Indexed In

- Open J Gate

- Academic Keys

- JournalTOCs

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

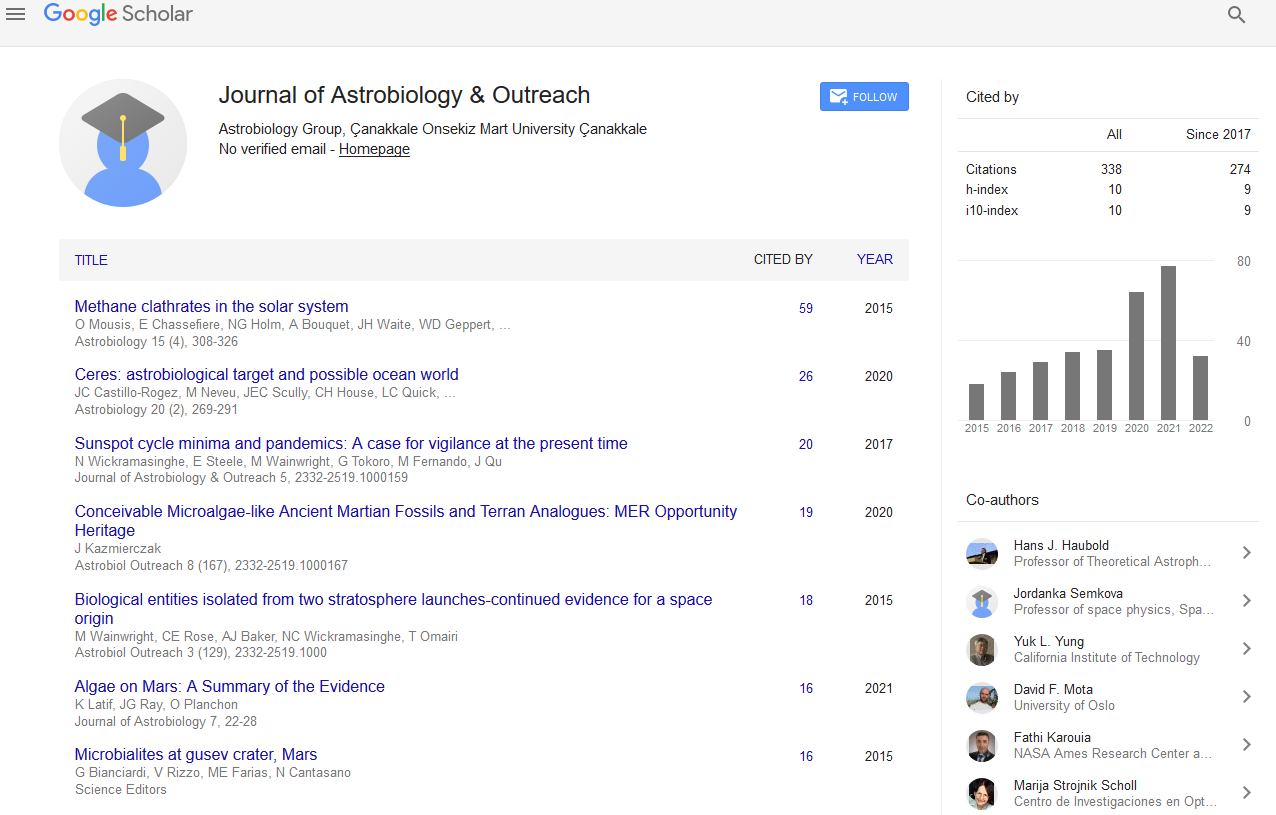

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Opinion Article - (2024) Volume 12, Issue 1

Authentication of Extremophiles and Microreactors in Biocatalysis

Victor Patricia*Received: 27-Feb-2024, Manuscript No. JAO-24-26398; Editor assigned: 01-Mar-2024, Pre QC No. JAO-24-26398 (PQ); Reviewed: 15-Mar-2024, QC No. JAO-24-26398; Revised: 22-Mar-2024, Manuscript No. JAO-24-26398 (R); Published: 29-Mar-2024, DOI: 10.35248/2332-2519.24.12.337

Description

In the property of biocatalysis, where enzymes are pivotal for catalyzing biochemical reactions, the advent of microreactors equipped with naturally acid-resistant Histidine Ammonia Lyase (HAL) from extremophiles marks a significant leap forward. Extremophiles, organisms thriving in extreme environments, possess enzymes uniquely adapted to survive and function in harsh conditions. HAL, found in extremophiles, demonstrates exceptional resilience to acidic environments, making it a encouraging candidate for biotechnological applications in acidic industrial processes.

Capability of extremophiles

Extremophiles have long fascinated scientists due to their ability to thrive in environments considered inhospitable to most life forms. These organisms, ranging from thermophiles that thrive in high temperatures to acidophiles that flourish in highly acidic conditions, have evolved specialized enzymes to sustain their biological processes. Histidine ammonia lyase, crucial in the metabolism of histidine, is one such enzyme found in extremophiles adapted to acidic environments. Its natural ability to withstand extreme acidity makes it a valuable asset for industrial processes where conventional enzymes would denature or lose activity.

Microreactors: Engineering the imminent

Microreactors, miniature reaction vessels with dimensions on the micrometer scale, offer precise control over reaction conditions and enhanced efficiency compared to traditional batch reactors. Integrating acid-resistant HAL into microreactors allows for continuous enzymatic reactions under acidic conditions, optimizing process efficiency and reducing production costs. This combination of robust enzyme and advanced reactor technology unlocks new possibilities in biocatalysis, particularly in industries requiring acidic conditions such as pharmaceuticals, food processing, and environmental remediation.

Applications across industries

The application of HAL-equipped microreactors spans diverse industrial sectors. In pharmaceutical manufacturing, where precise control over reaction conditions is critical, microreactors facilitate the synthesis of complex molecules with higher yields and purity. The food industry benefits from HAL's ability to operate in acidic environments, enabling the production of specific flavor compounds and enhancing process efficiency in fermentation processes. Environmental applications include bioremediation, where HAL can catalyze the degradation of pollutants under acidic conditions, offering a sustainable approach to waste treatment.

Advantages over conventional methods

Compared to conventional chemical methods, biocatalysis with HAL-equipped microreactors offers several advantages. Firstly, enzymes are highly specific, leading to fewer by-products and minimizing waste generation. Microreactors operate continuously, minimizing the downtime associated with batch processing and enhancing overall productivity. Moreover, the ability to function under acidic conditions extends the range of applications where enzymatic processes can be applied, from acidic synthesis routes to biodegradation of acidic waste streams. Despite their potential, integrating HAL in to microreactors presents challenges such as enzyme stability over extended operational periods and scalability to industrial levels. Future research focuses on enhancing enzyme immobilization techniques within microreactors to prolong enzyme activity and exploring genetic modification to customized HAL for specific industrial applications. Advances in microfluidics and reactor design also aim to optimize mass transfer and reaction kinetics, further enhancing the efficiency of enzymatic processes in microreactors.

The fusion of extremophile derived acid-resistant HAL with microreactor technology represents a change of opinion in biocatalysis. By utilize nature's resilience and engineering precision, this innovative approach not only enhances the efficiency and sustainability of industrial processes but also opens possibilities for applications in diverse fields. As research continues to push boundaries in enzyme engineering and reactor design, the future holds the potential for biocatalytic processes generated by extremophile enzymes, prepare towards a towards a more sustainable and efficient industrial landscape.

Citation: Patricia V (2024) Authentication of Extremophiles and Microreactors in Biocatalysis. J Astrobiol Outreach. 12:337.

Copyright: © 2024 Patricia V. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.