Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2020) Volume 11, Issue 1

Household Juice Extractor Comparison and Optimization

Michael Donaldson*Received: 18-Feb-2020 Published: 02-Mar-2020, DOI: 10.35248/2157-7110.20.11.819

Abstract

Background: Increased vegetable consumption is a cornerstone of improving personal dietary habits and meeting

national dietary guidelines. Vegetable juice is a beneficial way to increase vegetable consumption.

Aim: The aim was to scientifically compare six different juicers for quantity and quality of juice yield for a variety of

produce.

Method: Six juicers (Green Star Elite, Champion, NuWave vertical auger, LaLane centrifugal, Norwalk, Pure) were

tested side by side for the production of carrot, apple, celery, spinach and a combination juice of carrot, celery,

spinach, and lemon. Yields of 1 kg batches were measured four times for each combination of produce and juicer.

The quality of juice was measured by testing a panel of enzyme activities in each juice. Enzyme activity of carrot and

combination juices during storage up to 72 hours was also measured.

Results: The Pure Juicer had the highest yields on all types of products tested, followed by the Norwalk and Green

Star Elite, then the Champion, NuWave and LaLane juicers. The Pure Juicer and Norwalk both did significantly

better at producing pure spinach juice than any other juicer. The Champion juicer had yields that were very similar to

the Green Star Elite for carrots and combination juices.

Enzyme activity was very comparable in all of the juicers. Differences between batches of produce were often greater

than differences between juicers.

An optimized two-step method of juicing using a high-powered blender as a homogenizer and a hydraulic press for a

squeeze produced higher yields (83% yield with carrots) and higher quality juice from all types of produce.

Conclusion: The Pure Juicer is the most advanced commercially available juicer on the market, yielding the most

juice of excellent quality for a variety of produce. For optimal yield and quality, a two-step process with a blender and

hydraulic press is ideal.

Keywords

Vegetable; Juice; Fruit; Juice extraction; Juicer; Blender; Juice press

Abbrevations

%CV: Coefficient of Variation; SD: Standard Deviation

Introduction

Increased consumption of vegetables has been a cornerstone piece of health advice from official sources such as the Dietary Guidelines from U.S. Department of Health and Human Services and the U.S. Department of Agriculture [1], disease-prevention organizations like the Produce for Better Health Foundation with its campaign “Fruits and Veggies-More Matters” [2], the American Cancer Society [3], American Heart Association [4], the World Cancer Research Fund-American Institute for Cancer Research (WCF-AICR) [5], and even from many mothers who instinctively understand that vegetables are good for you.

Despite decades of encouragement to “eat more vegetables” the intake of vegetables in the USA remains at a paltry level [1]. Vegetable juice has been advocated as a beneficial, convenient way to increase vegetable consumption. With the reduced amount of fiber, it is believed that digestion, extraction, and absorption of nutrients are improved in the liquefied form.

Vegetable juices have been incorporated into programs that have demonstrated remarkable health results. A retrospective study of the Gerson Therapy showed much longer survival of melanoma cancer patients who followed their program compared to historical controls [6]. An observational study of 30 people with fibromyalgia found very significant results with the Hallelujah Diet, which included daily portions of vegetable juice [7]. Beet juice has been shown to improve the endurance of trained athletes [8] and lower blood pressure [9]. An 8-ounce serving of carrot juice was given daily to 69 overweight breast-cancer survivors that increased total plasma carotenoids to over 4.0 μmol/L, which is a disease-protective level [10] while lowering markers of oxidative stress among subjects who had the highest increases in plasma carotenoids [11]. The prospective Kame study in King County, Washington of 1,836 Japanese Americans found that those who reported drinking fruit and vegetable juice at least 3 times a week had a markedly lower risk of probable Alzheimer’s disease than those who drank fruit or vegetable juice less than once a week [12].

While vegetable juice can now be purchased in many grocery stores, often it is pasteurized, which destroys naturally occurring enzymes and bio-photonic light, and possibly other heat-sensitive nutrients. Anecdotal evidence implies these heat-sensitive substances in foods actually play a role in health and vitality and there is little evidence which disproves this theory and anecdotal evidence. So, many consumers desire and purchase juices that are unpasteurized or cold-processed, such as hyperbaric treatment at about 5,000 bar of pressure. In order to get the freshest juice at the most economical price many people also purchase household juicers for their own use.

In this study, five different styles of juicers were tested for juice quality and quantity. The quality of the juice was judged by a panel of 5 or 6 endogenous enzyme activities, depending on which enzymes were present in the produce. Lower enzyme activity is indicative of poorer extraction or increased denaturation of enzymes during extraction due to heat or air exposure. Some enzymes are much more vulnerable to heat and oxidation than vitamins and other nutrients, so they make excellent markers for even small changes in processing conditions.

This study is an evaluation of these different types of juicers and gives direction for further research and development into a better juicer, which gives higher yield and better quality juice.

Materials and Methods

Description of juicing machines

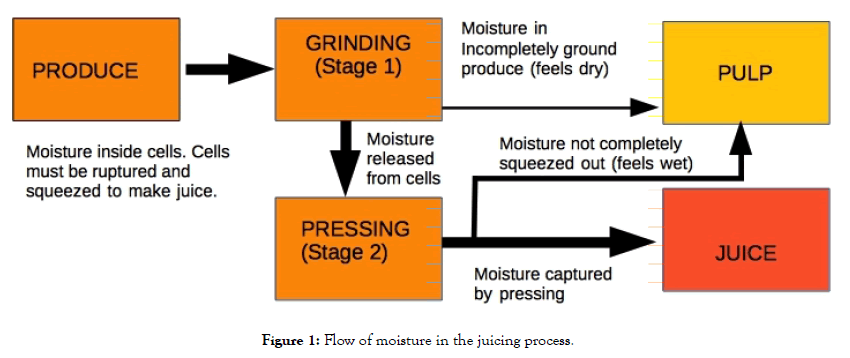

The vegetable juicing process consists of two unit operations performed in batch or continuous operation. The first stage of grinding the produce is followed by a pressing extraction stage. Figure 1 shows the flow of moisture through the juicing process. Initially, all of the moisture is intracellular. In the grinding stage, inefficient grinding will leave some of the moisture still inside the plant cells, which will end up in the discarded pulp. Since the moisture is still inside the cells, this moisture is not felt if the pulp is handled. Inefficient pressing will not remove all of the available extracellular moisture from the pulp. This moisture will feel wet in the pulp, as it can be squeezed out with enough pressure. These two inefficiencies are the reason for lower than ideal yields in all types of juicers. All juicers have these two unit operations in them. Different designs deal with these inefficiencies differently and have different strengths and weaknesses.

Figure 1: Flow of moisture in the juicing process.

Table 1 lists the juicers used in this study and their main features. A centrifugal pulp ejecting juicer (Jack LaLane juicer, Tristar Products, Coral Springs, FL) uses a high-speed disc to finely shred the produce and then a slanted screen basket to allow the juice to pass through a screen while ejecting the pulp over the top of the spinning screen. This is a very fast style of juicing machine.

| Juicer | Type | Operation | Process | RPM |

|---|---|---|---|---|

| Green Star Elite | Twin counter-rotating gear | Crush, mix, press in screw flights | Continuous with screen | 110 |

| Champion | Masticating | Fine-tooth shredding, soft press, | Continuous with screen | 1725 |

| NuWave | Vertical, single auger | Chop, crush, grind | Continuous with screen | 48 |

| Jack LaLane Power Juicer | Centrifugal, pulp ejecting | Fine-tooth shredding, press by centrifugal force | Continuous with screen | 3,600 |

| Norwalk, 260 | 2 Stage-grinder and press | Hammermill grinder, hydraulic press | Batch | 3,450 |

| Pure Juicer | 2 Stage-grinder and press | Hammermill grinder, hydraulic press | Batch | 3,450 |

Table 1: Juicer characteristics.

A masticating juicer (Champion, Plastaket Mfg., Lodi, CA) uses a fine-toothed rotating impeller to finely shred the produce. The impeller then pushes the pulp into a reduced area cone that increases the pressure so that juice goes through a fine screen before the pulp is ejected in a continuous process.

A vertical single-auger juicer (NuWave, NuWave LLC, Libertyville, IL) cuts the produce into bite-sized portions with a relatively slow (48 rpm) auger that crushes and grinds the produce against a screen to extract the juice in a continuous operation.

A twin-gear auger juicer (Green Star Elite, Tribest Corp., Anaheim, CA) crushes the produce at 110 rpm between counterrotating gears and then squeezes the juice through a fine screen in a section of screw-press flights.

A two-stage grinder-press (Norwalk, Norwalk Juicers, Bentonville, AR; Pure Juicer, Pure Juicer Co., Seattle, WA) has a solid impeller style hammermill grinder to continually process produce into a fine wet mash. The mash was pressed batch-wise in press cloths or bags in an electrically operated hydraulic press. The Pure Juicer is a refinement of the two-stage juicer, featuring an offset feed chute, shaped pusher, improved impeller design, stronger press plates, a more robust hydraulic press, and larger juice tray compared to the industry standard Norwalk juicer.

Each juicer is an attempt at optimizing juice yield and quality without sacrificing operability and ease of use at a particular price point. Ease of use is especially important as complicated and time-consuming devices tend to be used less frequently.

The use of a high-speed blender (Vitamix, Cleveland, OH; Blendtec, Orem, UT) combined with a hydraulic press was also tested. Produce was added in batches into the blender jar and homogenized without generating significant amounts of heat. The homogenate is pressed batchwise in press cloths or bags in a hydraulic press (Pure Juicer).

Produce

Conventionally grown carrots, spinach, celery, and lemons were purchased a local restaurant supply store (Smart Food Service, Union Gap, WA). Apples were purchased from a local apple warehouse (Apple King, Selah, WA). Carrots were peeled and ends cut off. Celery ends were removed and celery was rinsed to remove dirt. Apples were rinsed. Lemons were peeled prior to juicing. Spinach was used from pre-washed bags and was not rinsed before using. A combination recipe, by initial weight of produce, of 50% carrots, 10% spinach, 20% celery, and 20% lemon was tested along with single ingredient juices. The combination juice was based on feedback reports of types of juice made in a recent group event. Many people who made their own juice used lemons, some kind of leafy green, often included celery or cucumbers, used very little apple or fruit, and usually included some carrots in their common juice recipes.

Chemicals

Enzyme substrates (4-nitrophenyl phosphate, 4-nitrophenyl α- D-mannopyranoside, 4-nitrophenyl N-acetyl β-Dglucosaminide, L-leucine p-nitroanilide, 4-nitrophenyl β-Dglucopyranoside, 2-nitrophenyl β-D-galactopyranoside) and buffer chemicals (potassium chloride, sodium phosphate monobasic, sodium phosphate dibasic, magnesium chloride, sodium acetate, sodium hydroxide pellets) were purchased from Sigma Aldrich (St. Louis, MO). Glacial acetic acid was purchased from Sciencelab.com (Houston, TX).

Enzyme assays

Enzymes were chosen for detection based on abundant presence in vegetables, availability of substrates for colorimetric detection, and for a variety of cellular locations or types of enzymes. α- Mannosidase is often found in vacuoles or lysosomes and has an acidic pH optimum [13]. N-Acetyl β D-glucosaminidase is also a lysosomal enzyme with an acidic pH optimum [14]. βGlucosidases are abundant in microbes, plants, and fungi [15]. The activity detected in vegetables has a neutral pH optimum. βGalactosidase, also commonly known as lactase, is involved in plant growth, lactose hydrolysis and fruit ripening [16]. Though βGalactosidase from fungi has an acidic pH optimal, the activity found in vegetables has a neutral pH optimum. Acid phosphatase is very common in vegetables and is easily released into the supernatant upon homogenization [17]. It is one of the most easily detectable enzymes in plants. The neutral pH form of leucine aminopeptidase is ubiquitous in plants and is involved in protein turnover [18].

Acid phosphatase, α-mannosidase, and N-acetyl βD-glucoaminidase enzymes were all assayed in 0.3 M acetate buffer, pH 5.0. Briefly, 20 μl of the sample (only 5 μl for most acid phosphatase assays) was added to 200 μl of 0.3 M acetate buffer, pH 5.0 in a 96-well polypropylene assay incubation microplate (Corning 3343, Corning, NY). The assay was initiated in a water bath at 37°C by an introduction to the wells, using a repeater pipette, of the chromogenic substrate specific to each enzyme. After an appropriate amount of time, usually between 2 and 30 minutes, the assay was terminated with 20 μl of 1 M NaOH. Sample blank wells without substrate, blank wells with no substrate or sample, and substrate control wells with the substrate but no sample were included on each assay plate. Six wells were used per individual assay or blank of a sample. Seven samples were arranged on a single 96-well plate.

Leucine aminopeptidase, βglucosidase, and βgalactosidase enzymes were assayed in Z buffer (60 mM Na2HPO4, 40 mM NaH2PO4, 10 mM KCl, 1 mM MgCl2•6H2O, pH 7.6, 0.05% Tween 20). βglucosidase and βgalactosidase assays were terminated with 1.0 M NaOH, but leucine aminopeptidase assays were terminated with 20 μl of 50% glacial acetic acid, which lowered the pH to about 3.75 and deactivated the leucine aminopeptidase enzyme.

Assay microwell plates were spun in a swinging bucket centrifuge (Jouan CR422, Thermo Fisher Scientific, Waltham, MA) at 1,000 Xg for 60 seconds after completion of the assays. 200 μl aliquots were removed from the assay wells and transferred to a 96-well plate (Greiner 655101) for measurement in the plate reader (PowerWave X Select, Bio-Tek, Winooski, VT). The chromogenic substrates were measured at 410 nm, except for ONPG, which was measured at 420 nm. KC4 plate reader software (Bio-Tek, version 3.4) was used to calculate enzyme activities.

Statistics

Each produce-juicer combination was tested four times for carrots, celery, spinach, the combination juice and six times for apples. As there were four batches of produce for each producejuicer combination, there was more variability detected in enzyme activity measurements than if a single batch of produce was used for testing. The comparison of blender/press combination and the Pure Juicer combination had only 3 tests for the Pure Juicer and 4 tests for the blender/press combination using only one batch of produce purchased all at one time.

Outliers in the individual assay wells were detected by the Median Absolute Deviation (MAD) method [19], using a spreadsheet template on the computer with the plate reader software to quickly identify outliers. The median is less sensitive to outliers than the mean and standard deviation and is better at detecting outliers in small samples than using the mean plus or minus 2, 2.5 or 3 standard deviations from the mean as the limit of acceptable values. The MAD method was applied to the results of the four runs of each produce-juicer to detect outliers for yields and enzyme activities. Results reported are without the inclusion of outliers.

The averages of enzyme activity levels were calculated first by finding the average enzyme activity for each experimental run, compared to juice from the Norwalk on day 0, and then averaging the runs together to provide the final average enzyme activity level. Statistical analysis for standard deviations and significant differences in average enzyme activities were calculated on the matrix of averages from each experimental run.

Student T-Tests were used to test for statistically significant differences between tests. A p-value of 0.05 was used as the limit of significance. Corrections for multiple comparisons were done with the Benjamini-Hochberg test [20] with a false discovery rate of 0.10.

Error bars in the average enzyme activity charts are plus or minus the coefficient of variation (%CV), calculated by dividing the standard deviation by the mean value, for the measurements. Error bars in the measurements of individual enzymes are given as the Standard Deviation (SD) of the average.

Results

Yield

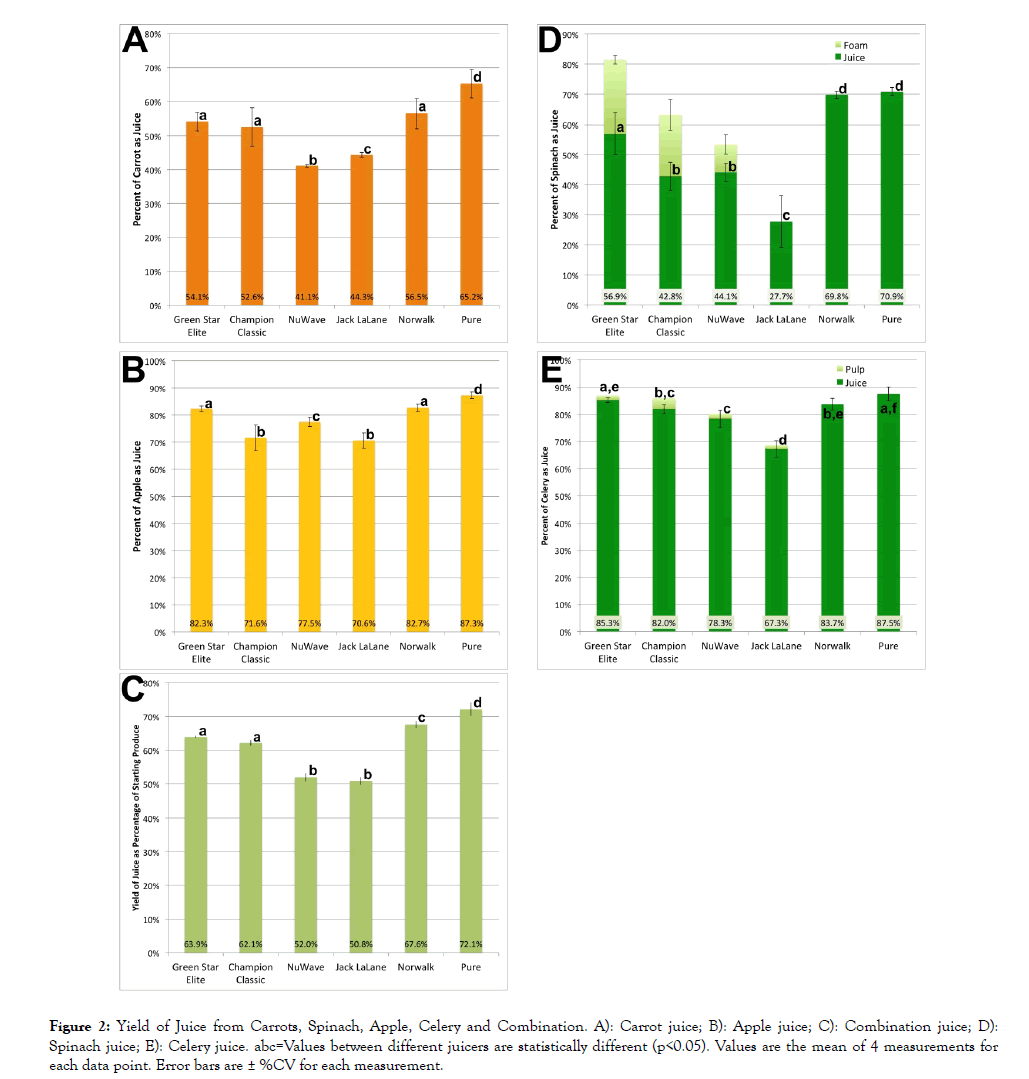

Table 2 gives a detailed yield of juice from each juicer with each type of produce. The LaLane juicer consistently had the lowest yield of juice followed closely by the NuWave juicer with just a couple of exceptions for carrots and apples. The Champion and Green Star frequently had very similar yields with only small differences in yield for carrots, celery, and the combination juice. The Green Star Elite had significantly better yields for apples and spinach compared to the Champion juicer. However since many people combine leafy greens with other vegetables, as in the combination juice, the importance of higher yield on spinach did not translate into a much higher yield of the combination juice.

| Juicer | Carrot | Apple | Celery | Spinach | Combination |

|---|---|---|---|---|---|

| Green Star Elite | 54.1 ± 2.7%a | 82.3 ± 0.9%a | 85.4 ± 1.3%a,c | 56.9 ± 7.0%a | 63.9 ± 0.3%a |

| Champion | 52.6 ± 5.6%a | 71.6 ± 3.4%b | 82.0 ± 1.5%b,d | 42.8 ± 4.7%b | 62.1 ± 0.8%a |

| NuWave | 41.1 ± 0.4%b | 77.5 ± 1.3%c | 76.5 ± 0.3%b | 41.7 ± 0.1%b | 52.0 ± 1.3%b |

| Jack LaLane | 44.3 ± 0.7%c | 70.6 ± 2.0%b | 67.3 ± 3.0%e | 27.7 ± 8.6%c | 50.8 ± 1.2%b |

| Norwalk | 56.5 ± 4.4%a | 82.7 ± 1.1%a | 83.7 ± 2.2%a,d | 69.8 ± 1.2%d | 67.6 ± 1.0%c |

| Pure Juicer | 65.2 ± 4.2%d (8 mm grid) 71.3 ± 0.3%e (6 mm grid) | 87.3 ± 1.0%d | 87.5 ± 2.5%c | 70.9 ± 1.4%d | 72.1 ± 2.1%d |

Table 2: Comparison of yields of juice from 6 juicers. Yields from different juicers in the same column of produce with different superscripts are significantly different.

The Norwalk juicer yields were very similar to the Green Star Elite yields, not being significantly different for carrots, apples or celery. The Norwalk surprisingly had better yield for spinach, though the Green Star juicer is marketed as being able to do really well with leafy greens. The yield of combination juice was significantly (3.7% absolute yield) higher with the Norwalk compared to the Green Star Elite.

The Pure Juicer had higher yields than the Norwalk juicer for carrots, apples, celery and combination juices (Table 2). The yield of spinach juice from both these machines was quite a bit higher than from any other juicer.

Figure 2A-2E gives a graphical presentation of the yield data. The biggest variation in yield, from highest to lowest, was seen in spinach (43.2% highest to lowest, 29.2% highest to second lowest), followed by carrot (23.8%), combination juice (21.3%) and celery (20.2%). The lowest variation in yield was seen in apples, which were firm and crisp Washington state apples (16.7% highest to lowest). These are absolute values in the change in yield.

Figure 2: Yield of Juice from Carrots, Spinach, Apple, Celery and Combination. A): Carrot juice; B): Apple juice; C): Combination juice; D): Spinach juice; E): Celery juice. abc=Values between different juicers are statistically different (p<0.05). Values are the mean of 4 measurements for each data point. Error bars are ± %CV for each measurement.

When the relative yield is considered going from the lowest yield juicer to the Pure juicer, yields of 156% more spinach juice (70% more for the second-lowest to Pure Juicer), 59% more carrot juice, 42% more combination juice, 30% more celery juice, and 24% more apple juice. Table 3 can be used to estimate the relative yield of any 2 juicers tested by adding individual comparisons together. Large differences are underestimated using this method because of the large differences in the denominators.

| Juicer | Carrot | Apple | Celery | Spinach | Combo |

|---|---|---|---|---|---|

| LaLane vs Pure | 47%/61% | 24% | 30% | 156% | 42% |

| Nuwave vs Pure | 59%/73% | 13% | 14% | 70% | 39% |

| LaLane vs NuWave | -7.2% | 10% | 14% | 51% | 2.4% |

| NuWave vs Champion | 28% | -7.6% | 7.2% | 2.6% | 19% |

| Champion vs Green Star | 2.9% | 14.9% | 4.1% | 32.9% | 2.9% |

| Green Star v Norwalk | 4.4% | 0.5% | -2.0% | 23% | 5.8% |

| Norwalk vs Pure | 15%/26% | 5.6% | 4.5% | 1.6% | 6.7% |

Table 3: Relative Yield from 1 kg of produce for 6 Juicers. Differences between other comparisons not listed can be estimated by summing the relative differences between the juicers of interest. For example relative yield of celery juice for NuWave vs Green Star=7.2+4.1=11.3%. Large differences tend to be underestimated in this table because of large differences in the denominator of the comparison. The second number under the carrot column for the Pure Juicer is calculated based on 71.3% yield from Table 2.

Enzyme activity

The quality of the fresh juice was measured by enzyme activity. Lower enzyme activity is indicative of poorer extraction or increased denaturation of enzymes during extraction due to heat or air exposure. Retention of enzyme activity over a 72-hour period after juice extraction was measured to determine which, if any, machines produced juice which retained most of its original enzyme activity.

Carrot

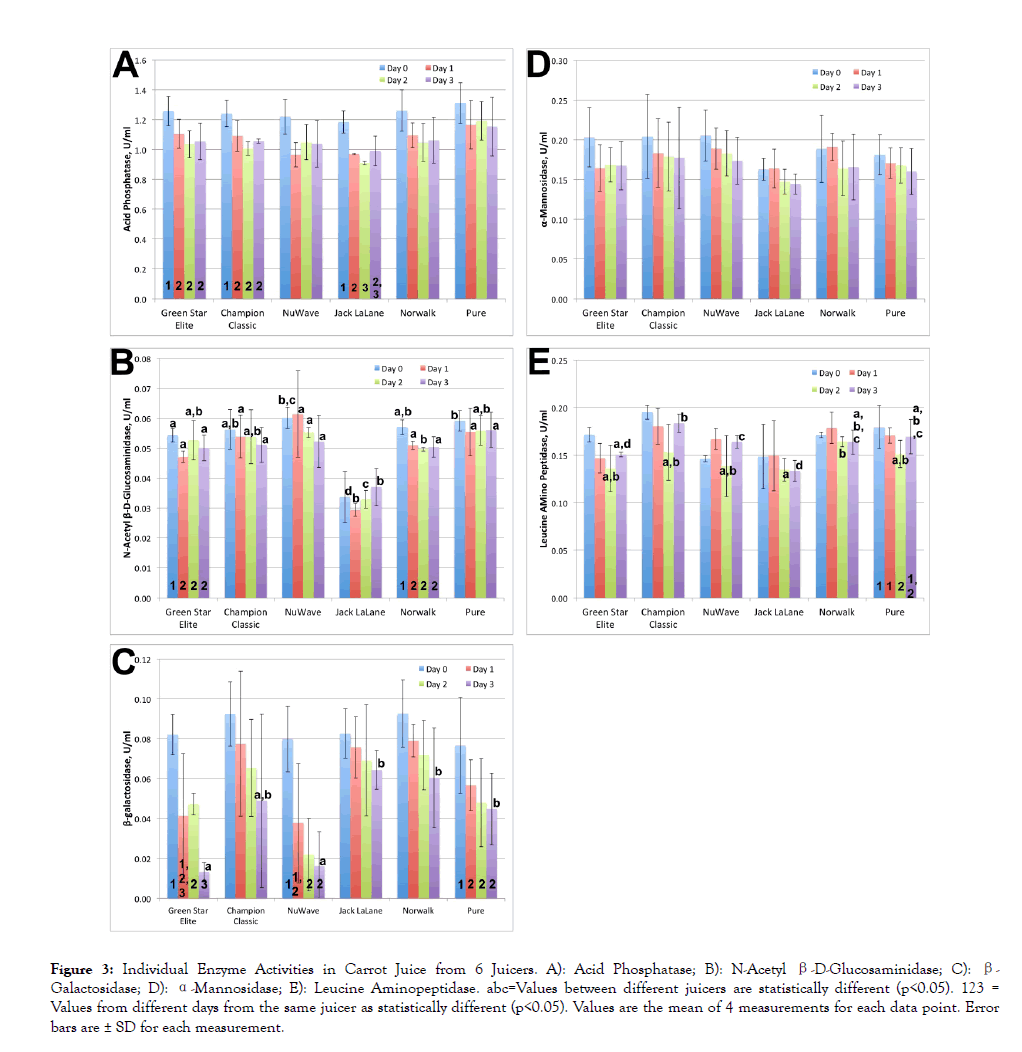

Enzyme activity was very consistent between the various juicers, except for the LaLane juicer. Figure 3A-E shows the individual enzyme activities in carrot juice for days 0, 1, 2, and 3. When looking at just the day 0 data (in blue columns) there is not a large degree of separation between the juicers for most of the enzymes tested. There were no significant differences in activities of acid phosphatase, α-mannosidase, leucine aminopeptidase or βgalactosidase on day 0. The most notable difference was the lower amount of N-acetyl βD-glucosaminidase in the juice from the Jack LaLane juicer, which was significantly lower than the enzyme activity from all of the other juicers for each day.

Figure 3: Individual Enzyme Activities in Carrot Juice from 6 Juicers. A): Acid Phosphatase; B): N-Acetyl ß-D-Glucosaminidase; C): ß- Galactosidase; D): α-Mannosidase; E): Leucine Aminopeptidase. abc=Values between different juicers are statistically different (p<0.05). 123=Values from different days from the same juicer as statistically different (p<0.05). Values are the mean of 4 measurements for each data point. Error bars are ± SD for each measurement.

As seen in Table 4, with the enzyme activity of the Norwalk Juicer set at 100% on day 0, variations in day 0 enzyme activity were about 5%-8% for acid phosphatase, α-mannosidase, N-acetyl β-D-glucosaminidase, about 15% for leucine aminopeptidase and 10%-20% for β-galactosidase. The amount of variation can also be judged by the size of the coefficient of variation, also in Table 4. No β-glucosidase activity was detected in carrots. No single juicer had the highest enzyme activity for all tested enzymes. As seen in the last column of Table 4, there was only a slight variation in average enzyme activity, with no statistically significant differences between juicers on day 0. Even the LaLane juicer, with only 83% average enzyme activity, had enough variation in the four separate experiments that this difference was not statistically significant when corrected for multiple comparisons.

| Juicer | Acid Phosphatase | α-Manno-sidase | N-acetyl β-D-glucosa-minidase | Leucine Amino-peptidase | β-Galactosidase | Average |

|---|---|---|---|---|---|---|

| Green Star Elite | 99.7 ± 7.9% | 107.7 ± 18.4% | 95.2 ± 4.2% | 100.2 ± 4.5% | 88.5 ± 12.4% | 98.3 ± 2.7% |

| Champion Classic | 98.4 ± 7.2% | 108.2 ± 25.9% | 98.6 ± 11.9% | 114.0 ± 3.7% | 99.7 ± 17.3% | 103.8 ± 5.2% |

| NuWave | 96.7 ± 9.6% | 108.9 ± 15.7% | 105.4 ± 6.0% | 85.4 ± 2.2% | 86.2 ± 20.7% | 96.5 ± 3.9% |

| Jack LaLane | 93.9 ± 6.3% | 86.3 ± 8.4% | 59.0 ± 25.3% | 86.8 ± 22.8% | 89.1± 15.0% | 84.9 ± 10.3% |

| Norwalk | 100.0 ± 11.0% | 100.0 ± 22.3% | 100.0 ± 4.3% | 100.0 ± 1.7% | 100.0 ± 18.2% | 100.0 ± 7.3% |

| Pure | 104.0 ± 10.4% | 96.0 ± 13.9% | 103.7 ± 5.8% | 104.8 ± 12.6% | 82.7 ± 31.3% | 100.9 ± 5.3% |

Table 4: Individual enzyme activity in carrot juice on day 0. For comparison, 100% activity is set as the amount of enzyme activity in carrot juice in the Norwalk juicer on day 0. The amount of error reported is the % CV for 4 measurements per data point.

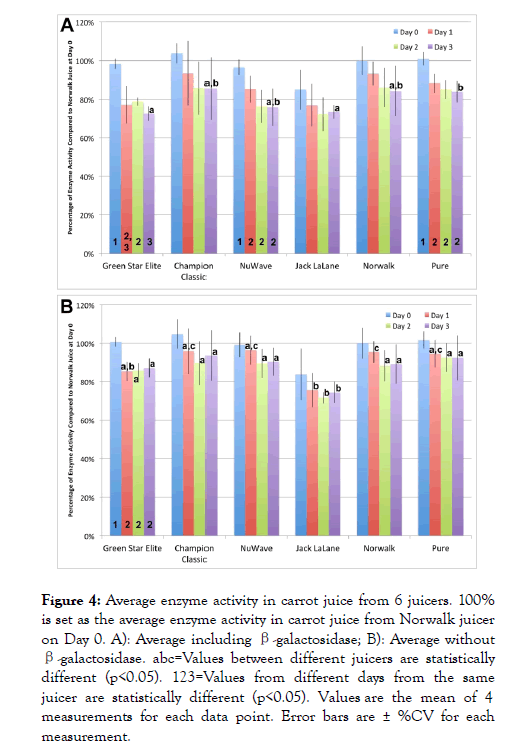

Retention of enzyme activity in carrot juice was tested 1, 2 and 3 days after the extraction. There was a greater amount of variability in β-galactosidase activity than in other enzymes. There was a non-significant trend in a decrease in average enzyme activity for all juicers combined, from 85.6% to 80.6% and 79.3% on days 1, 2 and 3, respectively. The biggest change in enzyme activity was in βgalactosidase. Without including βgalactosidase, average enzyme retention for all of the juicers was 90.5%, 86.2% and 88.0% on days 1, 2 and 3, respectively. Without including the data from the LaLane juicer, which was statistically significantly lower in enzymatic activity compared to the other juicers, the average enzymatic activity remained near 90% through day 3.

Statistical analysis including βgalactosidase showed only a few statistically significant differences on day 3 of storage of the juices, marked in Figure 4A. The Green Star and Jack LaLane juicers had significantly lower amounts compared to the Pure Juicer while the other juicers were in-between these ones. The error bars, which are plus/minus the coefficient of variation, were smaller without βgalactosidase, so a few more differences were statistically significant (Figure 4B). There were still no significant differences on day 0, but the carrot juice from the Jack LaLane juicer had significantly lower average enzyme activity compared to all of the other juicers, except for the Green Star Elite juicer on day 1.

Figure 4: Average enzyme activity in carrot juice from 6 juicers. 100% is set as the average enzyme activity in carrot juice from Norwalk juicer on Day 0. A): Average including β-galactosidase; B): Average without β-galactosidase. abc=Values between different juicers are statistically different (p<0.05). 123=Values from different days from the same juicer are statistically different (p<0.05). Values are the mean of 4 measurements for each data point. Error bars are ± %CV for each measurement.

The change in average enzyme activity during storage was significant for the Green Star Elite, NuWave, and Pure juicer when βgalactosidase activity was included in the average (Figure 4A). The activity of βgalactosidase fell much more than other enzymes during storage. When βgalactosidase was not included in the average only the Green Star Elite had a significant decrease in enzyme activity during storage. The change was within the first 24 hours, after which the enzyme activity appeared to be stable in all of the juices produced.

The main results here are that all of the juicers produced enzyme-rich carrot juice and they all worked for producing carrot juice that retained enzyme activity. The variation between batches of carrots was greater than the variation between performances of different juicers. Only the Jack LaLane juicer was consistently significantly lower than the other juicers in average enzyme quality.

The Pure Juicer with its higher yield did not suffer by having lower or diluted enzyme activity. It had more complete extraction in terms of yield and quality.

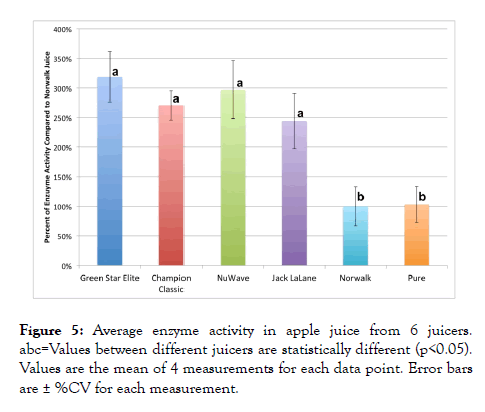

Apple

Experimentation with clarified apple juice, made by centrifugation, showed that enzyme activity was closely related to soluble fiber (data not shown). The press cloths used in the 2- stage juicers create a more clarified juice and this is reflected in average enzyme activity in apple juice, as seen in Figure 5. The other four juicers have much higher enzyme activity than the Norwalk and Pure Juicers, by 2.5 to 3-fold as much. There is a statistical difference between these 4 juicers and the 2-stage juicers that use a press cloth.

Figure 5: Average enzyme activity in apple juice from 6 juicers. abc=Values between different juicers are statistically different (p<0.05). Values are the mean of 4 measurements for each data point. Error bars are ± %CV for each measurement.

Spinach

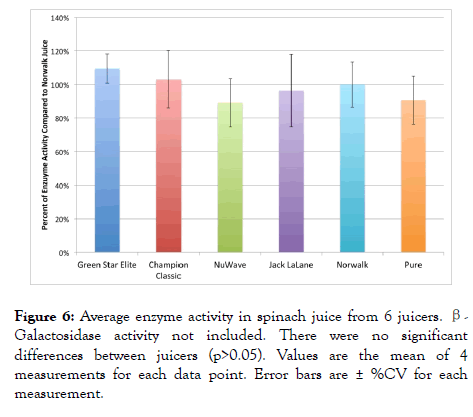

Even though the extraction of spinach juice is a foamy mess in most juicers, the enzymatic activity of the juice from all six juicers was excellent, with no statistical difference in average enzyme activity between any of the juicers. So, the quality of juice is excellent, but some juicers don’t make very much juice from spinach, as seen in Figure 2. The 2-stage juicers had the least amount of foam and had excellent enzymatic activity, as seen in Figure 6.

Figure 6: Average enzyme activity in spinach juice from 6 juicers. β- Galactosidase activity not included. There were no significant differences between juicers (p>0.05). Values are the mean of 4 measurements for each data point. Error bars are ± %CV for each measurement.

Celery

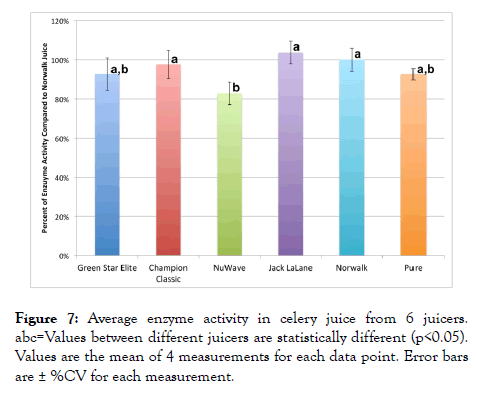

Celery juice is fairly easy to make in high yield with a household juicer. The strings from the celery, even cut at one or two inches long (2.5 cm to 5 cm) caused the Champion juicer to run hotter due to more friction. But enzymatic activity was good in all six juicers. The celery juice does not have β-glucosidase or β- galactosidase activity in it and is not as rich in enzymes as other vegetable juices (Compare enzyme concentrations in various juices in Table 5). The NuWave juicer was significantly lower in average enzyme activity than the Champion, LaLane and Norwalk juicer, as seen in Figure 7.

| Enzyme | Carrot | Apple | Celery | Spinach | Combo |

|---|---|---|---|---|---|

| Acid phosphatase | 1.242 | 0.318 | 0.71 | 12.84 | 1.527 |

| α-Mannosidase | 0.204 | 0.007 | 0.048 | 0.347 | 0.079 |

| N-Acetyl β-D-glucosaminidase | 0.056 | 0.0093 | 0.039 | 0.148 | 0.035 |

| Leucine aminopeptidase | 0.195 | 0.0041 | 0.043 | 0.374 | 0.012 |

| β-glucosidase | nd | 0.002 | nd | 0.0301 | 0.0041 |

| β-galactosidase | 0.092 | nd | nd | 0.0994 | nd |

Table 5: Comparison of enzyme activity in different produce. Levels of enzyme activity in carrots, apples, celery, spinach, and combination juices are shown here, all from the Champion juicer. Units are U/ml. nd=not detected.

Figure 7: Average enzyme activity in celery juice from 6 juicers. abc=Values between different juicers are statistically different (p<0.05). Values are the mean of 4 measurements for each data point. Error bars are ± %CV for each measurement.

Table 5 shows enzyme activities for juices of all the produce made with the Champion juicer. Spinach had higher levels of all enzymes. Previous work with kale also found high enzyme levels in kale leaves, so this higher enzyme activity may be true of leafy greens in general. Carrots had more enzyme activity than celery, with apple juice being very low in enzyme activity. The combination juice surprisingly had a lower amount of some enzymes, like leucine aminopeptidase, than expected based on additive amounts of individual ingredients. At least 50% of the enzyme content of carrots was expected, but not seen.

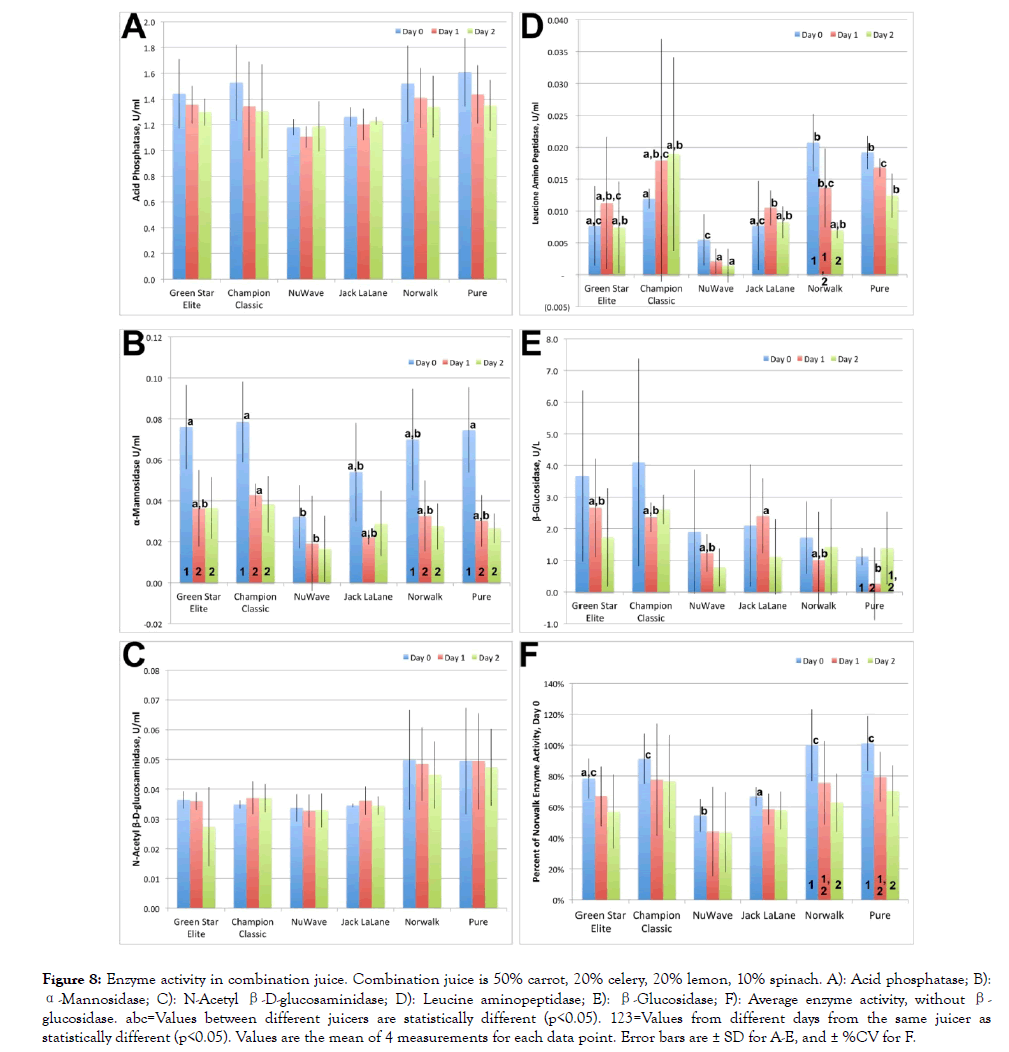

Combination juice

Variations between batches of juice were as great as the variations between juicers for the combination juice so that overall there were few significant differences between juicers. For acid phosphatase, the NuWave and LaLane juicers tended to be lower than other juicers, but the differences were not significant when corrected for multiple comparisons. The day 0 activity of αmannosidase in the NuWave juicer was significantly lower than the activity in the Green Star, Champion, and Pure Juicer. The day 0 leucine aminopeptidase activity in the Pure and Norwalk juicers was significantly higher than activity in all of the other juicers. The leucine aminopeptidase level was particularly low in the NuWave juicer. The overall average enzyme activity on day 0 tended to be lower in the NuWave and LaLane juicers, with statistically significant differences between these two juicers and the Norwalk and Pure Juicer (Figure 8A-8F).

Figure 8: Enzyme activity in combination juice. Combination juice is 50% carrot, 20% celery, 20% lemon, 10% spinach. A): Acid phosphatase; B): α-Mannosidase; C): N-Acetyl β-D-glucosaminidase; D): Leucine aminopeptidase; E): β-Glucosidase; F): Average enzyme activity, without β- glucosidase. abc=Values between different juicers are statistically different (p<0.05). 123=Values from different days from the same juicer as statistically different (p<0.05). Values are the mean of 4 measurements for each data point. Error bars are ± SD for A-E, and ± %CV for F.

After the first day of storage, enzyme activity dipped, but only significantly with the Norwalk and Pure Juicer. αMannosidase activity, in particular, tended to decrease in all juicers while most of the other individual enzymes were quite stable in the activity. Table 6 shows the average enzyme levels without β-glucosidase in the combination of juice. While Norwalk and Pure Juicer are about 100%, Champion is next at 91%, Green Star Elite at 78%, and LaLane (67%) and NuWave (54%) at the lower end of enzyme activity. By the second day the Champion retained the most enzyme activity (77%), then the Pure Juicer (70%), then the Norwalk, LaLane and Green Star Elite juicers at around 60% and the NuWave juicer at the end with 44%. The enzyme activity tended to even out between juicers during storage, with no significant differences between juicers on days 1 and 2 (Figure 8F). There was on average about a 24% decline in enzyme activity during storage of the combination juice, with higher declines in the Norwalk and Pure Juicer. The juice from the Champion juicer retained enzymatic activity very well with only a relative 16% decline from its high starting value.

| Juicer | Day 0 | Day 1 | Day 2 | Δ% |

|---|---|---|---|---|

| Green Star Elite | 78.4 ± 12.9% | 66.9 ± 19.3% | 57.1 ± 23.9% | -27.2% |

| Champion Classic | 91.1 ± 16.1% | 77.6 ±36.3% | 76.6 ± 30.1% | -16.0% |

| NuWave | 54.4 ± 10.6% | 44.0 ± 28.8% | 43.7 ± 25.9% | -19.8% |

| Jack LaLane | 66.7 ± 6.1% | 58.5 ± 10.0% | 57.7 ± 12.3% | -13.4% |

| Norwalk | 100.0 ± 23.2% | 75.6 ± 27.1% | 62.7 ± 18.8% | -37.3% |

| Pure | 101.1 ± 17.8% | 79.5 ± 16.1% | 70.4 ± 16.5% | -30.4% |

Table 6: Average enzyme activities in combination juice (not including β-glucosidase). The amount of error reported is the %CV for 4 measurements per data point. Δ% is the relative change in enzyme activity calculated as (Day 2-Day 0)/Day 0.

Juicer optimization

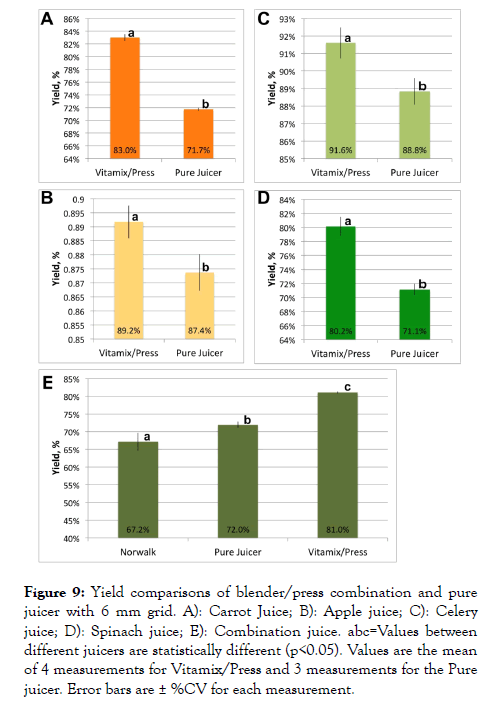

Is it possible to design a better juicer than those already in commercial production? In order to do this, the two-unit operations, grinding and pressing, need to be individually optimized and combined to minimize inefficiencies in either stage (Figure 1). The best grinder unit operation for produce is not a hammermill like the Norwalk or Pure Juicer. It is a blender. A commercial blender, such as the Vitamix or Blendtec blenders, does a fine job in completely homogenizing produce. When combined with a hydraulic press, as the Pure Juicer press, the process is very efficient for yield and quality.

Yields for carrots, celery, apple, spinach, and combination juices are all significantly higher when combining a blender with the press of the Pure Juicer (Figure 9A-9E). Even when a smaller grid, 6 mm versus the standard 8 mm grid, is used in the Pure Juicer the yield is better with the blender. For carrots, the yield increased from 71.7% with a 6 mm grid to 83.0% in the blender/press combination, both of which are excellent yields.

Figure 9: Yield comparisons of blender/press combination and pure juicer with 6 mm grid. A): Carrot Juice; B): Apple juice; C): Celery juice; D): Spinach juice; E): Combination juice. abc=Values between different juicers are statistically different (p<0.05). Values are the mean of 4 measurements for Vitamix/Press and 3 measurements for the Pure juicer. Error bars are ± %CV for each measurement.

Losses of 15% are typical for peeling and removing ends of carrots, so a loss of only 17% during the extraction process might be near the theoretical maximum yield possible with carrots.

Similar increases (72.0% to 81.0%) were seen with the combination of juice. Yield increases for celery, apple, and spinach were smaller, as the Pure Juicer with a 6 mm grid already produces high yields.

Does the use of a high-speed blender reduce the quality of the juice? Enzyme activity was used to detect even small changes in juice quality. The blender was able to homogenize the produce before there was a substantial temperature increase, so the heat was not an issue of concern.

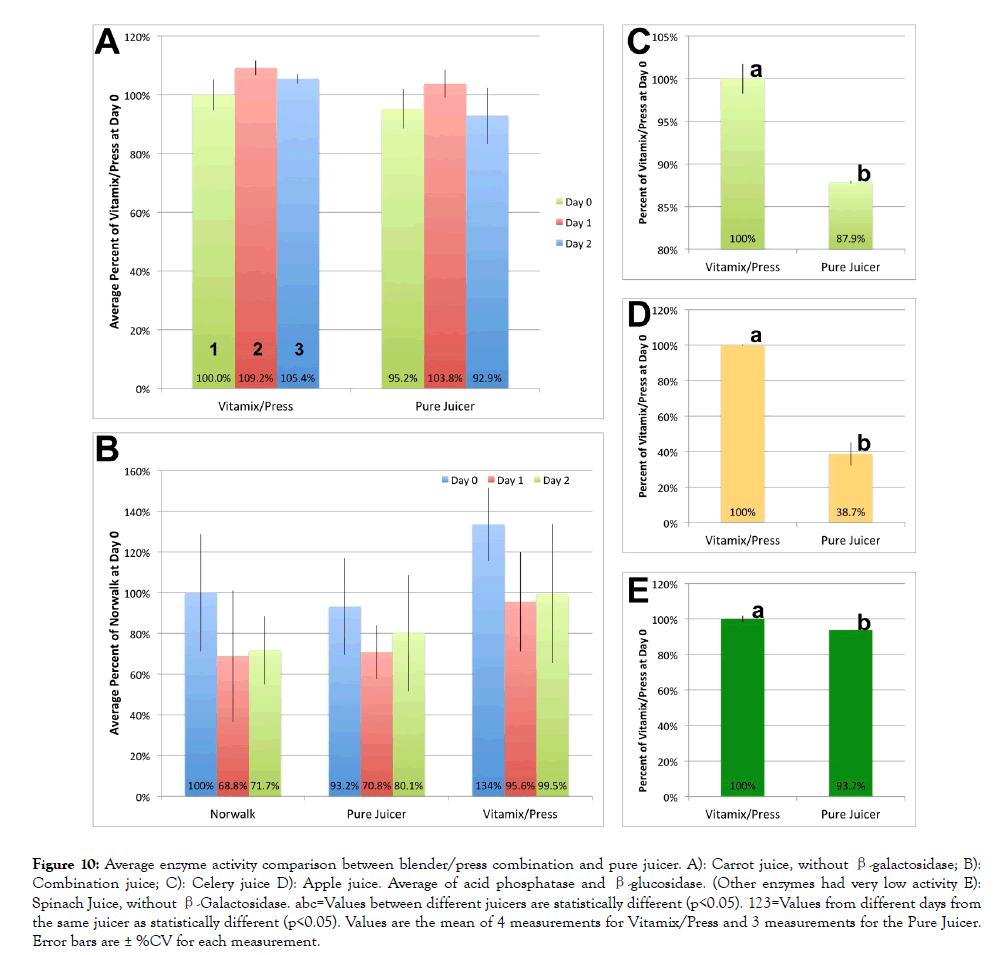

As shown in Figure 10A-10E, enzyme activity was significantly higher for the blender/press combination for the combination juice (+33 or 40% higher than Norwalk or Pure Juicer, respectively), carrot juice (+5%), celery juice (+12%), apple juice (+61%) for the 2 enzymes with significant activity) and spinach juice (+6%). So not only does the high-speed homogenization not hinder quality, it appears that the quality of juice is actually enhanced by blender homogenization.

Figure 10: Average enzyme activity comparison between blender/press combination and pure juicer. A): Carrot juice, without β-galactosidase; B): Combination juice; C): Celery juice D): Apple juice. Average of acid phosphatase and β-glucosidase. (Other enzymes had very low activity E): Spinach Juice, without β-Galactosidase. abc=Values between different juicers are statistically different (p<0.05). 123=Values from different days from the same juicer as statistically different (p<0.05). Values are the mean of 4 measurements for Vitamix/Press and 3 measurements for the Pure Juicer. Error bars are ± %CV for each measurement.

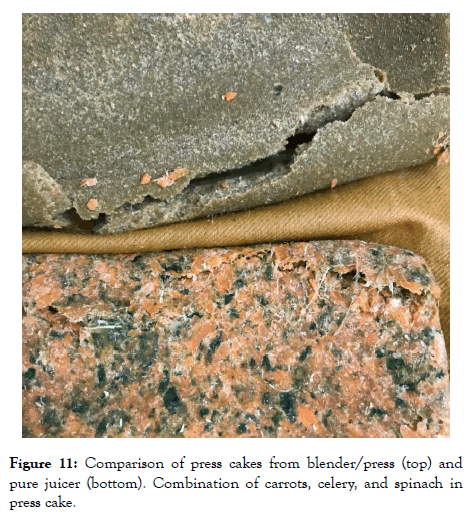

Figure 11 shows the pulp of a combination of carrot, celery, and spinach after grinding with the Pure Juicer or after homogenization by the blender. Complete extraction of nutrients is not possible with a Pure Juicer, or any other juicer commercially available. Only after complete homogenization can efficient extraction be done. Many nutrients must necessarily be left in the pulp when grinding is incomplete.

Figure 11: Comparison of press cakes from blender/press (top) and pure juicer (bottom). Combination of carrots, celery, and spinach in press cake.

Discussion

The degree to which a juicer efficiently implements the two stages of grinding and pressing determines the yield of the juice. Any loss of moisture due in incomplete grinding or inadequate squeezing causes a drop in yield, as indicated in Figure 1. The yields of juice from the six tested juicers reflect their design to grind and press. The Green Star Elite and the NuWave vertical auger juicers do not grind the produce as fine as the other juicers. The yields from the Green Star Elite are still in the medium range because the pressing section of the twin augers exerts enough pressure to effectively squeeze most of the moisture out that was released during the grinding stage. The pulp from the Green Star Elite feels dry because most of the remaining moisture remains inside intact plant cells.

On the other hand, the Champion and Jack LaLane juicers grind quite finely but do not exert a great deal of force in the pressing stage, so the expelled pulp feels wetter. The available moisture in the pressing stage is not fully extracted from the pulp. The rating of the grinding and pressing performance of each juicer is given in Table 7.

| Juicer | Stage 1 (Grinding) | Stage 1 Rating | Stage 2 (Pressing) | Stage 2 Rating | Inefficiencies | Yield |

|---|---|---|---|---|---|---|

| Green Star | Chunky | * | Hard | *** | Stage 1 | Medium |

| Champion | Fine grind | *** | Soft | ** | Stage 2 | Medium |

| NuWave | Chunky | * | Hard | *** | Stage 1and 2 | Low |

| LaLane | Fine grind | *** | Very soft | * | Stage 2 | Lowest |

| Norwalk | Fine grind | *** | Hard | **** | Stage 1 and 2 | High |

| Pure | Finer grind | **** | Hardest | ***** | Stage 1 | Higher |

| Blender/Press | Homogenized | ***** | Hardest | ***** | None | Highest |

Table 7: Rating of grinding and pressing performance of juicers. 5 Stars (*) is the best rating. The stage that causes less than optimal yield is noted.

The Pure Juicer produces the highest yield across all of the different types of products for a commercially available juicer. Only for spinach did the Norwalk equal the yield of the Pure Juicer. The combination of the impeller and grid design produced a more finely ground pulp that yielded more juice than from other grinding methods. The stronger press plates of the Pure Juicer, compared to the Norwalk juicer, allowed higher pressure to be applied continuously as well to maximize yield. The Norwalk juicer either has lower pressure for longer times or higher pressure for a short time, depending on the model. In the testing here, the Norwalk Model 260 was limited to 10 seconds of consecutive pressing time. Yields recorded here for the Norwalk juicer were the result of multiple 10-second pressings, so the yield was only limited by the pressure, not the length of time held at that pressure.

Enzyme activity was used in this study to assess juice quality. Rather than relying on single enzyme activity for reporting quality, a panel of six enzymes was utilized. This resulted in greater confidence in the method, as variations in individual enzyme activities were modulated in the average of the panel of enzyme activities. The same general trends were seen in individual enzymes as well, indicating that the method was measuring reliable trends in the data. The activity of β- galactosidase and β-glucosidase was not as stable during storage as the other enzymes. The reasons for this may be due to the pH of the juice or inactivation due to some other influence not clear at this time.

There was a high degree of consistency between the enzyme activities in the different juicers. Even when yields were very different, like with spinach juice, the differences in average enzymatic activity were small, often not statistically significant. On day 0, when juice was produced, the only significant decreases in average enzyme activity were in the NuWave juicer for celery and the NuWave and LaLane juicer for the combination juice and for the pressed juices for apples.

The soluble fiber in apple juice, and possibly other fruit juices, was strongly associated with enzymatic activity. The two-stage method’s only weakness was in over-clarifying apple juice. Other produce tested was not affected like apples, but this is an area where improvement is desirable.

During the storage of carrot juice, there was only about a 10% decline in enzymatic activity over the 72-hour storage period. This indicates that carrot juice is quite stable and quality remains high during storage. The combination juice had larger drops in enzymatic activity during storage. By the second day, there was an average relative decline of about 24% in average enzymatic activity (Table 6). It is not clear why this juice was not as stable as the carrot juice. Perhaps the inclusion of lemon juice was a factor.

The results here, including the blender/press method testing, indicate that the speed of the impeller is not the main criteria for high-quality juice. Rather, the fineness of the grind and the pressure applied in the second stage of extraction determine the yield and quality of the juice. None of the juicing methods heated the pulp to any significant amount in the one-kilogram batches tested here. As long as heat is not generated the speed of the impeller apparently is irrelevant to juice quality. A highspeed impeller, like a Vitamix or Blendtec blender, can produce a higher quality juice than a 2-step juicer, which is at least as high quality as a twin gear grinder at 110 rpm or single auger at 48 rpm.

The fiber in the homogenate from blending was so fine that other juicing machines could not separate the juice from the fiber. Separating juice from blended fiber seems to require a membrane or cloth to perform the separation.

Carrot juice was made using 3 mm and 4 mm grid holes without an increase in overall yield (data not shown). However, the back pressure on the pusher was very significant with the smaller grids. An impeller design with faster tip speed would be needed to make a more finely ground pomace.

One of the strengths of this study is the replication of the data. Four measurements were taken of each juicer/produce combination when comparing all 6 juicers. The replication of the measurements using different batches of produce helped reveal the variation in enzyme activity between batches as well as variation between juicers. A single measurement might be easier to initially interpret, perhaps wrongly, but repeated measures give an estimate in the uncertainty of the numbers as well. So, many people may boast of testing juicers and determining which juicer is better with a quick estimate of yield and a subjective taste of the juice, but this is the first test comparing carefully measured, repeated juice yields and measuring quality using a panel of enzyme activity assays to determine which juicer yields the best juice.

Conclusion

This study gives an understanding of the juicing process, examines how well different designs of juicers perform at grinding and pressing moisture from produce and gives a clear path toward optimization of the juicing process to minimize waste and maximize yield and quality of juice.

Acknowledgments

The author would like to express gratitude to George Malkmus for the gift of the Norwalk juicer and to David Feinberg for the loan of the Pure Juicer. This study was funded by Hallelujah Diet. The author declares that he has no conflict of interest in publishing this work.

REFERENCES

- U.S. Department of Health and Human Services and U.S. Department of Agriculture 2015-2020 Dietary Guidelines for Americans. 8th Edition. https://health.gov/dietaryguidelines/2015/guidelines

- Produce for better health foundation have a plant. In: Have Plant. https://fruitsandveggies.org/

- Kushi LH, Doyle C, McCullough M, Rock CL, Demarkâ€ÂWahnefried W, Bandera EV, et al. American cancer society guidelines on nutrition and physical activity for cancer prevention: reducing the risk of cancer with healthy food choices and physical activity. CA Cancer J Clin. 2012;62:30-67.

- How to eat more fruit and vegetables. In: www.heart.org. https://www.heart.org/en/healthy-living/healthy-eating/add-color/how-to-eat-more-fruits-and-vegetables

- WCRF/AICR. Eat whole grains, vegetables, fruit and beans. In: World Cancer Res. Fund. https://www.wcrf.org/dietandcancer/recommendations/wholegrains-veg-fruit-beans, 2018

- Hildenbrand GL, Hildenbrand C, Bradford K, Cavin S. 5-year survival rates of melanoma patients treated by diet therapy after the manner of Gerson. Alt Ther Health Med. 1995;1:29-37.

- Donaldson MS, Speight N, Loomis S. Fibromyalgia syndrome improved using a mostly raw vegetarian diet: an observational study. BMC Complement Altern Med. 2001;1:7.

- Nyakayiru J, Jonvik KL, Trommelen J, Pinckaers PJ, Senden JM, Van Loon LJ, et al. Beetroot juice supplementation improves high-intensity intermittent type exercise performance in trained soccer players. Nutrients. 2017;9:314.

- Bahadoran Z, Mirmiran P, Kabir A, Azizi F, Ghasemi A. The nitrate-independent blood pressure-lowering effect of beetroot juice: A systematic review and meta-analysis. Adv Nutr. 2017;8:830-838.

- Donaldson MS. A carotenoid health index based on plasma carotenoids and health outcomes. Nutrients. 2011;3:1003-1022.

- Butalla AC, Crane TE, Patil B, Wertheim BC, Thompson P, Thomson CA. Effects of a carrot juice intervention on plasma carotenoids, oxidative stress, and inflammation in overweight breast cancer survivors. Nutr Cancer. 2012;64:331-341.

- Dai Q, Borenstein AR, Wu Y, Jackson JC, Larson EB. Fruit and vegetable juices and Alzheimer’s disease: the Kame Project. Am J Med. 2006;119:751-759.

- Dey PM, Brownleader MD, Harborne JB. The plant, the cell and its molecular components. In: Dey PM, Harborne JB (eds) Plant Biochemistry. Academic Press, London, 1-47.

- Giordani R, Benyahia S, Teissère M, Noat G. Purification and properties of N-acetyl-β-D-glucosaminidase from Hevea brasiliensis latex. Plant Sci. 1992;84:25-34.

- Cairns JR, Esen A. β-Glucosidases. Cell Mol Life Sci. 2010;67:3389-3405.

- Saqib S, Akram A, Halim SA, Tassaduq R. Sources of β-galactosidase and its applications in food industry. 3 Biotech. 2017;7:79.

- Parish RW. The intracellular location of phenol oxidases, peroxidase and phosphatases in the leaves of spinach beet (Beta vulgaris L. subspecies vulgaris). Eur J Biochem. 1972;31:446-455.

- Tu CJ, Park SY, Walling LL. Isolation and characterization of the neutral leucine aminopeptidase (LapN) of tomato. Plant Physiol. 2003;132:243-255.

- Leys C, Ley C, Klein O, Bernard P, Licata L. Detecting outliers: Do not use standard deviation around the mean, use absolute deviation around the median. J Exp Soc Psychol. 2013;49:764-766.

- McDonald JH. Multiple comparisons. Handbook of biological statistics. 2014:3.

Citation: Donaldson M (2020) Household Juice Extractor Comparison and Optimization. J Food Process Technol 11:819. doi: 10.35248/2157-7110.20.11.819

Copyright: © 2020 Donaldson M. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.