Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

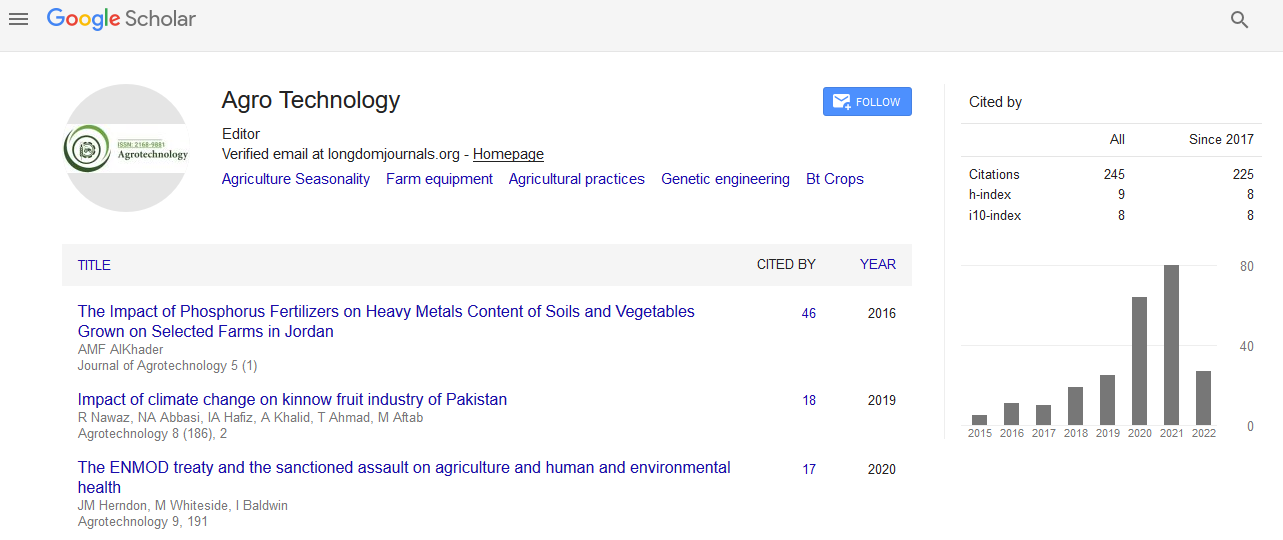

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Commentary - (2022) Volume 11, Issue 4

Evaluation of the Performance of Solar Dryers with Reasonable Heat Storage for Agricultural Products

Received: 04-Apr-2022, Manuscript No. AGT-22-16535; Editor assigned: 07-Apr-2022, Pre QC No. AGT-22-16535 (PQ); Reviewed: 21-Apr-2022, QC No. AGT-22-16535; Revised: 28-Apr-2022, Manuscript No. AGT-22-16535 (R); Published: 05-May-2022, DOI: 10.35248/2168-9881.22.11.254

Description

The potential for climate-resilient energy practices depends on integrating sustainable energy with energy storage, such as solar energy. Solar energy provides desired thermal energy for several purposes, such as industry, domestic use and food preservation. This review provides a comprehensive report on the design availability of solar dryers and other important aspects and summarizes the different applications of different agro-food products. Several recent advances, challenges and limitations of large-scale solar drying are presented. This review provides valuable information on the current state of solar dryers to facilitate the development of this renewable, green and sustainable food drying technology. It shows that solar drying technology can be considered as a small-scale (dimensions) energy-saving dehydration technology to produce shelf-stable products [1].

Drying is the oldest technique for preserving agricultural products, and sun drying is still widely used to preserve agricultural products in tropical and subtropical regions. Previous attempts at solar drying of grains, fruits, vegetables, spices, medicinal plants and fish are seriously revisited. Recent developments of solar dryers such as tunnel solar dryer, upgraded version of tunnel solar dryer, roof integrated solar dryer and dryer Greenhouse solar energy for drying fruits, vegetables, spices, herbs and fish is also rigorously tested for drying performance and product quality and economy in rural areas of the tropics and subtropics. Experimental performances of different types of solar dryers, have demonstrated their potential in drying fruits, vegetables, spices, medicinal plants and fish in tropical and subtropical regions. , as well as simulated operations of different types of solar dryers discuss the agreement between simulation and experimental results is very good, within acceptable limits (10%). The developed simulation models can be used to provide design data and also for optimal design of dryer components. Preservation of materials by drying is undoubtedly the oldest practiced approach and it remains the most commonly used approach in the world. Drying, affects the physical parameters of the goods, through the means of water removal, the reasons for reducing weight and improving storage capacity. While grains and beans are the most important, in terms of tonnage, the variety of dry goods is vast and includes meat, fish, fruit, vegetables, spices, and nuts. The traditional drying equipment for storing fruits, vegetables, grains, fish, meat, wood and other agricultural products is solar drying, a free and renewable energy source. However, for large-scale production, there are many recognized barriers to solar drying such as damage to crops by animals, birds and rodents, eventual degradation due to direct exposure to solar radiation, dew or rain, infection by dirt, dust or debris. In addition, the system is laborious and time- consuming, as the trees must be covered at night during bad weather, and must be protected against invasion by domestic animals [2].

Mobile Solar Tent Dryer

Mobile Solar Dryer in Greenhouse (MSTD) 8 ft. × 4 ft. is made of polyurethane insulation. This material makes up the walls and floor of the solar tent dryer is constructed by steel dryer with 6 drying trays. The interior surfaces are painted black to accelerate heat absorption while the upper frames are made of hollow ½ inch galvanized pipe to form domes that serve as the base for the transparent sheet/film. The top of the MST is equipped with a compressed air exhaust fan that dehumidifies the dried products [3].

Greenhouse dryer

It is designed to combine the function of a solar collector with a greenhouse system. The roof and walls of this dryer can be made of transparent materials such as glass, fiberglass, UV stabilized plastic or polycarbonate sheet. The transparent materials are fixed on a steel support or wooden roof with bolts and nuts and sealed to prevent moist air or rainwater from entering the interior of the cavity other than the gas being introduced through doors. Floor surface is painted black to increase absorption rate [4].

Parabolic Greenhouse Solar Dryer

NSPRI has developed a parabolic solar dryer. PGSD measures 26 ft × 18 ft with an effective drying area of 22 ft × 14 ft as shown in (Plate 3). The support frame is made of steel was shaped into a 7.5-foot-tall saucer. It features 2 steel drying racks made up of 56 trays with an effective drying space of 224 square feet. The floor of PGSD is a concrete floor sandwiched with polyurethane to prevent heat dissipation. The concrete floor is paved with black ceramic tiles that have been painted with food grade black enamel. The transparent material is made of 2 mm thick Perspex branded acrylic [5].

The following products Telefaria Occidentalis, Meat and Chilli have been dried using a solar dryer. Product samples were sorted, cleaned and weighed. The initial moisture content of the product is also determined by drying in an oven before drying in a solar dryer. The vegetables were sorted, washed, drained and grated with a knife to a thickness of 10 mm. Its moisture content is determined by means of an oven method and the products are weighed and simultaneously placed in a dryer for proper drying. Weighed portions were also sun-dried for control. Vegetable weight is checked periodically.

Purchased beef is cleaned to remove fat deposits. The meat is finely cut into 2 mm fillets. Humidity was determined by the oven method. Meat was weighed, spread on trays in all solar dryers and also exposed to full sun as a control. The weights were checked periodically. The peppers were purchased, sorted, cleaned and blanched at 80°C. The moisture content of the pepper was determined using the ASABE 2007 standard, weighed and spread on a tray in a copper and solar dryer time under direct sunlight as a control.

REFERENCES

- Abdullah K, Wulandani D, Nelwan LO, Manalu LP. Recent development of GHE solar drying in Indonesia. Dry Technol. 2001;19(2):245-256.

- Kumar A, Shrivastava V. Historical Trends and Recent Developments in Solar Greenhouse Dryer Operated Under Active Mode: A Review. Indian J Sci Technol. 2017;10(33):1-16.

- Banout J, Havlik J, Kulik M, Kloucek P, Lojka B. Effect of solar drying on the composition of essential oil of sacha culantro (Eryngium foetidumL) grown in the peruvian amazon. J Food Process Eng. 2010;33:83-103.

- Bala BK, Woods JL. Simulation of the indirect natural convection solar drying of rough rice. Sol Energy. 1994;53:259-266.

- Abano EE, Ma H, Qu W. Optimization of Drying Conditions for Quality Dried Tomato Slices Using Response Surface Methodology. Journal of Food Processing and Preservation. 201438(3):996-1009.

Citation: Wu Z (2022) Evaluation of the Performance of Solar Dryers with Reasonable Heat Storage for Agricultural Products. Agrotechnology. 11:254.

Copyright: © 2022 Wu Z. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.