Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Review Article - (2020) Volume 10, Issue 1

Epoxy/Fly ash from Thermal Power Plant/Nanofiller Nanocomposite: Studies on Mechanical and Thermal Properties: A Review

Shilpi Tiwari1*, Kavita Srivastava2, Gehlot CL3 and Deepak Srivastava12Department of Chemistry, Vikramajit Singh Sanatan Dharma College, Kanpur, India

3Department of Chemistry, School of Basic and Applied Sciences, Harcourt Butler Technical University, Kanpur, India

Received: 27-Nov-2019 Published: 22-Feb-2020, DOI: 10.35248/2252-5211.20.10.375

Abstract

A recent development in the field of eco-friendly, lightweight and high-performance nanocomposite and a broad range of their innovative applications attract enormous interest in the field of research. However, the search for lighter materials to replace legacy heavy materials in engineering structures especially in automobile and aerospace industries has made the study of tribological properties of epoxy resin based composites significant. Fly ash, from the thermal power plant, is an industrial by-product that can be utilized as filler in epoxy resin with different wt% owing to its distinctive properties like low density, wide availability, good filler factor, good thermal resistance, and glassy nature instead of dumping into the large area of landfills and ash ponds. This review article presents an expanded literature overview on the utilization of industrial waste fly ash, as reinforcement for matrix in making lightweight, high strength composites. In this investigation broaden literature groundwork also covers the effect of nanoparticles on thermal, morphological and mechanical characteristics such as impact strength, tensile strength and flexural strength of fly ash/epoxy nanocomposites.

Keywords

Fly ash; Nanofiller; Epoxy resin; Nanocomposites; Mechanical properties

Methods for Dispersion of Various Nanofillers in Matrix

During the fabrication of epoxy nanocomposite, two main greatest challenges endure i.e. homogeneous dispersion of nanofiller and interfacial nanofiller polymer interaction. Therefore, all the properties of nanocomposite are affected by better dispersibility of nanofiller, which provides maximum surface area for neighboring polymeric chains. Owing to an extremely higher ratio of surface to volume of nanofiller, the nanoparticles arrange adjacently and form micron-sized filler clusters aggregate which restricted homogeneous dispersion of nanoparticles in a polymer matrix. That attracts researchers to develop a preferred way of homogeneous dispersion and de-agglomeration of nanofillers [44,45]. This agglomeration of nanoparticle takes place due to a difference in the density of reinforced material and polymer matrix. This arises as an absence of needed force to breakdown it. By stirring at higher speed, the shearing force is enforced on polymer matrix resulting in transition for the reinforced phase to motion inside over the vortex produced by stirring. The higher speed of stirrer is capable to distribute the reinforced phase which creates homogeneous dispersion of incorporated phase into the polymer matrix. Consequently, the processing techniques affect the dispersion of nanofiller for any matrixes. Because of this issue, the numerous physical stirring methods such as mechanical stirring, high shear mixing, solvent mixing, and ultrasonic bath stirring were attempted. These methods have been explored to obtain a homogeneous dispersion of nanofiller in the matrix. The results showed that stirring methods had a significant effect on dispersion quality, as the inclusion of voids between nanofiller and matrix reduces the mechanical properties of polymer nanocomposite [47,48]. The appropriate dispersion of reinforcing material into the polymer matrix is also impressed by the pouring rate, pouring temperature and gating systems. The dispersion of reinforcement material is affected during various stages along with (a) dispersion in the matrix as a result of mixing, (b) dispersion in the matrix after mixing, but before curing and (c) redistribution as a result of curing. Some parameters such as relative density, wetting condition of material and settling velocity also affect the distribution of dispersed phase.

Ultrasonic oscillations

Among various mechanical stirring methods, the ultrasonic vibrations were found more impressive in improving the homogeneous distribution of nanofillers both in solution and melt polymers as compared to other methods. Ultrasonic vibration supply ultrasound waves of higher energy which are capable to break C-C bonds resulting in the generation of a large number of radicals that form chemical bonds on the clay surface of nanocomposite and interrupt physical and chemical interactions [101]. Therefore this technique has been extensively reported for crushing, emulsifying and dispersing the particles. Xia et al. [102] carried out the ultrasonication method to diminish the agglomeration of nanosilica particles. In aqueous phases, a redispersion of nano clay was also ascertained. In 2016, Pattanaika [103] examined the epoxy/fly ash composite by using Ultrasonic Technique. TOPSIS, a multicriteria decision method was performed to optimize the composite, whereas ANOVA help in enhancing the dry sliding wear of epoxy/ fly ash composite.

REFERENCES

- Senapati MR. Fly ash from thermal power plants-waste management’s and overview. Current Science. 2011;100:1791-1794.

- Singh S, Pillai A. A Compressive Review on Fly Ash Characteristics and Current Utilization Status in India. Proceedings 2019: Conference on Technologies for Future Cities (CTFC). (2019).

- Haque ME. Indian fly-ash: production and consumption scenario. International Journal of Waste Resources (IJWR). 2013;3:22-25.

- Flues M, Sato IM, Scapin MA, Cotrim MEB, Camargo IMC. Toxic elements mobility in coal and ashes of Figueira coal power plant. Brazil, Fuel. 2013;103:430-436.

- Fernandez-Turiel JL, Carvalho W.de, Cabanas M, Querol X, Lopez-Soler A. A Mobility of Heavy Metals from Coal Fly ash. Journal of Environmental Geology. 1994;23:264-70.

- Margallo M, Cobo S, Laso J, Fernández A, Muñoz E, Santos E, et al. Environmental performance of alternatives to treat fly ash from a waste to energy plant. Journal of Cleaner Production. 2019:231;1016-1026.

- Fulekar MH, Dev JM. Disposal of the fly ash-an environmental problem. International Journal of Environmental Studies. 1986;26:191-215.

- Anandhan S. Recent Trends in Fly Ash Utilization in Polymer Composites. International Journal of Waste Resources. 2014;4.

- Srivastava I, Koratkar N. Fatigue and fracture toughness of epoxy nanocomposites. JOM. 2010;62:50-57.

- He H, Li K, Wang J, Sun G, Li Y, Wang J. Study on thermal and mechanical properties of nano-calcium carbonate/epoxy composite. Materials and Design. 2011;32:4521-4527.

- Hosokawa M, Naito M, Nogi K, Yokoyama T. Nanoparticle Technology Handbook, Elsevier, Oxford, UnitedKingdom. 2008;Chap 1.

- Borisenko Victor E, Ossicini Stefano. A Handbook on Nanoscience and Nanotechnology, Wiley-VCH Verlag GmbH, Weinheim German. 2004.

- Camargo PHC, Satyanarayana KG, Wypych F. Nanocomposites: Synthesis, Structure, Properties and New Application Opportunities. Materials Research. 2009;12:1-39.

- Page AL, Elseewi AA, Straughan IR. Physical and chemical properties of flyash from coal-fired power plants with reference to environmental impacts. Residue Rev. 1979;71:83- 120.

- Ibraheem S, Bandyopadhyay S. A review of the structure-property research on hybridreinforced polymer composites. Hybrid Polymer Composite Materials. 2017;163-191.

- Ahmaruzzaman M. A review on the utilization of fly ash. Prog Energy CombustSci. 2010;36:327-363.

- Carlson CL, Adriano DC. Environmental Impacts of Coal Combustion Residues. Journal of Environmental Quality. 1993;22:227-247.

- Lokeshappa B, Dikshit AK. Disposal and Management of Fly ash International Conference on Life Science and Technology IPCBEE IACSIT Press, Singapore. 2011.

- Satapathy S, Nando GB, Nag A, Raju KVSN. HDPE-Fly Ash/Nano Fly Ash Composites. J App Polym Sci. 2013;130:4558-4567.

- Nath S, Jena H, Priyanka Sahini D. Analysis of Mechanical Properties of Jute Epoxy Composite with Cenosphere Filler. Silicon. 2019;11:659-671.

- Naik TR, Singh SS. Fly Ash Generation and Utilization - An Overview, For publication in the book titled Recent Trend in Fly Ash Utilization. 1993.

- Yadav VK, Fulekar MH. The current scenario of thermal power plants and fly ash: production and utilization with a focus in India. International Journal of Advance Engineering and Research Development. 2018;5:768-777.

- Manz OE. Worldwide Production of Coal Ash and Utilization in Concrete and Other Products, Proceedings of the Tenth International Ash Use Symposium, ACAA, Orlando, Florida. 1993;64:1-12.

- Manz OE, Faber JH, Takagi H. Worldwide Production of Fly Ash and Utilization in Concrete, Proceedings of the Third International Conference on the Use of Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete. 1989;1-15.

- Senapati AK, Bhatta A, Mohanty S, Mishra PC, Routra BC. An Extensive Literature Review on the Usage of Fly Ash as a Reinforcing Agent for Different Matrices. International Journal of Innovative Science and Modern Engineering (IJISME). 2014;2:4-9.

- Singla M, Chawla V. Mechanical Properties of Epoxy Resin - Fly Ash Composite. Journal of Minerals & Materials Characterization & Engineering. 2010:9;199-210.

- Gu H, Ma C, Gu J, Guo J, Yan X, Huang J, et al. An overview of multifunctional epoxy nanocomposites. Journal of Materials Chemistry C. 2016;4:5890-5906.

- Mohanty NR, Nayak SK. Synthesis and Modifications of Epoxy Resins and Their Composites: A Review. Polymer-Plastics Technology and Engineering. 2014;53:1723-1758.

- Srivastava VK, Shembekar PS, Prakash R. Fracture behavior of fly-ash filled FRP composites. Composite Structures. 1988;10:271-279.

- Srivastava VK. Effect of fibres coating on fracture properties of composite. Engineering Fracture Mechanics. 1989;34:777-782.

- Ibraheem S, Devasahayam S, Standard O, Bandyopadhyay S. Use of Secondary Ion Mass Spectrometry (SIMS) to identify fly ash mineral spatial and particulate distribution in epoxy polymer. International Journal of Mineral Processing. 2015;142:139-146.

- Krishna MP, Kireeti MP, Krishna MR, Jyothi Y, Swami GRK. Mechanical properties of fly ash/sawdust reinforced epoxy hybrid composites. Journal home page for Materials Today: Proceedings. 2018;5:13025-13030.

- Barpanda P, Kulkarni SM Kishore. Sliding Behavior of an Epoxy System Reinforced with Particulate Fly Ash Filler. Advanced Composites Letters. 2009

- Ramakrishna HV, PadmaPriya S, Rai SK. Utilization of fly ash as filler for polybutyleneterethalate-toughened epoxy resin. 2006.

- Raja RS, Manisekar K, Manikandan V. Effect of fly ash filler size on mechanical properties of polymer matrix composites. International Journal of Mining, Metallurgy & Mechanical Engineering (IJMMME). 2013;1:2320-4060.

- Kishore Kulkarni SM, Sharathchandra S, Sunil D. On the use of an instrumented set-up to characterize the impact behavior of an epoxy system containing varying fly ash content. Polymer Testing. 2002;21:763-771.

- Kulkarni SM, Kishore. Effects of surface treatments and size of fly ash particles on the compressive properties of epoxy-based particulate composites. Journal of Material Science. 2002;37:4321-4326.

- Liu S, Chevali VS, Xu Z, Hui D, Wang H. A review of extending performance of epoxy resins using carbon nanomaterials. Composites Part B: Engineering. 2018;136:197-214.

- Verma D, Joshi G, Dabral R, Lakhera A. Processing and evaluation of mechanical properties of epoxy-filled E-glass fiber-fly ash hybrid composites. Woodhead Publishing Series in Composites Science and Engineering. 2019;293-306.

- Wittman C, Shook GD. Hand Lay-Up Techniques. Handbook of Composites. 321-367.

- Purohit R, Sahu P, Rana RS, Parashar V, Sharma S. Analysis of Mechanical Properties of Fiber Glass-Epoxy-Fly Ash Composites. Materials today Proceeding. 2017;4:3102-3109.

- Niroumand. Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods. Trans. Nonferrous Met.Soc.China. 2010;20:788-793.

- Mahapatra MM. Fabrication and Characterizations of Mechanical Properties of Al4.5%Cu/10TiC Composite by In-Situ Method. Journal of Minerals and Materials Characterization and Engineering. 2012;1075- 1080.

- International Organization for Standardization (ISO). Nanotechnologies—Vocabulary. In Part 2: Nano-Objects; International Organization for Standardization: Geneva, Switzerland 2015.

- Hosokawa M, Naito M, Nogi K, Yokoyama T. Nanoparticle Technology Handbook; Elsevier Science: Oxford, UK. 2007.

- Bugnicourt E. Development of Sub-Micro Structured Composites based on an Epoxy Matrix and Pyrogenic Silica: Mechanical Behavior Related to the Interactions and Morphology at Multi-Scale. Ph.D. Thesis, Intelligence and National Security Alliance (INSA), Villeurbanne, France. 2005.

- Bhushan B. Springer Handbook of Nanotechnology. (3rdedn); Springer: Berlin, Germany. 2010.

- Hosokawa M, Naito M, Nogi K, Yokoyama T. Nanoparticle Technology Handbook, Elsevier, Oxford, United Kingdom Chap 1. 2008.

- Tomi MD, Dunji B, Likić V, Bajat J, Rogan J, Djonlagić J. The use of nanoclay in preparation of epoxy anticorrosive coatings. Prog Organ Coat. 2014;77:518-527.

- Yano K, Usuki A, Okada A. Synthesis and properties of polyimide-clay hybrid films. J Polym Sci Part A. 1997;35:2289-2294.

- Azeez AA, Rhee KY, Parkb SJ, Huiac D. Epoxy clay nanocomposites- processing, properties, and applications: A review. Composites Part B: Engineering. 2012;45:308-320.

- Wang K, Chen L, Wu J, Toh ML, He C, Yee AF. Epoxy Nanocomposites with Highly Exfoliated Clay: Mechanical Properties and Fracture Mechanisms. Macromolecules. 2005;38:788-800.

- Zolotuchin I. Carbon Nanotubes, Soros Educational Journal: Voronezh State University. 1999;3:111-115.

- Holister P, Harper T, Vas CR. Nanotubes. White Paper. [e-journal] Las Rozas: CMP Científica. 2003.

- Yue L, Pircheraghi G, Monemian SA, Manas-Zloczowe I. Epoxy composites with carbon nanotubes and graphene nanoplatelets—Dispersion and synergy effects. Carbon. 2014;78:268- 278.

- Rasheed A, Khalid FA. Fabrication and properties of CNTs reinforced polymeric matrix nanocomposites for sports applications. IOP Conf Ser Mater Sci Eng. 2014.

- Prolongo SG, Gude MR, Ureña A. Water uptake of epoxy composites reinforced with carbon nanofillers. Composites Part A: Applied Science and Manufacturing. 2012;43:2169-2175.

- Marriama I, Xua F, Tebyetekerwa M, Gaoa Y, Liu W, Liu X, et al. Synergistic effect of CNT films impregnated with CNT modified epoxy solution towards boosted interfacial bonding and functional properties of the composites. Composites Part A: Applied Science and Manufacturing. 2018;110:1-10.

- Tao K, Yang S, Grunlan JC, Kim YS, Dang B, Deng Y, Thomas RL, et al. Effects of carbon nanotube fillers on the curing processes of epoxy resin-based composites. Applied Polymer. 2006;102:5248-5254.

- Allaoui A, Baia S, Cheng HM, Bai JB. Mechanical and electrical properties of a MWNT/epoxy composite. Composites Science and Technology. 2002;62:1993-1998.

- Meeuw H, Viets C, Liebig WV, Schulte K, Fiedler B. Morphological influence of carbon nanofillers on the piezoresistive response of carbon nanoparticle/epoxy composites under mechanical load, European Polymer Journal. 2016;85:198-210.

- Yuen SM, Ma CCM, Wu HH, Kuan HC, Chen WJ, Liao SH, et al. Preparation and thermal, electrical, and morphological properties of multiwalled carbon nanotube and epoxy composites. Journal of Applied Polymer Science. 2007;103:1272-1278.

- Tanabi H, Erdala M. Effect of CNTs dispersion on electrical, mechanical and strain sensing properties of CNT/epoxy nanocomposites. Results in Physics. 2019;12:486-503.

- Arbaoui J, Moustabchir H, Vigué JR, Roye FX. The effects of various nanoparticles on the thermal and mechanical properties of an epoxy resin. Materials Research Innovations. 2016;20:145-150.

- Fu JF, Shi LY, Zhong QD, Chen Y, Chen LY. Thermally conductive and electrically insulative nanocomposites based on hyperbranched epoxy and nano Al2O3 particles modified epoxy resin. Polymer Advanced Technologies. 2011;22:1032-1041.

- Sajjad M, Feichtenschlager B, Pabisch S, Svehla J, Koch T, Seidler S, et al. Study of the effect of the concentration, size and surface chemistry of zirconia and silica nanoparticle fillers within an epoxy resin on the bulk properties of the resulting nanocomposites. Polymer International. 2012;61:274-285.

- Al-Turaif HA. Effect of nano TiO2 particle size on mechanical properties of cured epoxy resin. Progress in Organic Coatings. 2010;69:241-246.

- Thind KS, Singh J, Saini JS, Bhunia H. Mechanical and wear properties of epoxy hybrid nanocomposite. Indian Journal of Engineering and Material Science. 2015;22:421-428.

- Ng CB, Schadler LS, Siegel RW. Synthesis and mechanical properties of TiO2- epoxy nanocomposites. Nanostructured Materials. 2016;12:507-510.

- Mahesha CR, Shivarudraiah Mohan N, Rajesh M. Role of nanofillers on Mechanical, and Dry sliding wear behavior of Bosalt-Epoxy Nanocomposites. Materials Today: Proceedings. 2017;4:8192-8199.

- Bezy NA, Fathima AL. Effect of TiO2 nanoparticles on Mechanical Properties of EpoxyResin System. International Journal of Engineering Research and General Science. 2015;3:143-151.

- Laarej M, Benyoucef B, Abadie MJM, Charles JP. Characterization and Mechanical Properties of Epoxy Resin Reinforced with TiO2 Nanoparticles. Experimental Techniques. 2014;38:59-66.

- Carballeira P, Haupert F. Toughening effects of titanium dioxide nanoparticles on TiO2/epoxy resin nanocomposites. Polymer Composites. 2009;31:1241-1246.

- Han JT, Cho K. Nanoparticle-induced enhancement in fracture toughness of highly loaded epoxy composites over a wide temperature range. Journal of Material Science. 2016;41:4239- 4245.

- Chan KL, Mariatti M, Lockman Z, Sim LC. Effects of the size and filler loading on the properties of copper and silver nanoparticle filled epoxy composites. Applied Polymer Science. 2011;121:3145-3152.

- Salehi HR, Salehi M. Experimental Study on the Mechanical, Creep, and Viscoelastic Behavior of TiO2/Glass/Epoxy Hybrid Nanocomposites. Mechanics of Composite Materials. 2016;52:623-636.

- Zheng Y, Ning R. Effects of nanoparticles SiO2 on the performance of nanocomposites. Mater Lett. 2003;57:2940-2944.

- Mohan AC, Renjanadevi B. Effect of Zinc Oxide Nanoparticles on Mechanical Properties of Diglycidyl Ether of Bisphenol-A. J Material Sci Eng. 2016;5:291.

- Wang J, Li KX. Study on mechanical properties of nano-calcium carbonate/thermoplastic composites. Journal of Thermoplastic Composite Materials. 2015;28.

- Wang X, Jin J, Song M. An investigation of the mechanism of graphene toughening epoxy. Carbon. 2013;65:324-333.

- Ladani RB, Bhasin M, Wu S, Ravindran AR, Ghorbania K, Zhang J, et al. Fracture and fatigue behavior of epoxy nanocomposites containing 1-D and 2-D nanoscale carbon fillers. Engineering Fracture Mechanics. 2018;203:102-114.

- Mauroa M, Acocella MR, Corcione CE, Maffezzoli A, Guerra G. Catalytic activity of graphite-based nanofillers on cure reaction of epoxy resins. Polymer. 2014;55:5612-5615.

- Geim AK, Novoselov KS. The rise of graphene. Nat Mater. 2007;6:183-191.

- Bunch JS, Verbridge SS, Alden JS, van der Zande AM, Parpia JM, Craighead HG, et al. Impermeable atomic membranes from graphene sheets. Nano Lett. 2008;8:2458- 2462.

- Leenaertsa O, Partoensb B, Peeters FM. Graphene: A perfect nanoballoon. Appl Phys Lett. 2008;93.

- Yoo BM, Shin HJ, Yoon HW, Park HB. Graphene and graphene oxide and their uses in barrier polymers. J Appl Polym Sci. 2014;131.

- Huang PY, Ruiz-Vargas CS, van der Zande AM, Whitney WS, Levendorf MP, Kevek JW, et al. Grains and grain boundaries in single-layer graphene atomic patchwork quilts. Nature. 2011;469:389-392.

- Suh DJ, Lim YT, Park OO. The properties and formation mechanism of unsaturated polyester-layered silicate nanocomposite depending on the fabrication methods. Polymer. 2000;41:8557-8563.

- Carrado KA, Xu LQ. In situ synthesis of polymer-clay nanocomposites from silicate gels. Chem Mater. 1998;10:1440-1445.

- Messersmith PB, Giannelis EP. Synthesis, and characterization of layered silicate-epoxy nanocomposites. Chem Mater. 1994;6:1719-1725.

- Al-Harthi MA, Bahuleyan BK. Mechanical Properties of Polyethylene-Carbon Nanotube Composites Synthesized by In Situ Polymerization Using Metallocene Catalysts. Advances in Materials Science and Engineering. 2018.

- Salmi Z, Benzarti K, Chehimi MM. Diazonium Cation-Exchanged Clay: An Efficient, Unfrequented Route for Making Clay/Polymer Nanocomposites. Langmuir. 2013;29:13323-13328.

- Cardoso RS, Aguiar VO, Marques MFV. Masterbatches of polypropylene/clay obtained by in situ polymerization and melt-blended with commercial polypropylene. J Compos Mater. 2017;51:3547-3556.

- Korivi NS. Preparation, characterization, and applications of poly(ethylene terephthalate) nanocomposites. Manufacturing of Nanocomposites with Engineering Plastics. 2015;167-198.

- Shen Z, Simon GP, Cheng YB. Effects of molecular weight and clay organo‐ ions on the melt intercalation of poly(ethylene oxide) into layered silicates. Polymeric Engineering and Science. 2002;42:2369-2382.

- Vaia RA, Giannelis EP. Polymer melt intercalation in organically-modified layered silicates: Model predictions and experiment. Macromolecules. 1997;30:8000-8009.

- Halder S, Prasad T, Khan NI, Goyat MS, Chauhana SR. Superior mechanical properties of polyvinyl alcohol-assisted ZnO nanoparticle reinforced epoxy composite. Materials Chemistry and Physics. 2017;192:198-209.

- Vaia RA, Giannelis EP. Lattice model of polymer melt intercalation in organicallymodified layered silicates. Macromolecules. 1997;30:7990-7999

- Jiankun L, Yucai K, Zongneng Q, Xiao‐ Su Y. Study on intercalation and exfoliation behavior of organoclays in epoxy resin. Journal of Polymer Science: Part:B. 2001;39:115-120.

- Tomic M, Dunjic B, Nikolic MS, Maletaškic J, Pavlovic VB, Bajat J, et al. Dispersion efficiency of montmorillonites in epoxy nanocomposites using solution intercalation and direct mixing methods. Applied Clay Science. 2018;154:52-63.

- Lam CK, Lau KT, Cheung HY, Ling HY. Effect of ultrasound sonication in nanoclay clusters of nanoclay/epoxy composites. Materials Letters. 2005;59:1369-1372.

- Xia H, Wang Q. Preparation of conductive polyaniline/nanosilica particle composites through ultrasonic irradiation. J Appl Polym Sci. 2003;87:1811-1817.

- Pattanaika A, Satpathy MP, Mishra SC. Dry sliding wear behavior of epoxy fly ash composite. Taguchi optimization Engineering Science and Technology, an International Journal. 2016;19:710-716.

- Bhuiyan MA, Pucha RV, Karevan M, Kalaitzidou K. Tensile modulus of carbon nanotube/polypropylene composites—A computational study based on experimental characterization. Comput Mater Sci. 2011;50:2347-2353.

- Bhuiyan MA, Pucha RV, Karevan M, Kalaitzidou K, Worthy J. Defining the lower and upper limit of the effective modulus of CNT/polypropylene composites through integration of modeling and experiments. Compos Struct. 2013;95:80-87.

- Wetzel B, Rosso P, Haupert F, Friedrich K. Epoxy nanocomposites-fracture and toughening mechanisms. Engineering Fracture Mechanics. 2006;73:2375-2398.

- Tjong SC. Structural and mechanical properties of polymer nanocomposites. Materials Science and Engineering: R: Reports. 2006;53:73-197.

- He H, Zhang Z, Wang J, Lib K. Compressive properties of nano-calcium carbonate/epoxy and its fibre composites. Composites Part B: Engineering. 2013;45:919-924.

- Chatterjee S, Nafezarefi F, Tai NH, Schlagenhauf L, Nüescha FA, Chua BTT. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon. 2012;50:5380-5386.

- He H, Li K, Wang J, Sun G, Li Y, Wang J. Study on thermal and mechanical properties of nano-calcium carbonate/epoxy composite. Materials & Design. 2011;32:4521-4527.

- Khashaba UA, Aljinaidi AA, Hamed MA. Nanofillers modification of Epocast 50A1/946 epoxy for bonded joints. Chinese Journal of Aeronautics. 2014;27:1288-1300.

- Gurusideswar S, Velmurugan R. Strain rate sensitivity of glass/epoxy composites with nanofillers. Materials & Design. 2014;60:468-478.

- Saba N, Jawaid M, Alothman OY. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. Journal of Reinnforced Plastics and Composites. 2016;35.

- Özsoy I, Mimaroglu A, Una H. Comparison of the tribological and mechanical performance for nano and micro filler epoxy composites. Materials Testing. 2016;58:376-380.

- Shimpi NG, Mishra S. Sonochemical Synthesis of Mineral nanoparticles and Its Applications in Epoxy Nanocomposites. Polymer-Plastics Technology and Engineering. 2012;51:111-115.

- Kavitha D, Sindhu TK, Nambiar TNP. Effect of Nanoparticles on the Dielectric Strength and PD Resistance of Epoxy Nanocomposites. Proceedings of the International Conference on Soft Computing Systems. 2015;397:277-286.

- Majeed AH, Hamza MS, Kareem HR. Effect of adding nano carbon black on the mechanical properties of epoxy. Iraqi Academic Scientific Journals. 2014;l7:94-108.

- Wanga Q, Wen G, Chena J, Su DS. Reinforcing epoxy resin with nitrogendoped carbon nanotube: A potential lightweight structure material. Journal of Materials Science & Technology. 2018;34:2205-2211.

- Eskizeybek V, Ulus H, Kaybal HB, Şahin ÖS, Avcı A. Static and dynamic mechanical responses of CaCO3 nanoparticle modified epoxy/carbon fiber nanocomposites. Composite Part B: Engineering. 2018;140:223-231.

- Zeng S, Shen M, Yang L, Xue Y, Lu F, Chen S. Self-assembled montmorillonite-carbon nanotube for epoxy composites with superior mechanical and thermal properties. Composites Science and Technology. 2018;162:131-139.

- George J, Ishida H. A review on the very high nanofiller-content nanocomposites: Their preparation methods and properties with high aspect ratio filler. Progress in Polymer Science. 2018;8:1-39.

- He H, Yang J, Huang W, Cheng M. Influence of Nano-Calcium Carbonate Particles on the Moisture Absorption and Mechanical Properties of Epoxy Nanocomposite. Advances in Polymer Technology. 2018;37:022-1027.

- Silvestre J, Silvestre N, De Brito J. Polymer nanocomposites for structural applications: Recent trends and new perspectives. Mechanics of Advanced Materials and Structures. 2016;23:1263-1277.

- Asiri AM, Hussein MA, Abu-Zied BM, Abou-Elhagag Hermasac A. Effect of NiLaxFe2−xO4 nanoparticles on the thermal and coating properties of epoxy resin composites. Composites Part B: Engineering. 2013;51:11-18.

- Mishra A. Mechanical properties of Coconut Shell Dust, Epoxy-Fly Ash Hybrid Composites. AJER. 2017;6:166-174.

- Chen P, Li J, Zhang L. Analysis of mechanical characteristics of fly ash cenospheres reinforced epoxy composites. Journal of the Wuhan University of Technology- Mater Sci Ed. 2018;33:139-145.

- Dong Y, Chaudhary D, Ploumis C, Lau KT. Correlation of mechanical performance and morphological structures of epoxy micro/nanoparticulate composites. Composites Part A: Applied Science and Manufacturing. 2011;42:1483-1492.

- Saleem H, Edathil A, Ncube T, Pokhrel J, Khoori S, Abraham A, et al. Mechanical and Thermal Properties of Thermoset-Graphene Nanocomposites. Macromolecular Materials and Engineering. 2016;301:231-259.

- Shokrieh MM, Ghoreishi SM, Esmkhani M, Zhao Z. Effects of graphene nanoplatelets and graphene nanosheets on fracture toughness of epoxy nanocomposites. Fatigue and Fracture of Engineering Material and Structure. 2014;37:1116-1123.

- Sonawane SS, Mishra S, Shimpi NG. Effect of Nano-CaCO3 on Mechanical and Thermal Properties of Polyamide Nanocomposites. Polymer-Plastics Technology and Engineering. 2009;49:38-44.

- Zhou Y, Jeelani S, Lacy T. Experimental study on the mechanical behavior of carbon/epoxy composites with a carbon nanofiber-modified matrix. Journal of Composite Materials. 2014;48:3659-3672.

- Gkikas G, Barkoula NM, Paipetis AS. Effect on dispersion condition on thermomechanical and toughness properties of multiwalled carbon nanotubes reinforced epoxy. Composites Part B: Engineering. 2012;43:2697-2705.

- Saw SK. Static and Dynamic Mechanical Analysis of Coir Fiber/Montmorillonite Nanoclay-Filled Novolac/Epoxy Hybrid Nanocomposites. Eco-friend Polymer Nanocomposite. 2015;75:137-154.

- Üstün T, Ulus H, Karabulut SE, Eskizeybek V, Şahin ÖS, Avcı A, et al. Evaluating the effectiveness of nanofillers in filament wound carbon/epoxy multiscale composite pipes. Composites Part B: Engineering. 2016;305:1-6.

- Chaowasaako T, Sombatsompop N. Mechanical and morphological properties of fly ash/epoxy composites using conventional thermal and microwave curing methods. Composites Science and Technology. 2007;67:282-2291.

- Kumar K, Ghosh PK, Kumar A. Improving mechanical and thermal properties of TiO2 epoxy nanocomposite. Composites Part B: Engineering. 2016;97:353-360.

- Prabu VA, Johnson RDJ, Amuthakkannan P, Manikandan V. Usage of industrial wastes as particulate composite for environment management: Hardness, Tensile and Impact studies. Journal of Environmental Chemical Engineering. 2017;5:1289-1301.

- Baheti V, Militky J, Mishra R, Behera BK. Thermomachenicals properties of glass fabric/epoxy composites filled with fly ash. Composite B: Engineering. 2016;85:268-276.

- Zhang QX, Yu ZZ, Yang M, Ma J, Mai YW. Multiple melting and crystallization of nylon-66/montmorillonite nanocomposite. J Polym Sci. Part B. 2003;41:2861-2869.

- Mu B, Wang Q, Wang H, Jian L. Nonisothermal crystallization kinetics of nylon 66/montmorillonite nanocomposites. J Macromol Sci Part B. 2007;46:1093-1104.

- Nam JY, SinhaRay S, Okamoto M. Crystallization behavior and morphology of biodegradable polylactide/layered silicate nanocomposite. Macromolecules. 2003;36:7126-7131.

- Lincoln DM, Vaia RA, Krishnamoorti R. Isothermal crystallization of nylon- 6/montmorillonite nanocomposites. Macromolecules. 2004;37:4554-4561.

- Li L, Li CY, Ni C, Rong L, Hsiao B. Structure and crystallization behavior of nylon 66/multi-walled carbon nanotube nanocomposites at low carbon nanotube contents. Polymer. 2007;48:3452-3460.

- Phang IY, Pramoda K, Liu T, He C. Crystallization and melting behavior of polyester/clay nanocomposites. Polym Int. 2004;53:1282-1289.

- Wu D, Zhou C, Fan X, Mao D, Bian Z. Morphology, crystalline structure and isothermal crystallization kinetics of polybutylene terephthalate/montmorillonite nanocomposites. Polym Compos. 2005;13:61-71.

Acknowledgement

I express to my sincere thanks to Prof. Deepak Srivastava, Head of Plastics Technology for providing me the guidance and facilities.

Conclusion

In this context, nanocomposites are suitable materials to meet the emerging demands arising from scientific and technologic advances. They are generally more advantageous composites because the enhancement in properties of nanocomposite can be acquired from the addition of the small amount of nano-sized filler content having a high aspect ratio. The review article covers the effect of nanoparticles on mechanical characteristics including impact strength, flexural strength and tensile strength of fly ash/epoxy composite and fly ash/epoxy nanocomposites. It has concluded that the reinforcement of nanofiller even in small content enhances the mechanical properties of fly ash/epoxy composite. Because the homogeneous dispersion of nanofillers reduced the defects between fillers and polymer interface, resulting in improvement in the mechanical properties of filler/fly ash/epoxy nanocomposites. Finally, the review core provides a few awareness of safety and predictability features that would impact the market comeback for new nanocomposites. The increment in the progressive rate of utilization of fly ash also depends upon the government directives. The utilization of fly ash will sustain the natural raw material and diminished the disposal cost. While keeping safe the environment, fly ash will also bring out the business opportunities at the same time. To develop the epoxy nanocomposites with enhanced mechanical properties is associated with (a) The modification of nanofillers with functionalities to enhance the dispersion quality of the nanofillers (b) To improve the interfacial interaction between the nanofillers and the polymer matrix is mandatorily required. Hence, to explore the new functionalities of filler/fly ash/epoxy nanocomposites is the main effort for researchers in the future.

Research Gap Where the Work is Aimed

The literature review was revealed that work on composite based on fly ash, epoxy resin and nanofiller has hardly done in the past. In the literature survey, it has also reported that the mostly mechanical properties dramatically reduce with further excessive addition of fly ash and nanofillers. Therefore, for a particular application, the optimum level should be analyzed. So, an idea of developing highperformance composite matrices by utilization of waste material fly ash, nanofiller, and epoxy resin has emerged into mind based on literature survey. A lot of efforts have been required to utilize the industrial waste fly ash. With the incorporation of inorganic and nanoparticles, nucleation of crystallization can appear. The nucleation of crystallization developed with the reinforcement of inorganic and nanoparticles. Therefore at the nanoscale, the nanoparticle can change for deficiency of primary nuclei emulating with trapped crystallization. At higher content of nanofiller, lower crystallization kinetics is achieved due to higher viscosity. At low concentrations, the nucleation of crystallization was monitored by the Onset temperature of crystallization (Tc) and crystallization half-time. Slightly an interruption in the rate of crystallization has been observed at higher concentrations. This was alike observed in specific composites, where nucleation viewed at low concentrations [139-145].

Applications of Fly Ash/Epoxy/Nanocomposites

The Fly ash/epoxy/nanocomposite is a multiphase system with excellent properties and eco-friendly. Therefore, the applications of nanocomposite propose new opportunities for several sectors of aerospace, automotive and electronics applications. However, no single application establish 100% utilization of fly ash thus a large number of skillful application is needed for assisting and bettering the utilization of fly ash. The innovative applications of fly ash offer opportunities to further enhance the utilization.

Effect of Nanofillers on Mechanical, Morphological, and Thermal Properties of Polymer Nanocomposites

In the literature survey, the enhancement in mechanical properties such as Tensile strength, Yield strength, Compressive strength, Hardness, resistance, wear-resistance, and thermal properties are taken into consideration for study the effect of reinforcement of nanofiller with different wt% into the polymer matrix. The mechanical, optical, rheological, flame retardancy and dielectric properties of polymer nanocomposites have been extensively studied.

In 2006, Tjong et al. [107] studied the structure-property relationship of polymer composite reinforced with layered silicates, ceramic nanoparticles, and carbon nanotubes. The CaCO3 and silica nanoparticles were arranged on a nanometer scale with large surface areas and revealed the enhancement in mechanical properties when introduced into a matrix. The desired mechanical and physical properties can be acquired from a uniform and homogeneous distribution of nanofillers in the polymer matrix.

In 2013, He et al. [108] evaluated that matrix modification is an effective way to improve the properties of the composite. An interfacial modifier KH550 was introduced to improve the interfacial interactions. There was an appropriate enhancement of 13.5%, 6.1%, 42.5% and 106.3% in compressive strength, elastic modulus, displacement, and the total fracture work of epoxy resin cast filled with 4 wt% nano-CaCO3 as compared to neat epoxy resin. It indicated that the modification of nano CaCO3 leads to enhancement in compressive properties. Chatterjee et al. [109] studied the incorporation of two different dimensions of (GnPs) Graphene nanoplates with flake size of the 5 micro meter and 25 micrometer and various mixture proportions of carbon nanotubes with GnPs into epoxy matrix. In GnP reinforced composites, larger flakes of GnP Help to vigorously dominate the failure mechanisms in composites. The fracture toughness was improved with 76% in the mixture sample having the highest CNT content (9:1). He et al. [110] observed that thermal stability and mechanical strength of epoxy resin enhanced by surface modification of nano CaCO3 particles. The mechanical and TGA tests were carried out to investigating the effect of nano CaCO3 on the thermal and mechanical properties of epoxy resin. Interfacial modifier as silane coupling agent KH550 was introduced into nanocomposite to improve interfacial interaction between epoxy and nano CaCO3. Khashaba et al. [111] modified the Epocast epoxy resin with different nanofillers' immersion. The nanofillers with different wt% were ultrasonically dispersed in epoxy resin. The shear strength of these nanocomposites was enhanced by 5.5%, 4.9% and 6.3% and shear moduli enhanced by 10.3%, 16%, and 8.1%. Gurusideswar [112] evaluated the effect of nanoclay on tensile modulus of neat epoxy and glass/epoxy composites at low strain rates. The ultrasonication technique disperses the nanofiller in epoxy resin by different wt% (1.5, 3, and 5)%. SEM, TEM and XRD technique characterized the nanoclay. They observed that longitudinal strength and stiffness increases just as clay loading increases. As the content of clay increases, the tensile modulus enhances both epoxy and epoxy/glass nanocomposite. Saba et al. [113] studied mechanical and morphological hybrid nanocomposites, by dispersion of nanofiller (nano OPEFB, MMT, OMMT) by 3% loading with the help of wet-hand lay-up technique. Mechanical and morphological characteristics were found improved. Ozsoy et al. [114] investigated and compared the tribological and mechanical performance of nano and micro epoxy composite nanofillers such as Al2O3, TiO2 and clay and micro fillers like Al2O3, TiO2 and fly ash. On pin-ondisc arrangement, wear test was examined under dry atmospheric conditions values 5, 10,15 N, Sliding speed 0.8 m/s and sliding distance by 2000 m. They concluded that the tribological and mechanical performance of micro filler epoxy composite was found better than nanofiller epoxy composite. Shimpi et al. [115] studied the effect of mineral nanofiller on the thermal and morphological properties of the epoxy composite. The ultrasonic cavitation technique was performed to disperse (2 to10%) nano CaCO3. The noticeable change in cross-linking density was found by reinforcing the nanoparticles. Thermal properties of epoxy nanocomposites were found to be enhanced as compared to neat epoxy resin. Ultrasonic synthesis technique help in the formation of long term stable polymerization which consists of polymer/ inorganic nanoparticle composite. Kavitha et al. [116] observed the effect of nanofillers like CaCO3, TiO2, Al2O3 and layered silicate on dielectric strength and partial discharge resistance of the epoxy matrix. The result showed that the improvement in dielectric strength and partial discharge resistance depend on the percentage loading and type of nanofiller. Majeed et al. [117] investigated the significant mechanical behavior of epoxy nanocomposites reinforced with nano carbon black particles (N220). Ultrasonic Wave bath Machine was performed to disperse the nanofiller with (1 to 10%). They observed that properties like tensile strength, the tensile modulus of elasticity, flexural strength and impact strength were enhanced by (24.02%, 7.93%, 17.3%, and 6%) respectively at 2 wt% of nanofiller. The hardness and compressive strength were enhanced by (44.4%, 12%) at 4 wt% of nanofiller. Wang et al. [118] evaluated that nitrogen-doped carbon nanotubes epoxy nanocomposites show better mechanical properties as compared Carbon nanotubes/epoxy nanocomposites because NCNT has a relatively low viscosity which favors for subsequent applications as compared to Carbon nanotubes epoxy nanocomposite. The reinforcement of nitrogen-doped Carbon nanotubes was proposed for the development of lightweight and high-performance composite. Eskizeybek et al. [119] studied the static and dynamic properties of CaCO3 modified epoxy/carbon fiber. The nano CaCO3 with different wt% was dispersed into the epoxy matrix. Vacuum-assisted resin infusion method (VARIM) was used to impregnation of carbon fabrics into epoxy. The tensile, bending and low-velocity impact loadings test was carried out for these prepared nanocomposites. The tensile strength, flexural strength was improved by about 48% and 47% with 2 wt% reinforcement of nano CaCO3. By low-velocity impact tests, they observed that nano CaCO3 reinforced CF/epoxy having higher impact performances as compared to neat CF/epoxy composites. Zeng et al. [120] developed montmorillonite-multiwalled carbon nanotube [Mt-MWCNT] as reinforcing nanofiller for epoxybased composites. They observed that Mt restrict the micro crack path and thus arrest thermal transfer while MWCNTs attached to Mt nanosheets could smooth the stress and heat transfers and extend the mechanical interlocking with epoxy matrix. The tensile strength and modulus of epoxy-based composites enhanced by 42% and 20.3% with reinforcement of 0.5 wt% Mt-MWCNT (Mt:MWCNT=10:1) as compared to pure epoxy. The storage modulus in the glassy region was also improved by 21.2%. Zeorge and Ishida [121] studied the mechanical, electrical gas barrier and flame retarding properties and various novel techniques for the fabrication of high filler-content nanocomposites. However, for many years the reinforcement of inorganic filler content was surpassed only 10 vol%. He H.et al. [122] studied the effect of nano CaCO3 on the moisture absorption and diffusion properties of epoxy-based composites. The moisture absorption capacity was found educed with the addition of nano CaCO3 with 2 wt% and 4 wt%. As compared to dry nanocomposites the flexural strength of epoxy/nano CaCO3 impaired. Silvestre et al. [123] studied the effect of different reinforcement materials at nano-scale like CNT, nanoclay, graphene, nano-silica to the polymer matrix and the results indicate the enhancement in mechanical characteristics of polymer composites. From a noticeable period, the Polymer nanocomposites (PMC’S) have been extensively studied due to their appropriate mechanical, thermal and durable properties. Asiri et al. [124] investigated the epoxy nanocomposite which was prepared from reinforcement of Ni-La-Fe-O nanoparticles with different wt%( 0, .5, 1, 1.5 and 2) into the epoxy resin by Ultrasonic technique. FTIR, XRD, DSC, TGA, SEM characterized the nanocomposite. The compressive coating properties, coating, ionic charge transfer resistance were enhanced by the dispersion of Ni-La-Fe-O nanoparticles.

In the literature survey, it was revealed that the mostly mechanical properties dramatically reduce with further excessive addition of fly ash and nanofillers. Because fly ash particles are a type of rigid particle help to deliver a part of the load to assure the epoxy matrix form. But the excessive addition of fly ash creates agglomeration of fly ash as stress concentration points which posses’ physical defects, resulting in damage from these points. Mishra [125] investigated the mechanical properties and water absorption capacity of fly ash/epoxy/coconut shell dust (CSP). Tensile strength was enhanced by 15% by an increment of CSP although dramatically reduced with 20 wt% of CSP. Recently, Chen et al. [126] studied the mechanical properties like impact strength, flexural strength and flexural modulus of Fly ash Cenospheres/EP composites. Fly ash Cenosheres (FAC) is an industrial waste was utilized as a filler to enhance the properties of the epoxy matrix. With the incorporation of increasing weight fraction of FAC with epoxy matrix, the mechanical properties were found better. Higher values were obtained when the weight fraction of FAC’s exceeding to 15 wt%. However the further increment in FAC content reduced the mechanical properties of FACs/EP composites.

Dong et al. [127] studied nanocomposites. Zinc oxide nanoparticles, alumina nanoparticles and nanoclays with 1, 3, 5 and 8 wt% were dispersed by ultrasonically and mechanical stirring. The results show that composite modulus enhanced by 27% with the incorporation of alumina microparticles for 8 wt%. Flexural modulus was also found quite improved. Saleem et al. [128] studied the effect of graphene in the bettering of mechanical, thermal and electrical properties of polymer nanocomposite. They also observed the enhancement in properties of commercially relevant thermosetting materials. Shokrieh et al. [129] studied the effect of graphene nanoplatelets(GPLs) and graphene nanosheets (GNSs) on the fracture toughness and tensile strength of epoxy resin. The incorporation of 0.5 wt% GPLs enhances the fracture toughness of nanocomposite by 39% and 16% for 0.5 wt% GPSs. Sonawane, et al. [130] studied the polyamide CaCO3 nanocomposite, which was fabricated by melt intercalation on the twin-screw extruder. In-situ deposition technique synthesized CaCO3 of particle sizes (23, 17 and 11 nm). Nano CaCO3 was reinforced with 1 to 4 wt% 9 in polyamide. The results indicate that tensile strength, elongation, hardness and flame retardancy were enhanced for polyamide CaCO3 nanocomposite as compared to commercial CaCO3 nanocomposite. Polyamide CaCO3 nanocomposite shows enhancement in Young’s modulus by 3 fold contrast to commercial CaCO3 and 4-7 folds to neat polyamide. Zhou et al. [131] evaluated the tensile fatigue and fracture test of epoxy/Carbon nanofibre (CNF) nanocomposite. CNF with different (1, 2, and 3) wt% were dispersed by the high-intensity ultrasonic liquid processor. The result showed that tensile and flexural strength were enhanced by 11 wt% and 22.3 Wt% with the incorporation of CNF by 2 wt%. The reinforcement of 2 wt% CNF showed superior enhancement in strength. Gkikas et al. [132] analyzed the reinforcement of MWCNT into the epoxy matrix to improve the thermo-mechanical and toughness characteristics of the nanocomposite. The dispersion of CNT with 0.5 and 1 wt% ultrasonically in polymer matrix enhances the modulus and glass transition temperature. Saw [133] prepared nanocomposite based on natural coir fiber, organically modified montmorillonite [ommt] with the different weight ratio of blends of novolac (ENR) and (DGEBA) resin. Ustuna et al. [134] evaluated the experimental results of epoxy nanocomposite reinforced with carbon nanotubes and for boron nitride nanoplates (BNPs). The Burst and Hoop strengths were enhanced by up to 17 wt% and 31.7% with reinforcement of nanofiller. Chaowasakoo et al. [135] have determined or evaluated the effect of conventional thermal and microwave curing methods on the morphological and mechanical properties of fly ash/epoxy composite. The conventional thermal curing was achieved at 70°C for 80 min. while the microwave curing was performed at 240 W for 18 min to attain the optimum cure of the composite. The results reveal that the tensile, flexural moduli of the fly ash/epoxy composite improved with the increase in the fly ash content while the mechanical strength (tensile, flexural and impact strength) continuously reduced with an increase in fly ash content. The enhancement in mechanical properties could be achieved with the addition of 0.5 wt.% coupling agent. Kumar et al. [136] prepared TiO2-epoxy nanocomposites, by addition of nano TiO2 with different wt% 5, 10 and 15 into epoxy resin. The mixing was performed by the ultrasonic dual mixing process (UDM) process. The effect of nano TiO2 on the thermal and mechanical properties of these nanocomposites was studied. The distribution of nanoparticle in the matrix was analyzed by field emission scanning electron microscopy (FESEM) while analysis of thermal stability of nanocomposite was performed by TGA. Prabu, et al. [137] studied for utilization of industrial pollutant such as sawdust, rice husk, fly ash and red mud as reinforcing material such as epoxy and polyester for developing high-performance composite. The fillers were incorporated in different wt% of 2, 4, 6, 8, 10, 20, 30, 40, and 50. Hand-layup technique was performed for the fabrication of composites and tensile strength, impact strength and hardness were studied. The tensile strength of sawdust and rice husk reinforced composites was enhanced by 14 and 18% and impact strength by 61 and 142%. SEM technique was analyzed to study the failure mechanism of composites. The tensile and impact strength of fly ash/epoxy composite was improved by 63% and 42% due to the good mechanical performance of fly ash in a polyester matrix. Baheti et al. [138] prepared the fly ash/epoxy composite by ball milling technique. Three-layered laminated composite of glass fabrics was prepared with reinforcement of nanofiller into the epoxy matrix. The obtained results indicate that with the incorporation of activated fly ash with different weight 1, 3, 5 and 10 wt% at 2000C, the storage modulus of the nanocomposite was improved by 85.71, 38.09, 104.76 and 80.95% as compared to neat composites.

Characterization of Polymer Nanocomposites

To install the structure-property relationships for nanocomposite, the characterization of morphology is important. Various techniques such as Scanning electron microscopy (SEM), Transmission electron microscopy (TEM), Infrared spectroscopy (IR) or Atomic force microscopy (AFM) have been reported for characterization of the surface of nanocomposites. Bhuiyan et al. [104,105] carried out Atomic force microscopy (AFM) to evaluating the morphological variations of the areas around the particle surface. Among these techniques, TEM is the most appropriate method to analyze the state of dispersion of nanoparticles, filler size, local crystallinity, size and shape of void. The only drawback of TEM is that only a small area of material could be analyzed. Wetzel [106] carried out the TEM technique to investigate the scattering aspect of nanoparticles. They revealed the homogeneous dispersion of nanoparticles with few cramped aggregates in the polymer matrix. Further, the SEM technique has been carried out for analysis of the cross-sectional area as well as the dispersibility of nanofiller in the matrix. In the SEM technique, a beam of electrons is carried out, which scans the sample and generates images of the samples at various magnifications. X-ray diffraction (XRD) is also an appropriate technique to analyze the space between clay layers. The thermal stability of nanocomposite can be examined by TGA (thermal gravimetric analyzer).

Limitations and Process of Improvements

Due to improper and insufficient dispersion of nanoparticles, the processing of nanocomposites is one of a major challenge. The nanoparticles exhibit extremely higher surface area and volume effect which causes agglomeration. The improvement in various properties of nanocomposite is strongly associated with the microstructure of nanocomposite.

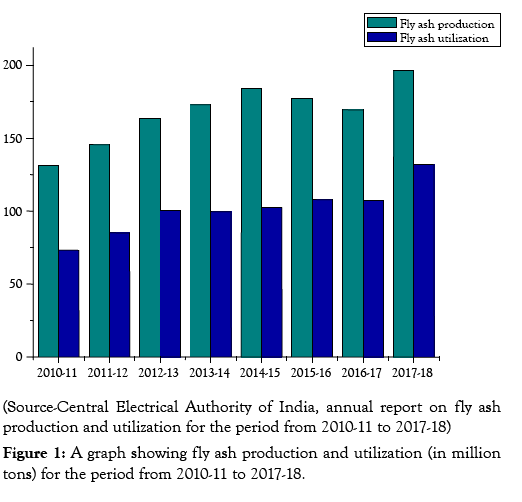

Introduction

Fly ash is an industrial waste residue generated by the combustion of pulverized coal in the Thermal power plant. During the combustion of coal in the boiler, the volatile matter and carbon burn off while the impurities like shale, quartz, clays feldspar, become fuse and stay in suspension. These fuse lightweight particles are ejecting out of the boiler of the combustion chamber with flue gases. When flue gas accesses the low-temperature zone, the fused particles solidify rapidly to form spherical particles. Earlier to draining the flue gases, spherical particles of ash are arrested by electrostatic precipitators. These spherical particles are known as fly ash. And the resting particles which aggregate rest down at the bottom of the furnace are called bottom ash [1]. About 90% of the total thermal power generation in India is based on coal. At present scenario in India, there are 167 coals based thermal power plants where 400-550 MT coal is being used every year which discharges 190 MT ashes and out of this 70-80% is fine to fly ash. By the end of the year 2018, about 200 million tons of fly ash was produced by various thermal power plants in India. The production of fly ash expected to increase to 250-300 MT/year by 2019-20. Therefore the stock of fly ash is increasing every year [2,3]. Apart from a small quantity of fly ash is primarily utilized by the cement industry, while an abundant proportion goes to ash ponds and landfills which cause huge environmental problems. In 2012, six million metric tons fly ash was produced by the UK out of which only 50% was utilized by the construction sector, while 50% proportion was gone to landfills. Fly ash also contains toxic metals and traces the concentration of heavy metals such as cadmium, chromium, cobalt, lead, manganese, mercury, molybdenum, and selenium. These heavy metals affect human health like permanent respiratory disorder on inhalation of the presence of toxic metals especially by persons living in the vicinity of disposal sites [4,5]. The toxicity of heavy metals also leached out to underground water. The presence of excess chromium (VI) in fly ash could lead to damage circulatory systems and causes carcinogenic changes due to mutagenic properties associated with its oxidizing activity. Here it becomes obvious to reduce the environmental concern, greenhouse emissions, and disposal issues. So the utilization of fly ash becomes necessary. Fly ash has low-cost effectiveness as compared to other inorganic fillers [6,7]. The article presents the utilization of industrial waste like FA as reinforcement for matrix in making lightweight, high strength composites. The main objective for the utilization of fly ash in polymer composites has been its surface polarity due to the presence of silanol, aluminol and other types of -OH groups attached to the metal/non-metal atoms of the constituents of fly ash [8]. Generally, the metallic particles are costly so the spherical particles of FA could assist the above objective.

Overall, the polymer matrices are chosen on account of adhesive strength, fatigue resistance, heat resistance, chemical and moisture resistance, etc. For the matrix mechanical strength compatibility with that of the incorporating material is necessary. Therefore for strengthening applications, a structural resin-like thermosetting matrix such as epoxy-based on DGEBA [diglycidyl ether Bisphenol A], needs to be used. Epoxy resin can be widely used to develop composite material due to its superior properties like excellent adhesion to filler, higher thermal stability, easy processing ability, good chemical resistance and low density [9]. However, properties associated with epoxy like undesirable brittleness due to a high degree of cross-linking structure, delamination, low impact strength, and poor cracking resistance made the limited application of epoxy. From a notable time, researchers have been investigating to get rid of these drawbacks of epoxy and observed that the advancement in mechanical and physical properties such as toughness, rigidness, and strengthening can be acquired from the modification of matrix or by reinforcement of various fillers. The filler/epoxy nanocomposites are extensively used in engineering, anti-corrosive coatings, electronic materials, and aerospace industries [10]. So the question arises, “What are nanocomposites"? In nanotechnology, the nanocomposites are classified as advanced heterogeneous solid material having two or more phase where at least one phase has a dimension in nanometer [1 nm to 100 nm], which are regarded as promising alternatives to overcome the drawback of the polymer matrix, micro, and conventional composites. The development of nanotechnology has induced material restructure which change the properties of the material. It has reported that epoxy resin, reinforced with nanofiller has superior mechanical strength and thermal stability. The nanofillers help to enhance the quality of the product when introduced into the polymer matrix even at very low content (less than 10%). The improvement of mechanical properties and thermal stability is credited to intensely higher surface area and uniform dispersion of nanoparticles with low volume fraction [11]. The nanofillers are incorporated in the form of particles, nanotubes, and whiskers (metallic or nonmetallic single crystal). The performance and characteristics of composites expect the size of reinforcement material, shape, concentration, adaptability with the matrix, the way the filler distributed in matrix, and volume fraction. The interface is also an imperative property of nanocomposite.

In the literature survey, during the fabrication of epoxy nanocomposite, two main challenges i.e. homogeneous dispersion of nanofiller and interfacial nanofiller polymer interaction are encountered. Because nanofiller attributing to a higher ratio of surface to volume, nanoparticles arranged adjacently and form aggregate which restricted homogeneous dispersion of nanoparticles in the polymer matrix [12]. Due to injurious effect of the inorganic nanofillers, there is the strong prospect of agglomeration. Hence, the use of surface modifiers such as silane is used to enhance the dispersion stability of the nanoparticle and evolve the interfacial interactions between inorganic nanofiller and organic matrix is notable. Debonding and agglomeration of particle are major problem encountered in the fabrication of polymeric nanocomposites; induce the most problems in nanocomposite research. The results are reported that stirring methods had an indicative effect on dispersion quality because voids exist between nanofiller and matrix reduces the mechanical properties of polymer nanocomposite. Numerous physical stirring methods such as mechanical stirring, high shear mixing, solvent mixing, and ultrasonic bath stirring have been explored to attain a homogeneous dispersion of nanofiller in the matrix. Ultrasonic vibrations make effectiveness in improving the uniform dispersion of nanofillers [13]. Therefore this review article discusses the polymer nanocomposites reinforced with fly ash, epoxy and nanofiller due to their interesting as well as their unique applications. The knowledge of the immense value of nanocomposites will enable the manufacturer to recognize that polymer nanocomposites will herald a new era in material advancement just as polymer composites transformed the face of industry many years ago.

General Methods of Fabrication of Filler/Polymer-Based Nanocomposites

The surface modification for every type of nanofillers is achievable. The reinforcement of various types of nanofillers in any type of matrix has to need pre-treatment to enhance the interaction between matrix and nanofiller [88]. Based on various parameters the fabrication methods of polymer-based nanocomposites are classified. The process which occurs at the surface of material resulting in different physical and chemical behavior from one originally exhibit on the surface of the material is known as a surface modification. The different techniques such as the sol-gel process, in-situ polymerization, and solution mixing process, melt mixing process and in-situ intercalative polymerization were used for the fabrication of nanocomposites. The following techniques have been reported to modify the nanofillers and reinforced within the polymer to form a nanocomposite.

In-situ polymerization

In-situ word is derived from a Latin phrase that translates literally to "on-site" or "in position. In this method, nanoparticles are dispersed in monomer as well as in monomer solution. Further, this homogeneous mixture was initiated either by radiation or heat, relevant initiator or catalyst [89,90]. The main approach of In-situ-polymerization must be the desirable dispersion of nanofiller in the monomer. However, the difficulty arises due to the control of intragallery polymerization that makes limited applications. Al-Harthi [91] prepared PET/MWCNT nanocomposite by in-situpolymerization with the use of metallocene catalyst (Cp2ZrCl2). Ever in-situ polymerization gives an impressive way to the synthesis of various polymer/nanoclay composites [92]. Cardoso et al. [93] fabricated PP/MMT composites by in-situ polymerization. An enhancement in mechanical characteristics was observed. Korivi [94] also prepared PET/MWCNT nanocomposite by in-situpolymerization.

Melt-intercalation method

This method is employed for polymer nanocomposite which consists of layered silicates such as montmorillonite and silica. In this method, nanocomposite fabricated with a uniform dispersion of plate-like inorganic nanofillers intercalated to exfoliation of layered silicate. Shen et al. [95] studied Poly (ethylene oxide/ Na-montmorillonite and PEO/organo modified bentonite nanocomposite by using the intercalation method. FTIR shows no variation in the spectrum of these nanocomposites. Melt Intercalation methods are environmentally well dispose of but not compatible with industrial polymer processes [96].

Sol-gel method

This method is a tangled combination of in situ polymerization process and in situ formation of nanofiller as reinforcing phase. Halder S.et al. [97] studied the effect of polyvinyl alcohol ZnO nanoparticles on the thermal and mechanical properties of epoxy/ ZnO nanocomposites. The sol-gel method was used to synthesize the modified ZnO nanoparticles. The enhancement in tensile strength, tensile modulus, compressive strength, flexural strength and flexural modulus by 24, 47, 48, 44 and 77% respectively as compared to the neat epoxy system is reported.

Intercalation method

The approach of this method is based on the reducement of fillers into nano dimensions. In this method, the exfoliation of layered silicates acts as inorganic filler exhibits by intercalating an organic compound into the interlayer space of silicate, resulting in a uniform and homogeneous dispersion of plate-like nanofillers [98].

Template method

This method is performed to form particular shapes such as layered, hexagonal shape to nanocomposite materials. The formation of layers exhibits due to the presence of soluble polymer as a template. Mesoporous materials are widely synthesized by the template method but still lacking development of layered silicates. [99].

Direct mixing of matrix and nanoparticles

In the direction polymerization method, the reinforcement between nanoparticles as the reinforcing phase and in polymerization takes place simultaneously. A catalyst or radical initiator starts the polymerization. The approach of direct mixing is based on the disruption of the agglomeration of fillers during the process of mixing [100]. Generally, the mixing of polymer and nanofiller followed in two ways. The first way is based on the mixing of polymer and nanofiller, in the absence of solvent whereas the second, the mixing of nanofiller and polymer matrix as in a solution is.

The above attempts were made to the uniform dispersion of nanofillers by using different methods for the fabrication of the surface of nanofillers. But the production of nanocomposite on an industrial scale, by these fabrication techniques, not suitable because these techniques required complicated chemical reactions. So the Direct melt-compounding method, a conventional method was developed because in this method the surface modification of nanofillers is not required.

Although, the prosperous applications of above various techniques for fabrication of polymer nanocomposites have been reported but the report on several factors is still deficient like the approach of convenient and lower cost process-based method for fabrication of high content nanofiller reinforced polymer nanocomposite to provide optimum property combinations.

Characteristics of Nanofillers

Nanofillers are those additives which enhance the properties of the material. Due to having a higher surface area, the nanoparticles show a tendency to form aggregates, resulting in micron-sized filler clusters. A major problem creates in the homogeneous dispersion of nanofillers in the polymer matrix [44,45]. The interfacial interaction between nanofiller and matrix material plays an important role. Certainly, the overall material properties adapt by the diversity in the macromolecular state region around the nanoparticles due to the high surface area of nanoparticles [46]. A well-dispersed system generally yields the most desirable properties. The dispersion of nanoparticles was characterized by the nano and micro scale. Carbon nanotubes and Graphenes draw enormous interest due to their unique structure and excellent properties. Various authors have developed the polymer nanocomposites based on various polymer matrixes with the nanofillers such as calcium carbonate, aluminum oxide, graphene, silica, carbon nanotubes and nanofibers [47].

Classifications of nanofillers

Generally, nanofillers can be classified according to their number of dimensions 1D, 2D or 3D in nanocomposites, shape, and morphology [48]. The nanofillers are usually incorporated in the form of particles, nanotubes, fibers, and whiskers. The three types of nanofiller are given the following.

The first type of nanofiller is described by one dimension in the nanometer scale like needle-shaped material, laminas and/or shells. In this category, the filler consists of sheets of 1 to a few nm thicknesses and hundreds to thousands nanometer long. For example: nanoclay, nanosheets, nanoplatelets, and nanorods, etc.

The second type is characterized by one large and two-dimension in nanometer range forming elongated structure. In this group nanofiber, nanotubes or whiskers are studied. The nanotubes are generally classified into three main categories (1) SWNT (singlewalled nanotubes) (2) DWNT (double-walled nanotubes) (3) MWNT (multiwalled nanotubes).

The third type of reinforcement consists of all three dimensions in the nanometre range. In this group, spherical silica, metal particles, semiconductor nanoclusters, and nanogranules are studied. Metalbased nanomaterials are those nanomaterials which can be obtained from the metals including quantum dots, nanogold, nanosilver and metal oxides, such as aluminum oxide, titanium oxide. Nanofillers are reinforced into the matrix at very low content from 1% to 10% (in weight).

Nanofillers are also reinforced in inclusion to other fillers like fly ash, sawdust, and additives, and ultimately incorporated with some fibers such as carbon, E-glass, etc. The various nanofillers based nanocomposites are described as following.

Nanoclay (clay-modified epoxy nanocomposites)

The organoclay nanoparticles of layered silica are known as nanoclay. The classification of nanoclay is based on the morphology of particles, crystalline structure, and chemical composition. Montmorillonite is most commonly nanoclay which is reinforced in polymer nanocomposite. And many material applications have revealed an enhancement in properties. Phyllosilicates consist of a shell-shaped structure with thickness in the nanometer range and their crystal lattice is made up of 2-D layers. The natural availability of clay and high form factor plays an important role in developing nanoclay based nanocomposites which create enhancement in physical performances. Nanoclay has a tendency of hydrophilic nature which creates difficulties in homogeneous dispersion within polymer matrixes [49]. Further, the better dispersion of a large amount of nanoclay within polymer matrixes can be acquired with hydrophobic surfactants by the exchange of metal ions with alkylammonium ions. The enhancement in chemical compatibility (interaction of nanoclay with matrix, resulting in good dispersion) may be attributed to the alkylammonium ions constituting the surface functionalities on nanoclays. Recently the related clays like kaolinite, hectrite and saponite have also reinforced in polymer nanocomposite [50]. In 2012, Azeez et al. [51] studied the applications of nanocomposites. Due to high intercalation chemistry and high aspect proportion nanoclay, perform an important role with incorporation in the epoxy matrix. These epoxy/clay nanocomposites have widely used in various applications like aerospace, defence, and automobile industries. Wang et al. [52] developed epoxy/clay nanocomposites exhibiting exfoliated morphology. TEM and optical microscopy were carried out to characterize the nanocomposites. Young's modulus and fracture toughness were enhanced with reinforcement of 2.5 wt% nanoclay. Nanosized clays have commonly used in the advancement of nanocomposites with improved mechanical, thermal, and flame retardant properties grazing from automobile parts to packaging materials.

Carbon nanotubes (properties and carbon tubes-modified epoxy nanocomposites)

Carbon nanotubes (CNT) were discovered in 1991 and gave an interesting approach to the modification of nanocomposites. The main aim of incorporation of CNT is based on the achievement of maximum dispersion into the polymer matrix. CNT is thin, carbon-containing long tubes including unique size and shape show superior mechanical and physical properties. CNT is a special type of fullerene thus the walls of CNT consists of hexagonal graphite structure. Generally, the three types of CNT are examined i.e. single-walled CNT (SWCNT), Double-wall carbon nanotubes (DWCNT) and multi-walled CNT (MWCNT). SWCNT exhibits a hollow structure procured by covalent bonding of carbon atom. The diameter of a SWCNT exists in the range of 0.6-2 nm, the diameter of DWCNT lies between 2 and 4 nm, while the inner diameter of MWCNT in the 1.5-15 nm and the outer diameter of 2.5-50 nm [53,54]. In a vacuum, MWCNTs are thermally reliable up to 28000C. CNT exhibits superior electrical conduction similar to copper. CNT possesses 1/6 of the density of steel and shows 100 times better tensile strength than steel [55]. CNT also has excellent thermal stability than the purest diamond. The heat conductivity of CNT is 3000 W.m-1K-1, electric conductivity of 107 S.m-1. These unique properties of CNT make them compelling material for nanotechnology [56]. The CNT has wide applications in electronics, thermal and structural industry. In 2012, Prolongo [57] considered the water absorption behavior of neat epoxy resin and epoxy resin with a distinct proportion of CNTs and carbon nanofibres. During the hygrothermal ageing, a noticeable change in mechanical properties took place due to the effect of water absorption. Initially, the mechanical strength decreases but later it is renewed. Recently, Marriam et al. [58] studied that the extension of carbon nanotubes thin films (CNTf) in a polymer such as epoxy resin, significantly enhanced the properties like strain sensing, conductivity and thermal properties of various composites. The poor bonding or CNTf with polymers reduces the properties of composites, to get rid of this problem, first the polymer modified with CNT with different wt% and then CNTf introduced to modified polymer solution which demonstrated a new CNT to CNT interphase and interlocking interactions which results in enhancement in tensile strength by 164.76% and peeling strength by 74.38% as compared to unmodified CNTf/epoxy composites.

Tao et al. [59] examined that at lower temperatures the thermal deterioration of epoxy composites induced due to the inclusion of CNT. SEM technique investigated the better interfacial dispersion of CNT with the epoxy matrix. Allaoui et al. [60] determined the electrical and mechanical characteristics of epoxy/Multiwalled carbon nanotube nanocomposite. MWCNT were reinforced with different wt%. They observed that incorporation of MWCNT by 1 wt% and 4 wt% make, double and quadruple improvement in Young’s modulus and yield strength. The insulator to conductor transition occurs with MWCNT conc. between 0.5 and 1 wt%. Whereas, Meeuw et al. [61] studied the morphological characteristic of MWCNT/epoxy nanocomposite with different aspect ratio and content of filler. The strain sensing capabilities were improved by the alignment of particles in load direction. Yuen et al. [62] developed Multiwalled carbon nanotube (MWCNT)/epoxy composites by reinforcement of 0.5 wt% MWCNT into epoxy resin. The morphological properties and characteristics were studied. The glass transition temperature enhances from 167°C for neat epoxy to 189°C for 0.5 wt% CNT/epoxy. However, the bulk resistivity and surface resistivity were reduced from the addition of MWCNT. The bulk resistivity was reduced from .21 × 1016 Ω cm for neat epoxy to 6.72 × 108 Ω cm for 1 wt% MWCNT/epoxy. The surface resistivity of CNT/epoxy composites also reduces from 4.92 × 1012 Ω for neat epoxy to 3.03 × 109. The dielectric constant was found improved from 3.5 for neat epoxy to 5.5 for 1 wt% MWCNT/epoxy. Tanabi and Erdal [63] prepared CNT/ epoxy nanocomposite under different dispersion conditions. They determined that the dispersion process and concentration of CNT also affect the mechanical, electrical and strain sensing properties of CNT/epoxy nanocomposite. Based on the results, two reversion models were carried out to conclude the electric conductivity and the tensile strength of the CNT/epoxy nanocomposites. Implementing verification tests were performed to certify the robustness and efficiency of the models. The obtained results revealed that the fabrication of nanocomposite by dispersion of a lesser amount of CNT with high mixing speeds and long mixing times had enhanced the sensory properties that were much convenient for strain sensing applications.

Metallic nanoparticles (metallic nanoparticles-modified epoxy nanocomposites)

Since 1990, the metallic nanoparticles are in existence in the research field. The particle size of nanoparticles gravely relies upon the production approach of nanoparticles. Metallic nanoparticles correlate to spherical crystal shape of metals such as Ag, Au, and Fe. The main objective of the reinforcement of this type of nanoparticle into the polymer matrix is based on the enhancement of the electrical conductivity of composites. The examples of Metallic nanoparticles are nanogold, nano zinc, nanosilver, nanodiamond, and quantum dots. These nanoparticles show catalytic property which creates antibacterial effects at the surface. Metallic nanoparticles consist of the dimension of particles in the range of 20 to 300 nm with surface areas of 20–500 m2g-1. In comparison to their bulk counterparts, metallic nanoparticles possess different physical and chemical characteristics to have an enormous attraction to industrial applications. The property of high surface area to volume ratio makes metallic nanoparticles unique. In 2016, Arbaoui et al. [64] developed epoxy/different nanoparticle composites with reinforcement of different nanoparticles such as alumina, spinel, and graphite with different wt% into the epoxy matrix. They studied the mechanical and thermal properties of these nanocomposites and revealed that with an increment of nanoparticle concentration into the matrix, the nanocomposite gradually reduces their plasticity and embrace a brittle behavior.

Metal nano oxides-based modified epoxy nanocomposites

The objective with nano-oxides is to obtain a maximized exfoliation and full dispersion into the matrix. The main aim of reinforcement of nano-oxide is to achieve homogeneous distribution and maximum exfoliation into the polymer matrix. Metal nano oxides are also used in commercial applications. In general, the examples of metal oxides are ZnO, CuO, SiO2, TiO2, Fe2O3, and Al2O3.

Nanoalumina-based nanocomposites: The alumina particles have a broad range of sizes from 20 nm to micrometer. Alumina particles have made up of spherical crystal particles of alumina. In 2011, Fu et al. [65] evaluated the effect of nano Al2O3 particles on structure, mechanical characteristics, thermal conductivity, bulk resistivity and thermal stability of Hyper branched [HTTE]/DGEBA analyze the impact properties of these nanocomposites. SEM technique analyzed the impact properties of nanocomposites. The results revealed that the toughness of epoxy composite embellished by the addition of Al2O3 nanoparticles and HTTE epoxy due to the distribution of nanoparticles in the epoxy matrix and clarify the hindrance of single filler reinforced epoxy nanocomposite.