Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2021) Volume 11, Issue 3

Effect of Single-Walled Carbon Nanotubes on the Physical Properties of Cement Paste

Alicia Páez-Pavón1*, M Isabel Lado Touriño1, Felipe Asenjo1, José A. Caballero1, Arisbel Cerpa1, Alberto Galindo1, Mohammed H. Alanbari1 and Andrea García-Junceda22Department of Materials, IMDEA Materials Institute, Getafe, Spain

Received: 02-Feb-2021 Published: 23-Feb-2021, DOI: 10.35248/2252-5211.21.11.398

Abstract

This study is focused on the effect of adding Single-Walled Carbon Nanotubes (SWCNTs) on the rheological and mechanical properties of cement paste, as well as its influence on porosity and microstructure of the final material. The rheological properties were measured by rotational rheometry, while the evaluation of mechanical properties was carried out by compression tests. Porosity was measured with a pycnometer. The microstructure of the samples was analyzed by Scanning Electron Microscopy (SEM). Finally, this investigation includes the results of molecular modeling. Molecular dynamics simulations were performed to study the interaction of pristine of functionalized SWCNTs with a cement surface.

Keywords

Cement; Carbon nanotubes; Molecular dynamics

Introduction

Recently, the addition of carbon nanostructures to construction materials has been generating great interest, especially due to the improvement of mechanical, electrical and thermal properties of cement. The addition of the nanostructures to cement, without a significant weight change, expands its field of use beyond conventional construction applications since reinforced cement presents more insulating sound capacity and higher thermal and electrical conductivity than conventional cement. These new cements could be used to manufacture sensors to monitor deformations in structures, to control the corrosion of metallic structures of reinforced concrete, as cathodic protection, as an electromagnetic shielding material, as a protector of electrical systems, etc [1-4].

However, because of the increased viscosity, which affects the workability and the modification in hydration process, the addition of carbon nanoparticles to cement based materials has some detrimental effects [5,6]. In this context, the aim of this study is to analyses the effect of the addition of single-walled carbon nanotubes (SWCNTs) on the rheological behavior of cement paste, and the effect of the reinforcement on mechanical properties, porosity and microstructure.

The theoretical study of the properties and structure of cementitious materials can be carried out by molecular simulation techniques [7-10]. Among the different methods of simulation, those that describe the interactions between the atoms that make up the system by means of a set of equations and parameters, the so-called force fields are the most appropriate for the study of these materials, since they allow to manage a greater number of atoms in reasonable computation times [11]. In particular, the Molecular Dynamic method (MD) studies the time evolution of a system by applying Newton's equations of motion and gives access to calculating a great variety of properties such as structure, free energy, viscosity, diffusion coefficients or energies of interaction between different components among others [12-15].

Experimental Procedure

Materials

Portland cement type II/B-L 32,5R and single-walled carbon nanotubes (SWCNT), with 2-10 nm diameter and 1-5 μm length (Sigma Aldrich) were used in this study.

Methods

Cement paste was prepared in a ratio 2:1 weight cement-water. The SWCNTs were dispersed previously in water, and then added to cement powder. Cement paste was reinforced with a 0.02% by weight of SWCNTs. Cement paste without SWCNTs was prepared as a control sample.

The steps of the experimental procedure are the following

Dispersion of the SWCNTs in water: The SWCNTs were mixed with water and the mixture was ultrasonicated in a horn sonicator (Sonoplus HD 2070, Bandelin) for 1 h.

Mixture and specimen preparation: The SWCNTs-water dispersion was incorporated into cement powder. The reinforced cement paste was prepared according to the procedure UNE EN 196-1: 2005. A final high speed mixing step was implemented (maximum speed of 18000 rpm). With the freshly prepared cement paste, cylindrical specimens of 2 cm high and 1 cm diameter were molded for the mechanical properties measurements.

Characterization of reinforced cement properties: The rheological properties of cement paste were characterized by a rotational rheometer, (Rheostress 6000), using a double-cone and plate system (60 mm in diameter, 28 cone angle). A three-stage measuring program was used, with a linear increase of shear rate from 0 to 1000 s-1 in 300 s, a plateau at 1000 s-1 for 120 s and a further decrease to zero shear rate in 300 s. The measurements were made at room temperature. The compressive strength was measured, with a universal testing machine, on the test pieces after 7 days after their preparation. Total porosity was measured by a pycnometer, according to the standard UNE EN 1936-07. The microstructure of materials was observed by SEM.

MD simulations to study the interaction of pristine or functionalized SWCNTs with a cement surface: Measurement was performed by using the Forcite module as implemented in the Materials Studio software [16]. The adsorption process was investigated in the NVT ensemble at 298K using a time step of 1 fs. The COMPASSII force field was used to describe energy interactions [17].

To study the adsorption process, a pristine or functionalized SWCNT was initially placed ~19 Å apart from a (001) surface of tobermorite (22.5 Å thick). This crystalline material was used to represent the real structure of cement paste. SWCNTs were functionalized with carboxylic acids (CNT-COOH), carboxylate groups (CNT-COO-) or the anionic Surfactant Dodecyl Sodium Sulfate (SDS) (CNT-SDS). A vacuum slab of 60 Å was introduced to avoid interaction between the system and its periodic images.

Results

Rheological properties

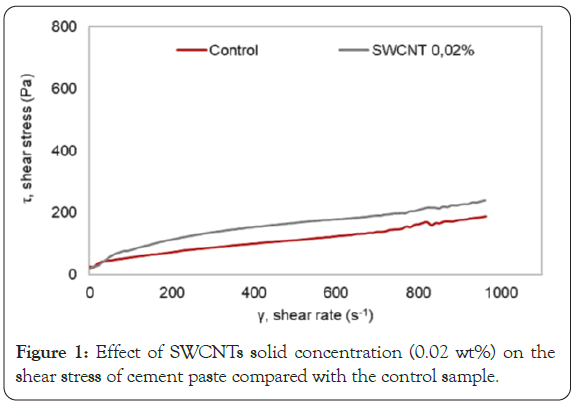

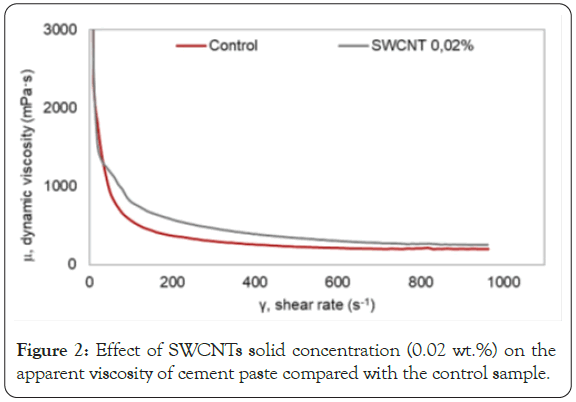

Figure 1 shows the variation of shear stress with the shear rate for unreinforced cement and for the 0.02 wt.% SWCNT reinforced cement paste. As can be seen, both samples show the rheological behavior of a non-Newtonian fluid, in this case it corresponds to the model of a pseudoplastic fluid. Figure 2 shows the dynamic viscosity as a function of the shear rate. In both samples, dynamic viscosity decreased with shear rate. Moreover, the addition of SWCNTs to the cement increased its viscosity. This behavior is due to the high specific surface of the SWCNTs, which attract water molecules, reducing the lubrication of cement powder particles [18].

Figure 1: Effect of SWCNTs solid concentration (0.02 wt%) on the shear stress of cement paste compared with the control sample.

Figure 2: Effect of SWCNTs solid concentration (0.02 wt.%) on the apparent viscosity of cement paste compared with the control sample.

Microstructure

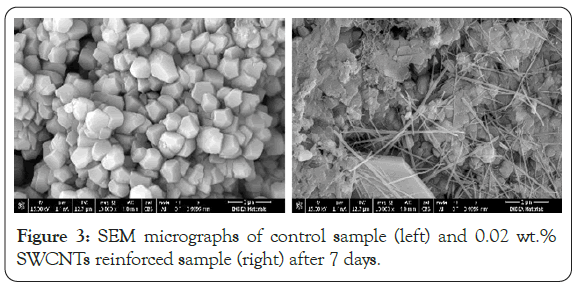

The microstructure of samples 7 days after its preparation can be observed in Figure 3. The reinforced sample showed a developed microstructure, in which hydration products were formed. In contrast, in the control sample it was observed that the setting process was less advanced.

Figure 3: SEM micrographs of control sample (left) and 0.02 wt.% SWCNTs reinforced sample (right) after 7 days.

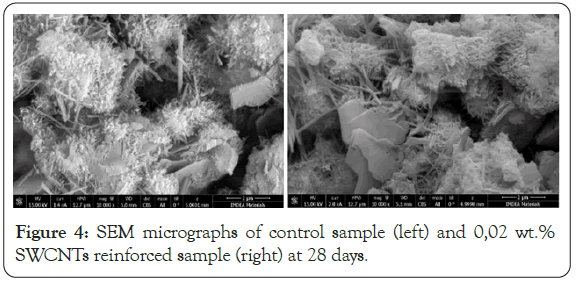

Figure 4 shows the microstructure of control sample and the reinforced one 28 days after its preparation. It can be seen that both microstructures are similar.

Figure 4: SEM micrographs of control sample (left) and 0,02 wt.% SWCNTs reinforced sample (right) at 28 days.

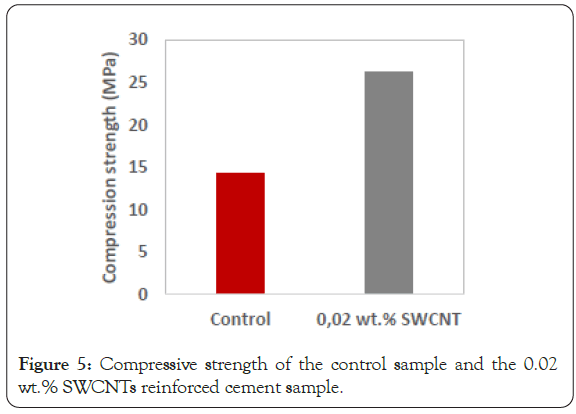

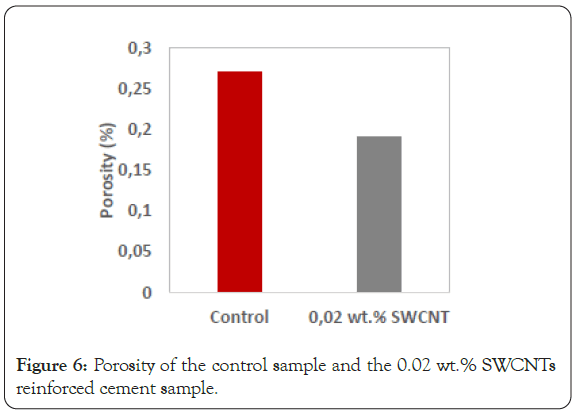

Mechanical properties and porosity

The compressive strength of the samples can be seen in Figure 5. The addition of SWCNTs increased the compressive strength of cement. Moreover, the reinforced sample with a 0.02 wt.% of SWCNTs showed a lower amount of porosity than the control sample (Figure 6). The addition of SWCNTs acts as a pore filler increasing the final density of the material [19].

Figure 5: Compressive strength of the control sample and the 0.02 wt.% SWCNTs reinforced cement sample.

Figure 6: Porosity of the control sample and the 0.02 wt.% SWCNTs reinforced cement sample.

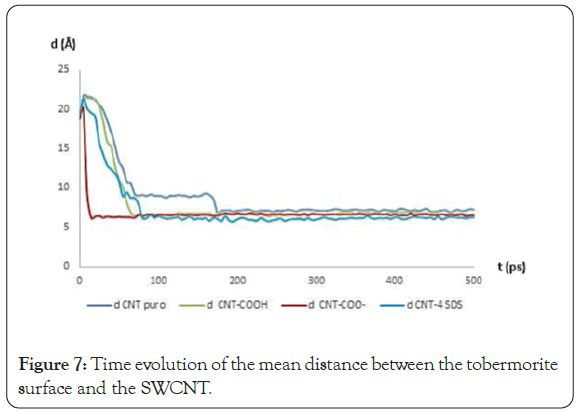

Distance between the SWCNT and the tobermorite surface is shown in Figure 7.

Figure 7: Time evolution of the mean distance between the tobermorite surface and the SWCNT.

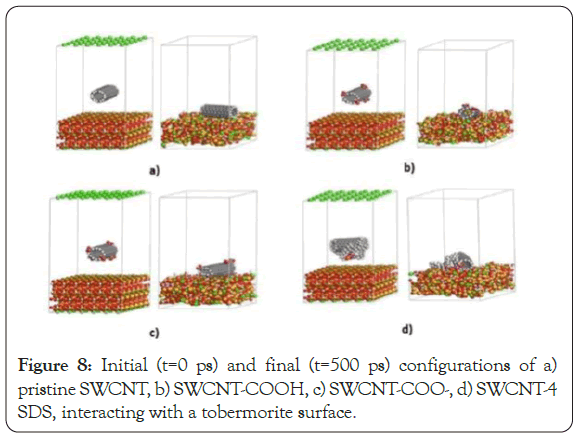

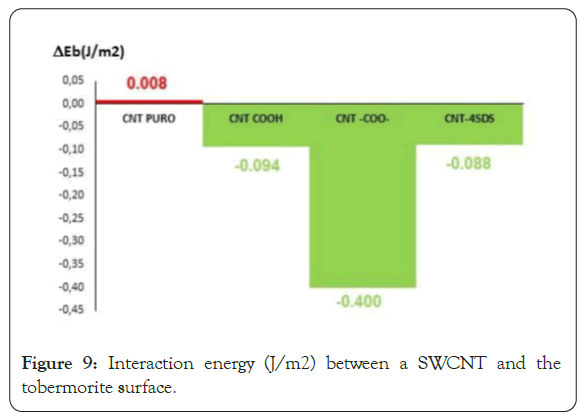

Initial (t=0 ps) and final (t=500 ps) snapshots of the simulations are shown in Figure 8, taking special attention on how the positions of the SWCNT interact with the tobermorite surface. Interaction energies are shown in Figure 9.

Figure 8: Initial (t=0 ps) and final (t=500 ps) configurations of a) pristine SWCNT, b) SWCNT-COOH, c) SWCNT-COO-, d) SWCNT-4 SDS, interacting with a tobermorite surface.

Figure 9: Interaction energy (J/m2) between a SWCNT and the tobermorite surface.

MD simulations show that a pristine or functionalized SWCNT and a (001) surface of tobermorite interact, give rise to the adsorption of the SWCNT. Figures 7 and 8 show that the distance between the CNT and the surface decreases with time. In all cases studied, an equilibrium situation has been reached at the end of the simulation (500 ps). The final average distance varies between 6 and 9 Å depending on the type and degree of functionalization of the SWCNT. SWCNT functionalized with COO- groups clearly stands out from the rest, reaching the equilibrium position at 15 ps of simulation. Possibly, the electrostatic attraction between negative charge of the COO- groups and positive charge of the Ca2+ ions on the tobermorite surface is responsible for a faster interaction in this case.

Interaction energy values (Figure 9) show that the adsorption process is favorable except in the case of the pristine SWCNT (slightly positive energy). This result is not surprising, since pristine SWCNTs are highly hydrophobic, while the tobermorite surface is hydrophilic. In the rest of the cases, the interaction energy is negative being the adsorption process of the SWCNT functionalized with COO- groups the most favored. The introduction of carboxylic groups or the use of SDS also improves the adsorption process.

Conclusion

The addition of SWCNTs nanotubes does not modify the pseudoplastic behavior of cement paste, but it does increase viscosity of the material.

The addition of SWCNTs to cement paste reduces the porosity of the material, which leads to an increase in the compressive strength of cement.

The addition of SWCNTs does not modify the microstructure of the final material. However, the SWCNTs accelerates the hydration process of cement paste.

MD simulation results show that functionalizing a SWCNT with different polar groups or an anionic surfactant improves the interaction between cement surfaces and the SWCNT. This could help to achieve a good dispersion of the SWCNTs in cement paste.

Acknowledgement

Authors thank Universidad Europea de Madrid (project 2018/ UEM18) for the financial support.

REFERENCES

- Konsta-Gdoutos MS. Effect of CNT and CNF loading and count on the corrosion resistance, conductivity and mechanical properties of nanomodified OPC mortars." Constr Build Mater. 2017; 48-57.

- Shang Y, Zhang D, Yang C, Liu Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr Build Mater. 2015; 20- 28.

- Tian X, Hu H. Test and study on electrical property of conductive concrete. Procedia Earth Planet Sci. 2012; 5: 83-87.

- Yunchuan Z, Liang B, Shengyuan Y, Guting C. Simulation analysis of mass concrete temperature field. Procedia Earth Planet Sci. 2012; 5: 5-12.

- Lu Z. Early-age interaction mechanism between the graphene oxide and cement hydrates. Constr Build Mater. 2017; 152: 232-239.

- Makar JM, Chan GW. Growth of cement hydration products on singlewalled carbon nanotubes. J Am Ceram Soc. 2009; 92: 1303-1310.

- Pellenq RJM, Kushimac A, Shahsavarib R, Vlietd KV, Buehlerb JM, Sidney Y, et al. A realistic molecular model of cement hidrates. PNAS. 2009; 106: 16102-16107.

- Bauchy M, Qomi MJA, Ulm FJ, Pellenq RJM. Order and disorder in calcium-silicate-hydrate. J Chem Phys. 2014; 140: 214503-2145039.

- Dolado JS, Griebel M, Hamaekers J. A molecular dynamic study of cementitious calcium silicate hydrate (C-S-H) gels. J Am Ceram Soc. 2007; 90: 3938-3942.

- Zaoui A. Insight into elastic behavior of calcium silicate hydrated oxide (C-S-H) under pressure and composition effect. Cem Concr Res. 2012; 42: 306-312.

- Guvench O, MacKerell AD. Molecular Mechanics. Curr Pharm Des. 2012; 20(20): 3281-3292.

- Allen MP. Introduction to molecular dynamics simulation. NIC Series. 2004; 23: 1-28.

- Wang J, Hou T. Application of molecular dynamics simulations in molecular property prediction density and heat of vaporization. J Chem Theory Comput. 2011; l 7: 2151-2165.

- Jimenez-Saez J, Perez-Martin A, Jimenez-Rodriguez J. A molecular dynamics study of atomic rearrangements in Cu clusters softly deposited on an Au (001) surface. Nucl Instrum Methods Phys Res B. 2006; 249: 816-819.

- Martínez L, Andrade R, Birgin EG, Martínez JM. Packmol: A package for building initial configurations for molecular dynamics simulations. J Comp Chem. 2009; 30: 2157-2164.

- The Biovia. 2018.

- Sun H, Ren P, Fried JR. The COMPASS force field: Parameterization and validation for phosphazenes. Comput Theor Polym Sci. 1998; 8: 229-246.

- Wang Q, Wang J, Lv C, Cui X, Li S, Wang X. Rheological behavior of fresh cement pastes with a graphene oxide additive. New Carbon Mater. 2016; 31: 574-584.

- Rashad AM. Effect of Carbon Nanotubes (CNTs) on the properties of traditional cementitious materials. Constr Build Mater. 2017; 153: 81-101.

Citation: Páez-Pavón A, Touriño MIL, Asenjo F, Caballero JA, Cerpa A, Galindo A, et al. (2021) Effect of Single-Walled Carbon Nanotubes on the Physical Properties of Cement Paste. Int J Waste Resour.11:398.

Copyright: © 2021 Páez-Pavón A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.