Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2021) Volume 10, Issue 4

Design and evaluation of Tef row seeder and fertilizer applicator

Geta Kidanemariam*, Solomon Tekeste and Abebe TekluReceived: 30-Mar-2021 Published: 23-Apr-2021, DOI: 10.35248/2168-9881.21.10.209

Abstract

Tef is a typical cereal produce and a staple food of Ethiopians. To produce this crop a great amount of time and labor are required from field preparation (plowing, harrowing, seeding and weeding, etc.) to harvesting and post harvesting operations. The grain is ground into flour, fermented and made into enjera a sour-dough type flat bread. Tef production needs six to eight times of plowing and then during the seeding operation the farmers use trampling and broadcasting. Farmers’ traditional practice is to broadcast at the rate of 40-50 kg.ha-1. Now a day, new research results show that row planting increase yield by 200% and the recommended seeding rate becomes 3-5 kg.ha-1. It would be very difficult to evenly distribute this rate because of the small seed size; weight of 1000 seeds is only 0.265gr. To achieve the new rate and combat the Farmers’ problem of planting, a hand-pulled drum-type Tef seeder was developed and tested at Bahirdar Agricultural Mechanization and Food Science Research Center. The three row seeder and fertilizer applicator has seeding rate of planting 3.5-5 kg.ha-1 Tef seeds and applying 50-200 kg.ha-1 fertilizer. Its capacity /coverage/ is 0.20 ha.hr-1. This technology is appropriate and recommended for small scale Tef producers. It should be evaluated at different soil type and moisture level and promoted to different areas.

Keywords

Tef; Row seeder; Fertilizer applicator

Introduction

Different types of cereals are grown in almost all regions of Ethiopia. The area coverage is out of the total grain crop area, 78.17% (9,601,035.26 hectares) was under cereals. Tef, M, Sorghum and Wheat took up 22.23% (about 2,730,272.95 hectares), 16.39% (about 2,013,044.93 hectares), 13.93% (1,711,485.04 hectares) and 13.25% (1,627,647.16hectares) of the grain crop area, respectively. Also in production cereals contributed 84.96% (about 196,511,515.46 quintals) of the grain production. Maize, Tef, Wheat and Sorghum made up 26.63% (61,583,175.95quintals), 16.28% (37,652,411.66 quintals), 14.85% (34,347,061.22 quintals) and 15.58% (36,042,619.65 quintals) of the grain production, in the same order. The area coverage for Tef, Sorghum and Maize are 26.03%, 13.56% and 10.24%, respectively, of the total cultivated land of the Amhara region. Based on production, Tef, Maize and Sorghum are 21%, 19.33% and 15.58%, respectively, of the total cereal production of the region (CSA, 20018). In East Gojjam, the dominant crop is Tef which covers 39.47% (170,168.53 ha) of land and yields 36.33 % (1,971.905 Tonnes) of total cereal production. Similarly in West Gojjam, Tef has a land coverage 25.08 % (102,895.72 ha) and in yields 15.69% (896.714 Tonnes) (CSA, 2008).These statistics show that in both West and East Gojjam, Tef is one of the dominant crops.

It is obvious that productivity of agriculture is strongly related to among other factors, the timely and efficient land preparation activities. Most of the farmers in the country usually prepare their land either using human power or drafting animals. By its nature, Tef is a labor intensive crop and farmers currently use a high tillage frequency compared to other cereal crops grown in Ethiopia [1]. The reason for the high tillage frequency is that the Tef seed is very small and thus germination is difficult in heavy and unbroken soil. According to Melesse [2] the tillage frequency for Tef in Ethiopia ranges from 3 to 5 times for low rainfall and 5 to 9 times especially in high rainfall areas Tarekegne et al., [3] and 3 up to5 times in west and east Gojjam [4]. Generally, the Tef tillage frequency varies from place to place depending on the agroecology, the type of soils, and other characteristics of the area including farmers’ working ability.

The seeding rate of Tef varies according to the farmers’ practice and the type of seeding. About 15-55 kg of Tef seeds are sown per hectare under different conditions. If sowing is to be done by hand broadcasting, it would be difficult to evenly distribute the 15 kg.ha-1 of seeds because of the small seed size 1000 seed weight is only 0.265 grams. Therefore 25-30 kgha-1 seeds recommended for broadcasting. Farmers’ traditional practice is to broadcast Tef at the rate of 40- 50 kg.ha-1 [5]. There are different challenges and constraints facing Tef production, among the firsts are trampling, row seeding and weeding, especially in West Amhara region and also at Tef producing area of the country.

Ethiopian farmers use the method of broadcasting for sowing Tef seeds. This is mainly due to the very small seed size of the crop which makes row planting difficult. Tef seeds’ equivalent diameter was reported to vary between 0.71 to 0.87 mm and a thousandgrain mass 0.257 to 0.421 gram in the moisture content range 5.6% to 29.6% w.b. [6]. Typically, the farmers apply 25 to 50 kgs of Tef seeds per hectare. Planting Tef in rows (using hand dropping) by keeping 20 cm between rows gave 200% yield increment than broadcasting [7].

The time of sowing differs from place to place. In East Gojjam Zone, Degen and Bichena area where the soil is black soil (heavy clay), the framers sowing on the mud condition locally they said ‘‘sinesrew” means after the soil become saturated (after the half of July and the beginning of August in rainy season); this is happened due to so money reasons among these are to protect from lodging, weeds and lastly to minimize loss at harvest/due to rain at harvest time/(personal communication with Farmers).

After promotion of row seeding some Farmers utilize hand dropping system, which require more labor and time. Since the seeds are very small, the Farmers need to work closer to the ground otherwise the seeds are blown away by the wind making it difficult to keep in row. Also this method requires to plant seeds in different rows with limited distance between rows (mostly 20 cm apart). The Farmers said ‘row seeding is useful but the mentioned requirements are very difficult and to work with the system is pain full in their back (personal communication). So, to combat the burden of Farmers’ and apply the agronomical requirements (to keep the specified row distance and seeding rate) it should be done by equipment.

Since the origin of Tef is Ethiopia, it is not possible to search technology from elsewhere. Therefore, the objective of this research was to develop and evaluate appropriate Tef seeder and fertilizer applicator.

Materials and Methods

The design started with its conceptual design and followed as milestone using the literature with agronomical recommendation, farmers’ needs and our personnel communication. By considering these the following design requirements were listed.

The technology design requirements were:

• Easy for transportation and operation

• To be pulled by a single person

• Should be able to work at any level of soil moisture

• To have coverage of 0.10- 0.25 ha hr-1

• Seeding rate of 3-5 kgha-1

• Distance between rows (discharge points ) should be 20 cm apart

• Rate of fertilizer to be 50-200 kgha-1 (with fertilizer applicator)

• Material selection was considered using available raw material

that is environmentally friendly and easy to produce and maintain.

• Ergonomically suitable for operator handling and operating condition considered (the height of the handle was determined by taking the average height of the farmers in the area & position of the handle to be easy for manipulation)

• The price was set at affordable level (1000 ETB (about 30USD))

Crop parameter and seeder size determination

Tef is the smallest grain in the world, ranging from 1-1.7 mm long and 0.6-1mm diameter with l000 seed weight averaging 0.3-0.4 gram. The small seed should pass regularly with uniform flow rate to the given line of pull on the soil. By considering affordability and easy of manufacture and maintain of the equipment, most parts were fabricated from sheet metal. The seed plate shape decided to be round as to be simple in manufacture and it was fabricated from sheet metal having the small diameter of the opening. The size of the sieve opening was determined based on the size of Tef seed. The openings were designed and fabricated with three levels of opening, the small opening 2 mm, average opening 2.5 mm and the large opening with the diameter of 3 mm. These openings were tested by making sieve and shaking with hands by reciprocating motion on the sieve, collect the fallen seeds for 1 minute time and then calculated the amount of flow on the given time.

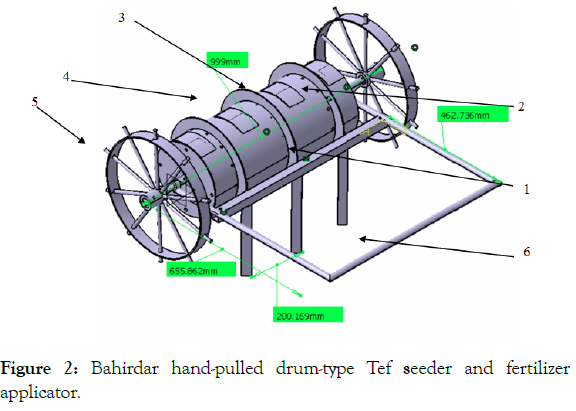

Then, among the openings the ideal opening i.e. 2.5 mm diameter was chosen. After determination of the openings size the drums’ hole diameter was decided to be 2.5 mm. The metering plate for fertilizer was determined with fertilizer size and the amount of flow was regulated by the partitions plate with four holes and located inside the hopper. The drum is used as hopper and it has two partition separates with plates which serve as seed metering units. The hopper holding capacity (size) was determined based on the size of the majority farm land owner ship it is estimated around 0.25-1 hector of land, and considered at least to cover this area with three or four times filling of hopper with Tef seed. The major components of the seeder are shown (Tables 1 & 2). Based on the conceptual design and size determination, the manufacturing drawing were prepared and the prototype was manufactured at Bahir Dar Agricultural Mechanization and Food Science Research Center (Figures 1 & 2).

Figure 1: Bahirdar hand-pulled drum-type Tef seeder and fertilizer applicator.

Figure 2: Bahirdar hand-pulled drum-type Tef seeder and fertilizer applicator.

| S/N | Parameters | Value |

|---|---|---|

| 1 | Number of rows | 3 |

| 2 | Distance between rows | 20 cm |

| 3 | Seeding rate | 3.5-5 kg.ha-1 |

| 4 | Overall size (L x W x H) | 140 x 100 x 40 cm3 |

| 5 | Over all weight | 21 kg |

| 6 | Rate of coverage capacity | 0.20-0.23 ha.hr-1 |

| 7 | Fertilizing rate | 50-200 kg.ha-1 |

Table 1: Specification of the hand-pulled drum-type Tef seeder.

| S/N | Part | Material | Size | Main purpose |

|---|---|---|---|---|

| 1 | Furrow opener frame | Square pipe | 40x40 mm2 & L=800 mm | To connect the furrow opener to the handle |

| 2 | Main shaft | Steel shaft and galvanized pipe | L=1000xØ 20mm | To connect the drum to the ground wheel |

| 3 | Hopper | Sheet metal | LxØ=600x500mm | To hold the seed and fertilizer |

| 4 | Plate | Sheet metal | Ø250x2mm | To divide seed from fertilizer |

| 5 | Ground wheel | Sheet metal | Ø400x 4 mm | To transfer motion from ground to the drum |

| 6 | Handle | Galvanized pipe | Ø22x2000 | To pull the seeder in the right way |

Table 2: Parts of seeder.

Operation

Bahirdar drum-type three-row Tef seeder and fertilizer applicator works by human labour. It is a pulled type. When the ground wheel rotates, the drum is rotates with it at the same speed and numbers of rotation as the ground wheel, to overcome the slippage the wheels has pegs at its outer ring (the motion is transferred from the ground wheel to the drum through the main shaft). There are ten openings on the drum (cylinder) with equal distances on the same line. Since there are three rows, that means there are thirty holes for seed and thirty holes for fertilizer. The seeds and fertilizers dropped by gravitational force and internal movement of seeds and fertilizers. There are two compartments for each hopper. The first one is used as hopper with one side having a partition with a different size and number of holes which controls the seed and fertilizer rate. The second compartment helped to distribute to the external opening holes.

The rotated seeds and fertilizers in the internal part of cylinder coincided with the opening of the cylinder holes then can be discharged, the seeds and fertilizers flow (slide) regularly on the external part of drum with the help of tangential force. Since the Tef and fertilizers are rounded in shape, it is easy to roll and coincide with the hole of any opening by the motion of the drum. When the seeder pulled the furrow opener opens the soil for the fallen seeds and covered by the soil itself. The distance between rows is 20cm apart. The ground wheel with its pegs were adjusted to use as marker on the side plots in order to identify the planted with unplanted plots.

Technical evaluation

The seeder hopper was filled with Tef seed and then the two wheels of the seeder were lifted by a stand from the level ground, marking of wheel side in order to count the full rotation of the wheel. The seeds were collected for the given number of wheel rotations. The plate with its opening which helped to separate the internal part of the cylinder was opened at two sides (both holes). The rotations of wheels were 50 times for each test and the lapped times were registered for this specific rotation (Tables 3 & 4). To keep the uniformity of evaluation, one person was practiced and used to complete the rotation of the wheel and whole test. The amount of seed at a given period and speed were calculated by using simple descriptive analysis. Based on the obtained amount of seeds, it was possible to determine the amount of seeds for a given speed of the machine (Table 3). In regard of determining the fertilizer rate, there were four openings at the fertilizer disc (plate), which can give possibilities of controlling different rate of fertilizer. Each opening can deliver around 50 kg.ha-1 of fertilizer, its result shown in Table 4. These amounts of intervals could obtain using the different opening of the fertilizer disc (plate). There are four openings with 900 in opposite direction and different edge of the plate.

| Hopper level | Time (s) | Speed (ms-1) | Weight of seeds (g) | Seed rate (kg.ha-1) |

|---|---|---|---|---|

| Full hopper | 68.83 | 1.14 | 7.28 | 4.64 |

| 68.88 | 1.13 | 6.54 | 4.16 | |

| 66.89 | 1.17 | 6.34 | 4.04 | |

| Average | 68.20 | 1.14 | 6.72 | 4.28 |

| Half hopper | 69.34 | 1.13 | 5.88 | 3.74 |

| 67.14 | 1.16 | 6.05 | 3.85 | |

| 66.49 | 1.18 | 5.80 | 3.60 | |

| Average | 67.65 | 1.15 | 5.91 | 3.73 |

| Average Seed rate is 3.6-4.6 kg.ha-1 | ||||

Table 3: Testing parameters of the seeder and its calculated value.

| Hopper level | Rep | Amount of fertilizer in each hole (partition hole) |

Time (s) |

Speed (m.s-1) |

Fertilizer rate (kg.ha-1) |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | ||

| Full hopper | 1 | 70 | 142 | 182 | 302 | 88.0 | 80.60 | 86.15 | 85.20 | 0.89 | 0.97 | 0.91 | 0.92 | 44.58 | 90.45 | 115.92 | 192.36 |

| 2 | 95 | 148 | 185 | 312 | 90.0 | 76.80 | 94.0 | 87.10 | 0.87 | 1.02 | 0.83 | 0.90 | 60.51 | 94.27 | 118.03 | 198.73 | |

| 3 | 86 | 135 | 221 | 320 | 89.0 | 85.15 | 83.10 | 84.60 | 0.88 | 0.92 | 0.93 | 0.93 | 54.77 | 85.98 | 140.76 | 203.82 | |

| 4 | 76 | 144 | 265 | 298 | 91.0 | 73.04 | 94.02 | 72.30 | 0.86 | 1.07 | 0.83 | 1.08 | 48.41 | 91.72 | 168.78 | 189.80 | |

| 5 | 71 | 138 | 208 | 325 | 85.0 | 81.49 | 82.10 | 78.60 | 0.92 | 0.96 | 0.95 | 0.99 | 45.22 | 87.90 | 132.48 | 207.00 | |

| Average | 79.6 | 141.4 | 212.2 | 311.4 | 88.60 | 79.42 | 87.87 | 81.56 | 0.90 | 0.98 | 0.89 | 0.96 | 50.70 | 90.06 | 135.20 | 198.02 | |

| Half hopper | 1 | 83 | 178 | 268 | 310 | 84.30 | 90.30 | 78.40 | 81.30 | 0.93 | 0.86 | 1.01 | 0.96 | 52.86 | 113.40 | 170.69 | 197.45 |

| 2 | 73 | 142 | 208 | 318 | 89.10 | 93.20 | 85.10 | 95.40 | 0.88 | 0.84 | 0.92 | 0.82 | 46.49 | 90.45 | 132.48 | 202.53 | |

| 3 | 91 | 136 | 190 | 305 | 86.20 | 85.40 | 92.00 | 86.30 | 0.91 | 0.92 | 0.85 | 0.91 | 57.96 | 86.62 | 121.02 | 194.27 | |

| 4 | 94 | 160 | 223 | 294 | 83.35 | 82.15 | 90.10 | 88.35 | 0.94 | 0.95 | 0.87 | 0.88 | 59.87 | 101.91 | 142.04 | 187.26 | |

| 5 | 77 | 165 | 214 | 306 | 92.40 | 80.40 | 93.20 | 91.40 | 0.85 | 0.97 | 0.84 | 0.85 | 49.04 | 105.10 | 168.15 | 194.24 | |

| Average | 83.6 | 156.20 | 220.60 | 306.60 | 87.07 | 86.29 | 87.76 | 88.55 | 0.90 | 0.91 | 0.89 | 0.88 | 53.24 | 99.49 | 146.87 | 195.15 | |

Table 4: Testing parameters of the seeder on its fertilizer rate and its calculated value.

The laboratory test was conducted based on the test procedure [8]. At one rotation of the wheel the ground distance is 1.57 m and within 50 rotation of the wheel it covers the length of 78.50 m. During this distance the dropped seed and fertilizer was collected at the discharge outlet of the seeder and fertilizer and then calculated using simple arithmetic (Tables 3 & 4). To calculate the seeding and fertilizer rate of the seeder the following assumptions and calculation were applied.

To determine the required seeding rate literature and agronomical recommendation was employed, that is 4-6 kg per hector for Tef seed and 50-200kg.ha-1for fertilizers. Theoretically, the seed rate can be calculated using the following information. The diameter of the ground wheel is 50 cm. The distance between the two rows is 20 cm. Number of rows at one pass (rows of the seeder) are three; at one pass the seeder can operate three lines. The size of one hector is 100 mx100 m. The length (L) on which the seeder at one row travel is determined by dividing the hector width by the space between two rows times the length of the hector (l).

In our case, L=100/0.20 x l=500 x 100=50000m this is divided by the number of rows of the seeder (the seeder can cover with one pass) 50000/3=16666.67m. The ground wheel can travel at one revolution without slippage is to be:

Lw= ПxD=3.14 x 0.50=1.578 m=1578 mm

Then, the seeder can cover the above distance with 167 pass, the width of one hector divided by the number of rows and distance between rows ( 10000/3 x20)=166.67=167. And it is possible to calculate the amount of seed per meter, this leads to know the seeding amount of the seeder in line with the laboratory test result. That means seed rate per meter can be calculated according to the Recommended Seed Rate (RSR). For this purpose the recommended seed rate is selected 6 kg .ha-1 and it used as reference.

R.S.R ==6000 g/16666.67 m=0.36 g/m or 0.57 g of seed for one revolution of the seeder wheel. The working speed of the machine is depending on the speed of the laborer (operator). The speed of normal walking person is estimated 1.0-1.25 m.s-1. In laboratory, the seed rate was checked under the operating speed of 1.13-1.18 m.s-1and the data’s depicted on the Table 3. In the same way the fertilizer rates were determined and shown in the Table 4.

Results and Discussions

Based on the test procedure Smith et al., the following results were obtained and depicted in Tables 3 & 4. The hopper filling level has influence in the fallen of seeds at the furrow, the full and half level of the hopper shows some difference and after arithmetic calculation the result revealed the standard deviation around +12% [8]. This means there is no a big difference of hopper filling in delivering the amount of seed at a given rotation (time). When the hopper is closer to empty or less than the quarter of the hopper, the seed rate becomes under the recommendation rate less than 3kg.hr-1. The seeder could plant keeping 20 cm distance between rows at the seed rate of 4-6 kg.ha-1, that means it fulfill the agronomical recommendations. The fertilizer rate was between 50-200 kg.ha-1 Table 4. These amounts of intervals could obtained using the different opening of the fertilizer disc (plate).

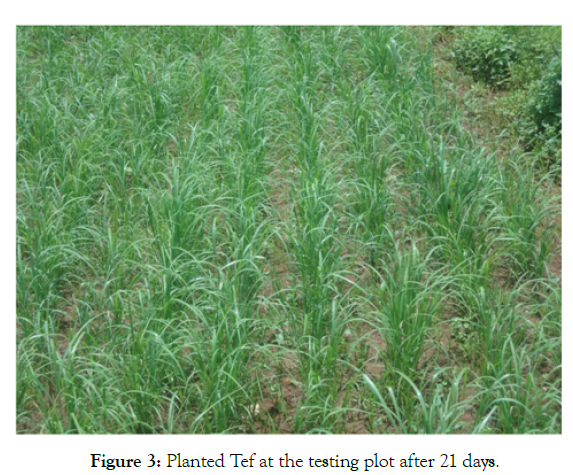

After determination of the seed rate at the laboratory level, the performance of the prototype was evaluated in the field at clay soil with 28 % of the average soil moisture content and after 21 days of planting the crop stand was observed (Figure 3). The result shows that the distance between plants were 18 cm-23 cm apart with uniform amount of plant population at a given area. The farmers and other expertise that could have possibility to see this field, suggested that ‘the technology shows promising result in keeping recommended row space and uniform plant population and should be demonstrated in different area’.

Figure 3: Planted Tef at the testing plot after 21 days.

Conclusion

The drum type seeder and fertilizer applicator showed to plant the Tef seed and its fertilizer as agronomical recommendation. The seed rate is 3.6-4.6 kg.ha-1 and the fertilizer rate is 50-200 kg.ha-1. The technology is simple for operation, easy for manufacturing and transportation. Hence, it can be useful for small scale Tef producers. The technology should be evaluated at different soil type and moisture level and promote to different area.

Acknowledgment

The authors acknowledge the Amhara Agricultural Research Institute for the research financial support. And the work shop technicians at Bahir Dar Agricultural Mechanization and Food Science Research Center for their valuable comments and prototype production.

REFERENCES

- Gebretsadik H, Haile M, Yamoah CF. Tillage frequency, soil compaction and N-fertilizer rate effects on yield of teff (Eragrostis tef (Zucc) Trotter) in central zone of Tigray, Northern Ethiopia. Momona Ethio J Sci. 2009;1(1).

- Leye MT. Conservation tillage systems and water productivity-implications for smallholder farmers in Semi-Arid Ethiopia. Institute for Water Education, Delft, The Netherlands. CRC Press; 2007.

- Tarekegne A, Gebre A, Tanner DG, Mandefro C. Effect of tillage systems and fertilizer levels on continuous wheat production in Central Ethiopia. The Ninth Regional Wheat Workshop for Eastern, Central and Southern Africa. CIMMYT, Addis Ababa, Ethiopia 1996;56-63.

- Gelaw GK, Likeleh G, Getahun A, Liben M. Participatory evaluation and demonstration of animal drawn compactor for Tef seedbed preparation. Agric Eng Int: CIGR J. 2013;15(2):112-121.

- Ketema S. Tef. Eragrostis tef (Zucc.) Trotter. Promoting the conservation and use of underutilized and neglected crops. International Plant Genetic Resources Institute, Rome, Italy. 1997.

- Zewdu AD, Solomon WK. Moisture-dependent physical properties of Tef seed. Biosyst Eng. 2007;96(1):57-63.

- Agricultural Transformation Agency. Value chain programs: Tef.2013.

- Smith DW. Testing and evaluation of agricultural machinery and equipment: principles and practices. FAO. 1994.

Citation: Kidanemariam G, Tekeste S, Teklu A (2021) Design and Evaluation of Tef Row Seeder and Fertilizer Applicator. Agrotechnology 10: 209.

Copyright: © 2021 Kidanemariam G, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.