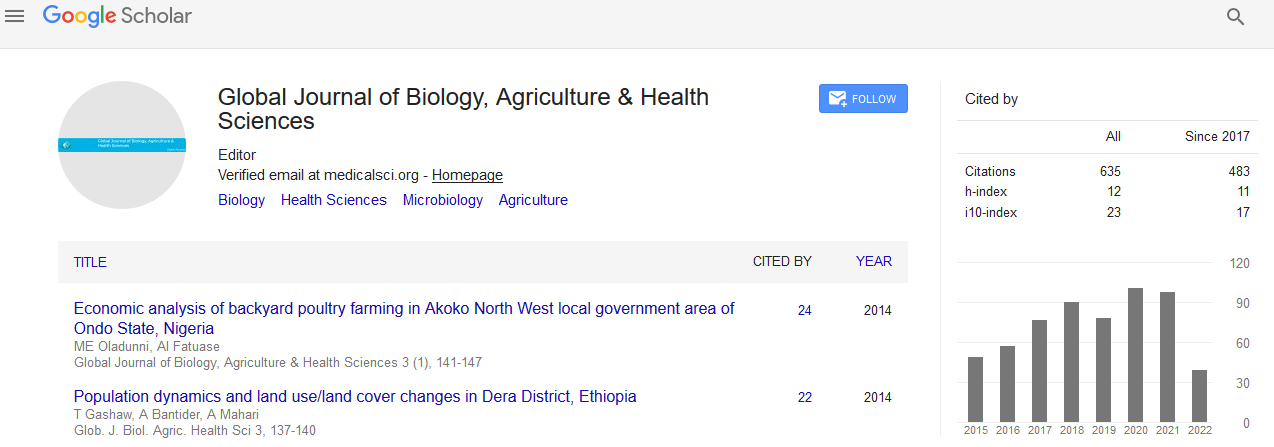

Indexed In

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2021) Volume 10, Issue 1

A Review on Biodegradation and Biological Treatments of Cellulose, Hemicellulose and Lignin

Asrat Mekonnen Teto*Received: 22-Dec-2020 Published: 01-Feb-2021, DOI: 10.35248/2319-5584.21.10.103

Abstract

In nature, cellulose, lignocellulose and lignin are major sources of plant biomass; therefore, their recycling is indispensable for the carbon cycle. Each polymer is degraded by a variety of microorganisms which produce a battery of enzymes that work synergically. In the near future, processes that use lignocellulolytic enzymes are based on microorganisms could lead to new environmentally friendly technologies. This study reviews recent advances in the various biological treatments that can turn these three lignocellulose biopolymers into alternative fuels. In addition, biotechnological innovations based on natural delignification and applied to pulp and paper manufacture are also outlined.

Keywords

Cellulose; Hemicellulose; Lignin; Biodegradation; Microorganism

Introduction

This review is very important to know biodegradation and biological treatments of cellulose, hemicelluloses and lignin. Lignocellulose is the major component of biomass, makes up about half of the matter produced by photosynthesis. It consists of three types of polymers cellulose, hemicellulose, and lignin that are strongly intermeshed and chemically bonded by non-covalent forces and by covalent cross-linkages. A great variety of fungi and bacteria can fragment these macromolecules by using a battery of hydrolytic or oxidative enzymes. In native substrates, binding of the polymers hinders their biodegradation. Lignocelluloses in nature derive from wood, grass, agricultural residues, forestry wastes and municipal solid wastes.

Composition of lignocelluloses materials and structure of the wood wall

The major component of lignocellulose materials is cellulose, along with lignin and hemicellulose. Cellulose and hemicellulose are macromolecules from different sugars; whereas lignin is an aromatic polymer synthesized from phenylpropanoid precursors. The composition and percentages of these polymers vary from one plant species to another. Moreover, the composition within a single plant varies with age, stage of growth, and other conditions [1]. Long cells enveloped by a characteristic cellular wall form wood. This wall is a complex structure that acts at the same time as plant skin and backbone.Cellulose can appear in crystalline form, called crystalline cellulose. In addition, there is a small percentage of non-organized cellulose chains, which form amorphous cellulose. In this conformation, cellulose is more susceptible to enzymatic degradation [2].

Cellulose appears in nature associated with other plant substances and this association may affect its biodegradation.Lignin (along with cellulose) is the most abundant polymer in nature. It is present in the cellular cell wall, conferring structural support, impermeability, and resistance against microbial attack and oxidative stress. Structurally, lignin is an amorphous heteropolymer, non-water soluble and optically inactive; it consists of phenyl propane units joined together by different types of linkages. Fungi are the bestknown microorganisms capable of degrading these three polymers. Because the substrates are insoluble, both bacterial and fungal degradation have to occur exocellularly, either in association with the outer cell envelope layer or extracellularly. Microorganisms have two types of extracellular enzymatic systems: the hydrolytic system, which produces hydrolases and is responsible for cellulose and hemicelluloses degradation; and a unique oxidative and extracellular ligninolytic enzyme which depolymerizes lignin.

Cellulose biodegradation

Most of the cellulolytic microorganisms belong to eubacteria and fungi, even though some anaerobic protozoa and slime molds able to degrade cellulose have also been described. Cellulolytic microorganisms can establish synergistic relationships with non- cellulolytic species in cellulosic wastes. The interactions between both populations lead to complete degradation of cellulose, releasing carbon dioxide and water under aerobic conditions, and carbon dioxide, methane and water under anaerobic conditions [2,3].

Microorganisms capable of degrading cellulose produce a battery of enzymes with different specificities, working together. Cellulases are enzymes that hydrolyze the b-1, 4-glycosidic linkages of cellulose. Traditionally, they are divided into two classes referred to as Endoglucanases and Cellobiohydrolases. Endoglucanases (endo- β-(1,4)-glucanases EGs) can hydrolyze internal bonds (preferably in cellulose amorphous regions) releasing new terminal ends. Cellobiohydrolases (exo-1,4-β-glucanases, CBHs) act on the existing or endoglucanase generated chain ends. Both enzymes can degrade amorphous cellulose but, with some exceptions, CBHs are the only enzymes that efficiently degrade crystalline cellulose. CBHs and EGs release cellobiose molecules. CBHs act synergistically with EGs to solubilize high-molecular-weight cellulose molecules. They are also glycosylated and present an optima activity at acidic pH. P. chrysosporium has several β-glycosidases, whereas only one isoenzyme has been described in T. reesei.

Among aerobic cellulolytic bacteria, species from the genera Cellulomonas, Pseudomonas, and Streptomyces are the best studied [2]. About 5–10% of cellulose is degraded in nature under anaerobic conditions. The cellulose system of anaerobic microorganisms is clearly different from that of aerobic fungi and bacteria. The best characterized is that of Clostridium thermocellum, a strict anaerobic gram-positive, sporulated bacteria. The advantages of these arrangements of cellulolytic enzymes are that, since the Cellulosome is attached to the cell surface, the enzymes are located at the interface between the cell and the insoluble substrate. The products of cellulolysis (such as cellobiose) can pass inside the bacterium via extended fibrous materials that are present between the cell and cellulose. However, these microorganisms require high temperatures for growth and cellulose degradation, for this reason they probably play a minor role in cellulose biodegradation in nature. Several Mesophilic cellulolytic anaerobes have been isolated from common environments including soil and sediments, compost, sewage, sludge, and anaerobic digestors [3]. Other well-known anaerobic cellulolytic microorganisms are rumen bacteria, fungi and protozoa, which degrade vast amounts of cellulose [3].

Hemicellulose biodegradation

Hemicelluloses are biodegraded to monomeric sugars and acetic acid. Hemicellulases are frequently classified according to their action on distinct substrates. Xylan is the main carbohydrate found in hemicellulose. Its complete degradation requires the cooperative action of a variety of hydrolytic enzymes. An important distinction should be made between endo-1,4-β-xylanase and xylan 1,4-β-xylosidase. The former generates oligosaccharides from the cleavage of xylan; the latter works on xylan oligosaccharides, producing xylose [1].

In addition, hemicellulose biodegradation needs accessory enzymes such as xylan esterase, ferulic and p-coumaric esterases, a-l-arabinofuranosidases, and a-4-O-methyl glucuronosidases acting synergistically to efficiently hydrolyze wood xylans and mannans.

Xylanases, the major component of hemicellulases, have been isolated from many ecological niches where plant material is present. Due to the important biotechnological exploitations of xylanases, especially in Biopulping and bleaching, many publications have appeared in recent years [4]. The white-rot fungus Phanerochaete chrysosporium has been shown to produce multiple endo xylanases [5]. Also, bacterial xylanases have been described in several aerobic species and some ruminal genera [4,6]. Optimum temperatures for xylanases from bacterial and fungal origin ranges from 40 to 60Co. Fungal xylanases are generally less thermo stable than bacterial xylanases.

Lignin biodegradation

The structural complexity of lignin, its high molecular weight and its insolubility make its degradation very difficult. Extracellular, oxidative, and unspecific enzymes that can liberate highly unstable products which further undergo many different oxidative reactions catalyse the initial steps of lignin depolymerisation. This nonspecific oxidation of lignin has been referred to as ‘‘enzymatic combustion’’ [7]. White-rot fungi are the microorganisms that most efficiently degrade lignin from wood. Of these, Phanerochaete chrysosporium is the most extensively.

Degradation of lignin and lignin-degrading enzymes has also been reported for actinobacteria from the Streptomyces genus [8]. Even though lignin biodegradation is accepted as an aerobic process, some authors have reported that anaerobic microorganisms in the rumen may alter, if not partially degrade, portions of lignified plant cells [9].

Biological treatments of cellulosic and lignocellulosic materials

Biotransformation of lignocellulosic biomass in to alternative fuels

Obtaining ethanol as alternative fuel using cellulose and lignocellulosic residues as a raw material has been strongly considered, especially after the fossil fuel crisis. World-wide, the conversion of starch from corn and other crops into ethanol is one of the largest-scale applications of biotechnology. Ethanol blended with gasoline (10:90) reduces carbon monoxide emissions.

The transformation of lignocellulose into ethanol is completed in two steps:

(1) Hydrolysis of the polymer, delignification to liberate cellulose and hemicelluloses from their complex with lignin, and depolymerisation of carbohydrate polymer to produce free sugars

(2) Fermentation to ethanolusing pentoses and hexoses liberated in the first step. Anaerobic digestion to convert lignocellulosic biomass into methane has been assayed; however, further advances in this technology, such as enhancing the enzyme levels for the breakdown of cellulose into fermentable sugars, and improved organisms that tolerate wider pH differences, are required to achieve economic potential [10].

Fungal and enzymatic treatments of wood chips and pulps: biopulping and biobleaching

Biopulping is defined as the appropriate treatment of wood chips with lignin-degrading fungi prior to pulping. This biotreatment not only reduces energy consumption in the process of pulping, but also improves paper strength and removes wood extractives, leading to additional benefits such as fewer pitch problems and lower effluent toxicity [11]. The pulp and paper industry uses mechanical or chemical pulping processes or a combination of both to produce pulps. Mechanical pulping involves mechanical force to separate wood fibers. With this method, the yield is high, and the paper produced is good quality. In chemical pulping processes the yield is low, but the pulp produced has a higher strength.

Bleaching of pulps using enzymes or ligninolytic fungi is known as biobleaching. The use of ligninolytic enzymes and hemicellulases aids in pulp bleaching and decreases the amount of chemical bleach required to obtain a desirable brightness of pulps. Treating Kraft pulps with fungal hemicellulases reduces subsequent chlorine bleaching requirements. [12] Ligninolytic fungi have also been evaluated for biobleaching.

Discussion and Conclusion

This reviews shown that a variety of microorganisms can degrade the three major natural biopolymers that make up lingo cellulosic materials: cellulose, hemicellulose, and lignin. Many laboratories around the world are involved in research on the different aspects of natural bio de gradation of these compounds. Our current knowledge of the enzymology, physiology, biochemistry and molecular biology of these enzymes and of the producer fungi and bacteria is considerable. Consequently, processes that use enzymes and microorganisms are being developed to explore the potential for their biotechnological applications. Production of ethanol and other alternative fuels from lignocellulosic biomass can reduce urban air pollution, decrease the release of carbon dioxide in the atmosphere, and provide new markets for agricultural wastes. Biopulping and Biobleaching are leading to cleaner and more efficient pulp and paper manufacture. Despite the progress achieved, more effort is needed for lignocellulosic enzymes or microorganisms to have significant industrial impact.

Recommendation

In the future natural biopolymers that make up lignocellulosic materials: cellulose, hemicellulose, and lignin are used for research studies by different researchers in the world including me. Generally, these polymers biodegradation are useful for bio treatment, industrial products, west water treatments and controlling environmental pollution.

REFERENCES

- Jeffries TW. Biodegradation of lignin and hemicelluloses. Biochemistry of microbial degradation. 1994; 233-277.

- Beguin P, Aubert JP. The biological degradation of cellulose. FEMS Microbiol Rev. 1994; 13 (1):25-58.

- Leschine SB. Cellulose degradation in anaerobic environments. Annu Rev Microbiol. 1995; 49 (1):399-426.

- Kulkarni N, Shendye A, Rao M. Molecular and biotechnological aspect of xylanases. FEMS Microbiol Rev. 1999; 23 (4):411–456.

- Kirk KT, Cullen D (1998) Enzymology and molecular genetics of wood degradation by white rot fungi. Environmental friendly technologies for pulp and paper industry, edited by Young RA, Akhtar M. 273–307.

- Blanco A, Diaz P, Zueco J, Parascandola P, Pastor JFI. A multidomainxylanase from a Bacillus sp. with a region homologous to thermostabilizing domains of thermophilic enzymes. Microbiology. (1999); 145(8):2163–2170.

- Kirk TK, Farrel RL. Enzymatic ‘‘combustion’’: the microbial degradation of lignin. Annu Rev Microbiol. 1987; 41:465–505.

- Berrocal M, Rodriguez J, Ball AS, Perez-Leblic MI, Aria ME. Solubilization and mineralisation of 14C lignocelluloses from wheat straw by Streptomyces cyaneus CECT 3335 during growth in solid-state fermentation. Appl Microbiol Biotechnol. 1997; 48:379–384.

- Akin DE. Attack on lignified cell walls by facultatively anaerobic bacterium. Appl Environ Microbiol.1980; 40 (4):809–820.

- Whyman CE, Goodman BJ. Biotechnology for production of fuels, chemicals, and materials from Biomass. Appl Biochem Biotechnol. 1993; 39:41–59.

- Akhtar M, Scott GM, Swaney RE, Kirk TK. Overview of Biomechanical and Biochemical Pulping Research Enzyme applications in fiber processing. 1998; 2:15–26.

- Viikari L, Ranua M, Katelinen A, Linko A, Sundquist L. Bleaching with enzymes. Proceedings of the 3th international conference on biotechnology in pulp and paper industry. 1986; 67–69.

Citation: MekonnenTeto A (2021) A Review on Biodegradation and Biological Treatments of Cellulose, Hemicellulose and Lignin. Glob J Agric Health Sci 10:103. doi: 10.35248/2319-5584.21.10.103

Copyright: © 2021 MekonnenTeto A. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.