Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Original Research Article - (2020) Volume 10, Issue 1

Comparison of Technologies to Serve Waste to Energy Conversion

Rafey A*, Prabhat K and Mohd SamarReceived: 17-Jan-2020 Published: 04-Feb-2020, DOI: 10.35248/2252-5211.20.10.372

Abstract

The increasing demand of energy has led to a chaos among the existing energy sources whether it may be thermal, nuclear, hydro or solar power. Hence, it becomes important for an alternate, feasible and sustainable energy source. Municipal solid waste (MSW) serves as an efficient and reliable option for the conversion of waste to energy since long. But the problem exists with the conversion technology which imposes restriction on its use. This paper discusses the different conversion technologies which include incineration, pyrolysis, gasification and biomethanation. The technologies are compared on various physical and chemical parameters with keen interest on environmental sustainability of the waste to energy (WtE) system. The evaluation results reveal that the biological methods are best suited for the waste to energy conversion with least degradation of the environment. Other methods such as incineration, pyrolysis and gasification are quite efficient and give a high yield but they harm the environment in the form of harmful gaseous emissions which certainly lead to global warming and greenhouse effect. This study can overall contribute to the development of more efficient and specific WtE technology which would help lower the MSW reaching the landfills generating cleaner energy to serve the future generation.

Keywords

Municipal solid waste; Waste to energy; Landfill; Composting; Biomethanation; Pyrolysis; Gasification

Introduction

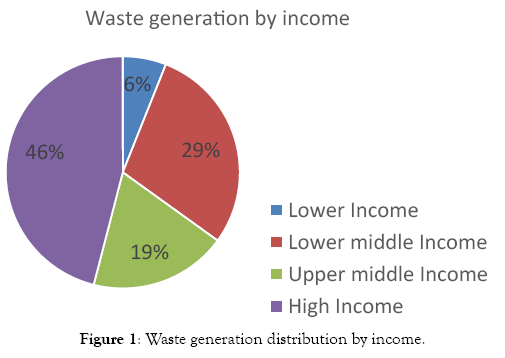

With the increase in population both at urban and rural level there is a tremendous increase in the demand for various resources which eventually lead to simultaneous increase in generation of waste and particularly MSW which has become a major topic of debate globally. Municipal solid waste (MSW) includes domestic waste and garbage, streets cleaning, construction and demolition waste, sanitary residues, trade and non-hazardous industrial waste and some treated biomedical solid waste [1,2]. The contribution largely revolves around households where improper segregation and management lead to the disposal of MSW in landfill. The landfills have not only become the dumping ground for inefficient MSW but also the recyclables are being dumped due to the improper solid waste management. According to the World Bank report of 2012, annually 1.3 billion tonnes of solid waste is generated, and by 2025 its volume is expected to increase to 2.2 billion tonnes. Countries with higher per capital income have more waste than countries with lower income (Figure 1). More income and urbanization indicate higher affordability and higher consumption of goods; therefore more waste is generated.

Figure 1: Waste generation distribution by income.

Rapid urbanization and change over the last few decades has resulted in 31.2% of the population living in urban areas. There are three mega cities- Greater Mumbai, Delhi, and Kolkata- that support a population of more than 10 million people. In addition to these, 53 cities have more than 1 million population and 415 cities have a population of 100,000 and above (Census, 2011). This huge growth in urbanization in our country has resulted in an increase in domestic and industrial waste. It is estimated that over 160,000 metric tonnes (MT) of municipal solid waste is generated daily in the country. The per capita waste generation is estimated to increase at 1.33% to generate around 260 million tonnes of waste generated in 1997. Further, if this waste is not disposed and systematic manner, we would need a big city as big as Delhi to dump this waste. Typical rates estimated that the amount of solid waste generated in urban areas of India increases by about 1.3% per year [1,3]. The generation and collection trend of MSW by different states as given in CPCB report of 2018 is shown in Table 1.

| S. No. | States | ULBs (Urban local bodies) | Solid Waste Generated TPD | Solid Waste Collected TPD |

|---|---|---|---|---|

| 1 | Arunachal Pradesh | 17 Urban Divisions | 203.96 | 166.82 |

| 2 Municipal Councils | ||||

| 2 | Madhya Pradesh | 378 | 7212 | 6537 |

| 3 | Meghalaya | 7 | 210 | 175 |

| 4 | Nagaland | 32 | 348 | 252 |

| 5 | Orissa | 114 | 539.44 | 471.58 |

| 6 | Sikkim | 7 | 73.34 | 63 |

| 7 | Tripura | 20 | 379.2 | |

| 8 | Jammu & Kashmir | Jammu Division: 78 | 666.68 | 617.83 |

| Kashmir Division: 42 | 930.6 | 833.3 | ||

| 9 | Chhattisgarh | 166 | 2000 | |

| 10 | Uttarakhand | 101 | 1099 | 1099 |

| 11 | Chandigarh | 1 | 500 | 463 |

| 12 | Tamil Nadu | 12 Corporations | 15176.612 | 14568.333 |

| 124 Municipalities | ||||

| 528 Town panchayats | ||||

| 13 | Telangana | 73 | 7804 | 7023 |

Table 1: MSW generation and collection in major states, 2017-2018 (CPCB, 2018).

The first historic attempt to transform waste energy was in the postindustrial era. Syngas is produced through a gasification process to supply urban lighting infrastructure. Indeed, the so-called city gas is stored in the gazometers and can be found in most of the surrounding big cities as an industrial heritage. To minimize waste generation, it is vital to concern sustainable development of society [4,5], but the energy harvesting from its flow is the most viable option for social transformation with renewable technologies [4-7]. More and more waste produced wouldn’t be an issue if garbage is treated as a resource and properly managed. However, despite the large amount of waste generated, cities still suffer from power shortages due to excessive dependence on fossil fuel power and electricity use generator.

Although it has been found that fossil fuel deposition can meet human energy needs but this type of deposit is limited. Exploration and production costs make them an exorbitant product in the market. Our energy needs are also growing corresponding to population growth and technology progress [8,9]. It is necessary to explore renewable energy and waste to energy to reduce dependence on fossil fuel power generation which results greenhouse gases, which in turn deplete the ozone layer, leading to global warming and is highly accepted by the scientific community. Appropriate use of municipal solid waste plays a vital role in reducing pollution and Greenhouse gases, which reduce the impact on the atmosphere. Energy recovered from Municipal solid waste (MSW) can also reduce the consumption of fossil fuels. It also reduces the amount of land needed to dispose of municipal solid waste. Bad emissions from landfills to air and water. MSW is a resource with immense scope in materials and energy recovery [8-10].

Optimum use of MSW can generate a reasonable amount of electricity which can power the communities and even small factories. On a global scale, people have made tremendous efforts to develop processing technology to unlock resources and economic value of surplus waste as population grows and demand for optimal sustainability of waste management [11].

Sources of MSW

MSW can be categorized into 3 types:

Biodegradable waste

Comes from plants or animal sources and can be degraded or broken down by other living organisms

Non-biodegradable waste

This is made up of man-made material that cannot be broken down naturally by other organisms.

Household hazardous waste

This waste may be dangerous, toxic or flammable. This waste is classified as its own category because it is non-biodegradable and cannot be disposed along with other inorganic municipal solid waste.

In order to convert the waste to energy, it is important to know the composition of waste as to which part of the waste can be converted to fuel. Table 1 shows the different categories and specific material type that a typical MSW contains.

Waste to energy conversion methods

Incineration: As with almost all other combustion processes, the main products of waste incineration are carbon dioxide (CO2) and water vapour, since the main process that takes place is the oxidation of carbon and hydrogen in the waste. Net energy production depends on the density and composition of the waste. The main residue of municipal solid waste incineration is slag. The amount produced depends on the ash content of the waste. Energy recovered from waste can be used in the following ways [12,13]:

A. Generation of Power (electricity),

B. Generation of Heat,

C. Generation of Heat and Power (CHP).

Table 2 represents the process parameters within which the incineration process works best

| Parameter | Desirable content |

|---|---|

| Temperature | 760°C-870°C |

| Organic matter recovered | 65-80% (97% when subjected at a temperature of 1600 degree Celsius) |

| Calorific value (Net calorific value) | >12000 kcal/kg |

| P.H. of bottom ash from incinerator | 11.2 |

| M.C. of bottom ash from incinerator | 1.61 % |

| Bulk Density (kg (m3) −1) | 1277.6 |

| Net Energy Production to Grid | 544 kWh/ton MSW |

| Residue | Ash |

Table 2: Process parameters for incineration.

. Pyrolysis

Pyrolysis can be defined as thermal decomposition of carbonbased materials. The heat is used to generate an oxygen-deficient atmosphere to produce syngas. Currently, no direct combustion occurs and the process is endothermic. MSW is pretreated to remove profitable materials and recyclables. The pretreated material is then sent to the pyrolysis reactor where indirect heat source raises the temperature of the material for the production of crude syngas at the top of the tower, bottom ash, carbon coke and metal from the reactor [14]. Table 3 represents the process parameters for pyrolysis.

| Parameter | Desirable content |

|---|---|

| Temperature of process | 649°C - 1204°C |

| Moisture content of feedstock | <45% |

| Organic matter of feedstock | >40% |

| Total inert of feedstock | <35% |

| Calorific value of feedstock | <1200kcal/kg |

| Net Energy Production to Grid Residue |

571 kWh/ton MSW Ash/char |

Table 3: Process parameters for pyrolysis [27,28]

Gasification

Traditional gasification is a thermal process that converts carbonaceous materials for example MSW, using a limited amount of air or oxygen to convert into syngas. C0, H2 and CH4 are the basic components of the gasification process for producing a gas mixture (Table 4) [14].

| Parameter | Desirable content |

|---|---|

| Temperature of process | 760°C – 1537 °C |

| Moisture content of feedstock | <45% |

| Organic matter of feedstock | >40% |

| Total inert of feedstock | <35% |

| Calorific value of feedstock | <1200kcal/kg |

| Net Energy Production to Grid | 685 kWh/ton MSW |

| Residue | Ash/Slag |

Table 4: Process parameters for gasification [27,28].

Biomethanation/Anaerobic digestion

Biomethanation is a process by which organic material is microbiologically converted under anaerobic conditions to biogas. Biomethanation has several merits: first, the emission of CO2 from tends to be 25% to 67% less than that from composting [15]. Second, anaerobic digestion is better at treating waste with high moisture content than direct combustion and landfilling. Similarly, cooking oil is better treated in an anaerobic digestion process than through composting. Third, anaerobic digestion requires less space than aerobic composting. The digestate from anaerobic digestion contains about 7.6 kg/ton nitrogen and 1.1 kg/ton phosphorus (dry weight), which are not as effective fertilizer as compost residues [15]. Table 5 represents the process parameters required for effective biomethanation [16-20].

| Parameter | Desirable content |

|---|---|

| Particle Size | Feed in the form of slurry or with an optimum size between 25-75 mm |

| Temperature | Between 328-333 K |

| pH | Adjusted to about 6.7 |

| Moisture content | 70% |

| C/N ratio | Optimum ratio should be 20-30 |

Table 5: Process parameters for biomethanation.

To summarize the comparison of the various aspects above, to find the most suitable technology for India, scores ranging from 0 (the worst) to 3 (the best) were assigned by ranking each of the technologies in each parameter. For example, anaerobic digestion is the most preferred option in the aspect of air pollution, followed by pyrolysis, gasification and lastly, incineration. Table 6 summarizes the scores of the four technologies in all the aspects considered without any special weightage for any of the parameters. The table shows that, without weightage, incineration and anaerobic digestion are generally the most attractive WtE options, followed by pyrolysis and, lastly, gasification. Incineration is attractive mainly because of its capacity and maturity. Anaerobic digestion is advantageous in terms of its environment-friendliness and cost [21-25].

| Incineration | Anaerobic Digestion | Gasification | Pyrolysis | |

|---|---|---|---|---|

| Air pollution | 0 | 3 | 1 | 2 |

| Cost | 2 | 3 | 0.5 | 0.5 |

| Side products | 1.5 | 1.5 | 0 | 3 |

| Capacity | 3 | 2 | 1 | 0 |

| Maturity | 3 | 2 | 0.5 | 0.5 |

| Energy efficiency | 1.5 | 0 | 3 | 1.5 |

| Waste type | 2 | 0 | 2 | 2 |

| Total | 13 | 11.5 | 8 | 9.5 |

Table 6: Comparison of WtE technologies without weightages.

In practice, India has two main concerns regarding its waste treatment strategy, i.e., environment-friendliness and economy. Therefore, more weightages should be assigned to the relevant parameters in comparison. The main parameter that is relevant to environment-friendliness is air pollution, while that for the economy is cost. A double weightage was therefore given to these two parameters. The results are presented in Table 7. The table shows that anaerobic digestion seems to be the most attractive solution for India in general. It is both environment-friendly and economical. The technology is relatively mature. The inability of anaerobic digestion to treat non-biodegradable waste is actually consistent with India’s national waste management strategy to reduce, reuse and recycle waste. However, the energy production efficiency of anaerobic digestion is relatively low as compared to the other alternatives. Furthermore, it is seriously lacking in its waste treatment capacity. Therefore, in order for this option to be successful in its implementation nationwide, it is crucial to ensure the effectiveness of the existing national waste management strategy to reduce, reuse and recycle [26-31].

| Weightage | Incineration | Anaerobic Digestion | Gasification | Pyrolysis | |

|---|---|---|---|---|---|

| Air pollution | 2 | 0 | 6 | 2 | 4 |

| Cost | 2 | 4 | 6 | 1 | 1 |

| Side products | 1 | 1.5 | 1.5 | 0 | 3 |

| Capacity | 1 | 3 | 2 | 1 | 0 |

| Maturity | 1 | 3 | 2 | 0.5 | 0.5 |

| Energy efficiency | 1 | 1.5 | 0 | 3 | 1.5 |

| Waste type | 1 | 2 | 0 | 2 | 2 |

| Total | 15 | 17.5 | 9.5 | 12 |

Table 7: Comparison with special weightages on environmental and economic aspects.

Conclusion

This paper discusses the different waste-to-energy (WtE) technologies. Moreover, the total amount of waste generated has been steadily increasing over the years and is expected to continue to rise following the country’s economic and population growths. Various alternative technologies are available to treat waste in a more sustainable manner. Four technologies were discussed and compared: incineration, anaerobic digestion, gasification, composting and pyrolysis. The aspects in focus were air pollution, cost, side products, waste treatment capacity, commercial maturity, energy efficiency and type of waste treated. Without any special weightage to any of the parameters, incineration is the most attractive option. It is a very mature technology and is able to treat any type of waste effectively. However, environment-friendliness and cost are especially important for India. Therefore, more weightages were given to the air pollution and cost aspects. From the comparison, it was found that anaerobic digestion/biomethanation seems to be the most attractive solution for the country. Anaerobic digestion plants are environment-friendly and economical. It is also consistent with India’s existing waste management strategy. The major limitations of anaerobic digestion are its low energy production efficiency and its limited waste treatment capacity. It is noted, therefore, that this option has to run in tandem with an effective national strategy to reduce, reuse and recycle waste in the country since this energy can be a viable option and can be replaced for other sources of energy such as petrol, coal and natural gas.

REFERENCES

- Pamnani A, Srinivasarao M. Municipal Solid waste management in India: A review and some new results. International Journal of Civil Engineering and Technology (IJCIET). 2014;5:01-08.

- Joseph K. Perspectives of solid waste management in India. International Symposium on the Technology and Management of the treatment and Reuse of the Municipal Solid Waste. 2002.

- Imura H, Yedla S, Shinirakawa H, Memon MA. Urban Environmental Issues and Trends in Asia – An Overview, International Review for Environmental Strategies. 2005;5:357-382.

- Umberto Di M, Benedetto N, Angelo A, Davide AG. Energy Contribution of OFMSW (Organic Fraction of Municipal Solid Waste) to Energy-Environmental Sustainability in Urban Areas at Small Scale. MDPI, Energies. 2017;10:229.

- Wang NY, Shih CH, Chiueh PT, Huang YF. Environmental Effects of Sewage Sludge Carbonization and Other Treatment Alternatives. Energies. 2013;6:871-883.

- Salata F, Golasi I, Domestico U, Banditelli M, Lo Basso G, Nastasi B, et al. Heading towards the nZEB through CHP + HP systems. A comparison between retrofit solutions able to increase the energy performance for the heating and domestic hot water production in residential buildings. Energy Convers Manag. 2017;138:61-76.

- Rovense F, Amelio M, Ferraro V, Scornaienchi V. Analysis of a Concentrating Solar Power Tower Operating with a Closed Joule Brayton Cycle and Thermal Storage. Int J Heat Technol. 2016;34:485-490.

- Abubakar A, Maigida HB, Baba MT. The Physico-Chemical Composition and Energy Recovery Potentials of Municipal Solid Waste Generated in Numan Town, North-Eastern Nigeria, Energy and Power Engineering. 2018;10:475-485.

- Ujam AJ, Eboh F. Thermal Analysis of Small-Scale Municipal Solid Waste-Fired Steam Generator: A Case Study of Enugu State, Nigeria. Journal of Energy Technologies and Policy. 2012;2:38-49.

- Hassan AA, Kenan J, Amimul A. Environmental Performance and Energy Recovery Potential of Five Processes for Municipal Solid Waste Treatment. Journal of Cleaner Production. 2015;105:233-240.

- Kuleape R, Cobbina SJ, Dampare SB, Duwiejuah AB, Amoako EE, Asare W. Assessment of the Energy Recovery Potentials of Solid Waste Generated in Akosombo, Ghana. African Journal of Environmental Science and Technology. 2014;8:297-305.

- Avinash AP, Amol AK, Balasaheb BP. Waste to Energy by Incineration. Journal of Computing Technologies. 2014;3:2278-3814.

- Johnke B. Emissions from Waste Incineration. Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories. 2009;455-468.

- Leena S, Sunderesan R, Renu S. Waste to Energy Generation from Municipal Solid Waste in India. International Journal of ChemTech Research, CODEN( USA): IJCRGG. 2014;6:1228-1232.

- Finnveden G, Johansson J, Lind P. Life cycle assessment of energy from solid waste—part 1: general methodology and results. J Clean Prod. 2005;13:213-229.

- Rada EC. Energy from municipal solid waste. WIT Transactions on Ecology and The Environment. 2014;190:1743-3541.

- Cleary J. Life cycle assessments of municipal solid waste management systems: A comparative analysis of selected peer-reviewed literature. Environment International. 2009;35:1256-1266.

- Rada EC, Istrate IA, Ragazzi M. Trends in the management of the Residual Municipal Solid Waste. Environmental Technology. 2009;30:651- 661.

- Ionescu G, Rada EC, Ragazzi M, Marculescu C, Badea A, Apostol T. Integrated municipal solid waste scenario model using advanced pre-treatment and waste to energy processes. Energy Conversion and Management. 2013;76:1083-1092.

- Hanrahan S, Ramakrishna. International Journal for Engineering and Science. 2006;220-230.

- Sharma S, Shah KW. Generation and disposal of solid waste in Hoshangabad. In: Book of Proceedings of the Second International Congress of Chemistry and Environment, Indore, India. 2005;749-751.

- Central Pollution Control Board (CPCB). Management of Municipal Solid Waste, Ministry of Environment and Forests, New Delhi, India. 2004.

- Pappu A, Saxena M, Asokar SR. Solid Waste Generation in India and Their Recycling Potential in Building Materials. Journal of Building and Environment. 2007;42:2311-2324.

- Santibañez-Aguilar JE, Ponce-Ortega JM, Betzabe González- Campos J, Serna-González M, El Halwagi MM. Optimal planning for the sustainable utilization of municipal solid waste. Waste Management. 2013;33:2607-2622.

- Alam P, Kafeel A. Impact of Solid Waste on Health and the Environment. Special Issue of International Journal of Sustainable Development and Green Economics (IJSDGE). 2013;2:2315-4721.

- Royal Commission on Environmental Pollution. 10th Report tackling pollution experience and prospects London: HMSO. 1984.

- Tunmise AO, Lau S. Municipal Solid Waste Management: Household Waste Segregation in Kuching South City, Sarawak, Malaysia. American Journal of Engineering Research (AJER) 2014;3:82-91.

- Hargreaves JC, Adl MS, Warman PR. A review of the use of composted municipal solid waste in agriculture. Agric Ecosyst Environ. 2008;123:1-14.

- Young GC. Municipal Solid Waste to energy conversion processes, Economic, technical, and renewable comparisons From Waste Solids to Fuel. Pollution Engineering. 2008.

- Jaya R, Srinivasulu K, Vivek R, Gokak DT, Sanjay B. Environmental Friendly Ways to Generate Renewable Energy from Municipal Solid Waste. Procedia Environmental Sciences. 2016;35:483-490.

- Mata-Alvarez J, Mace S, Llabres P. Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresourcetechnol. 2000;74:3-16.

Citation: Rafey A, Prabhat K, Samar M (2020) Comparison of Technologies to Serve Waste to Energy Conversion. Int J Waste Resour 10:372. doi: 10.35248/2252-5211.20.10.372

Copyright: © 2020 Rafey A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Competing interests: The authors have declared that no competing interests exist.