Indexed In

- Online Access to Research in the Environment (OARE)

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- Scimago

- Ulrich's Periodicals Directory

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- University Grants Commission

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2022) Volume 13, Issue 2

Evaluation of Productivity and Profitability of Nile Tilapia (O. niloticus) with Beetroot (Beta vulgaris) and Carrot (Daucus carota)

Teklay Gebru*Received: 28-Jan-2022, Manuscript No. JARD-22-15671; Editor assigned: 01-Feb-2022, Pre QC No. JARD-22-15671(PQ); Reviewed: 15-Jan-2022, QC No. JARD-22-15671; Revised: 18-Feb-2022, Manuscript No. JARD-22-15671(R); Published: 27-Feb-2022, DOI: 10.35841/2155-9546-22.13.669

Abstract

Integrated fish farming system with vegetables using poultry manure as a fertilizer can play an important role in increasing food production, income generation, employment opportunities and waste removal. Thus, the main objective of this study was to evaluate the productivity and profitability of fish-vegetable (beetroot and carrot) integrated aquaculture system. The experiment was conducted from December 2020 to March 2021 in Hawassa University, Ethiopia. For this experiment, one pond with a size of 10 m × 15 m × 1.7 m for fish stocking and 114 m2 lands for vegetable growth was used. In this pond 200 fingerlings of Nile tilapia (O. niloticus) were stocked at a stocking density of 1.3 fish/m2 with average weight of 7.84 g. The pond was fertilized with 0.1 kg/m2/week of poultry manure. In addition to this, the fish was given a supplementary feed. For vegetable growth 24 plots of 2 m × 2 m were prepared and two vegetables namely, beetroot (Beta vulgaris), and carrot (Daucus carota) were planted in three replications of four treatments, i.e., plants treated only with pond water (T1), fertilizer (DAP and Urea) and tap water (T2), manure and tap water (T3) and as a control tap water only (T4). The experimental design for vegetable production was 2 × 4 factorial designs. The average final weight of the fish was 61.76 g and total production of fish was 12,352 g. The results revealed that the edible parts of beetroot and carrot productions were 12.9, 14, 11.8 and 5 kg/plot and 3.8,6.2,3.5 and 2.6 kg/plot in T1, T2, T3 and T4, respectively. Results of the general linear model revealed that beetroot productions of T1 were significantly different (p˂0.05) from T4 but not from (p˃0.05) T2 and T3 while, for carrot production T1 was different from (p˂0.05) T2 and T4 but not from T3. Based on the yield obtained beetroot production was more profitable than carrot production. Cost benefit analysis of the system revealed that net returns of the integrated aquaculture system were higher than unitary farming practices. Depending on the current study fish farmers could improve yields and net profits by using beetroot as vegetable component in integrated fish farming system.

Keywords

Beetroot production; Carrot production; Integrated aquaculture; O. niloticus; Poultry manure

Introduction

Global fish demand is constantly growing due to population growth, increased urbanization and rising incomes. In this regard, fisheries and aquaculture are vital sources for ensuring food security and income, especially for small-scale farmers and fishing communities. Capture fisheries production remained almost stable from the year 2000 to 2018 (from 95.6 to 96.4 million tons) while aquaculture production rose from 35.5 million tons to 114.5 million tons. However, in most parts of the world except Asian countries (such as china and India) aquaculture production was minimal due to outdated fish farming technology, shortage of good quality fish seed and high cost of aquaculture operation [1]. The need for a low-cost system of fish production to meet the food needs of rural and urban poor and also minimize the utilization of resources for greater output become pertinent. This can be done through integrated aquaculture system.

Integrated fish farming system is defined as an aquaculture system that is integrated with livestock and in which fresh animal waste is used to feed fish [2]. The integration of agriculture and aquaculture enables the generation of synergies between farm components. Synergies happen as “waste product from one system in an integrated fish farming system which may be a source of menace to the environment becomes an input to another system leading in a greater efficiency of end product of desired productions from the water and/or land under the farmers control”[3].

Integrated fish farming system is a low cost, more production and no waste disposal in which the waste products of one component are used as an input to another component [4]. Integrated fish culture which has been practiced in Asia for several centuries, has been considered an ideal method of land-use and the common farming activity is cultivation of fish with rice and vegetables [5]. Integrated fish farming aims at minimizing production costs and enhances production by combining two or more normally separate farming systems and it leads to productive use of agricultural byproducts and increases the returns per unit of land area giving a farmer a high disposable income. One of the main organic manure used for pond fertilization is poultry manure because of its adequate amount of major elements (N, P and K) and trace elements [6]. Poultry manure is preferred among all the commonly used manure due to its solubility and high level of phosphorus content [7].

Integrated fish farming is still at rudimentary stage in Africa and only few successful impacts are documented in certain African countries [8]. Potential benefits of integrated Agro-aquaculture are not only a more even distribution of opportunities to generate cash, but also a more efficient and ecologically sustainable use of scarce resources [9]. Integrated fish farming system enhances ecological sustainability since waste materials are recycled, thus reducing their potential for environmental pollution [10]. Recycling of waste products from one product to another not only decreases the production cost but also increases the total production. The production of fish, poultry and vegetable could lead to wealth creation in production unit instead of single product. Elimination of the cost of the water for vegetable irrigation is another economic benefit of integrated agro-aquaculture system.

The common agricultural activity of integrated aquaculture production systems are fish, livestock and crops. They use small area of land and they are suitable and compatible to the agroforestry system of the Ethiopia. In this country, availability of favorable agro-ecology, abundant seasonal rainfall and several small water bodies create conducive environment for integrated aquaculture system. Vegetable productions such as beetroot, lettuce, spinach and carrot are common in Ethiopia but they are not produced though integrated aquaculture system. They are cultivated by using fertilizers and the cost of spinach, lettuce and carrot is high as compared to other vegetables. In addition to that, they are nutritious food items (in health aspect) and they are cultivated in every parts of the country. The abundance of small water body can be used to integrate aquaculture and these vegetables and thereby to reduce poverty in rural areas of Ethiopia particularly in southern region where the population density is high [11]. Despite the availability of huge water resources, healthy climatic conditions, topography and varied soil conditions conducive to start integrated fish farming with other agricultural activities in Ethiopia, it is still very limited [12].

Ethiopia has great potential for integrated aquaculture development and the initiation of this system seems to be one of the means of providing animal protein. The current increasing market demand for fish protein in Ethiopia can be met through diversified aquaculture especially integrated aquaculture. Some studies have been carried out by different authors [13-17]. However, integrated aquaculture production system is not well evaluated by researchers and not manipulated by farmers in such a way that increases yield from small area of land by minimizing the overall input costs and maximizing the net profit. Therefore, the present research was undertaken to evaluate the productivity and profitability of integrated aquaculture production system of fish with chicken manure and vegetable farming in Hawassa University of Southern Ethiopia. The general objective of this study was to evaluate the productivity and profitability of integrated aquaculture production system with fertilizer (DAP and Urea), compost and tap water for improved farming practices.

Materials and Methods

Description of the study area

The experiment was conducted at the experimental site of Centre for Aquaculture Research and Education (CARE) Hawassa University and which is found in the southern part of Ethiopia at 275 km South of Addis Ababa, the capital city of Ethiopia. It is located at 7°3’7” N latitude and 38°3’17” E longitude and situated at 1714 meter above sea level. The experiment was conducted from December 2020 to March 2021.

Experimental design

The experimental design was 2 × 4 factorial designs with 3 replications (Table 1).

| Code | Treatments |

|---|---|

| T1 | Vegetable production with pond water only (300 L/plot/week) |

| T2 | Vegetable production with tap water+Fertilizer (300 L/plot/week and 100 kg/ha, DAP and urea) [15] |

| T3 | Vegetable production with tap water+compost (300 L/plot/week and 5 kg/plot) |

| T4 | Vegetable production with tap water only (300 L/plot/week) |

Table 1: Treatment design for vegetable production.

Land and pond preparation

For fish stocking, 15 m × 10 m × 1.70 m size of pond was prepared and filled with water at 1.30 m depth. For vegetable production, a total of 24 vegetable plots with 2 m × 2 m size on 114 m² of land were prepared and used for planting of two types of vegetables, namely: Beet root (Beta vulgaris) and carrot (Daucus carota).

Supplementary feed preparation and pond fertilization

Supplementary fish feed was prepared from feed ingredients such as meat bone meal (20.8%), soya bean cake (33.4%), maize flour (18.3%), wheat flour (25%) and soya bean oil (2.5%) which is processed by mixing the ingredients and preparing in pellet form. Daily feed requirement of the fish was calculated based on 2% body weight of fish [18]. Daily feed requirement was adjusted based on average weight calculated from the two weeks of weight measurements. Chicken manure was applied weekly at 10:00 am by spreading all over the pond at a rate of 0.1 kg/m² poultry manure [19]. In addition to poultry manure, the fish fingerlings were given a supplementary feed two times a day (from 9:00 A.M to 10:00 A.M and from 16:00 P.M to 17:00 P.M) by broadcasting over the pond [18]

Experimental fish and vegetable seeds collection

O. niloticus fingerlings were obtained from experimental site of CARE Hawassa University, Sidama Region, Ethiopia. The average weight of the fingerlings was 7.84 g. The vegetable seeds were purchased from vegetable seed market in Hawassa town.

Fish stocking and preparation of vegetable seed lings

200 fingerlings of O. niloticus were stocked in to 15 m × 10 m × 1.70 m size pond at a stocking density of 1.3 fish/m2. After proper preparation of the plots, carrot seeds were mixed with sand at 3:1 and sowed directly to plots as carrots are not transplanted plants. The other vegetable (beetroot) were sowed near the pond and transplanted to the plots after five weeks. Each of the 24 plots was planted with the two different types of vegetables in triplicates. The space between plots was 20 cm and between each seedling was 10 cm. Watering was conducted with the respective water types three times a week. The inorganic fertilizers DAP and urea 100 kg/ hectare was applied at sowing and after 40 days of vegetable sowing [15], respectively. Similarly, compost was added at sowing and after 40 days of vegetable transplanting at a ratio of 5 kg/plot.

Data collection

Estimation of growth parameters of O. niloticus: The main body measurement parameters of fish such as body weight and length were recorded twice a month. Fish weight was recorded to the nearest 0.1 g with a weighing balance (SF 400A, Electronic Compact Scale) and total length (TL) was determined using a graduated ruler to the nearest 0.1 cm. The main growth parameters such as average final weight gain, average final length gain, dailsy weight gain, specific growth rate, Fulton’s condition factor and survival rate were calculated as used by [20].

Average initial weight (g)=(sum of individual weight at the begning)/ (total number of individuals)

Average final weight (g)=(sum of the individual weight at the end )/ (total number of individuals)

Weight gain (g)=Final weight (g)-Initial weight (g)

Daily weight gain (g/fish/day)=((average final weight-average inital weight) )/(culturing period(days))

Specific growth rate (% per day)=((In final weight-In initial weight))/ ((cultuting period(days))*100)

Fulton condition factor=weight/(length³*100)

Survival rate (%)=(final number of fish)/(initial number of fish*100)

Estimation of total production of vegetables: At the end of the experimental period roots of beetroot and carrot were harvested once in four months of the experimental period. Their yield was weighed using a weighing balance (SF 400 A, electronic compact scale) and the yield of each plot from every treatment was recorded. Finally, the yields of both Rooty vegetables in four treatments were reported as kg/plot and kg/hectare.

Cost benefit analysis of the system: The cost benefit analysis of fish and vegetable production was determined by calculating the difference of total cost and total revenue generated from the system. Total revenue was calculated from a total income of vegetable yield and fish yield values and total cost included pond maintenance, fertilizer, supplementary feed, pesticide, vegetable seeds purchase, labor cost and land preparation. Net profit was calculated by subtracting total cost from total revenue. Costs and revenue analysis were made using the estimated cost-revenue of the local area at the first week of April 2021. Total return or profit of the system was calculated by summation of profit from the two subsystems. The economic variables determined included net return or profit of the integrated aquaculture system. Cost benefit analysis was calculated based on the following formulas cited in [19].

Total Variable cost (TVC) given by Price of unit Input (Px) × Quantity Input (Qx)

Total cost=TVC+fixed cost

Total Revenue (TR) given by Price per unit (P) × Quantity in Kg (Q)

Profit=Total revenue-Total Cost

Physicochemical parameters: The main water quality parameters such as water temperature, dissolved oxygen (DO), pH and secchi depth visibility were measured once in a week. Samples for temperature and dissolved oxygen (DO) measurements were taken by using (HI 9145, DISSOLVED OXYGEN METER) while, pH was measured using (ECO-CHECK). Secchi depth visibility of the pond was measured by secchi-disc once in a week and ammonia concentration was measured in the laboratory by Palin test method once in a month.

Data analysis: Data analysis was done with the use of Microsoft excel 2010 and SPSS Statistical package and the differences at P<0.05 was considered significant [21]. Length weight relationship and growth performance of fish were analyzed by Microsoft excel 2010. Vegetable yield data was analyzed using two-way ANOVA in SPSS. Vegetable yields using different treatments were subjected to ANOVA using General Linear Model (GLM) procedure of SPSS Version 25 (SPSS 2017). Means was compared using Duncan’s Multiple range test at P<0.05. The model used for analysis of the two vegetable yields in four treatments was

Yi=μ+αi+βi+еi

Where: Yi=Vegetable yield in kg (i=beetroot and carrot); μ=over all mean; αi=effect of four treatments; βi=effect of vegetables and ei=random error.

Results

Physicochemical parameters

Data on the physicochemical parameters measured during the study period such as temperature, pH, DO, NH³, and secchi depth visibility are presented in Table 2. There was an increasing trend in water temperature from December up to March. Dissolved oxygen content showed an inverse relation with water temperature in which minimum (3.9 mg/l) value was recorded in March and maximum (4.3 mg/l) in December. The minimum and maximum pH recorded during the experimental period was 8.0 and 8.6, respectively. The ammonia concentration showed slight increase from December up to February. Similarly, chlorophyll a concentration showed steady increase from December to March. The growth performance of O. niloticus in this study was not significantly affected by physicochemical parameters thus, the condition was normal for fish growth (Table 2).

| Parameters | Average value |

|---|---|

| Temperature (°C) | 25.9 |

| PH | 8.3 |

| dissolved oxygen (mg/l) | 4.1 |

| NH3 (mg/l) | 0.065 |

| Secchi depth visibility (cm) | 34 |

| Chlorophyll a (µg/l) | 60.7 |

Table 2: Physicochemical values of the integrated aquaculture system (Mean ± Standard error).

Growth performance of O. niloticus

The data on the growth parameters of fish such as final weight gain, Fulton’s condition factor, specific growth rate and survival rate are summarized in Table 3. The average initial length of fishes stocked was 8.28 cm and the average initial weight was 7.84 g. After four months of rearing, the fish attained 61.76 g average final weight and 14.8 cm average final length with 53.92 g body weight gain, 0.45 daily growth rates, 1.72% SGR and 1.92 condition factors. About 8% of the fish attained weight greater than 100 g and 28% of fishes were more than 80 g (Table 3).

| Growth parameters | Growth performance |

|---|---|

| Mean | |

| Average initial length (cm) | 8.28 ± 1.4 |

| Average final length (cm) | 14.8 ± 2.3 |

| Average initial weight (g) | 7.84 ± 1.6 |

| Average final weight (g) | 61.76 |

| Weight gain (g) | 53.92 |

| Daily weight gain (g) | 0.45 |

| Specific growth rate (%) | 1.72 |

| Fulton’s condition factor | 1.92 |

| Survival rate (%) | 100 |

Table 3: Growth parameters of O. niloticus (Mean ± SE).

Growth performance of O. niloticus

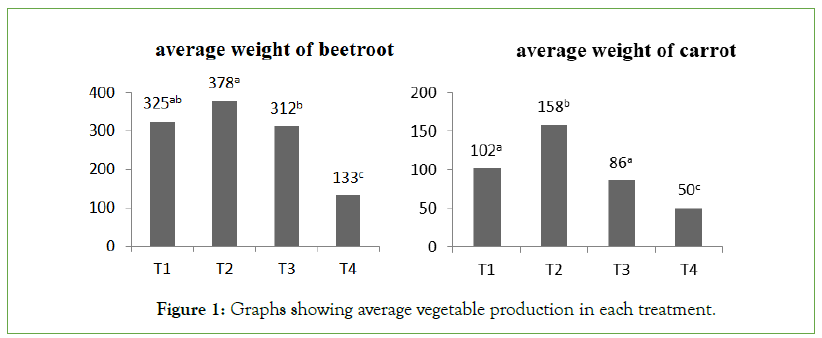

The data on the growth parameters of fish such as final weight gain, Fulton’s condition factor, specific growth rate and survival rate are summarized in Table 3. The average initial length of fishes stocked was 8.28 cm and the average initial weight was 7.84 g. After four months of rearing, the fish attained 61.76 g average final weight and 14.8 cm average final length with 53.92 g body weight gain, 0.45 daily growth rates, 1.72% SGR and 1.92 condition factors. About 8% of the fish attained weight greater than 100 g and 28% of fishes were more than 80 g (Figure 1).

Figure 1: Graphs showing average vegetable production in each treatment.

For beetroot the highest yield (14 kg/plot) was obtained from treatment (T2) followed by T1 (12.9 kg/plot) and T3 (11.8 kg/ plot) while, the least was obtained from T4 (5 kg/plot). Beetroot productions of T1 were significantly higher than (p˂0.05) T4 but not from T2 and T3. For carrot the highest yield (6.2 kg/plot) was obtained from treatment (T2) followed by T1 (3.8 kg/plot) and T3 (3.5 kg/plot) while, the least was obtained from T4 (2.6 kg/ plot). Moreover, carrot productions of T1 were significantly lowers than (p˂0.05) T2 and were significantly higher than (p˂0.05) T4 but not from T3. The overall vegetable yield in each plot of land is presented in Table 4. The current study revealed that the average vegetable production using pond water (213.5 g) was significantly lower than (p<0.05) average vegetable production using fertilizer (268 g) but, significantly higher than (p<0.05) tap water (91.5 g) and it was not significantly different (p>0.05) from vegetable production using compost (199 g) (Table 4).

| Treatment | ||||||||

|---|---|---|---|---|---|---|---|---|

| Veg. type | T1 | T2 | T3 | T4 | ||||

| Estimated production | Estimated production | Estimated production | Estimated production | |||||

| kg/plot | kg/hec. | kg/plot | kg/hec | kg/plot | kg/hec | kg/plot | kg/hec. | |

| Beetroot | 12.9ab | 32,250 | 14.0a | 35,000 | 11.8b | 29,500 | 5.0c | 12,500 |

| Carrot | 3.8a | 9,500 | 6.2b | 15,500 | 3.5a | 8,800 | 2.6c | 6,500 |

Table 4: Estimated vegetable production kg/plot (kg/4 m²) and kg/hectare (kg/10,000 m²).

Cost benefit analysis

In the present study of integrated fish farming system, the total estimated cost of production in the T1, T2, T3 and T4 was 792.5ETB, 852.5ETB, 792.5ETB and 792.5ETB respectively with a total estimated production cost of 5480 ETB. The revenue obtained from T1, T2, T3 and T4 was estimated to 1036.5 ETB, 1374ETB, 953.4ETB and 537ETB, respectively. A total of 9900.9ETB was generated as revenue. The total cost for vegetables and fish was 5480 ETB. The estimated profit obtained from the four treatments and fish sell was 4420.9 ETB (Tables 5 and 6).

| Treatments | ||||

|---|---|---|---|---|

| Costs of vegetable production in 228 m2 | T1 | T2 | T3 | T4 |

| Vegetable seed purchase | 55 | 55 | 55 | 55 |

| Vegetable land preparation | 200 | 200 | 200 | 200 |

| Fertilizer | - | 60 | - | - |

| Insecticide | 37.5 | 37.5 | 37.5 | 37.5 |

| Monthly workers | 500 | 500 | 500 | 500 |

| Vegetable sell | 1036.5 | 1374 | 953.4 | 537 |

| Total input cost | 792.5 | 852.5 | 792.5 | 792.5 |

| Total income | 1036.5 | 1374 | 953.4 | 537 |

| Net profit from each treatment | 244 | 521.5 | 160.9 | -255.5 |

| Total profit of the whole system | 670.9 | |||

Table 5: Partial budget analysis of vegetable production.

| Fish production cost and net profit in Ethiopian birr (ETB) | |

|---|---|

| Pond maintenance | 1200 |

| Supplementary feed preparation | 1050 |

| Total cost in fish component | 2250 |

| Revenue generated from fish sell | 6000 |

| Total profit (revenue-cost) | 3750 |

| Vegetable production cost and net profit in Ethiopian birr (ETB) | |

| Estimated cost for land preparation, weeding | 800 |

| Purchase of vegetable seed | 220 |

| Purchase of pesticide and fertilizer | 210 |

| Estimated labour workers | 2000 |

| Total cost | 3230 |

| Revenue generated | 3900.9 |

| Profit from vegetable | 670.9 |

| Net profit of the whole system in Ethiopian birr (ETB) | |

| Total cost for fish and vegetables | 5480 |

| Total revenue generated from fish and vegetable sells | 9900.9 |

| Total profit (total revenue-total cost) | 4420.9 |

Table 6: Partial budget analysis of fish and vegetable production.

Discussion

Physicochemical parameters

Water temperature of the current study ranged from 24.6 ± 0.4°C to 27.3 ± 0.4°C with an average temperature of 25.9°C, where the minimum being in December and the maximum in March. Water quality parameters measured during the experimental period was remained within the acceptable range required for normal growth of O. niloticus. The metabolic activity and physiological functions of aquatic animals (e.g., feed utilization, feed conversion, and growth rates) can be affected by the water temperature [22-24]. This was evident from the result wherein fish growth rate increased when water temperature increased.

Temperature results of the current study was within the recommended values for better growth rate of O. niloticus ranging from 24°C to 30°C and 24.2°C-27.7°C [25,26]. The mean pH value of this experiment was found within the recommended range of 6.7- 8.6 and 6.5-9.0 [27-29]. Ideally, an aquaculture pond should have a pH range between 6.5 and 9 which is optimum and conducive to fish life [30,31]. The mean value of DO of this experiment was 4.1 mg/l, this value is more than the required amount for tilapia because it can survive below 2.3 mg/l as long as the temperature and the pH value remained constant [28]. DO greeter than 5 mg/l support good fish production. The result of the present study is inconsistent with results recommended by [24,31]. The reason for the lower DO value in this study may be due to decomposition of chicken manure used and feed remains, consequently resulting into depletion of dissolved oxygen within the fish pond.

Ammonia is a toxic material that is found in organic materials and many fertilizers. It is released in pond water during metabolism as an end product of digestion of the fish feed as a main nitrogenous waste excreted by most fish and freshwater invertebrates through the gills and faeces and decomposition of organic matter by bacteria. The amount of NH³ excreted by the fish is dependent on the amount of protein present in the feed, the quantity of feed added in to the aquaculture ponds and the rate of feeding. The amount of toxic ammonia increases about 10 times for every pH increase of one unit [32]. The optimal range of NH³ is 0.02-0.05 mg/l in fish ponds [29]. The desirable range of ammonia for fish farming is <0.1 mg/l [33]. The higher water temperature and pH, the greater the concentration of the toxic ammonia (NH³) formed. Increasing pond aeration, regular water change, addition of quicklime’s are some of the ways that farmers can use for managing ammonia concentration within their fish ponds [34]. Transparency is the ability of light to penetrate and support photosynthesis and is the resultant effect of several factors [19]. A secchi depth visibility of 15 to 80 cm is good for fish health in aquaculture while a secchi depth visibility below 12 cm may cause stress to fish. The average secchi depth value 34 cm recorded from the present study was within the recommended range of the above authors [25,31].

Growth performance of O. niloticus

In the current experiment there was high daily growth rate, Fulton’s condition factor, specific growth rate and survival rate of fish. This may be due to the good water quality management and the availability of natural food in the culture pond grown as a result of the application of organic manure and the remains of artificial fish feeds. Supplementary feeding is recommended in small scale and/or commercial fish culture because natural fish food organism (plankton) may not be enough to meet protein requirement of fish [35]. It has been suggested that higher gross fish production is probably supported by the role of both organic manure and supplementary feed [36].

Daily growth rate of O. niloticus in the present study was 0.45 gram/ day/fish. The daily growth rate of the current study was higher compared with 0.3 gram/day/fish [37]. The difference in daily growth rate may be due to the difference in application of poultry manure. The daily growth rate of O. niloticus of the current study was very similar with (0.46 gram/day/fish) reported by [13,38]. Daily growth rate in this study were lower than those reported for O. niloticus (0.75 gram/day/fish) by [16]. The reason for higher weight gain may be due to higher initial body weight at stocking (32.0 ± 7.51) or it may be due to higher amount of poultry manure applied to the pond 10 kg fresh poultry manure per week. Another reason for higher daily growth rate may be due to they used a fresh chicken manure which is of higher quality than older manure collected from poultry farm or dairy farm [39]. Furthermore, in integrated fish-poultry farming the pond is continually fed in gradual amounts with dropping from chicken, whereas poultry manure application is time bound.

The specific growth rate of the current study was 1.72. Specific growth rate reported in this study was lower compared to 2.79 in an integration of chicken manure with supplementary feed which [19]. The reason for the lower specific growth rate of the current study may be due to the application of lower amount of poultry manure. The specific growth rate of the current study is in agreement with the specific growth rate ranging from 1.8 to 2.2 reported by [37]. However, the specific growth rate of the current study is higher than 1.45 reported by [38].

Condition factor is affected by several environmental factors such as seasonal variation, types of feed and age of the fish [40]. There may be differences in the condition factor due to sex and environmental conditions such as pollution [41]. Since Fulton’s condition factor, K is a measurement involving the length and weight for a particular fish; therefore it could be influenced by the same factors as length weight relationship. If the K value is 1.00, the condition of the fish is poor, long and thin, besides, a 1.20 K value indicates that the fish is of moderate condition and acceptable to many anglers, a good and well-proportioned fish would have a K value that is approximately 1.40 [42]. Based on this criterion, the sampled fishes in the present study were in a good condition (K=1.92). The survival rate of O. niloticus in the present study was 100%. The reason for higher survival rate obtained in the present study could be due to the favorable environmental conditions for survival of O. niloticus throughout the experimental period.

Vegetable production of the system

It has been reported that poultry manure is the most efficient way of adding nitrogen and other essential nutrients in fish ponds [43]. Integrated agro-aquaculture farming is ecologically sound because water from fish ponds improves soil fertility by increasing the availability of nitrogen and phosphorus [44].

Beetroot production results of the present study (12.9 kg/plot) confirmed the previous works of better yield of beetroot in an integrated poultry-fish vegetable and recorded a yield of 12.8 kg/ plot [45]. Similarly, the current findings of Beetroot production recorded in this study are also in agreement with the productivity yield of 11.2-16.17 kg/plot [39]. In addition, Beetroot production recorded in this study is also in agreement with yield of 12 kg/plot [46]. Carrots produced in this study (3.8 kg/plot) did not agree with the yield of 20.6-32.2 kg/plot in an integrated aquaculture system [39]. Higher yield of carrot ranging from 12-16 kg/plot was also reported elsewhere [46]. This may be due to the difference in germination of the seed and also the suitability of the soil.

The advantage of having horticulture component in the integration can be seen as alternative way of vegetable production for home consumption and also as a source of income, minimizing input cost and environmental pollution [14]. The system also minimized environmental pollution caused by waste from poultry farm and fish pond, rather recycled the waste to produce food. The study revealed that vegetable plots that received water from the pond water attained high yields and income next to fertilizer.

Depending on the current study integrated aquaculture production system to food production could be used in combating the wide spread problem of malnutrition which prevails in most rural areas of Ethiopia. The production of animal protein from fish and poultry and other integrated animals could contribute significantly to wealth creation in our country. Integrated farming systems also serve as a possible approach towards the conservation, reuse and efficient management of the scarce water resources [39].

Economic benefits of the system

In the present study the highest net profit was generated from treatment one (T1) this was because of higher yields of fish and vegetable compared to vegetable productions only. In the present study fish and vegetable production using pond water 7036.5 ETB was 5.1 times more profitable than vegetable production using fertilizer 1374 ETB. Fish and vegetable production using pond water was 7.4 times more profitable than vegetable production using compost 953.4 ETB. Fish and vegetable production using pond water was 13.1 times more profitable than vegetable production using tap water 537 ETB. The profitability of the current study in 24 m2 vegetable plots and 150 m2 ponds is 7036.5 ETB (293.2 ETB/m2) was higher than the profitability of 12,030 ETB in 260 m2 land usage and 150 m2 (29 ETB/m2) of pond [14]. Moreover, the profitability of the current study was also higher than the net profit of 9,336.13 ETB in 0.25 hectare of land usage and 150 m2 (3.5 ETB/m2) of pond [15]. The reason for the higher profitability of the current production system may be due to lower labor cost and there was no poultry production cost.

In the current study significantly higher net income from tilapia cultured in fertilized pond with supplementary feeding was recorded. About 60 to 70% of fish farm operation cost is fish feeds and fish feed prices have increased significantly which reduced the profit margin of fish farming. Thus, the use of manure to fertilized ponds may lead into reduction of supplementary feed and increase yield and income.

Chicken manure has been used extensively in small scale fish farming for increasing availability of natural food in pond hence reducing requirements of artificial feeds consequently leading to reduction on production costs and therefore improving farm income [47]. However, for better fish growth performance and yield additional feed to optimize production of fish as well as vegetables is emphasized. Supplementary feed is required to increase fish yield in fertilized ponds. The present study confirms that integrated aquaculture using manure and supplementary feed improve income. This proves that integrated fish-poultry-vegetable farming is not only technically feasible but also economically viable. Integrated production approach with poultry, fish and vegetables lead to improving diversification of food production and income generation of the resource poor farm households [48]. Furthermore, economic analysis from the present study suggests that using water from fish ponds increase vegetable productivity hence increase economic returns.

Generally small scale farmers can have an access to sufficient vegetables round the year for their nutrition by applying integrated agro aquaculture system. In this case, vegetable production in integrated aquaculture system can be maximized the year round availability of vegetables for family consumption of the farmers. Moreover, cash from selling of additional vegetables can contribute to increased total income of the households. Nevertheless, this system for vegetable production can demonstrate a remarkable impact on the resource utilization for small-scale farmers having similar ponds for family nutrition and income generation.

Conclusion and Recommendations

The use of poultry was manure as a pond fertilizer was found to be effective for integrated fish farming. In the current study there was high daily growth rate, specific growth rate, condition factor and survival rate of the fish. Moreover, in the current study high amount of chlorophyll a was recorded which indicates that there was plenty of phytoplankton biomass needed for pond productivity and for fish feed, these phytoplankton was grown as a result of poultry manure application. According to the current finding the highest production was obtained from beetroot while, the least was obtained from carrot. In the present study the highest total revenue and net profit was obtained from the integrated aquaculture system than the unitary farming system.

Generally, sustainable integrated farming system leads to overall farm productivity and better economic return of rural pond-based farming community. Therefore, pond based integrated farming practice may be one of the significant, efficient and viable option to achieve optimum production with cost effective low investment, recycling of wastes and residues from one farming system to other farming system.

• Further research is needed to enhance carrot production in an integrated aquaculture system.

• Further research is needed on fish growth performance with one vegetable type.

• Beetroot production using integrated fish production system is recommended for integrated fish farmers.

REFERENCES

- FAO. The State of World Fisheries and Aquaculture 2020. Sustainability in action. Rome, 2020;224.

- Edwards P. Sustainable food production through aquaculture. Aquac Asia. 1997;2(1):4-7

- Edwards P. A systems approach for the promotion of integrated aquaculture. Aquac Econ Manag.1998;2(1):1-12.

- Ayinla O. Integrated fish farming: A veritable tool for poverty alleviation/Hunger eradication in the Niger Delta Region. Conference Proceedings of Fisheries Society of Nigeria, Owerri, Nigeria. 2003; 40-41.

- Eyo A, Ayanda J, Adelowo E. Essentials of integrated fish farming. National Institute of Fresh Water Fisheries Research, P.M.B 6006, New Bussan, Niger State. 2006;1-207.

- Vohra A, Narejo N, Naeem M, Wadhar G, Dayo A. Effect of dry poultry wastes on the physicochemical and fish growth parameters of C. carpio at carp hatchery (District Badin), Sindh, Pakistan. Res Jour Sci. 2012;44(2):239-244.

- Knud H, Batterson T, McNabb C, Harahat I, Sumantadinata K, Eidman H. Nitrogen input, primary productivity and fish yield in fertilized freshwater ponds in Indonesia. Aquac. 1991;94:49-63.

- Rasowo J, Auma E, Ssanyu G, Ndunguru M. Does African Cat Fish (C. gariepinus) affect rice in integrated rice-fish culture in Lake Victoria Basin, Kenya? Afr J Environ Sci Technol. 2008;2(10):336-341.

- Prein M. Integration of aquaculture into crop–animal systems in Asia. Agricultural Systems. 2002;71:127–146.

- Jayanthi C, Mythili S, Balusamy M, Sakthivel N, Sankaran N. Integrated nutrient management through residue recycling in lowland integrated farming systems. Madras Agric J. 2003;90:103-107.

- Hussein Abegaz. The pilot project on aquaculture development in Ethiopia: Bridging the gap of fish seed demand through hatchery establishment & village-based extension approach. Ministry of Agriculture and Rural Development, Kampala. 2009;24:52-58.

- Javed M, Muhammad H, Sial M. Fish pond fertilization. IV. Effect of Cow-Dung on the growth performance of major Carps. Pakistan J Agri Sci.1992;29(2):111-115.

- Adugna B, Prabha D, Sreenivasa V, Aschalew Lakew. A study on the profitability of fish and horti crop integrated farming at Nono District, West Shoa Zone, Ethiopia. Greener J Agric Sci. 2016;6(2):041-048.

- Tugie D, Abebe A, Endebu M. Potential of integrated fish-poultry-vegetable farming system in mitigating nutritional insecurity at small scale farmer’s level in East Wollega, Ethiopia. Inter J Fish & Aqua. Stud.2017;5:377-382.

- Getu D, Amare F, Berhanu T, Kinfo H, Terefe T. Evaluation of integrated fish farming with chicken and vegetables in Silte district of southern Ethiopia. J Biol Agric & Healthcare. 2017;7(23):51-59.

- Endebu M, Tugie D, Negisho T. Fish growth performance in ponds integrated with poultry farm and fertilized with goat manure: a case in Ethiopian rift valley. Int j aquac fishery sci. 2016;3:40-45.

- Debebe S. Studies on growing fish farming practices in selected districts of SNNPRS, Ethiopia. American-Eurasian J Agric & Environ Sci. 2017;17:155-160.

- El-Sayed A. Tilapia feed management practices in sub-Saharan Africa. In: On-farm feeding and feed management in aquaculture (M.R. Hasan M.B. New eds.), FAO Fish Aqua Tech Pap FAO, Rome, Italy. 2013;583:377–405.

- Mlelwa T. Growth performance and economic benefit of Nile tilapia (O. niloticus) and Chinese cabbage (Brassica rapachinensis) in aquaculture integration. Sokoine University of Agriculture. Morogoro, Tanzania. MSc. thesis. 2016;74.

- Gebreanenia G. Evaluation of growth performance and body proximate composition of three strains of O. niloticus L., (1758) under greenhouse condition. MSc. Thesis, Addis Ababa University, Addis Ababa. 2018; 55.

- Zar, J. Bio statistical Analysis 3rd edition. Northern Illinois University. 1999;663.

- Halver I, Hardy R. Fish nutrition an important of Elsevier science. London, academic press. 2002.

- Balkew K. Evaluation of growth performance, feed utilization efficiency and survival rate of juvenile O. niloticus reared at different water temperature. J Int Aqua. 2012;2(9):59-64.

- Santhosh B, Singh N. Guidelines for water quality management for fish culture in Tripura, ICAR Research Complex for NEH Region, Tripura Centre, Publication. 2007;29.

- Yimer A, Dagne A, Tadesse Z. Effects of feed additives (premix) on growth performance of O. niloticus (L, 1758) in concrete pond Sebeta, Ethiopia. J Afr Dev. 2015;5:16-36.

- Abdel-Tawwab M, Hagras A, Elbaghdady H, Monier M. Effects of dissolved oxygen and fish size on Nile tilapia: growth performance, whole-body composition and innate immunity. Aquac Int. 2015;23:1261-1274.

- FAO. 2011. Fisheries and Aquaculture Department

- Charles C, James R, and Bethuel O. A new guide to fish farming in Kenya. Department of Fisheries and Aquatic Sciences, Moi University. 2007;63.

- Bureau of Fisheries and Aquatic Resource (BFAR). Basic biology of Tilapia. 1992;2.

- Wurts W, Durborow R. Interactions of pH, carbon dioxide, alkalinity and hardness in fish ponds Southern Regional Aquaculture Centre. 1992;464.

- Bhatnagar A, Jana S, Garg S, Patra B, Singh G and Barman U. Water quality management in aquaculture. In: Course manual of summers school on development of sustainable aquaculture technology in fresh and saline waters, CCS Haryana agricultural, Hisar (India). 2004;203-210.

- Durborow R, Crosby M, Brunson M. Ammonia in fish ponds. SRAC. Aquac.1997;76 (3-4):293-301.

- Boyd, C. Water quality for pond aquaculture, research and development series No.43. International Centre for Aquaculture and Aquatic Environments, Alabama Agricultural Experiment Station, Auburn University, Alabama. 1998.

- Bhatnagar A, Devi P. Water quality guidelines for the management of pond fish culture. Int J Environ Sci.2013;3(6):1980–2009.

- Brown C, Bolivar R, Jimenez E, Szype J. Timing of the onset of supplemental feeding of Nile tilapia (O. niloticus) in ponds. Proceedings of the Fifth International Symposium, Rio De Janeiro, Brazil. 2000.237.

- Abass N, El-Wakil H, Seehy M, El-Dahhar A, Ibrahim M, Hemeida A. The effect of environmental condition of genetic background in Nile tilapia. J Arabian Aquac Soc. 2010;5(1):101-118.

- Ester E. Comparative evaluation of growth performance and yield of four tilapia species under culture conditions. MSc. Thesis. Sokoine University of Agriculture. Morogoro, Tanzania. 2013;83.

- Shoko A, Getabu A, Mwayuli G, Mgaya Y. Growth performance yields and economic benefits of O. niloticus and Kales (Brassica oleracea) cultured under vegetable-fish culture integration. Tanz J Sci. 2011;37:37-48.

- Prinsloo J, Schoonbee H, Theron J. The production of poultry in integrated aquaculture-agriculture systems. Water S. A. 1999;(2):231-238.

- Noor E, Deen A, Mona S. Impact of climate changes oxygen and temperature on growth and survival rates of Nile tilapia. Aquac. 2010;232:117-127.

- Olurin K, Aderibigbe O. Length, weight relationship and condition factor of pond reared juvenile O. niloticus. World J Zoology. 2006;1:82-85.

- Barnham C, Baxter A. Condition factor for Salmonid fish. Fisheries Notes. 1998;3.

- Ahmed E, Ali M, Aziz A. Length-weight Relationships and Condition factors of six fish species in Atbara River and Khashm el girba Reservoir, Sudan. Int J Agric Sci. 2011;3 (1):65-70.

- Dugan P, Dey M, Sugunan V. Fisheries and water productivity in tropical river basins: enhancing food security and livelihoods by managing water for fish, water management. J Agric Sci.2006;80:262-275.

- Prinsloo J, Schoonbee H. Investigations in to the feasibility of a duck-fish-vegetable integrated agriculture-aquaculture system for developing areas in south Africa. Water S. A. 1987;13(2):109-118.

- Coertze A. Vegetable information table. Vegetable and Ornamental Plant Institute. Agricultural Research Council. Rode plat, Pretoria. 1996; 7.

- Abdel-Wahab A, Abdel-Warith A. Effect of fertilization sources with artificial feeding on growth performance, water quality and returns of mono sex O. niloticus reared in earthen ponds. J Aquat Biol Fish.2013;17(2):91-104.

- Alam M, Robiul M, Akkas A, Akhtar H, Molla H,Islam F. Integrated approach of pond-based farming systems for sustainable production and income generation. Bangladesh J Agr Res. 2009;34:577-584.

Citation: Gebru T (2022) Evaluation of Productivity and Profitability of Nile Tilapia (O. niloticus) with Beetroot (Beta vulgaris) and Carrot (Daucus carota). J Aquac Res Dev. 13:669.

Copyright: © 2022 Gebru T. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.