate nanocomposites: an overview. Appl Clay Sci. 1999;15: 11-29.

- Subramaniyan AK, Sun CT. Toughening polymeric composites using nanoclay: Crack tipscale effects on fracture toughness. Compos Part A Appl Sci Manuf. 2006;38:34-43.

- Wang L, Chen L, Zhang Y, Wang K, He C. Preparation, morphology and thermal/mechanical properties of epoxy/nanoclay composite. Compos Part A Appl Sci Manuf. 2006;206:1090-1896.

- Qi B, Zhang QX, Bannister M, Mai YW. Investigation of the mechanical properties of DGEBA-basedepoxy resin with nanoclay additives. Compos Struct. 2006;75:514-519.

- Rafiee MA, Rafiee J, Wang Z, Song H, Yu ZZ. Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano. 2009;3:3884-3890.

- Ruiz-Perez L, Royston GJ, Fairclough JPA, Ryan AJ. Toughening by nanostructure. Polymer. 2008;49:4475-4488.

- Hydro RM, Pearson RA. Epoxies toughened with triblock copolymers. J Polym Sci Part B-Polymer Phys. 2007;45:1470-1481.

- Iqbal K, Khan SU, Munir A, Kim JK. Impact damage resistance of CFRP with nanoclay-filled epoxy matrix. Compos Sci Technol. 2009;69:1949-1957.

- Mishra K, Pandey G, Singh RP. Enhancing the mechanical properties of an epoxy resin using polyhedral oligomeric silsesquioxane (POSS) as nanoreinforcement. Polym Test. 2017;62:210-218.

- Mishra K, Singh RP. Quantitative evaluation of the effect of dispersion techniques on the mechanical properties of polyhedral oligomeric silsesquioxane (POSS)-epoxy nanocomposites. Polym Comp. 2018;39:E2445-E2453.

- Lee KM, Knight PT, Chung T, Mather PT. Polycaprolactone-POSS chemical/physical double networks. Macromolecules. 2008;41:4730-4738.

- Waddon AJ, Zheng L, Farris RJ, Coughlin EB. Nanostructured Polyethylene-POSS Copolymers: Control of Crystallization and Aggregation. Nano Letters. 2002;2:1149-1155.

- Lee YJ, SW Kuo, Su YC, Chen JK, Tu CW. Syntheses, thermal properties, and phase morphologies of novel benzoxazines functionalized with polyhedral oligomeric silsesquioxane (POSS) nanocomposites. Polym. 2010;45:6321-6331.

- Jones IK, Zhou YX, Jeelani S, Mabry JM. Effect of polyhedraloligomericsil-sesquioxanes on thermaland mechanical behavior of SC-15 epoxy. Express Polym Lett. 2008;2:494-501.

- Li GZ, Wang L, Toghiani H, Daulton TL, Koyama K. Viscoelastic and mechanical properties of epoxy/multifunctional polyhedral oligomeric silsesquioxane nanocomposites and epoxy/ladderlikepolyphenylsilsesquioxane blends. Macromolecules. 2001;34:8686-8693.

- Zhao F, Huang Y. Improved interfacial properties of carbon fiber/epoxy composites through grafting polyhedral oligomeric silsesquioxane on carbon fiber surface. Mater Lett. 2010;64:2742–2744.

- Xiao F, Sun Y, Xiu Y, Wong CP. Preparation, thermal and mechanical properties of poss epoxy hybrid composites. J Appl Polym Sci. 2006;104:2114-2121.

- Gnatowski A, Koszkul J. Investigations of the influence of compatibilizer and filler type on the properties of chosen polymer blends. J Mater Process Technol. 2005;162: 52-58.

- Randall W. Sulfuric acid resistance of multi-functional epoxy novolac resins utilizing different amine curing agent systems. Henkel Surface Technologies, North America. 2003.

- Active Standard ASTM D5528. Standard test method for mode interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites. 2017.

Citation: Mishra K, Babu LK, Vaidyanathan R (2019) Influence of POSS-PVP in Modification of CFRP Interlaminar Fracture Toughness. J Appl Mech Eng. 8:318. doi: 10.35248/2168-9873.19.8.318

Copyright: © 2019 Mishra K, et al. This is an open access article distributed under the term of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.