Indexed In

- Euro Pub

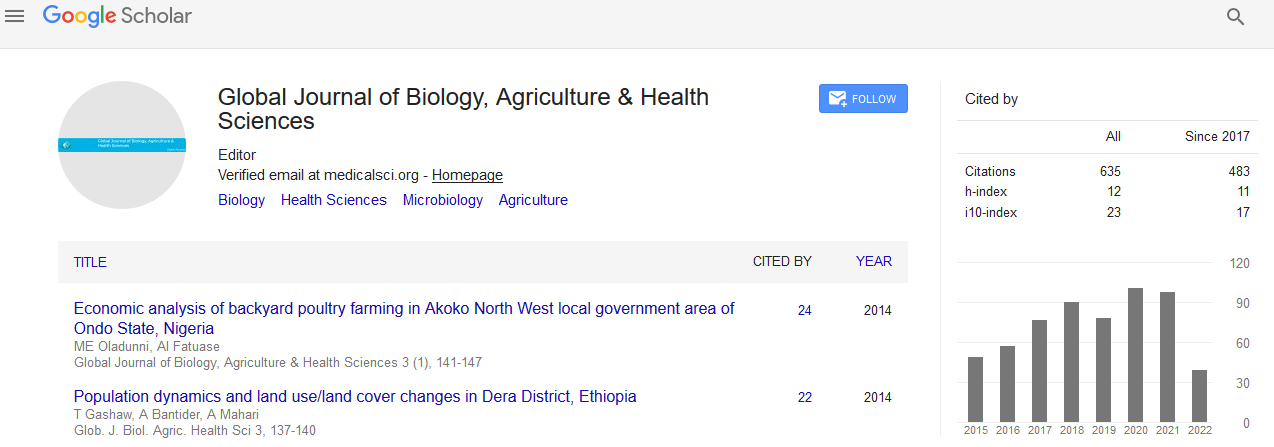

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

THE TREATMENTS COMBINATION (CENTRIFUGATION AND ADSORPTION) FOR REDUCING PRIMARY-SECONDARY OXIDATION PRODUCTS OF SARDINE OIL

Yosephina Margaretha Jawa Batafor, Sugeng Heri Suseno & Nurjanah

Canned fish industry produces by-products such as fish oil. Fish oil as by products of fish meal and fish canning industry was purified by centrifugation and adsorption using carp scales, scallop shells, and attapulgite. Centrifugation treatment was done at 2.500 rpm for 45 minutes. There were 12 treatments of adsorbent combination as a further step of purification after centrifugation. The lowest peroxide value can be found in a treatment of addition of attapulgite (4.75±0.25 meq/kg). The lowest free fatty acid value can be found in attapulgite treatment too (2.33±0.70%). The lowest p-anisidine value can be found in a treatment of gradual addition of adsorbent, which there were three steps of purification, firstly refined fish oil was adsorbed using carp scales, and it was then purified using scallop shell, after that there was attapulgite addition as a last purification step. Its p-anisidine value was 0.150.46 meq/kg. The lowest total oxidation had been reached in a treatment of attapulgite addition (9.680.54 meq/kg). Single attapulgite addition was determined as the best treatment which resulting a good quality of fish oil based on primary and secondary oxidation products parameters, free fatty acids, and its clarity.