Indexed In

- Open J Gate

- JournalTOCs

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Short Communication - (2023) Volume 11, Issue 6

Adoption of the Kanban Process for the Proper Functioning of the Cutting Section in a Selected Apparel Manufacturing Plant

Sam Niroshan Thayapararajah*Received: 04-Nov-2023, Manuscript No. MCA-23-23810; Editor assigned: 06-Nov-2023, Pre QC No. MCA-23-23810 (PQ); Reviewed: 21-Nov-2023, QC No. MCA-23-23810; Revised: 28-Nov-2023, Manuscript No. MCA-23-23810 (R); Published: 06-Dec-2023, DOI: 10.35248/2329-6798.23.11.449

Abstract

In the apparel industry, the cutting section serves an important role in the manufacturing process. It deals directly with raw materials stores and the production floor. This particular department has the responsibility to maintain a proper coordination between their suppliers (raw materials stores) and customers (production floor). The major intention of this project was to initiate the application of Kanban process for the proper material flow throughout the selected apparel plant as material flow plays a significant part in determining the inventory control and waste minimization. For this particular study, the relevant data were gathered from the cutting section over a specific period, and the mapping of the material flow with defining the responsibilities of each department were carried out. It was followed by the preparation of the Kanban cards and the direction of its movement was clearly specified while the results were examined over few weeks in terms of Material requisition note and the downtime analysis. The expected outcomes were reached over the long run of the implemented activity. Proper formulation of the activity provided a visual identification in the cutting section with a clear glance of duties and responsibilities.

Keywords

Apparel industry; Cutting section; Kanban process; Inventory control; Material requisition note; Downtime analysis

Introduction

In manufacturing process, there is a requirement to signal the demand of components for different stages. This is accomplished by “kanban” which trigger as an invisible conveyor, between processes [1]. It is a vital feature for lean concept, since the amount of ‘waste’ created during the production processes is minimized. Kanban can minimize raw material shortage by controlling amount of inventory [2]. The objective of this study is to provide solutions to cutting related issues by implementing an improved kanban process considering the material flow in between raw materials stores and production floor [3].

Material and Methods

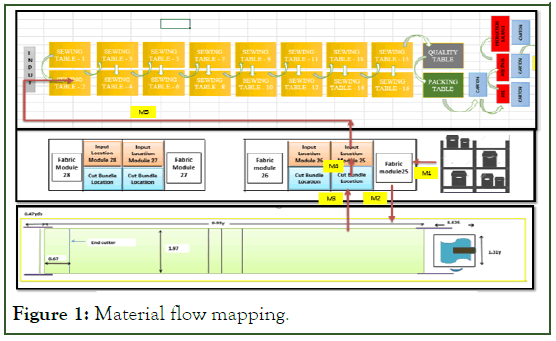

Based on the data collections and observations, the material path is depicted through a diagram as shown in Figure 1.

Figure 1: Material flow mapping.

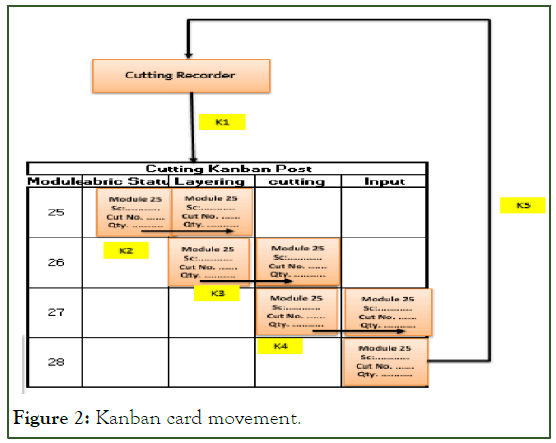

The Figure 2 shows the proposed Kanban card movement in a selected cutting module developed based on material flow mapping.

Figure 2: Kanban card movement.

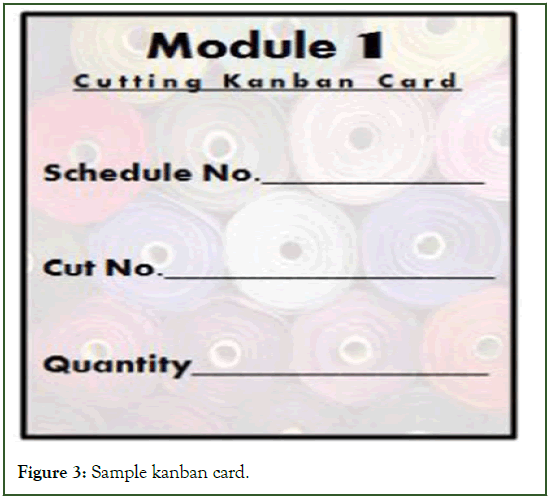

For this particular activity, the process flow can be explained as follows: The recorder takes the responsibility to place the order and initiate the writing task on the card. The sample card is shown in Figure 3.

Figure 3: Sample kanban card.

The recorder will fill out the required details and hang the card on the post. Once it is hanged, the operator from Raw material stores, takes the card to RM and bring the requested fabrics to the requested module along with the card. The fabric issuing operator hangs the card in the cut priority status board specifying the fabric status. Then the operators from cutting team, moves the card to next level showing that they are layering the specific fabric rolls. Once it is done, the cutting operators move the card to cutting column in the board while they are working with the same order. After the cutting and bundling, the card is shifted to next column showing that the input is ready for production floor. And finally water spider takes the responsibility to return the card back to the recorder once the cut panels are issued to the production module. This particular activity is done in a cyclic manner with proper indication the fabric status at each time.

The detail of the methodology can be summarized as shown in the Table 1.

| Material | Movement | Code | Kanban | Movement | Person | Card rotation | |

| From | To | From | To | ||||

| M1 | RM warehouse | Cutting table fabric area | K1 | Cutting recording area | Fabric status | Fabric issuing boy | 1st rotation |

| Cutting table fabric area | Laying on cutting bed | K2 | Fabric status | Layering area | Layering person | 2nd rotation | |

| M3 | Cut bundles | Input location | K3 | Layering area | Cutting | Cutting person | 3rd rotation |

| M4 | IPS bin | IMS bin | K4 | Cutting | Input | Input person | 4th rotation |

| M5 | IMS bin | Line in | K5 | Input | Cutting recording area | Cutting input person | 5th rotation |

Table 1: Kanban card movement.

Results and Discussion

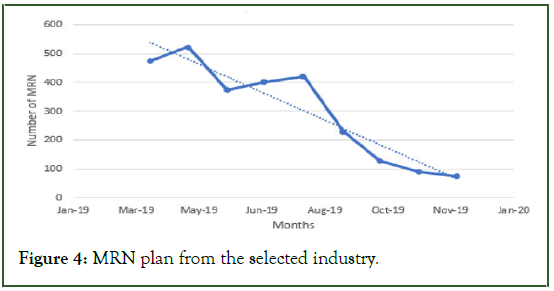

For the evaluation of the above practice, the indication the Material Requisition Note was used. Material Requisition Note (MRN) is an official document, in which the cutting section requests for an additional fabric due to the mistakes occurring in the cutting floor [4]. Before the implementation of this particular process, the MRNs were around 400 to 500 in a month. Once this process is implemented, it dropped to less than 100 for a month. The following graph shows the progress over the year (Figure 4).

Figure 4: MRN plan from the selected industry.

Moreover, there was clear indication of cutting section showing the actual state of the task. Due to the inclusion of details such as Schedule No. and Cut No., the operators became aware of the task being carried out. There was a proper control of inventory.

In order to implement the above task throughout the cutting floor, there was requirement to carry out an internal audit in the cutting section formulation. Once the practice become adapted in all the cutting section, the management can expect a remarkable change in the cutting with the improvement in the cutting floor.

Conclusion

Due to the implementation of improved kanban process, few remarkable benefits were acquired. A proper visual identification was provided. The scenario of cutting block was available at a glance. This research work streamlined the material flow throughout the plant with a remarkable drop in Material requisition Note.

References

- Nizam ME, Siddiquee MA, Biswas ER. Study and implementation of lean manufacturing tools in garment manufacturing process focusing cutting section.

- Junior ML, Godinho Filho M. Variations of the kanban system: Literature review and classification. Int J Prod Econ. 2010;125(1):13-21.

- Naufal A, Jaffar A, Yusoff N, Hayati N. Development of Kanban system at local manufacturing company in Malaysia–case study. Procedia Eng. 2012;41:1721-1726.

- Zarwell G, Davis EW. Note on Material-Requirements Planning. 2009.

Citation: Thayapararajah SN (2023) Adoption of the Kanban Process for the Proper Functioning of the Cutting Section in a Selected Apparel Manufacturing Plant. Modern Chem Appl. 11:449.

Copyright: © 2023 Thayapararajah SN. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.