Indexed In

- Open J Gate

- Genamics JournalSeek

- ResearchBible

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

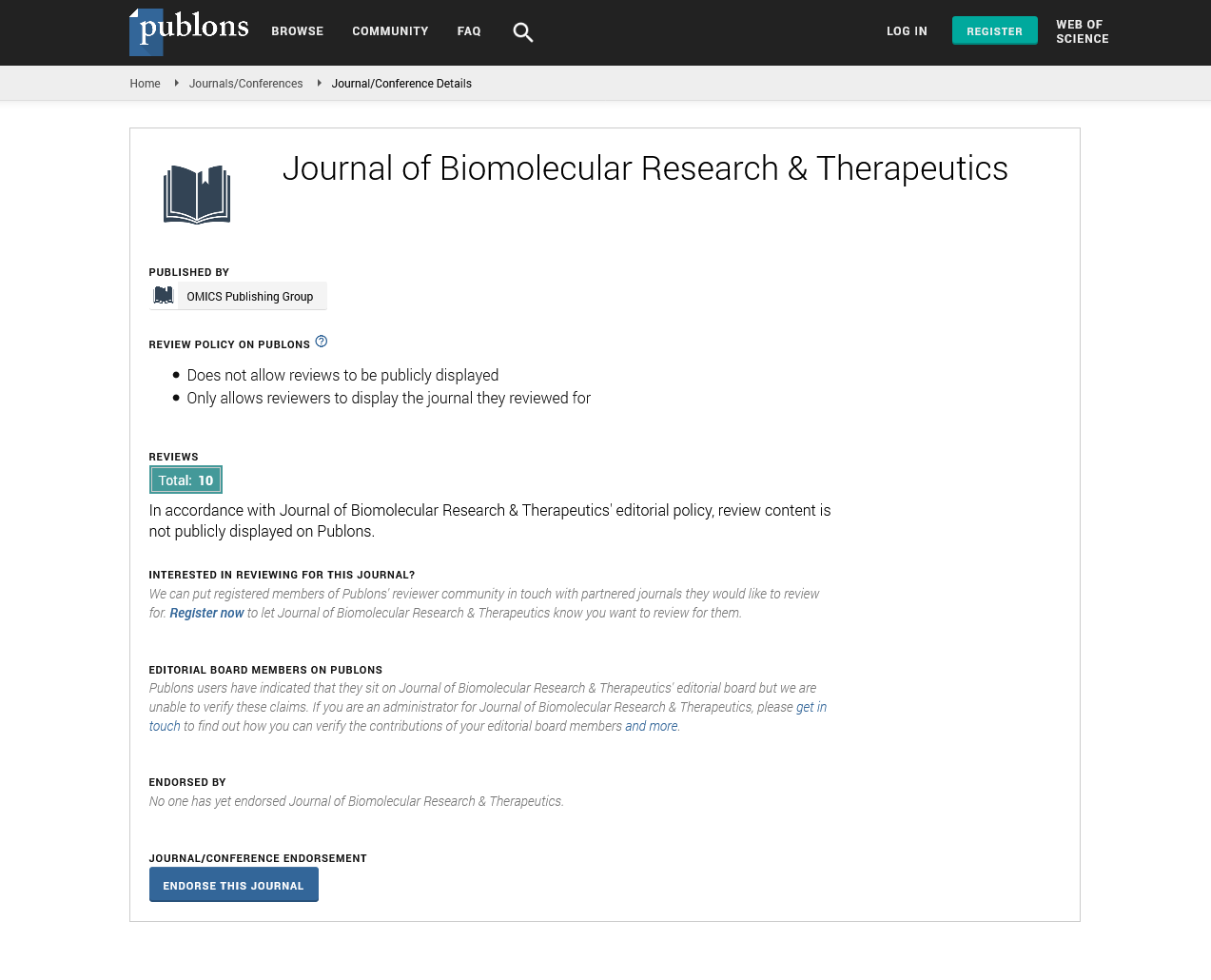

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Molecular Characterization of Purified Bacterial Cellulase Enzyme Immobilized in Magnetic Nanoparticle

Poorani Thiruvengadasamy Rajendran*, Velmanikandan Balasubramanian, Venupriya Vellingiri, Ragavi Ravichandran, Dhivya Dharshini Udhaya Kumar and Ponmani Varuna Ramakrishnan

Background: Plants were rich in lignocellulose and cellulosic content which forms highly complex structure and this needs effective enzymatic catalyzes reaction for useful product development. Various industries like textiles, paper, agriculture and biofuel need enzymatic treatment (cellulase) which costs up to the total cost production of 40% to convert into the useful product.

Methods: To get the better of this economical contingency, the cellulase cost was reduced by immobilizing with Magnetic Nanoparticle (MNP’s). It is hypothesized that cellulose enzyme immobilization with magnetic nanoparticle can meet the economically feasible cellulase production. Present study describes the cellulase molecular characterization isolated from cellulolytic bacteria and its growth parameters were optimized for its enzyme production. The cellulolytic bacteria with efficient substrate hydrolyzing property were chosen and its cellulase activity was evaluated. The cellulase kinetics was calculated using Michaelis - Menten Kinetics (MM kinetics) to find the Vmax and Km.

Results: The purified cellulase was immobilized with magnetic nanoparticle and its efficiency and yield was calculated and characterized with FTIR, SEM and XRD. The peptide mass finger printing of cellulase was evaluated using MALDI-TOF-TOF analysis. The free enzyme and immobilized enzyme was checked for its temperature optimization and stability, pH optimization and stability, substrate specificity, storage stability. The reusability of the immobilized enzyme was also evaluated.

Conclusion: In future, the enzymatically and molecularly characterized cellulase gene from cellulolytic bacteria will be over expressed in E.coli to make the cellulase cost feasible.

Published Date: 2021-10-30; Received Date: 2021-09-16